Académique Documents

Professionnel Documents

Culture Documents

Jurnal Buat TM Organik

Transféré par

Angga Maf'ud Cahayo0 évaluation0% ont trouvé ce document utile (0 vote)

9 vues5 pagesExtraction of acetic acid from aqueous solutions by an emulsion type liquid membrane process was investigated. Using Alamine 300 as carrier, Span 80 as surfactant, and Na 2 CO 3 solution as stripping agent. 86% extraction was achieved within 10 min in a stirred vessel. Acetic acid is a valuable compound for agricultural application (preservative E280) and substrate for preparing natural and industrially uncontaminated products.

Description originale:

Titre original

Jurnal Buat Tm Organik

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentExtraction of acetic acid from aqueous solutions by an emulsion type liquid membrane process was investigated. Using Alamine 300 as carrier, Span 80 as surfactant, and Na 2 CO 3 solution as stripping agent. 86% extraction was achieved within 10 min in a stirred vessel. Acetic acid is a valuable compound for agricultural application (preservative E280) and substrate for preparing natural and industrially uncontaminated products.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

9 vues5 pagesJurnal Buat TM Organik

Transféré par

Angga Maf'ud CahayoExtraction of acetic acid from aqueous solutions by an emulsion type liquid membrane process was investigated. Using Alamine 300 as carrier, Span 80 as surfactant, and Na 2 CO 3 solution as stripping agent. 86% extraction was achieved within 10 min in a stirred vessel. Acetic acid is a valuable compound for agricultural application (preservative E280) and substrate for preparing natural and industrially uncontaminated products.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 5

Indian Journal of Chemical Technology

Vol. 17, November 2010, pp. 441-445

Extraction of acetic acid from aqueous solutions by emulsion type liquid

membranes using Alamine 300 as a carrier

Aynur Manzak* & Melek Sonmezoglu

Department of Chemistry, Faculty of Science, Sakarya University, 54187 Adapazari, Turkey

*Email: manzak@sakarya.edu.tr

Received 4 March 2010; revised 25 August 2010

The extraction of acetic acid from aqueous solutions by an emulsion type liquid membrane process was investigated, using

Alamine 300 as carrier, Span 80 as surfactant, and Na

2

CO

3

solution as stripping agent. A number of significant parameters viz.

mixing speed, surfactant concentration, diluent type, concentration of the carrier Alamine 300, concentration of stripping agent,

pH and concentration of feed solution were investigated. Acetic acid was successfully extracted and concentrated from aqueous

solutions. Approximately 86% extraction of acetic acid was achieved within 10 min in a stirred vessel.

Keywords: Acetic acid extraction, Alamine 300, Emulsion liquid membrane, Surfactant, Diluent

Acetic acid is one of the simplest and most widely

used carboxylic acids, and has many important

chemical and industrial applications. Acetic acid is a

valuable compound for agricultural application

(preservative E280), and substrate for preparing

natural and industrially uncontaminated products

1

.

Until recently, the acid waste containing acetic acid

has been mostly subjected to neutralization without

any proper treatment. However, the conventional

neutralization treatment has problems of formation of

precipitation in a large quantity, cost of alkali, and

sludge disposal, which consequently cause an increase

in the treatment cost

2

. Recovery of carboxylic acids

such as acetic acid is important in a number of

industries. Removal of carboxylic acid from aqueous

waste streams is also important in the petrochemical,

chemical and pulp and paper industries

3

. Classical

methods for recovering low-volatility carboxylic acids

involve formation of the insoluble calcium

carboxylate salt

4

.

Many research groups are working in this field and

some methods

5-10

have been proposed for the

separation and recovery of acetic acid from different

waste sources. Most of these processes are concerned

with an aqueous solution that does not contain high

concentration of inorganic acids. In the absence of

any mature technology, a conventional physical

separation method such as distillation is preferred by

the industries; distillation is not economical because

of the high energy cost involved in the vaporization

process

2-11

. The extraction method has the potential to

replace the existing distillation process used for acetic

acid recovery. Solvent extraction processes have been

proposed by several research groups to separate acetic

acid from mixed acid waste

11

. Acetic acid is generally

recovered by a solvent extraction method

2

. The

recovery of acetic acid from waste streams is also

possible by extractive distillation

10

.

Membrane separation processes have been used for

many applications in the chemical industry, due to the

compactness, simple and efficient operation and low

energy consumption of membrane

12

. Emulsion liquid

membrane (ELM) is a highly sophisticated but an

energy-saving separation technique. Some studies have

been conducted to utilize liquid membrane technology

for the removal of organic acids

13-15

. In this technology,

solutes are not only removed but also concentrated.

The external phase to be treated is contacted with an

emulsion dispersed in globules. Each emulsion globule

consists of droplets of an aqueous internal stripping

phase, encapsulated in an organic membrane phase

containing a surfactant. During this contact, solute

transport occurs through the membrane phase into the

internal stripping phase, where it is concentrated. Since

extraction and stripping are done in a single step, ELM

technology is preferred when treating effluents. The

use of an emulsion liquid membrane in effluent

treatment has received widespread attention, due to its

ease of operation, lower power consumption and

modular design. Odorous distillery effluent was

treated for removal of acetic acid (solute) using ELM

in a batch process

16

. In the present investigation an

INDIAN J. CHEM. TECHNOL., NOVEMBER 2010

442

attempt has been made to use the ELM for removal

and concentration of acetic acid from its solutions.

Experimental Procedure

Materials

The liquid membrane phase (organic phase) is

composed of a surfactant (emulsion stabilizer), carrier

and diluent. Reagent grade surfactant Span 80 (sorbitan

monooleate) was purchased from Fluka and used as

such. The mobile carrier Alamine 300 was obtained

from Cognis Corp. Kerosene, Toluene, Escaid 100 and

Escaid 200 are used as diluents. Kerosene is a complex

mixture of aliphatic origin and also contains aromatics

about 15% w/w.

Preparation of ELM

The emulsion liquid membrane (ELM) used in this

work was a water-oil-water (W/O/W) type of emulsion,

formed by mixing the aqueous phase with the organic

phase. The liquid membrane phase (organic phase) is

composed of a nonionic surfactant, a carrier and

diluent. The external or feed phase is an acetic acid

solution. The surfactant is commercially known as

Span 80. The mobile carrier is Alamine 300

(trioctylamine). Kerosene, Toluene, Escaid 100, Escaid

200 are used as diluents.

The internal phase (V

S

) is a Na

2

CO

3

solution. The

external or feed phase (V

F

) is an acetic acid solution.

The stripping solution (V

S

: 50 mL) was added

dropwise to the membrane solution (V

m

: 50 mL),

stirred at 2000 rpm for 30 min and passed through a

burette in about 20 min. The appropriate liquid

membrane emulsion (V

E

) was added to a feed solution

(V

F

: 250 mL) in a 600 mL beaker with a Teflon-coated

four vertical baffle. The two-phase system was stirred

by a variable speed mixer, equipped with a turbine-type

Teflon impeller. Samples of 1 mL of the feed phase

were taken periodically for analysis. Extraction rates

were measured by analyzing the feed phase acetic acid

concentrations. Analysis of acetic acid samples was

performed by high performance liquid chromatography

(HPLC). At the end of each run, the emulsion was

recovered and subsequently broken into its constituent

organic and aqueous phases using a high-voltage

splitter with niobium electrodes. All the extraction

experiments were carried out batchwise.

Analysis

Acetic acid concentration was determined by

high performance liquid chromatography (HPLC)

(Shim-adzu LC-20AD, Japan), equipped with an

Hypersil C18 ODS column (250 4.6 mm) and

detected with UV detector (Shimadzu SPD-M20A) at

210 nm. All the aqueous solutions were prepared

using deionized water.

Results and Discussion

Effect of mixing speed of feed solution

Figure 1 shows extraction efficiency at mixing

speeds of 250, 300 and 400 rpm (C/C

o

which expresses

the extent of remaining acetic acid in the feed solution).

It was observed that the transfer of acetic acid

increased on increasing the mixing speed from 250 to

400 rpm.

According to Hirato et al.

17

increasing the mixing

speed, reduces the size of the emulsion globules

dispersed in the external phase, leading to greater

surface area for mass transfer, and results in increased

extraction rate. However, at the same time, the higher

mixing speed affects the stability of emulsion globules,

which may lead to breakage. Therefore, the rate of

extraction decreases in the long run, as shown with data

at 400 rpm. Thus, a mixing speed of 300 rpm was

found to be appropriate for conducting the

experiments.

Effect of diluent

Organic diluent influences the performance of many

liquid membrane systems. The role of the diluent is not

only to improve the physical properties of the

extraction system, but also to remove the interaction

product. This needs be taken into account in the choice

of diluent

18

.

In the present study diluents like toluene, kerosene,

Escaid 100 and Escaid 200 were used. The results

shown in Fig. 2 prove that toluene provided the better

performance.

Effect of surfactant concentration

Surfactant concentration has an important bearing

on the stability of the emulsion. Too little surfactant

renders the membrane weak, while an excess of

Fig. 1The effect of mixing speed of feed solution [diluent:

Toluene (91% w/w), extractant: Alamine 300 (5% w/w), surfactant:

Span 80 (4% w/w), external phase concentration: (10% w/v),

stripping phase: 50 mL (10% w/v) Na

2

CO

3,

treatment ratio (V

F

/V

E

)

:

5/2, phase ratio (V

S

/V

m

): 1/1, emulsion mixing speed: 2000 rpm]

MANZAK & SONMEZOGLU: EXTRACTION OF ACETIC ACID FROM AQUEOUS SOLUTIONS

443

surfactant concentration leads to larger diffusional

resistance. Experiments were performed with

surfactant concentrations ranging from 3 to 6%. The

emulsion stability improved with increased surfactant

concentration. Figure 3 shows that increasing the

surfactant concentration from 3 to 6% increased the

stability of the liquid membrane, leading to a decrease

in the break-up rate; hence the degree of extraction of

acetic acid was also increased.

Effect of Alamine 300 concentration

The effect of carrier concentration is shown in

Fig. 4. The efficiency of tertiary amines in the

recovery of various organic acids has been

demonstrated in some previous studies

19-21

. The initial

extraction rate of acetic acid is slightly higher for 3 and

5% (w/w) Alamine 300 than for 8%, as shown in

Fig. 4. A very high content of extractant in the

membrane does not result in a benefit, due to the

respective increase in viscosity, which leads to larger

globules

22

. The increasing concentration of extractant

also promotes permeation swelling, which dilutes the

aqueous receiving phase and reduces the efficiency of

the ELM process.

Effect of feed solution pH

The pH strongly affects the ionization of

carboxylic acids. Acetic acid is a weak acid (HA) that

partially ionizes in aqueous solutions. The

concentrations of dissociated and undissociated acids

(HA) are affected by the hydrogen ion (H

+

)

concentration or pH. At extremely low pH values, the

acid is mainly in undissociated form. Most aliphatic

amines extract undissociated acids from the aqueous

phase by forming an acid-base complex. The effect of

hydrogen ion concentration was examined by varying

the initial pH of the external phase between 1 and 4,

as shown in Fig. 5. The acetic acid solution had a pH

of 1.8. The extraction rate and ultimate yield of acetic

acid decreased with increasing pH. As the pH

Fig. 2The effect of diluent on the extraction of acetic acid [diluent:

(91% w/w), extractant: Alamine 300 (5% w/w), surfactant: Span 80

(4% w/w), feed solution concentration: (10% w/v), stripping phase: 50

mL (10% w/v) Na

2

CO

3

, pH of feed solution: 1.8, treatment ratio

(V

F

/V

E

): 5/2, phase ratio (V

S

/V

m

): 1/1, emulsion mixing speed: 2000

rpm]

Fig. 3The effect of surfactant on the extraction of acetic acid

[diluent: Toluene (89-92% w/w), extractant: Alamine 300 (5% w/w),

surfactant: Span 80 (3-6% w/w), feed solution concentration: (10%

w/v), stripping phase: 50 mL (10% w/v) Na

2

CO

3

, pH of feed solution:

1.8, treatment ratio (V

F

/V

E

) : 5/2, phase ratio (V

S

/V

m

): 1/1, emulsion

mixing speed: 2000 rpm]

Fig. 4The effect of extractant on the extraction of acetic acid

[diluent: Toluene (88-93% w/w), extractant: Alamine 300 (38%

w/w), surfactant: Span 80 (4% w/w), feed solution concentration:

(10% w/v), stripping phase: 50 mL (10% w/v) Na

2

CO

3

, pH of

feed solution: 1.8, treatment ratio (V

F

/V

E

): 5/2, phase ratio

(V

S

/V

m

): 1/1, emulsion mixing speed: 2000 rpm]

Fig. 5The effect of feed phase pH on the extraction of acetic

acid [diluent: Toluene (91% w/w), extractant: Alamine 300 (5%

w/w), surfactant: Span 80 (4% w/w), feed solution concentration:

(10% w/v), stripping phase: 50 mL (10% w/v) Na

2

CO

3,

pH of feed

solution: 1-4, treatment ratio (V

F

/V

E

) : 5/2, phase ratio (V

S

/V

m

):

1/1, emulsion mixing speed: 2000 rpm]

INDIAN J. CHEM. TECHNOL., NOVEMBER 2010

444

increased, the resulting decrease in the external phase

hydrogen ion concentration reduces the extent to

which the amine can couple with the acetic acid, and

thus the rate of extraction decreases. The data for a

pH level of 1 show that further decrease in pH results

in reduced extraction efficiency

23

. This process is

further accelerated by the stripping action of Na

2

CO

3

.

Effect of stripping solution concentration

Strip phase concentration was varied from 5 to

20%, as shown in Fig. 6. The difference in hydrogen

ion chemical potentials between the two aqueous

phases is the main driving force in the emulsion liquid

membrane process. It can be noted from Fig. 6 that,

when Na

2

CO

3

concentration is increased from 5 to

10%, extraction efficiency increases, but decreases

when Na

2

CO

3

concentration is further increased from

10 to 20%. At 20% Na

2

CO

3

concentration, the

emulsion swells up, and the extraction efficiency of

acetic acid is decreased.

Effect of feed concentration

The acetic acid concentration in the feed or

external phase was varied from 2 to 10%. The rate of

acetic acid extraction increased as the feed

concentration decreased, as shown in Fig. 7.

Extraction mechanism

The transport mechanism of acetic acid in ELM

can be explained via the following steps, as shown in

Fig. 8.

(i) The acetic acid dissociates into H

+

and acetate

ions as shown in Eq. (1).

HA H

+

+ A

-

... (1)

Fig. 6The effect of stripping phase concentration on the

extraction of acetic acid [diluent: Toluene (91% w/w), extractant:

Alamine 300 (5% w/w), surfactant: Span 80 (4% w/w), feed

solution concentration: (10% w/v), stripping phase: 50 mL (5-20%

w/v) Na

2

CO

3,

pH of feed solution: 1.8, treatment ratio (V

F

/V

E

):

5/2, phase ratio (V

S

/V

m

): 1/1, emulsion mixing speed: 2000 rpm]

Fig. 7The effect of feed phase concentration on the extraction

of acetic acid [diluent: Toluene (91% w/w), extractant: Alamine

300 (5% w/w), surfactant: Span 80 (4% w/w), feed solution

concentration: (2,10% w/v), stripping phase: 50 mL (10% w/v)

Na

2

CO

3

, pH of feed solution: 1.8, treatment ratio (V

F

/V

E

): 5/2,

phase ratio (V

S

/V

m

): 1/1, emulsion mixing speed: 2000 rpm]

Fig. 8Schematic mechanism of acetic acid extraction and stripping by tertiary amine (Alamine 300) and sodium carbonate

15

.

MANZAK & SONMEZOGLU: EXTRACTION OF ACETIC ACID FROM AQUEOUS SOLUTIONS

445

(ii) The tertiary amine reacts with the acetic acid to

form amine salt at the interface between the

external and membrane phases in the extraction

step, as given in Eq. (2).

H

+

(aq)

+ A

-

(aq)

+ R

3

N

(org)

R

3

N

H

+

A

-

(org)

(2)

(iii) Transport of the amine salt followed by stripping

at the interface between the membrane and

internal phase, after the amine salt had diffused

across the membrane, the complex reacts with the

stripping solution (Na

2

CO

3

) at the membrane-

stripping phase interface, as indicated in Eq. (3).

2R

3

NH

+

A

-

(org)

+ 2Na

+

(aq)

+ CO

2-

3(aq)

(R

3

NH

+

)

2

CO

2-

3(org)

+ 2Na

+

(aq)

+ 2A

-

(aq)

(3)

(iv) Finally, the amine carbonate formed in the

stripping reaction diffuses back to the external

phase interface where it dissociates into carbon

dioxide and water, and thus regenerates the free

amine as given by Eq. (4).

(R

3

NH

+

)

2

CO

2-

3(org)

2R

3

N

(org)

+ CO

2

+ H

2

O (4)

Conclusions

The proposed ELM can be successfully employed to

achieve acetic acid extraction from aqueous solutions.

The concentration of the carrier, Alamine 300, affects

the extraction rate. The highest acetic acid extraction

rate was obtained with 5% concentration of alamine

300. The optimum conditions obtained from the

experimets were: membrane phase with surfactant

Span 80 (4% w/w), the carrier alamine 300 (5% w/w),

and the diluent toluene (91% w/w), Na

2

CO

3

concentration in the feed solution (10% w/v). The

optimal feed phase pH was 1.8, and the mixing speed

of feed solution was 300 rpm. The use of toluene as a

diluent achieved 86% extraction of acetic acid.

Acknowledgements

The authors wish to express their sincere gratitude

to the State Planning Organization of Turkey which

supported this work, and Mehmet Yilmaz, coordinator

of BAPK in Sakarya University. Special thanks to

Assist. Prof. Osman Kola, Department of Food

Engineering, Sakarya University, for analyzing HPLC

data.

References

1 Wodzki R & Nowaczyk J, Sep Purif Technol, 26 (2002) 207.

2 Shin C H, Kim J Y, Kim H S, Lee H S, Mohapatra D, Ahn J

W, Ahn J G & Bae W, J Hazard Mater, 162(2-3) (2009)

1278.

3 Husson S M & King C J, Ind Eng Chem Res, 37 (1998) 2996.

4 Tung L A & King C J, Ind Eng Chem Res, 33 (1994) 3217.

5 Koga K & Kishimoto R, U.S. Pat. 4,353,784 (1978).

6 Chand S, Deepak D & Jain S K, Res Ind, 39 (1994) 261.

7 Sano T, Eijiri S, Hasegawa M, Kawakami Y, Enomoto N,

Tamai Y & Yanagishita H, Chem Lett, 2 (1995) 153.

8 Saha B, Chopade S P & Mahajani S M, Catal Today, 60

(2000) 147.

9 Singh A, Tiwari A, Mahajani S M & Gudi R D, Ind Eng

Chem Res, 45 (2006) 2017.

10 Demiral H & Yildirim M E, Water Sci Technol, 47 (2003)

183.

11 Shin C H, Kim J Y, Kim H S, Lee H S, Mohapatra D, Kim J

Y, Ahn J W &. Ahn J G, KOCS Int Symp, South Korea, July,

(2007) 173.

12 Hagg M B, J Sep Purif, 27(1) (1998) 51.

13 Thien M P & Hatton T A, Sep Sci Technol, 23 (1988) 819.

14 Brien D J O & Senske G E, Sep Sci Technol, 24 (1989) 617.

15 Manzak A & Tutkun O, Sep Sci Technol, 39 (2005) 2497.

16 Kumaresan T, Meera K M, Begum S, Svashanmugam P,

Anantharaman N & Sundaram S, Chem Eng J, 95 (2003)

199.

17 Hirato T, Kishigami I, Awakura Y & Majima H,

Hydrometallurgy, 26 (1991) 19.

18 Kyuchoukov G, Labbaci A, Albert J & Molinier J, Ind Eng

Chem Res, 45 (2006) 503.

19 Yabbanavar V M & Wang D I C, Ann N Y Acad Sci, (1987),

506,523

20 Wennersten R, J Chem Technol Biotechnol, 33B (1983) 85.

21 Chaudhury J B & Pyle D L, in Separation for biotechnology

edited by D L Pyle (Elsevier, Amsterdam), 2 (1990) 112.

22 Teramoto M, Sakai T, Yanagawa K, Ohsuga M & Miyake Y,

Sep Sci Technol, 18 (1983) 735.

23 Schller C, Chaudhuri J B & Pyle D L, Biotechnol Bioeng,

42 (1993) 50.

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Atomic and Molecular PhysicsDocument28 pagesAtomic and Molecular PhysicsAvinash GuptaPas encore d'évaluation

- EMI InstructionsDocument2 pagesEMI InstructionsAKSHAY ANANDPas encore d'évaluation

- Mole Concept: Chemfile Mini-Guide To Problem SolvingDocument18 pagesMole Concept: Chemfile Mini-Guide To Problem SolvingNaren ParasharPas encore d'évaluation

- IOSA Self Evaluation Form - 31 October 2014Document45 pagesIOSA Self Evaluation Form - 31 October 2014pknight2010Pas encore d'évaluation

- Biosafety FH Guidance Guide Good Manufacturing Practice enDocument40 pagesBiosafety FH Guidance Guide Good Manufacturing Practice enMaritsa PerHerPas encore d'évaluation

- Human Diseases A Systemic Approach 8th Edition-Páginas-15-26Document12 pagesHuman Diseases A Systemic Approach 8th Edition-Páginas-15-26Karime LopezPas encore d'évaluation

- Amaryllidaceae Family Guide with Endemic Philippine SpeciesDocument28 pagesAmaryllidaceae Family Guide with Endemic Philippine SpeciesMa-anJaneDiamos100% (1)

- Yanagiba Sharpening: Everything You Need To KnowDocument16 pagesYanagiba Sharpening: Everything You Need To KnowT ChenPas encore d'évaluation

- Darnell's Father Goes StrictDocument2 pagesDarnell's Father Goes StrictDavid Theodore Richardson IIIPas encore d'évaluation

- Catalyst Loading ProcedureDocument3 pagesCatalyst Loading ProcedureNaresh SamalaPas encore d'évaluation

- CHAPTER 15 Managing Current AssetsDocument26 pagesCHAPTER 15 Managing Current AssetsAhsanPas encore d'évaluation

- Environmental Science OEdDocument9 pagesEnvironmental Science OEdGenevieve AlcantaraPas encore d'évaluation

- Charlotte's Web: SynopsisDocument6 pagesCharlotte's Web: SynopsisAmbrosio MéndezPas encore d'évaluation

- Volume 1Document168 pagesVolume 1lalitendu jenaPas encore d'évaluation

- 1 The Fifth CommandmentDocument10 pages1 The Fifth CommandmentSoleil MiroPas encore d'évaluation

- SSMT ConplanDocument2 pagesSSMT ConplanJeffrey VillangcaPas encore d'évaluation

- DSUSJRC01161350 Corail ST-Total Hip SystemDocument20 pagesDSUSJRC01161350 Corail ST-Total Hip SystemXeniaPas encore d'évaluation

- Group 17-Solid State NMR - Questions-AnswersDocument5 pagesGroup 17-Solid State NMR - Questions-AnswersOmkar AkulwarPas encore d'évaluation

- Calculation of Lightning and Switching Overvoltages Transferred Through Power TransformerDocument9 pagesCalculation of Lightning and Switching Overvoltages Transferred Through Power TransformerBožidar Filipović-GrčićPas encore d'évaluation

- Test Units and Accessories: Sinteso™Document22 pagesTest Units and Accessories: Sinteso™Imad QsnPas encore d'évaluation

- Lab 9-Measurement of Filtrate Loss and Mud Cake Thickness of Drilling Mud Sample Using Dead Weight Hydraulic Filter Press Considering API Standard.Document17 pagesLab 9-Measurement of Filtrate Loss and Mud Cake Thickness of Drilling Mud Sample Using Dead Weight Hydraulic Filter Press Considering API Standard.Sunny BbaPas encore d'évaluation

- TESC CRC Office & Gym Roof Exterior PaintingDocument6 pagesTESC CRC Office & Gym Roof Exterior PaintinghuasPas encore d'évaluation

- Borri Ups b9000 Ups Service Manual - CompressDocument180 pagesBorri Ups b9000 Ups Service Manual - CompressArun SPas encore d'évaluation

- Holy Cross Academy Quarterly Cookery ExamDocument4 pagesHoly Cross Academy Quarterly Cookery ExamAlle Eiram Padillo95% (21)

- Secondary AssessmentsDocument12 pagesSecondary Assessmentsapi-338389967Pas encore d'évaluation

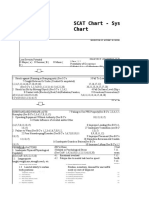

- SCAT Chart - Systematic Cause Analysis Technique - SCAT ChartDocument6 pagesSCAT Chart - Systematic Cause Analysis Technique - SCAT ChartSalman Alfarisi100% (1)

- Isolation and Characterization of Galactomannan From Sugar PalmDocument4 pagesIsolation and Characterization of Galactomannan From Sugar PalmRafaél Berroya Navárro100% (1)

- Ups Installation Method StatementDocument197 pagesUps Installation Method StatementehteshamPas encore d'évaluation

- SafewayDocument70 pagesSafewayhampshireiiiPas encore d'évaluation

- Experiment 4 (Group 1)Document4 pagesExperiment 4 (Group 1)Webster Kevin John Dela CruzPas encore d'évaluation