Académique Documents

Professionnel Documents

Culture Documents

A Lifestyle Analysis of New

Transféré par

Luqman Hakim Bin As'ariDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

A Lifestyle Analysis of New

Transféré par

Luqman Hakim Bin As'ariDroits d'auteur :

Formats disponibles

Perspectives QS 9000: an overview and comparison with ISO 9000

Jeffrey Lo Chi Fong and Jiju Antony

Introduction

QS 9000 is a quality system standard developed in the USA in 1994 by a team consisting of representatives of the three big automotive manufacturers (Ford, General Motors and Daimler-Chrysler) in the USA as well as the US truck manufacturers. The main objective of this standard was to standardise the procedures, responsibilities and processes in achieving consistent output. The reason for the development of such a system was to minimise the errors resulting from definitions, reports, procedures, and other documents unique to each manufacturer. Moreover, the big three have attempted to move towards a total management approach by including requirements for continuous improvement covering quality, costs, capability studies, failure mode and effect analysis (FMEA), process control, delivery and so on (Chi Fong, 2000). In the early 1990s, large and major automotive manufacturers developed their own standards for their suppliers. As a result, suppliers who were providing services to more than one customer in the automotive industry had to adapt to many different quality standards which contained similar documents and procedures. The costs of operations for the suppliers went up and the suppliers became inflexible and unable to manage the various requirements and duplication of effort and documentation required to satisfy the customers. Ford, GM and DaimlerChrysler cooperated to develop a single document system which comprises requisites from the big three and other truck manufacturers and now is a global compliance standard. The standard is fundamentally a suite of documents which includes a quality system assessment guide, an advanced product quality planning manual, a potential failure mode and effect analysis reference manual, a product part approval process manual, a measurement or gauge capability study manual and a fundamental statistical process control reference manual. This standard is viewed as a vehicle for the continuous improvement of product quality from development stage to its delivery.

The authors Jeffrey Lo Chi Fong and Jiju Antony are both based at the Internationa l Manufacturing Centre, Warwick Manufacturing Group, University of Warwick, Coventry, UK Keywords Quality systems, Automobile industry Abstract QS 9000 is a quality system standard for the automotive industry, developed in the USA in 1994 by Ford, General Motors, Daimler-Chrysler and the US truck manufacturers. It was developed with the objective of standardising the quality system procedures, responsibilities and processes within an organisation. The paper briefly illustrates a comparison of QS 9000 with other automotive standards. The paper also examines the relationship between ISO 9000, QS 9000 and TQM. Electronic access The research register for this journal is available at http://www.mcbup.com/research_registers The current issue and full text archive of this journal is available at http://www.emerald-library.com/ft

The TQM Magazine Volume 13 . Number 5 . 2001 . pp. 315318 # MCB University Press . ISSN 0954-478X

315

QS 9000: an overview and comparison with ISO 9000 Jeffrey Lo Chi Fong and Jiju Antony

The TQM Magazine Volume 13 . Number 5 . 2001 . 315318

Comparison of QS-9000 with other automotive standards

There are various other quality systems for the automotive industry around the world. They are ISO/TS 16949, VDA 6.1 (Germany), EAQF 94 (France) and AVSQ 94 (Italy). Heinloth in his study found that more than 20,000 suppliers are registered to these standards except ISO/TS 16949 (Heinloth, 2000). Table I shows the registration status for the QS 9000, VDA and ISO/TS 16949. ISO/TS 16949 harmonised different automotive standards around the world such as VDA, AVSQ, EAQF and QS 9000, and it is based on the 20 elements in ISO 9000 (http://www.transitionsupport.com/TS16949.htm). It was first released in March 1999 and it has many requirements similar to QS 9000, such as business plan, measurement system analysis, continuous improvement, production part approval process, failure mode and effect analysis, use of cross-functional team and so on. VDA is the association of German Automotive Industry which includes Audi, Mercedes, BMW and Volkswagen. The first edition of VDA 6.1 was published in 1991 and the latest version was released in January 1999. VDA 6.1 is divided into two parts: Part M with seven management elements and Part P with 16 product and process elements. Part M covers similar clauses to QS 9000 and has extra elements of financial considerations of quality systems, product safety and employees satisfaction. Part P has two new elements when compared to QS 9000; process planning and quality in servicing, after sales and market feedback.

Relationship between QS 9000 and TQM and their link to ISO 9000

The purpose of QS 9000 is to encourage automotive manufacturers and suppliers to build quality systems that focus on the continuous improvement of processes and thereby product quality. This characteristic forces organisations to transform their cultures toward total quality management (TQM). Although QS 9000 and TQM effectively complement one another, their stated objectives/goals, evaluation methodologies and improvement strategies are idiosyncratically different. QS 9000 is mainly aimed to meet goals and targets and achieve certification whereas TQM is focused on the continuous path in the improvement of product/process/service quality. It is important to note that an organisation that is already operating under a TQM culture will likely meet both the ISO 9001 and QS 9000 registration requirements typically with relatively small changes in documentation (Bramorski, et al., 2000). ISO 9000 does not properly address specific areas that need to be improved. It lacks the practical advice to the company regarding what should be done from the standard. QS 9000 has more detailed explanations regarding what a company can do and where they can improve. For instance, element 4.2.5.2 (quality and productivity improvement) and 4.2.5.3 (techniques for continuous improvement) lists out the examples of situations which might lead to improving projects and possible techniques that could be used for making such improvements.

Table I Registration status for QS, VDA and ISO/TS 16949 QS-9000 Number of registered companies worldwide Number of certified auditors Number of accredited registrars Year of first publication Current edition Original equipment manufacturers (OEMs) mandating conformity 13,128 3,200 115 1994 Third edition Ford GM DC VDA 6.1 7,000 500 32 1991 Fourth edition Volkswagen Audi Mercedes BMW ISO/TS 16949 0 30 0 1999 First edition Accepted by nearly all OEMs

Source: Pearch and Kitka (July 2000)

316

QS 9000: an overview and comparison with ISO 9000 Jeffrey Lo Chi Fong and Jiju Antony

The TQM Magazine Volume 13 . Number 5 . 2001 . 315318

The motive of implementation of QS 9000 and ISO 9000 is passive in that many companies are requested to register to these standards by their customers to maintain the business as certified suppliers. It might have negative effects on the company which is forced to conform to these standards without adequate understanding and sloppy implementation of the system. On the other hand, the TQM approach is rather active and preventative because it is a philosophy consisting of core values, tools and techniques rather than a system and does not require any auditing. It is good for an organisation to have a quality system such as ISO 9000 and use this as a stepping stone for QS 9000 and TQM respectively (Ho, 1994). Moreover, a recent study has shown that companies that systematically adopt best practice starting with ISO 9000 and moving towards a TQM culture achieve significantly higher performance levels (Prabhu, et al., 2000). This claim can be further reinforced by means of another study performed by Hongyi based on the survey of 316 private companies. The study reveals that in companies with ISO 9000 certification, the availability of quality information, quality assurance of the process/ product etc. are significantly higher. The authors believe that if a company starts with ISO 9000 and then moves towards QS 9000 and TQM, it then provides some advantages such as compliance of documented procedures and work instructions, integration of process steps across functional boundaries, awareness of quality within the organisation, prevention of non-conformance, early detection of defects and so on. The requirements in QS 9000 cover more elaborative quality control and improvement methods (capability analysis, SPC, PPAP, FMEA, etc.) when compared to ISO 9000. These tools and techniques for continuous improvement can also be applied to the TQM philosophy which is primarily focused on customer satisfaction. The stepping stone from ISO 9000 to TQM with QS 9000 as an intermediate stage can be demonstrated by a simple figure (See Figure 1). It is important to note that the successful implementation of QS 9000 requires management commitment, employees involvement, teamwork, training, quality awareness, document and data control, culture change, etc. The quality slope is used by the organization to determine where the process can be

Figure 1 Modified quality slope (ISO-9000 to TQM through QS-9000)

improved from time to time and therefore take actions and push the quality system upwards to meet further requirements. The method used here is called plan-do-check-act or PDCA cycle. plan-do-check-act refers to the Deming cycle of continuous improvement, which is a fundamental concept of TQM philosophy (Cohen, 1995).

Conclusions and further work

The critical success factors for the implementation of QS 9000 are management commitment, employees involvement, teamwork, training, quality awareness, document and data control, culture change, and advanced quality planning. Moreover, customer satisfaction, continuous improvement, corrective and preventive actions, and understanding of statistical techniques are also essential. It was found that other commonly used automotive quality systems in other countries are VDA in Germany, EAQF in France and AVSQ in Italy. Recently, a new quality system ISO/TS 16949 emerged in 1999 which could be a replacement of QS 9000 in the future because ISO/TS 16949 embraces the key elements of all automotive quality standards such as VDA, EAQF, AVSQ and QS 9000. It is widely accepted by all the original equipment manufacturers (OEMs). However, suppliers need more time to conform to the new automotive quality system ISO/TS 16949. Hence, QS 9000 would be the main quality system widely used in the automotive industry until ISO/TS 16949 is commonly accepted in this industry. Indeed, these standards are also based on 20 elements of

317

QS 9000: an overview and comparison with ISO 9000 Jeffrey Lo Chi Fong and Jiju Antony

The TQM Magazine Volume 13 . Number 5 . 2001 . 315318

ISO 9000: 1994 and composed of many other quality systems or standards. ISO 9000 is a product focused, systembased and quality detection standard with a short-term objective. It can be argued that QS 9000 falls in between ISO 9000 and TQM, which is concerned more about customer satisfaction, the use of cross-functional teams, application of statistical tools and techniques and addresses more practical advice on how to improve the process performance on a continuous basis in automotive manufacturing industries. QS 9000 may be treated as a stepping stone to implement the TQM philosophy in the case of the automotive industry.

References

Bramorski, T. et al. (2000), ``QS-9000 registration for lean manufacturing, The TQM Magazine, Vol. 12 No. 4, pp. 275-83. Chi, Fong, J. (2000), ``QS-9000: a case study in a manufacturing company, MSc thesis, University of Warwick, Coventry. Cohen, L. (1995), Quality Function Deployment (How to Make QFD Work for You), Addison-Wesley, Reading, MA. Heinloth, S. (2000), ``Good-bye QS 9000?, Quality, March, Vol. 39 Issue 3, pp. 50-4. Ho, S. (1994), ``Is the ISO 9000 Series for total quality management?, International Journal of Quality & Reliability Management, Vol. 11 No. 9, pp. 74-89. Prabhu, V. et al. (2000), ``The impact of ISO 9000 and TQM on best practice/performance, The TQM Magazine, Vol. 12 No. 2, pp. 84-91.

Commentary

A good in-depth consideration of a key standard for the automotive industry. 318

Vous aimerez peut-être aussi

- EPM Penjualan Per Outlet 111215 (Bima Sakti)Document21 pagesEPM Penjualan Per Outlet 111215 (Bima Sakti)Luqman Hakim Bin As'ariPas encore d'évaluation

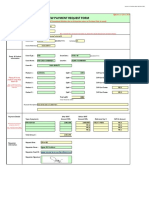

- FORM PRF DR - TangkasDocument13 pagesFORM PRF DR - TangkasLuqman Hakim Bin As'ariPas encore d'évaluation

- LUQMAN HAKIM - XAIJA - PD7S27 SalinDocument1 pageLUQMAN HAKIM - XAIJA - PD7S27 SalinLuqman Hakim Bin As'ariPas encore d'évaluation

- BFA Putaran XXI 03-12Document2 pagesBFA Putaran XXI 03-12Luqman Hakim Bin As'ariPas encore d'évaluation

- DENTAL SET - DikonversiDocument2 pagesDENTAL SET - DikonversiLuqman Hakim Bin As'ariPas encore d'évaluation

- EPM S Laporan Stock On Hand Su 260115 (Secondary CarE)Document11 pagesEPM S Laporan Stock On Hand Su 260115 (Secondary CarE)Luqman Hakim Bin As'ariPas encore d'évaluation

- MCL Agnes Q4Document12 pagesMCL Agnes Q4Luqman Hakim Bin As'ariPas encore d'évaluation

- Lapbul Tahap 1 Herta September 2014Document31 pagesLapbul Tahap 1 Herta September 2014Luqman Hakim Bin As'ariPas encore d'évaluation

- Epm Penjualan Per Outlet 040215 (Secondary Care)Document43 pagesEpm Penjualan Per Outlet 040215 (Secondary Care)Luqman Hakim Bin As'ariPas encore d'évaluation

- PThe Learning Organisation, Myth or RealityDocument1 pagePThe Learning Organisation, Myth or RealityLuqman Hakim Bin As'ariPas encore d'évaluation

- Regression analysis of customer satisfaction survey and product attributesDocument3 pagesRegression analysis of customer satisfaction survey and product attributesLuqman Hakim Bin As'ariPas encore d'évaluation

- Break Sales April 2014Document29 pagesBreak Sales April 2014Luqman Hakim Bin As'ariPas encore d'évaluation

- Discv 30 Aug 14Document45 pagesDiscv 30 Aug 14Luqman Hakim Bin As'ariPas encore d'évaluation

- So TW IV 2014 - RSM LpiDocument1 pageSo TW IV 2014 - RSM LpiLuqman Hakim Bin As'ariPas encore d'évaluation

- A Shared Strategic VisionDocument1 pageA Shared Strategic VisionLuqman Hakim Bin As'ariPas encore d'évaluation

- Organizational Behaviour Reassessed, The Impact of GenderDocument9 pagesOrganizational Behaviour Reassessed, The Impact of GenderLuqman Hakim Bin As'ariPas encore d'évaluation

- Inquiring Into Organizational EnergyDocument1 pageInquiring Into Organizational EnergyLuqman Hakim Bin As'ariPas encore d'évaluation

- Productivity Improvement ADocument11 pagesProductivity Improvement ALuqman Hakim Bin As'ariPas encore d'évaluation

- Automating BSC Business inDocument14 pagesAutomating BSC Business inLuqman Hakim Bin As'ariPas encore d'évaluation

- A New Perspective of BrandDocument21 pagesA New Perspective of BrandLuqman Hakim Bin As'ariPas encore d'évaluation

- Agents of Change Bank BrancDocument23 pagesAgents of Change Bank BrancLuqman Hakim Bin As'ariPas encore d'évaluation

- A Note On The Effect of PriDocument6 pagesA Note On The Effect of PriLuqman Hakim Bin As'ariPas encore d'évaluation

- Capital Input and Total ProDocument9 pagesCapital Input and Total ProLuqman Hakim Bin As'ariPas encore d'évaluation

- Project Management Theory ADocument37 pagesProject Management Theory ALuqman Hakim Bin As'ariPas encore d'évaluation

- An Elaborate Analysis of PRDocument9 pagesAn Elaborate Analysis of PRLuqman Hakim Bin As'ariPas encore d'évaluation

- Game Theory and OperationsDocument12 pagesGame Theory and OperationsLuqman Hakim Bin As'ariPas encore d'évaluation

- Back To Basics With ProductDocument6 pagesBack To Basics With ProductLuqman Hakim Bin As'ariPas encore d'évaluation

- Competition and Price DiscrDocument32 pagesCompetition and Price DiscrLuqman Hakim Bin As'ariPas encore d'évaluation

- Complaints about advertising in AustraliaDocument9 pagesComplaints about advertising in AustraliaLuqman Hakim Bin As'ariPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Leela Palace Bangalore IT ProjectDocument206 pagesLeela Palace Bangalore IT ProjectSharukh KhanPas encore d'évaluation

- Emotional Intelligence in Project ManagementDocument16 pagesEmotional Intelligence in Project ManagementJaved IqbalPas encore d'évaluation

- Project Management in ERP ImplementationDocument13 pagesProject Management in ERP Implementationkevmatin100% (1)

- Chnge MGT and OdDocument51 pagesChnge MGT and Odbabita_27Pas encore d'évaluation

- Success and Failure Factor of E-GovernenceDocument10 pagesSuccess and Failure Factor of E-GovernenceAmit KumarPas encore d'évaluation

- 71 Change Request Process FlowDocument47 pages71 Change Request Process FlowDebkumar ChakrabortiPas encore d'évaluation

- Thematic Presentation OdcDocument13 pagesThematic Presentation OdcChandra MohganPas encore d'évaluation

- Anushka Saha CVDocument2 pagesAnushka Saha CVabhishekroyitPas encore d'évaluation

- Efo QuestionnaireDocument3 pagesEfo QuestionnairebunklyPas encore d'évaluation

- Risk Management Policy and GuidelinesDocument22 pagesRisk Management Policy and Guidelineskenoly123Pas encore d'évaluation

- T27 - CALA 17025:2005 Handbook Revision 2.4 - November 2010Document57 pagesT27 - CALA 17025:2005 Handbook Revision 2.4 - November 2010Carlos Roque80% (5)

- LeanDocument154 pagesLeanZakria Ezzat Mohamed100% (1)

- International Vice President Operations in Denver CO Resume Robert FloresDocument2 pagesInternational Vice President Operations in Denver CO Resume Robert FloresRobertFlores1Pas encore d'évaluation

- ISO 9001-2008 Audit ChecklistDocument16 pagesISO 9001-2008 Audit Checklistfelix683Pas encore d'évaluation

- Plan quality standards projectDocument6 pagesPlan quality standards projectano_ni_mousePas encore d'évaluation

- Practices in Construction Change Order ManagementDocument6 pagesPractices in Construction Change Order ManagementMohamed Talaat ElsheikhPas encore d'évaluation

- Change Management: Muhammad HashimDocument11 pagesChange Management: Muhammad HashimMalkeet SinghPas encore d'évaluation

- Six Sigma Project WorkDocument34 pagesSix Sigma Project WorkDrpallavi NanavatiPas encore d'évaluation

- SAP PLM Product Life Cycle Management Overview - V01Document24 pagesSAP PLM Product Life Cycle Management Overview - V01Kishor kumar Bhatia33% (6)

- Management and Organizational BehaviorDocument13 pagesManagement and Organizational BehaviorMBAtermpapersPas encore d'évaluation

- ISPE GLChRiskBasedCommQualBnchmrkgDocument63 pagesISPE GLChRiskBasedCommQualBnchmrkgiv1607Pas encore d'évaluation

- Implementing Strategy Through Changing BehavioursDocument2 pagesImplementing Strategy Through Changing BehavioursRicha GargPas encore d'évaluation

- EPCM Services Engineering Procurement Construction ManagementDocument2 pagesEPCM Services Engineering Procurement Construction ManagementFarid FaridPas encore d'évaluation

- Sappress Change Request ManagementDocument53 pagesSappress Change Request Managementzahid948650% (2)

- Project Portfolio Management (PPM) : The Natural Evolution of Project ManagementDocument4 pagesProject Portfolio Management (PPM) : The Natural Evolution of Project ManagementStudy Study100% (1)

- Total Quality Management (TQM) and Business Process Re-Engineering (BPR)Document24 pagesTotal Quality Management (TQM) and Business Process Re-Engineering (BPR)Nazish Sohail50% (2)

- Change ManagementDocument25 pagesChange ManagementFred ChukwuPas encore d'évaluation

- Change Management - Organizing For Successful Change Management - (McKinsey Quarterly) - 2006 PDFDocument8 pagesChange Management - Organizing For Successful Change Management - (McKinsey Quarterly) - 2006 PDFjgonzalezsanz8914Pas encore d'évaluation

- Lean Production Power PointDocument34 pagesLean Production Power PointAndreMarcelPas encore d'évaluation

- BUS240 Assignment IndividualDocument5 pagesBUS240 Assignment IndividualRoyceLeePas encore d'évaluation