Académique Documents

Professionnel Documents

Culture Documents

Shear Behavior of Large-Size Concrete Beams

Transféré par

Việt Vớ Vẩn0 évaluation0% ont trouvé ce document utile (0 vote)

22 vues7 pagesThis paper presents test results of six large-size concrete beams reinforced with either conventionalor High-Strength Steel and tested up to failure. The beams were COllstructed without web reinforcement to evaluate the nominal shear strength provided by the concrete. The study shows that using high-. / the shear spandepth ratio, concrete compressive strength, as well as the type. Of longitudinal s teel reinforcement is investigated.

Description originale:

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentThis paper presents test results of six large-size concrete beams reinforced with either conventionalor High-Strength Steel and tested up to failure. The beams were COllstructed without web reinforcement to evaluate the nominal shear strength provided by the concrete. The study shows that using high-. / the shear spandepth ratio, concrete compressive strength, as well as the type. Of longitudinal s teel reinforcement is investigated.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

22 vues7 pagesShear Behavior of Large-Size Concrete Beams

Transféré par

Việt Vớ VẩnThis paper presents test results of six large-size concrete beams reinforced with either conventionalor High-Strength Steel and tested up to failure. The beams were COllstructed without web reinforcement to evaluate the nominal shear strength provided by the concrete. The study shows that using high-. / the shear spandepth ratio, concrete compressive strength, as well as the type. Of longitudinal s teel reinforcement is investigated.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 7

ACI STRUCTURAL JOURNAL TECHNICAL PAPER

Title no. 105-S18

Shear Behavior of Large Concrete Beams Reinforced

with High-Strength Steel

by Tarek K. Hassan, Hatem M. Seliem, Hazim Dwairi, Sami H. Rizkalia, and Paul Zia

This paper presents test results of six large-size concrete beams

reinforced with either conventional- or high-strength steel and

tested up to failure. The beams were COllstructed without web

reinforcement to evaluate the nominal shear strength provided by

the concrete. The shear behavior, ultimate load-carryirlg capacity,

and mode of failure are presented. The applicability oj the current

ACI design code to large-size concrete beams constructed without

web reinforcemelll is discussed. The influence 0/ the shear span-

depth ratio, concrete compressive strength, as well as the type Gild

the amount of longitudinal s teel reinforcement is investigated.

The study shows that using high-strength steel alters the mode of

failure from diagonal tension to shear compression failure and

results in higher shear strength compared with using conventional

steel. It was also found that the current ACI shear design

provisions are ullconservative for large-size concrete beams

without web reinforcement.

Keywords: beams; high-performance steel; high-strength steel; shear.

INTRODUCTION

The demand for high-perfonnance reinforcing materials

has been increasing over the past few years to combat

unnecessary repair costs, which are estimated to exceed

billions of dollars a year in the U.S.

i

,2 Extensive research

has been conducted in the past few years to evaluate the

materials characteristics of different types of high-petfonnance

steel. Nevertheless, the resulting impact on exi sti ng building

codes is sparse in relation to the effort put into research. The

lack of infonnation regarding the behavior of concrete

members reinforced with this type of material prevents

design engineers from using the full strength of the material.

Different types of high-petfonnance reinforcing bars are

currently being examined by different research institutions

and universities worldwide for various structural engineering

applications. By metallurgically modifying the microstructure

of the steel, the bars are less susceptible to conosion

compared with conventional steel and have a yield strength

that is almost twice that of conventional steel. Several

demonstration projects including bridge decks, airport

control towers, bridge piers, and high-rise condominiums

have been constructed successfully using high-strength

steel.

2

Nevertheless, in most of these applications, the high-

strength bars have been used by direct substitution of the

amount required for conventional steel and, thus, neglecting

the benefits of the higher yield strength of the material. It has

been recently reported that the higher yield strength of the

material could strongly influence the shear behavior, ultimate

load-carrying capacity, and mode of failure of concrete beams

reinforced with this type of material. J The use of high-

performance steel reinforcement in concrete footings and

mat foundations has an emergent potential to increase

longevity and, therefore, lead to substantial savings in the

ACI Structural Journal/March-April 2008

life-cycle cost of concrete structures. The high yield strength

of the material combined with its enhanced corrosion resistance

makes it ideal for substructure applications. In most cases,

the depth of footings and mat foundations is controlled by

either one- or two-way shear. Therefore, understanding the

shear behavior of concrete members reinforced with high-

performance steel is essential for a safe and economic. design

of foundations.

Despite numerous comprehensive studies over the last 50 years,

understanding of the shear behavior of conventionally-reinforced

concrete beams remains unclear. Several international codes,4-6

including the current ACI Building Code (ACI318-05),4 are

based on semi-empirical considerations. The calculated

shear strength could vary significantly among different code

approaches. Discrepancies up to 250% in the aJlowable shear

stress according to different codes of practice have been

reported

7

There is also substantial evidence that the shear

stress at failure decreases as the depth of the member increases

and as the aggregate size decreases

8

-

iO

Such a phenomenon

raises doubt about the use of current shear design provisions

for beams without web reinforcement. It should be highlighted

that 86% of all available test data compiled by the Subcom-

mittee F of Joint ACI-ASCE Corrunittee 445 pertain to beam

depths less than 500 mm (20 in.)9

One of the main factors affecting the nominal concrete

shear strength is the ability of concrete to transfer shear

across cracks in the web of the beams. Softening of the

concrete due to the biaxial state of tension-compression in the

web of beams loaded in shear has been investigated by many

researchers, and different fonnulations have been proposed in

the past 25 years. It has been observed that these models vary

widely even for concrete beams reinforced with conventional

steel. Some theories of biaxial softening of concrete do not even

predict concrete crushing at very high defonnations.

ii

This paper presents test results of six large-size concrete

beams reinforced with either high-strength or conventional

Grade 420 MPa (60 ksi) steel and tested up to failure. All the

beams were constructed without web reinforcement to evaluate

the concrete shear strength. The influence of the shear span-

depth ratio (a/d) as well as the type and the amount of

longitudinal steel reinforcement is investigated.

RESEARCH SIGNIFICANCE

Efficient use of the high tensile strength characteristics of

the high-petfonnance steel is expected to provide durable

ACI Structural Journal, V. 105, No.2, March-April 2008.

MS No. S-2oo6-398.RI received October 11 ,2006, and rcvie..-.ed under Institllte

publication policies. Copyright 2008, American Concrete Institute. All rights reserved,

including the making of copies unless pennission is obtained from the proprietors.

Pertinent di scussion including authors closure, if any, will be pubhshed to the January-

February 2009 ACI Slrncnfra/ JOImus/ if the discussion is received by September 1,2008.

173

Tarek K. Hassan is WI Associate Professor in the Department of Stmcturol Engineering,

Ain Shams University, Cairo, Egypt. He received his MSc and PhD from the University of

Manitoba. Winnipeg, ME. Canada, in 1999 and 2002, respectively. He is currently a

part-time Senior Structural Ellgineer at Dar At Handasah Consultants, Cairo, Egypt.

His research interests include nonlinear analysis wId design of concrere structures,

and repair and strengthening of concrere stmctures USing advanced composite materials,

ACI member Hatem M. ScHem is a Postdoctoral Research Associate in the Department

of Civil, Construction, and Environmental Engineering at NOr/h Carolina State

Universit)' (NCSU), Raleigh, NC. He received his PhD from NCSU in 2007 and his

ESc and MSc from Cairo Cairo, Egypt, in 2000 and 2002, respectively, His

reuarch interests include design of concrete structures using innovative materials and

retrofilling of reinforced nmcrete structures u.sing advanced composite materials.

Hazim Dwairi is an Assistant Professor in the Department of Civil EIIKineering,

Hashemire Unh'ersiry, Jordan. He received his PhD from North Carolina State

University in 2004. His research interests include design and analysis of concrete

structures and behavior of stmctures under lateral loads.

Sami H, Rizkalla, FACI, is a Distinguished Professor of Civil and Construction

Engineering in the Deportment of Civil, Constmction and Ellvironmental Engineering;

Director of the Constructed Facilities lAboratory (CFL); and Director of the NSF

Industry/University Cooperative Research Center at North Carolina State University.

He is also the immediate Past President and the founder of the Nerwork of Celllers of

Excellence on IlIIelligent Sensing of Innovative Stmctures (ISIS Canada). He is Past

Chair alld a current member of ACI Committees J 18, Use of Computers; 440, Fiber

Reinforced Polymer Reinforcement; E803, Faculty Network Coordinating Comm;lIee;

and a member of Joint AClASCE Committees 423, Prestressed Concrete, and 550,

Precast Concrete Structures.

ACI Honorary Member Paul Zia is a Distinguished University Professor Emeritus at

North Carolina State University, He is a member of ACI Committees 363, High-

Strength Concrete, and 440, Fiber Reinforced Polymer Reinforcement; loilll ACl-

ASCE Committees 423, Prestressed COl1crete, and 445, Shear and Torsion; ACl TAC

Technology Transfer Committee; and the COllcrele ResearclJ COllneil.

concrete structures with smaller reinforcement ratios and

significantly reduced maintenance requirements compared

with conventional steeL The present experimental study

allows quantifying the benefits of using high-strength steel

and provides experimental evidence of its high strength

capabilities. The impact of the high tensile strength of the

material on the shear beha:vior of concrete beams is

demonstrated. The study also evaluates the limitations of the

current shear design provisions in the ACI Code

4

to develop

design guidelines that recognize its contribution to the shear

strength of concrete beams.

EXPERIMENTAL INVESTIGATION

Test specimens

Six large-size concrete beams were constructed and

loaded to failure under concentrated load acting at midspan.

The main variables included in the study are the aid, concrete

compressive strength, and the type and amount of the longitu-

dinal steel reinforcement. All the beams had identical nominal

cross-sectional dimensions of 460 x 915 mm (18 x 36 in.) with

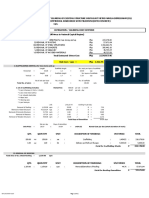

Table 1-Details of test specimens

Group A

a total length of 4900 mrn (16 ft). The dimensions of the

beams were selected to be much larger than those used in

developing the ACI shear design provisions established in

1962.

12

The beams were cast in three batches of different

concrete strengths, producing three groups (A, B, and C) of

identical dimensions. One beam of each group was rein-

forccd with conventional Grade 420 MPa (60 ksi) steel

while the other beam was reinforced with high-strength

steel bars , No transverse reinforcement was provided in

any of the specimens to evaluate the nominal concrete shear

strength. The first group of beams (Group A) was tested at an

aid of 1.9. The influence of the concrete compressive

strength on the shear behavior was investigated by testing

the second group of beams (Group B) using the same aid of

1.9, but with a lower concrete compressive strength. The

third group of beams (Group C) was tested using an aid of

2.7 to examine the flexural shear behavior of the beams. The

longitudinal reinforcement ratio used in the concrete beams

reinforced with high-strength steel was 40% less than that

used in concrete beams reinforced with Grade 420 MPa (60 ksi)

steel. This reduction in the reinforcement ratio is based on

using a yield strength of 690 MPa (100 ksi) for the high-

strength steel. The beams are identified by a numbering

code. The first letter denotes the type of the longitudinal steel:

G for Grade 420 MPa (60 ksi) steel and M for high-strength

steel. The second term represents the aid, while the third

number denotes the concrete compressive strength in MPa.

Details of the test specimens are given in Table 1. The

longitudinal steel was evenly distributed along the width of

the specimens leaving 40 mm (1.5 in,) concrete cover on

each side. Bottom cover was chosen according to ACI 318-05

4

for beams subjected to interior exposure. The bottom

longitudinal steel bars were hooked upward beyond the

supports to preclude the possibility of anchorage failure.

Materials

High-strength steel- A commercially available high-

perfOlTIlanCe steel known as microcomposite multistructural

formable (MMFX) steel, which conforms to ASTM

A1035,13 was selected for this study. Tension coupons were

tested according to AS1M A370

14

to determine the material

characteristics of the bars. Typical stress-strain behavior of

the MMFX bars compared with Grade 420 MPa (60 ksi)

steel bars is shown in Fig. I. The high-strength steel bars

exhibited a linear stress-strain relationship up to a stress

level of 690 MPa (100 ksi), followed by a nonlinear behavior

up to failure without a well-defined yield point. According to

Group B Group C

Specimen 0-1.9-51 M-1.9-51 0-1.9-38 M- 1.9-38 0 -2.7-32 0 -2.7-32

Shear span-depth ratio (aid) 1.9 1.9 1.9 1.9 2.7 2.7

Concrete compressive strength, MPa (psi) 51 (7400) 51 (7400) 38 (5500) 38 (5500) 32 (4650) 32 (4650)

Type of longitudinal reinforcement 0'

M'

0 '

M'

0' M'

Bottom reinforcement ratio, % 0.72 0.44 0.72 0.44 0.72 0.44

Top reinforcement ratio, % 0.36 0.22 0.36 0.22 0.36 0.22

Diagonal cracking load, kN (kips) 670 (150) 670 (150) 670 (150) 670 (150) 445 (100) 445 (100)

Failure load, k.N (kips) 871 (195) 1560 (350) 753 (170) 1364 (306) 552 (124) 638 (143)

Predicted failure load using ACI 318-05, kN (kips) 1103 (248) 1917 (431) 1103 (248) 1418 (319) 690 (155) 690 (155)

PTes/PACI318.05 0.8 0.81 0.68 0.96 0.80 0.92

G refers to Grade 60 steel.

tM refers to high-strength steel.

174 ACI Structural Journal/March-April 2008

ASTM A370

14

offset method (0.2%), the yield strength of

the bars was detennined to be 827 MPa (120 ksi). The

measured initial modulus of elasticity of the bars was 200 GPa

(29,000 ksi) up to a stress level of 690 MPa (100 ksi), beyond

which a considerable reduction in the modulus of elasticity

was observed. Based on test results, the average ultimate

tensile strength was 1120 MPa (162 ksi).

Grade 420 MPa (60 ksi) steel- The Grade 420 MPa (60 ksi)

reinforcing bars used in the current study met the requirements

of ASTM A6l5.

15

Based on tension coupon tests, the bars

had an average modulus of elasticity and yield strength of

200 GPa (29,000 ksi) and 469 MPa (68 ksi), respectively.

m

a.

w

w

<n

1200 174

1000 145

MPa (120 ksi)

800 116

600 87

400 58

200 29

a a

0.00 0.02 0.04 0.06 0.08 0.10 0.12 0.14 0.16 0.18

Strain (mm/mm), (in.lin.)

w

w

<n

Fig. i -Typical stress-strain behavior for conventional and

high-strength steel.

4900 mm (16 tt) .

Concrete- All beams were cast with nonnal-strength

concrete with a maximum aggregate size of 19 nun (0.75 in.)

using three different batches of concrete. The compressive

strength of the concrete was determined based on the average of

at least three 100 x 200 mm (4 x 8 in.) cylinders cast from the

same batch of concrete and cured under the same conditions as

the beams. The measured concrete compressive strength for

different specimens is given in Table 1.

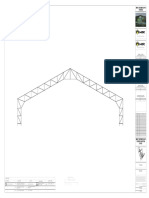

Test setup

The beams were tested under a concentrated load acting at

midspan, as shown in Fig. 2. The load was applied using a

2000 kN (450 kips) hydraulic actuator. The beams were

supported on either steel I-beams or concrete blocks secured

to the strong floor. Neoprene pads were placed between the

concrete beam and the supports to allow for rotation at both

ends of the beam. A 25 mm (1 in.) thick steel plate was

attached to the actuator to distribute the load to. the beam.

Neoprene pads were placed between the loading plate and

the concrete surface to prevent local crushing of the

concrete. Each beam was instrumented to measure the

vertical deflections at midspan and at the supports using

string potentiometers. Twelve horizontal and vertical linear

potentiometers were used to measure diagonal crack widths.

Two PI gauges were attached to the top and bottom of the

beam at midspan to measure the concrete defonnation. All the

data were continuously recorded up to failure. Instrumentation

layout is shown in Fig. 3 and 4 for beams with aid of 1.9 and

2.7, respectively.

EXPERIMENTAL RESULTS AND DISCUSSION

Deflections

The load-deflection behavior of the test specimens of

Group A having an aid of 1.9 and a concrete compressive

25 mm (1 in.) Thick Steel Plate

,2:bsomm

r

915 mm

10 in.)

(36 in.)

I

\

25 mm (lin.) Thick Neoprene Pad

-.

Steel I-beams

- --3050 mm (10 ft)}----->

...

.. -

- 4900 mm (16 ft}------ --- .-.-- - -- ---'

-.

r

.... ,.. -,

%Omm

1"111 in:J 65 mm

3 No. 19M 0" . , {2.5 In.}- "

(3#6) I

915 mm

(36 in.)

6 No. 19M ,

(6#6) 65 mil' --..

(2.5 in.)

Section a-a

Beam reinforced with high-strength steel

Fig. 2- Details of test specimens.

ACI Structural Journal/March-April 2008

25 mm (lin) Thick steel Plate

. .. .. :.J

460mm

tISTiif _ 65 mm

2 No. 25M+l No. 22MO . {2.5 in) i

(2#8+1#7) ,

91S'mm

(36 in.)

4 No. 2SM+2 No. 22M ,

(4#8+2#7) 65 mm I -

(2.5 in.)

Section a-a

Beam reinforced with conventional steel

175

strength of 51 MPa (7400 psi) is shown in Fig. 5. For both

specimens, linear behavior was observed up to the initiation

of the first flexural crack at a load level of 370 kN (83 kips)

followed by nonlinear behavior up to failure. Following the

fonnation of the flexural cracks, a major diagonal shear

crack developed and became visible in both specimens at a

load level of 670 kN (150 kips). After cracking, the

measured deflections of the concrete beam reinforced with

high-strength steel (Specimen M-1.9-51) were significantly

higher than those measured for the concrete beam reinforced

with Grade 420 MPa (60 ksi) steel (Specimen G-1.9-51).

This behavior is attributed to the reduced reinforcement ratio

Fig. 3- Instrumentation layout of beams with aid of 1.9.

Fig. 4- Instrumentation layout of beams with aid of 2. 7.

Mid-span deflection (in.)

0.0 0.2 0.3 0.5 0.6 0.8 0.9

1800 405

1600

- G-1.9-S1 a/d=1. 9

360

- M-1.9-51

1400 315

Z

1200 270 VI

is g

u

1000

225 "

.Q

.Q

u

800 180

0.

1

0.

<{

600

d J I

135

400 90

T a T

200

,

45

0 0

0 4 8 12 16 20 24

Mid-span deflection (mm)

Fig. 5-Load-deflection behavior of Group A specimens.

176

used in Specimen M-1.9-51, resulting in higher steel strain

and probable higher localized bond slip.

The behavior of concrete beams having the same aid of 1.9

but constructed with a lower concrete compressive strength

of 38 MPa (5500 psi) was investigated using Group B test

specimens. To simulate overloading conditions, both

Specimens G-1.9-38 and M-1.9-38 of Group B were initially

loaded to a load level of 450 kN (100 kips) and unloaded.

The specimens were reloaded up to failure to evaluate the

post-cracking stiffness for both specimens. The load-deflection

behavior of the second load cycle is shown in Fig. 6. The

measured post-cracking stiffness of Specimen G-1.9-38,

reinforced with Grade 420 MPa (60 ksi) steel, was 50%

higher than that of Specimen M-1.9-38, which is reinforced

with high-strength steel but with a reduced reinforcement ratio.

The load-deflection behavior of Group C beams with an aid

of2.7 and concrete strength of 32 MPa (4650 ksi) is shown

in Fig. 7. Similar to Group B specimens, the two specimens,

G-2.7-32 and M-2.7-32, were loaded to 225 kN (50 kips) and

unloaded before loading to failure to simulate overloading

conditions. The beam reinforced with high-strength steel

(M-2.7-32) exhibited higher deflections than the beam

reinforced with Grade 420 MPa (60 ksi) steel (G-2.7-32)

at the same load level. This behavior is attributed to the

smaller area of reinforcing steel used and higher induced

steel strain and probable more localized bond slips.

In general, concrete beams reinforced with Grade 420 MPa

(60 ksi) steel reinforcement exhibited less post-cracking

deflection at the same load level compared with beams

reinforced with high-strength steel because the latter had a

reduced reinforcement ratio. For beams reinforced with

Grade 420 MPa (60 ksi) steel, failure was sudden and was

preceded by relatively little cracking. The measured ultimate

midspan deflection for the three beams reinforced with

Grade 420 MPa (60 ksi) steel was less than the span/470. A

less brittle behavior was observed for the beams reinforced

with high-strength steel. Considerable deflections and much

wider cracks were observed for these beams prior to failure.

At failure, the deflections for the beams reinforced with the

high-strength steel and having an aid of 1.9 were equivalent

to the span/230, twice the deflections of the beams reinforced

with Grade 420 MPa (60 ksi) steel.

Mid-span deflection (in.)

0.0 0.2 0.3 0.5 0.6 0.8 0.9

1800 405

1600

....... G-1.9-38

a/d=1.9

360

1400 315

Z

1200 270

is :;;;

u

1000 225 :;-

.Q

.Q

u

160

800

0.

0.

<{

600 135

400 90

T

200 45

0 0

0 4 8 12 16 20 24

Mid-span deflection (mm)

Fig. 6-Load-deflection behavior of Group B specimens.

ACI Structural Journal/March-April 2008

i

Crack pattern

For aU specimens, flexural cracks were first initiated under

the applied load. With further increase of load, new flexural

cracks formed in the shear spans and curved toward the

loading area. The first diagonal shear crack was observed at

the same load level for identical specimens regardless of the

type of reinforcement. For specimens reinforced with

Grade 420 MPa (60 ksi) steel with an aid of 1.9, the first

diagonal shear crack was observed at a load level equivalent to

. 80% of the ultimate load. A similar crack was observed at a

load level of approximately 45% of the ultimate load for the

beams reinforced with high-strength steel. Such a phenomenon

demonstrates the reserved capacity for these beams and

provides adequate warning prior to shear failure. Figure 8(a)

depicts a typical crack pattern at the initiation of diagonal

shear cracks for Specimens M-1.9-51 and M-2.7-32, reinforced

with high-strength steel and having aid of 1.9 and 2.7, respec-

tively. Diagonal cracking loads for all the specimens are given

in Table 1. The width of the major diagonal shear crack for

different specimens is shown in Fig. 8(b). The figure clearly

shows that the major diagonal shear crack in the beams

reinforced with high-strength steel was almost three times

wider than that observed in identical beams reinforced with

Grade 420 MPa (60 ksi) steel before failure. This is attributed

to the reduced reinforcement ratio used for high-strength steel.

Failure mode

Beams reinforced with Grade 420 MPa (60 ksi) steel-

Diagonal tension failure was observed for the three concrete

beams reinforced with Grade 420 MPa (60 ksi) steel. Failure

occurred due to extension of the diagonal shear crack rapidly

toward the load point shortly after its initiation. Strain

measurements at the bottom of the concrete beams at

midspan implied that yielding of the conventional steel

reinforcement governed the failure mode. A separate

nonlinear finite element study16 confirmed the observed

behavior and indicated yielding of the longitudinal conventional

reinforcement at the location of shear cracks, as shown in

Fig. 9 for Specimen G-1.9-51. Upon yielding of the longitudinal

steel reinforcement at the location of a shear crack, the

section was no longer capable of resisting any additional

increase in load and the concrete beams failed abruptly in

shear. Detailed information about the finite element modeling

is reported elsewhere.

16

Mid*Span Deflection (in.)

0.0 0.2 0.3 0.5 0.6 D.B 0.9

1800 405

1600

--- M2.732

a/d=2.7

360

-+-G -2.7-32

1

1400

d I I

315

1200

"'

270 g

1000

T a T

225

,

0

u

BOD 1BO al

a. 'a.

600

135

'"

400 90

200 45

0 0

0 4 B 12 16 20 24

Mid"Span Deflection (mm)

Fig. 7- Load-deflection behavior of Group C specimens.

ACI Structural Journal/March-April 2008

Beams reinforced with high"strength steel- Failure was

controlled ptimarily by the compressive strength of the diagonal

strut (compression shear failure). The high yield strength of

the materials precluded diagonal tension failure and allowed

the failure to take place in the concrete strut at much higher

Diagonal crack width (in.)

o 0.02 0.04 0.06 0.08 0.1 0.12 0.14 0.16

1800 405

1600

1400

Z 1200

"-

1000

g

] 800

L

i

-- :::: : l

--M-2.732

--G-2.7-32

-----

J 600 l.... __

400

1

200

(b)

o 0.5 1. 5 2 2.5 3 3.5

Diagonal crack width (mm)

360

315

270 -;;)

225 g

u

0

180 :;;

..

135 J

90

45

0

4

Fig. 8-(a) Crack pattern at initiation of diagonal shear

crack; and (b) diagonal crack width of different specimens.

Mid-span "''''''"--1

G1.9-51

longitudinal steel reinforcement

i .. 0.002)

Fig. 9-Typical tensile strain distribution at ultimate of concrete

beams reinforced with conventional Grade 60 steeL 16

177

loads. Typical tensile strains at the midspan section, for

Groups Band C, are shown in Fig. 10 and 11 , respectively.

The figures show that at ultimate, the measured tensile strain

in the high-strength steel bars exceeded its yield strain

defined by the 0.2% offset method. Typical shear failure of

concrete beams reinforced with Grade 420 MPa (60 ksi) and

high-strength steel is shown in Fig. 12.

Concrete shear strength

Despite the reduction in the reinforcement ratio, the shear

strength of concrete beams reinforced with high-strength

steel was significantly higher than that of the beams reinforced

with Grade 420 MPa (60 ksi) steel. The high yield strength

of the material maintained the capacity of the tension tie and

allowed the beams to resist more load until crushing of the

diagonal strut occurred. This behavior was highly

pronounced for beams with a small aid (aid = 1.9). The ultimate

load-carrying capacity of Specimen G-1.9-51, reinforced

with Grade 420 MPa (60 ksi) steel and having an aid of 1.9,

was 871 leN (195 kips). Test results showed that the concrete

shear strength could be increased by 80% but using 40% less

area of high-strength steel (Specimen Similar

behavior was observed for Specimens G-1.9-38 and M- l. 9-38.

As the tensile stress in the high-strength steel bars

approached its yield strength, wide cracks were observed

1800 405

a/d=1 .9

1600 360

1400 31 5

....... 1200 270 Iii

z

6

6

1000 225 '0

ro

.Q

.Q

800 180 :

ro

'B..

a.

"

600 135 <C

400 90

200 T

45

0 0

0 0.002 0.004 0.006 0.008

Tensile strain (mm/mm). (in.lin.)

Fig. i O-Load-tensile strain behavior of Group B specimens.

1800 I

1

405

I 360 1600

-M-2.7-32

1400

j'"

! .!.

-1

270 I

Z

6

-g 1000 , 225 "0

.Q

.

BOO 180 ijl

a.

'5.

135 Jf

"

600

400 90

200 ald=2.7 45

0 0

0 0.002 0.004 0.006 0.008

Tensile strain (mm/mm), (inJ!n.)

Fig. ii-Load-tensile strain behavior of Group C 'pecimens.

178

and the beneficial effect of using high-strength steel started

to attenuate. Such a phenomenon was clearly observed for

beams with an aid of 2.7. Using high-strength steel as main

longitudinal reinforcement in these beams increased the

shear strength by only 16% while using 40% less steel.

Failure loads for all specimens are summarized in Table 1.

COMPARISON WITH AC1318-05

Beams with aid of i.9- A simple strut-and-tie model was

developed as required by the ACI 318-05

4

for beams with a

clear span less than four times the depth of the beam. The

strut-and-tie model consisted of a direct strut extending from

the loading plate to the reaction bearing plate, as shown in

Fig. 13. Failure mechanisms governing the strength were

typically crushing of the compressive strut or yielding of the

tie reinforcement. To account for the nonlinear stress-strain

behavior of high-strength steel, an exponential stress-strain

relationship was assumed as reported by the Concrete innova-

tion Appraisal Services.

17

The bearing dimensions were

sufficiently large to avoid crushing of the concrete at the

nodes in the strut-and-tie model. The predicted ultimate

capacities for different specimens are given in Table 1. In

Fig. 12- Typical shear failure for beams reinforced with

conventional and steel.

I

(5.5 in.)

i strut 5trut ': ....... ! 915 mm

i .:....... I (36 in.)

180 mm (7 In )i 28 65 mm (2. 5 in. ) TIe 2 i

150 mm , I

(6 in.) ' ...

1525 mm (5 ft.} -_ . . - - - 1525 mm (5 R:.)

150 mm

. (6 in.)

Fig. 13-Strut-and-tie model for beams with aid of 1.9.

ACI Structural Journal/March-April 2008

I

general, the analysis indicates that ACI 318-05

4

overestimated

the capacity of concrete beams reinforced with either

conventional- or high-strength steel. For Specimens G-1.9-51

and G-I .9-38 reinforced with Grade 420 MPa (60 ksi) steel,

failure was controlled by yielding of the tie. The predicted

capacity was independent of the concrete compressive strength

and, therefore, identical capacities were predicted for both

specimens. Conversely, crushi ng of the compressive strut

was the governing mode of failure for Specimens M-I.9-51

and M-1.9-38, reinforced with high-strength steel. Increasing

the concrete compressive strength by 34% increased the

predicted capacity by the same magnitude. The analysis

demonstrated the influence of the concrete compressive

strength on the shear strength of the concrete beams reinforced

with high-strength steel. The capacity of the compressive strut

was taken as O.S1i

e

', where/c' is the specified compressive

strength of concrete. It should be highlighted that, according

to ACI 318-05, the compressive capacity of the strut is

independent of the tensile strain in the reinforcement.

Beams with aid 0/2. 7-The nominal concrete shear strength

Vc was predicted according to ACI 318-05 using Eg. (I)

Vc = 0.167 Jt (MPa) (I MPa = 145 psi) (I)

The ACI 318-05

4

design method considerably overestimated

the shear strength of large-size concrete beams constructed

without web reinforcement. The diagonal shear crack was

initiated in the beams with an aid of2.7 and became visible at a

load level of 445 kN (100 kips), which corresponds to

0.11 Jt MPa. The predicted capacity for Specimen G-2.7-32,

reinforced with conventi onal steel, was 25% higher than the

measured value (shear strength corresponds to 0.134 Jt MPa).

It should be noled that the current ACI shear provisions were

based on testing shallow beams, 13 which did not account for the

size effect of large-size beams.

CONCLUSIONS

Based on the findings of this investigation, the following

concl usions can be drawn:

1. High-strength steel strongly influenced the shear

behavior of the concrete beams tested in the current study

and conslmcted without web reinforcement. Ignoring the

high strength characleristics of the material could provide

unreli able predictions of the ultimate load-carrying capacity

and mode of failure;

2. The diagonal cracking strength is a measure of the

concrete contribution at ultimate for members reinforced with

conventional steel and constructed without web reinforcement.

Such a relationship is inappropriate for high-strength steel as

the behavior is strongly influenced by the aid and the stress

level in the bars. Test results showed that initiation of diagonal

shear cracks is independent of the type or the amount of the

longitudinal reinforcement;

3. Concrete beams reinforced with Grade 420 MPa (60 ksi)

steel and constructed without web reinforcement exhibited a

very brittle failure due to yielding of the longitudinal steel

reinforcement. Shear failure occurred shortly after initiation

of the shear crack;

4. Despite the reduction in the reinforcement ratio by 40%,

the shear strength of concrete beams reinforced with high-

strength steel was significantly higher than that of the beams

reinforced with Grade 420 MPa (60 ksi) steel. The high yield

strength of the material maintained the capacity of the

ACI Structural Journal/March-April 2008

tension tie, and thus enabled the beams to resist more load

until crushing of the diagonal strut occurred;

5. A significant reserve in strength was observed for beams

reinforced with high-strength 'Steel after diagonal cracking.

Failure was due to crushing of the diagonal concrete Slmt at

much higher loads compared with beams reinforced with

conventional steel; and

6. The ACI 318-05 si mplified expression for the shear

contribution of concrete is unconservative for large-size concrete

beams without web reinforcement. The expression needs to

account for the size effect and the reinforcement characteristics.

ACKNOWLEDGMENTS

The authors gratefully acknowledge the donation of the materials provided by

MMFX Technologies Corp., CA. Special thanks are extended to A. Rasoy,

E. Thorup. and J. Atkinson at the Constructed Facilities Laboratory for their

valuable help during the experimental program.

REFERENCES

1. Reis, H.; Elvin, B. L.; Kuchma, D. A; and Bernhard, 1. T., "Estimation of

Corrosion Damage in Steel Reinforced Mortar Using Guided Waves,"

Journal of Pressure Vessel Technology, V. 127, No.3, 2005, pp. 255-261.

2. Darwin, D.; Browning, 1.; Nguyen, T. V; and Locke, C., "Mechanical

and Corrosion Properties of a High-Strength, High Chromium Reinforcing

Steel for Concrete," SM Report No. 66, University of Kansas, Lawrence,

KS, 2002, 106 pp.

3. Seliem, H.; Hosny, A.; Dwairi, H.; and RizkalJa, S . "Shear Behavior of

Concrete Beams Rcinforced with MMFX. Steel Without Web Reinforcement,"

Report No. IS-06-08, Constructed Facilities Laboratory, NOllh Carolina

State University, Raleigh, NC, 2006, 21 pp.

4. ACl Committee 318. "Building Code Requirements for Structural

Concrete (ACl318-05) and Commentary (3 18R-05)," Amencan Concrete

Institute. Fannington Hill s, MI, 2005, 430 pp.

5. Commission of the European Communities, "Design of Concrete

Structures. Part 1: General Rules and Rules for Buildings," Eurocode 2, 2003,

330pp.

6. DIN 1045- 1. Deutsche Norm. "Concrete. Reinforced and Prestressed

Concrete Structures- Part I : Design," Normenausschuss Bauwesen

(NABau) im DiN Deutsches l nsti tut fur Normung e. V. Beuth Verlag,

Berlin, Germany. 2001, pp. 1-48.

7. Hawkins, N. M.; Kuchma, D. A.; Mast, R. F.; and Reineck, K.,

"Simplified Shear Design of Structural Concrete Members," NCHRP

Report 549. Washington, DC, 2005, 54 pp.

8. Kani. O. N. 1. , "How Safe are Our Large Reinforced Concrete

Beams?" ACI Structural Journal, V. 64, No. 4, Apr. 1967, pp. 128-141.

9. BaZant, Z. P., and Yu. Q., "Designing Against Size Effect on Shear

Strength of Reinforced Concrete Beams without Stirrups: Formulation,"

Joumai ofSrnlctural Engineering, ASCE, V. 131, No. 12, 2005, pp. 1877-1885.

to. Sherwood, E. G. ; Bentz, E. C.; and Collins, M. P., "Evaluation of

Shear Design Methods for Large. Lightly-Reinforced Concrete Beams,"

Proceedings of the Advances in Engineering StruclUres, Mechanics and

Construction, ON, Canada. 2006, pp. 153-164.

I I. Duthinh, D. , "Senstivity of Shear Strength of Reinforced Concrete

and Prestressed Concrete Beams to Shear Friction and Concrete Softening

According to Modified Compression Field Theory," ACI Structural

Journal, V. 96, No.4, Jul y-Aug. 1999, pp. 495-508.

12. Joint ACI-ASCE Committee 326, "Shear and Diagonal Tension,"

ACIJOURNAL, Proceedings V. 59, No. 1-3, 1962. pp. 1-30,277-344,

and 352-396.

13. ASTM AI035-07, "Standard Specification for Deformed and Plain,

Low Carbon, Chromium, Steel Bars for Concrete Reinforcement," ASTM

International, West Conshohocken, PA, 2007, 5 pp.

14. ASTM A370-07, "Standard Test Methods and Definitions for

Mechanical Testi ng of Steel Products," ASTM International . West

Conshohocken, PA, 2007, 47 pp.

15. ASTM A615-06, "Standard Specification for Deformed and Plain

Carbon-Steel Bars for Concrete Reinforcement," ASTM International,

West Conshohocken, PA, 2006, 6 pp.

16. Hassan, T., "Behavior of Concrete Deep Beams Reinforced with

High Strength Steel," Ain Shams Scientific Bulletin, V. 41, No.3, 2007,

pp.109- 127.

17. Concrete Innovation Appraisal Services, (CIAS), "Structural Design

Criteria for High-Strength MMFX Microcomposite Reinforcing Bars,"

CIAS Report: 04- 1, 2004, 34 pp.

179

Vous aimerez peut-être aussi

- Vinfast and The Electric Vehicle Market in VietnamDocument6 pagesVinfast and The Electric Vehicle Market in VietnamViệt Vớ VẩnPas encore d'évaluation

- Washington,: This Between Agency (EPA) 1 Speed CodeDocument9 pagesWashington,: This Between Agency (EPA) 1 Speed CodeViệt Vớ VẩnPas encore d'évaluation

- The Strive for Perfection CollectionDocument25 pagesThe Strive for Perfection CollectionViệt Vớ Vẩn100% (1)

- Ghost Overview Brochure DigitalDocument48 pagesGhost Overview Brochure DigitalViệt Vớ VẩnPas encore d'évaluation

- Wraith: Rolls-Royce Motor CarsDocument21 pagesWraith: Rolls-Royce Motor CarsViệt Vớ VẩnPas encore d'évaluation

- J5500 LED TV: Product HighlightsDocument4 pagesJ5500 LED TV: Product HighlightsViệt Vớ VẩnPas encore d'évaluation

- Rolls Royce Dawn Model Overview RoWDocument28 pagesRolls Royce Dawn Model Overview RoWChanManPas encore d'évaluation

- Phantom Drophead Coupé Product Overview World PDFDocument24 pagesPhantom Drophead Coupé Product Overview World PDFViệt Vớ VẩnPas encore d'évaluation

- VA Rolls RoyceDocument11 pagesVA Rolls RoyceViệt Vớ VẩnPas encore d'évaluation

- Product Range: Rolls-Royce Motor CarsDocument35 pagesProduct Range: Rolls-Royce Motor CarsViệt Vớ VẩnPas encore d'évaluation

- Phantom 240x180 150dpiDocument29 pagesPhantom 240x180 150dpiViệt Vớ VẩnPas encore d'évaluation

- E229578 RRC Phantom Consumer Booklet PTDocument24 pagesE229578 RRC Phantom Consumer Booklet PTnaveenbaskaranPas encore d'évaluation

- (ME65B ME75B) User Manual PDFDocument222 pages(ME65B ME75B) User Manual PDFpoluxjaPas encore d'évaluation

- Led TV: User ManualDocument26 pagesLed TV: User ManualViệt Vớ VẩnPas encore d'évaluation

- Epoxy Adhesive for Bonding ConcreteDocument2 pagesEpoxy Adhesive for Bonding ConcreteViệt Vớ VẩnPas encore d'évaluation

- HYUNDAI GRAN I10-2015Document23 pagesHYUNDAI GRAN I10-2015DavisCahuatijo100% (1)

- 2018 Mazda6: 2017 Los Angeles Auto Show Press Kit Canadian SpecificationsDocument9 pages2018 Mazda6: 2017 Los Angeles Auto Show Press Kit Canadian SpecificationsViệt Vớ Vẩn100% (1)

- Grand I10 Ebrochure 2017 PDFDocument8 pagesGrand I10 Ebrochure 2017 PDFViệt Vớ VẩnPas encore d'évaluation

- H29 Sekisankijyun 3Document536 pagesH29 Sekisankijyun 3Việt Vớ VẩnPas encore d'évaluation

- Osha Construction PDFDocument65 pagesOsha Construction PDFAlex Xocoxic PeinadoPas encore d'évaluation

- Kumkang Kind PipeDocument24 pagesKumkang Kind PipeViệt Vớ VẩnPas encore d'évaluation

- Handbook Safety PDFDocument219 pagesHandbook Safety PDFJia IdrisPas encore d'évaluation

- New Road Form BrochureDocument12 pagesNew Road Form BrochureViệt Vớ VẩnPas encore d'évaluation

- 2014 2015 Sustainability ReportDocument102 pages2014 2015 Sustainability ReportViệt Vớ VẩnPas encore d'évaluation

- Kia MorningDocument2 pagesKia MorningViệt Vớ VẩnPas encore d'évaluation

- Apple Ccessory Design GuidelinesDocument176 pagesApple Ccessory Design GuidelinesViệt Vớ VẩnPas encore d'évaluation

- 2012 2013 Sustainability ReportDocument94 pages2012 2013 Sustainability ReportViệt Vớ VẩnPas encore d'évaluation

- Pfsolutions BrochureDocument24 pagesPfsolutions BrochureViệt Vớ VẩnPas encore d'évaluation

- Column Former Fast FormDocument8 pagesColumn Former Fast FormViệt Vớ VẩnPas encore d'évaluation

- Beam-Form permanent formwork system for ground beams and pile capsDocument1 pageBeam-Form permanent formwork system for ground beams and pile capsViệt Vớ VẩnPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Reflective EssayDocument3 pagesReflective Essaymikesarsonas12Pas encore d'évaluation

- Building Layout and Foundation Excavation ProcessDocument20 pagesBuilding Layout and Foundation Excavation ProcessVirgilio BiagtanPas encore d'évaluation

- Fire Proof Aluminum Composite Panel, Fire Proof ACP, Jiangyin Jiding Aluminum-Pla PDFDocument3 pagesFire Proof Aluminum Composite Panel, Fire Proof ACP, Jiangyin Jiding Aluminum-Pla PDFAngan KitaPas encore d'évaluation

- NR 12 Solar ShadingDocument52 pagesNR 12 Solar ShadingStrumfetaPipetaPas encore d'évaluation

- Moment Frames PDFDocument49 pagesMoment Frames PDFasmitha singhPas encore d'évaluation

- Print Reading For Constn (2013) D. DorfmuellerDocument51 pagesPrint Reading For Constn (2013) D. DorfmuellerBogasi Q.Pas encore d'évaluation

- Seismic Rehabilitation of Schools in CA-2012-SEAOC-ConvDocument7 pagesSeismic Rehabilitation of Schools in CA-2012-SEAOC-ConvMaldi KokalariPas encore d'évaluation

- Practice Guide Adaptive Reuse Heritage BuildingsDocument80 pagesPractice Guide Adaptive Reuse Heritage BuildingsXione Mirei ChoiPas encore d'évaluation

- Framing Vocabulary Test 2009Document26 pagesFraming Vocabulary Test 2009Randy Stribley100% (1)

- A.B.C.M: Long Span StructureDocument8 pagesA.B.C.M: Long Span Structuresanthu majiPas encore d'évaluation

- SMM Example Schedule of Rates - Bill of Quantities 10july2012.u - 3842828r - 1n - D12 23210355Document63 pagesSMM Example Schedule of Rates - Bill of Quantities 10july2012.u - 3842828r - 1n - D12 23210355Shakthi Thiyageswaran100% (1)

- Ad428 Gumallaoi Judelle v. RSW MT No.2 4aDocument21 pagesAd428 Gumallaoi Judelle v. RSW MT No.2 4aLuwella GumallaoiPas encore d'évaluation

- BR ClayRoofTiles TechnicalManual WADocument54 pagesBR ClayRoofTiles TechnicalManual WAjkrmasyitahPas encore d'évaluation

- Flexural Behavior of Two-Span Continuous Prestressed Concrete Girders With Highly Eccentric External TendonsDocument10 pagesFlexural Behavior of Two-Span Continuous Prestressed Concrete Girders With Highly Eccentric External TendonsAdam AhmadPas encore d'évaluation

- DuraSystems - Grease Duct Access Doors BrochureDocument2 pagesDuraSystems - Grease Duct Access Doors BrochureDuraSystemsPas encore d'évaluation

- Roof Plan: MDC Technology CenterDocument1 pageRoof Plan: MDC Technology CenterEljoy C. AgsamosamPas encore d'évaluation

- ECM1 Technical Information Warm-HumidDocument29 pagesECM1 Technical Information Warm-Humidank25795100% (1)

- REEFER CTNR - Structure MiscellaneousDocument17 pagesREEFER CTNR - Structure MiscellaneousLe Cuong ThinhPas encore d'évaluation

- Comparison Between Esteem & ManualDocument12 pagesComparison Between Esteem & ManualalialiPas encore d'évaluation

- Two Storey Commercial Warehouse W Mezzanine (Semi-Concrete) - 17-024 - VeteransDocument21 pagesTwo Storey Commercial Warehouse W Mezzanine (Semi-Concrete) - 17-024 - VeteransJohn Michael TalanPas encore d'évaluation

- Design and Construction of Driven Pile Foundations VolumeIDocument968 pagesDesign and Construction of Driven Pile Foundations VolumeIAyoPas encore d'évaluation

- Tile and Adhesive Weight Per Square Metre Weight Per SQ MetreDocument4 pagesTile and Adhesive Weight Per Square Metre Weight Per SQ MetreDean Farmer100% (3)

- Glazed Elements - Fenestration Performance RequirementsDocument1 pageGlazed Elements - Fenestration Performance RequirementsMUBASHIRPas encore d'évaluation

- Presentation 1Document20 pagesPresentation 1SMBEAUTYPas encore d'évaluation

- SSH 2021: Harga Bahan KonstruksiDocument528 pagesSSH 2021: Harga Bahan KonstruksiWawan Herawan100% (1)

- ESTAR HVACRaterChecklistDocument4 pagesESTAR HVACRaterChecklistMeshal Al-mutairiPas encore d'évaluation

- Design of Steel Structures Sample Question PaperDocument6 pagesDesign of Steel Structures Sample Question PaperRajiv BondePas encore d'évaluation

- Brosur Produk PT Beton Prima Indonesia 01Document2 pagesBrosur Produk PT Beton Prima Indonesia 01Kartika SaktiPas encore d'évaluation

- Pakyaw RatesDocument36 pagesPakyaw RatesKesMercado100% (5)

- Concrete EstimateDocument13 pagesConcrete EstimateKarl MonfortPas encore d'évaluation