Académique Documents

Professionnel Documents

Culture Documents

EISC - Service Report 1 May '14

Transféré par

Vijayakumar KarunanidhiTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

EISC - Service Report 1 May '14

Transféré par

Vijayakumar KarunanidhiDroits d'auteur :

Formats disponibles

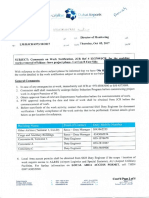

Consulting Service Report

Customer

EISC , MUSAFFAH ICAD 1 -ABU DHABI

1-May-14

Date of visit:

3) Recommend to install wall-mounted dosing pump for Sodium hypochlorite for ICW1,ICW2 &

CCM Secondary.

WORK PLAN

1.) Conduct Key performance indicator analysis on the recirculating system water / advise accordingly.

2.) Dosing of chemicals required.

OBSERVATIONS / RECOMMENDATIONS

1.) Water analysis conducted & recommendations are mentioned below.

2.) Sample points for collecting the water samples from softwater is not available. Kindly arrange to provide the sampling points.

ACTION - GE W&PT

1.) Conduct water analysis & accordingly advise actions

2.) Conduct Soft water analysis especially for calcium hardness test.

Sr

No

Analysis Parameters Units Make up Design

Value

ICW-1 Control

Limits

ICW-2

1 Temperature oC

2 pH 8.15 8.0-8.3 8.85 8.0-9.0 8.81

3 Conductivity uS/cm 127 130-180 749 600-800 739

4 Total Dissolved Solids -TDSPPM 88 90 - 130 519 400 -560 512

5 Calcium Hardness - CaH PPM 40 40 - 70 188 100-200 186

6 M Alkalinity- Malk PPM 47 45 - 80 178 186

7 Chloride - Cl- PPM 3 5.0 - 25 98 Max 150 95

8 Phosphate - PO4 PPM - - 3.7 4.0-8.0 3.2

9 Nitrite - N02- PPM - - - - -

10 Molybdate, Mo PPM - - - - -

11 Total iron -TFe PPM 0.02 <0.5 0.16 <1 0.19

12 Zinc Zn** PPM

13 Free Chlorine - Cl2 PPM

14 Total Chlorine- TCl2 PPM

14 Total Bacteria Count CFU/ml

15 Turbidity, NTUl <15

16 LSI 1.83 0.5 to +1.8 1.73

17 RSI 5.0-6.0

CCM Spray cooling:

Water sample were taken and analyzed, and it was observed that the calcium hardness is now ok. Phosphate chemical has been dosed today.

EAF & LRF :

ICW 2 :

Soft water:

Water sample has been analysed and it was observed that the calcium hardness is ok.

WATER ANALYSIS

CCM Primary:

Water sample were taken and analyzed, and it was observed that the calcium hardness is now ok. Phosphate chemical has been dosed today.

Water sample has been analysed and it was observed that the calcium hardness is still high . Conductivity is also going high which indicates that no actual blowdown was implemented despite consistent reportings and follow-ups for 2

weeks.However, If there may be, please check for any possible contaminants from the process affecting the increase of the conductivity. Blowdown is needed immediately to avoid chocking due to calcium deposition.

Make up water:

The system water parameters are ok.

ICW 1 :

Water sample has been analysed and it was observed that the conductivity and chloride levels are high. Three tankers of blowdown is needed immediately and/or until conductivity goes back to half the current reading at the least.

COMMENTS

Water sample has been analysed and it was observed that the calcium hardness is now ok.

FAO : CC:

Status

completed

completed

informed

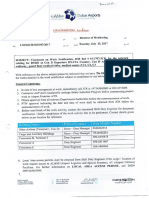

Consulting Service Report

EISC , MUSAFFAH ICAD 1 -ABU DHABI

ICW 1/2, CCM Prim & Secnd , EAF &

LRF

Treated System

Mr. Prasanna Bhat Mr S.K. Burman.

2.) Arrange for flow meters to record Make up & Blowdown of Cooling towers

WORK PLAN

Status

1.) Conduct Key performance indicator analysis on the recirculating system water / advise accordingly.

2.) Dosing of chemicals required.

OBSERVATIONS / RECOMMENDATIONS

1.) Water analysis conducted & recommendations are mentioned below.

2.) Sample points for collecting the water samples from softwater is not available. Kindly arrange to provide the sampling points.

update requested

update requested

update requested

3.) Rota meters to be fixed for all Corrosion Coupon Rack, corrosion rack prefferable to

be fixed on the return header.

ACTION -EISC

1.) Arrange for proper sampling points at pump discharge.

4) To install dosing tank w/pump for NT4201 chemical for EAF/LRF system.

update requested

update requested 5) To fix wall-mounted dosing pump for hypo required for ICW2, ICW1, CCM

Secondary .

Control

Limits

CCM Spray Control

Limits

Soft Water

M.U

Control

Limits

CCM

Primary

Control

Limits

EAF & LRF

8.0-9.0 8.63 8.0-9.0 8.62 7.8-8.2 8.74 8.5-9.5 8.63

600-800 1638 450-850 174.4 <180 865 400-500 393

400 -560 1135 300 -600 121 15 599 250- 400 272

100-200 192 70-150 0 <5 17 <10 9

132 - - - - -

Max 150 402 <130 - <6 - <50 -

4.0-8.0 1.25 2.0-5.0 - - - - -

- - - - - - - 105

- - - - - - 2.5 - 5.0 -

<1 1.53 <3 0.06 <0.3 0.12 <2 0.11

<15 <20 <20

0.5 to +1.8 1.44 0.5 to +1.8

5.0-6.0 5.0-6.0

CCM Spray cooling:

Water sample were taken and analyzed, and it was observed that the calcium hardness is now ok. Phosphate chemical has been dosed today.

EAF & LRF :

ICW 2 :

Soft water:

Water sample has been analysed and it was observed that the calcium hardness is ok.

WATER ANALYSIS

CCM Primary:

Water sample were taken and analyzed, and it was observed that the calcium hardness is now ok. Phosphate chemical has been dosed today.

Water sample has been analysed and it was observed that the calcium hardness is still high . Conductivity is also going high which indicates that no actual blowdown was implemented despite consistent reportings and follow-ups for 2

weeks.However, If there may be, please check for any possible contaminants from the process affecting the increase of the conductivity. Blowdown is needed immediately to avoid chocking due to calcium deposition.

Make up water:

The system water parameters are ok.

ICW 1 :

Water sample has been analysed and it was observed that the conductivity and chloride levels are high. Three tankers of blowdown is needed immediately and/or until conductivity goes back to half the current reading at the least.

COMMENTS

Water sample has been analysed and it was observed that the calcium hardness is now ok.

ICW 1/2, CCM Prim & Secnd , EAF &

LRF

Mr S.K. Burman.

WORK PLAN

Status

1.) Conduct Key performance indicator analysis on the recirculating system water / advise accordingly.

2.) Dosing of chemicals required.

OBSERVATIONS / RECOMMENDATIONS

1.) Water analysis conducted & recommendations are mentioned below.

2.) Sample points for collecting the water samples from softwater is not available. Kindly arrange to provide the sampling points.

update requested

update requested

update requested

update requested

update requested

Control

Limits

8.5-9.5

900-1400

620 - 970

<10

<25

-

100-150

-

<2

CCM Spray cooling:

Water sample were taken and analyzed, and it was observed that the calcium hardness is now ok. Phosphate chemical has been dosed today.

EAF & LRF :

ICW 2 :

Soft water:

Water sample has been analysed and it was observed that the calcium hardness is ok.

WATER ANALYSIS

CCM Primary:

Water sample were taken and analyzed, and it was observed that the calcium hardness is now ok. Phosphate chemical has been dosed today.

Water sample has been analysed and it was observed that the calcium hardness is still high . Conductivity is also going high which indicates that no actual blowdown was implemented despite consistent reportings and follow-ups for 2

weeks.However, If there may be, please check for any possible contaminants from the process affecting the increase of the conductivity. Blowdown is needed immediately to avoid chocking due to calcium deposition.

Make up water:

The system water parameters are ok.

ICW 1 :

Water sample has been analysed and it was observed that the conductivity and chloride levels are high. Three tankers of blowdown is needed immediately and/or until conductivity goes back to half the current reading at the least.

COMMENTS

Water sample has been analysed and it was observed that the calcium hardness is now ok.

FAO :

Mr. Prasanna

Bhat

1-May-14

Status

Completed

Sr

No

Analysis Parameters Units Make up Design Value ECW & QCW Control

Limits

1 Temperature oC

2 pH 8.15 8.0-8.3 8.21 8.0-9.0

3 Conductivity uS/cm 127 130-180 428 700-800

4 Total Dissolved Solids -TDS PPM 88.011 90 - 130 296.604 480 -560

Customer

ACTION - GE W&PT

Consulting Service Report

ACTION - EISC

Treated System :

WORK PLAN

1.) conduct KPI analysis 1.) Ensure Dosing stations are available at all

system.

1.) It is recomended to arrange for flow meters & Corrosion coupon racks.

2.) Arrange for rotameter equipped , corrosion

coupon racks. Corrosion Coupon racks to be fitted

on the return Header

3.) PCW Polymer dosing pump flow rate to be

analysed.

EISC -MUSAFFAH ICAD 1 -ABU

DHABI

Date of Visit:

1.) Conduct Key performance indicator analysis on the recirculating system .

OBSERVATIONS / RECOMMENDATIONS

4.) Arrange to provide flow meters for make up &

blowdown of the cooling tower / PCW return line.

5.) Provide actual water temperature at the top &

bottom of the CT of ECW & QCW / return water

temperature of PCW.

WATER ANALYSIS

5 Calcium Hardness - CaH PPM 40 40 - 70 86 100-200

6 M Alkalinity- Malk PPM 47 45 - 80 46 -

7 Chloride - Cl- PPM 3 5.0 - 25 9 Max 150

8 Phosphate - PO4 PPM - - 5 12.0-16.0

9 Total iron -TFe PPM 0.02 <0.5 0.63 <1

10 Zinc Zn** PPM

11 TSS PPM

12 Turbidity NTU 6.81

13 Total Bacteria Count CFU/ml <1000

14 LSI 0.3 0.5 to +1.8

15 RSI 5.0-6.0

System is in start-up.

Make up water:

The system water parameters are ok.

ECW & QCW system :

System is in start-up.

PCW System :

Status

update requested

update requested

update requested

update requested

update requested

PCW Control

Limits

9.28 7.6-8.0

411 Max 2000

284.823 Max 1400

ACTION - EISC

ECW & QCW , PCW

WORK PLAN

1.) Ensure Dosing stations are available at all

system.

1.) It is recomended to arrange for flow meters & Corrosion coupon racks.

2.) Arrange for rotameter equipped , corrosion

coupon racks. Corrosion Coupon racks to be fitted

on the return Header

3.) PCW Polymer dosing pump flow rate to be

analysed.

1.) Conduct Key performance indicator analysis on the recirculating system .

OBSERVATIONS / RECOMMENDATIONS

CC : Mr. Ali , Mr. Ramesh Matai

4.) Arrange to provide flow meters for make up &

blowdown of the cooling tower / PCW return line.

5.) Provide actual water temperature at the top &

bottom of the CT of ECW & QCW / return water

temperature of PCW.

WATER ANALYSIS

102 <800

63 -

34 Max 400

- -

1.64 <5

65 <50

34.9 <50

0.5 to +1.8

5.0-6.0

System is in start-up.

Make up water:

The system water parameters are ok.

ECW & QCW system :

System is in start-up.

PCW System :

Sr

No

Analysis Parameters Units Softwater Design Value BFW

1 pH 7.5 - 8.9

2 Conductivity uS/cm - - -

3 Calcium Hardness - CaH PPM <0.5 -

4 Phosphate - PO4 PPM - - -

5 Total iron -TFe PPM - - -

6 Silica - SiO2 PPM - - -

7 Oxy. Scavenger - Sulfite PPM - -

Softwater / Cation Exchange Outlet:

BOILER ANALYSIS

System is shutdown.

Date of Visit:

1-May-14

COMMENTS

Consulting Service Report

Customer

EISC -MUSAFFAH ICAD 1 -ABU DHABI

System is shutdown.

Steam BD

System is shutdown.

Boiler BD:

System is shutdown.

FAO :

Mr. Prasanna

Bhat

Control Limits Steam BD Control

Limits

Boiler BD Control

Limits

8.5 - 10 11 - 12 11 - 12

- - - <5000

- - - - -

- - - 10 - 20

- - - <10

- <10 <10

- - - - -

No action needed.

Softwater / Cation Exchange Outlet:

BOILER ANALYSIS

Treated System :

BFW

ACTIONS

Consulting Service Report

CC : Mr. Ali , Mr. Ramesh Matai EISC -MUSAFFAH ICAD 1 -ABU DHABI

Steam BD

No action needed.

Boiler BD:

No action needed.

No action needed.

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- LETTER IDocument10 pagesLETTER IVijayakumar KarunanidhiPas encore d'évaluation

- Laminated MDF Shelves For PoliceDocument4 pagesLaminated MDF Shelves For PoliceVijayakumar KarunanidhiPas encore d'évaluation

- Confined Space PTWDocument2 pagesConfined Space PTWVijayakumar KarunanidhiPas encore d'évaluation

- Hot Work PermitDocument1 pageHot Work PermitVijayakumar KarunanidhiPas encore d'évaluation

- Final General or Cold PTWDocument1 pageFinal General or Cold PTWVijayakumar KarunanidhiPas encore d'évaluation

- 140919-Hero Project-Phase 3Document11 pages140919-Hero Project-Phase 3Vijayakumar KarunanidhiPas encore d'évaluation

- Hot Work PTWDocument2 pagesHot Work PTWVijayakumar KarunanidhiPas encore d'évaluation

- General or Cold PTWDocument2 pagesGeneral or Cold PTWVijayakumar KarunanidhiPas encore d'évaluation

- 128466-Phone Booth RemovalDocument5 pages128466-Phone Booth RemovalVijayakumar KarunanidhiPas encore d'évaluation

- 135749-Smoking LoungeDocument4 pages135749-Smoking LoungeVijayakumar KarunanidhiPas encore d'évaluation

- Intrusive SurveyDocument4 pagesIntrusive SurveyVijayakumar KarunanidhiPas encore d'évaluation

- Kidney RemovalDocument11 pagesKidney RemovalVijayakumar KarunanidhiPas encore d'évaluation

- Telephone Booth Terminal2Document5 pagesTelephone Booth Terminal2Vijayakumar KarunanidhiPas encore d'évaluation

- 127263-New APS Pass OfficeDocument4 pages127263-New APS Pass OfficeVijayakumar KarunanidhiPas encore d'évaluation

- Inspection Report 1.0Document2 pagesInspection Report 1.0Vijayakumar KarunanidhiPas encore d'évaluation

- Inspection Report 1.0 (PRM)Document2 pagesInspection Report 1.0 (PRM)Vijayakumar KarunanidhiPas encore d'évaluation

- Change of Location: Assembly Point No.2 New Location: Between Masjid, Pm3 and Chemical GodownDocument1 pageChange of Location: Assembly Point No.2 New Location: Between Masjid, Pm3 and Chemical GodownVijayakumar KarunanidhiPas encore d'évaluation

- All Assembly PointsDocument3 pagesAll Assembly PointsVijayakumar KarunanidhiPas encore d'évaluation

- 4 Assembly Points Location: B Ackside of Admin Car Parking 2. O Pen Area Between Pm3 & MosqueDocument1 page4 Assembly Points Location: B Ackside of Admin Car Parking 2. O Pen Area Between Pm3 & MosqueVijayakumar KarunanidhiPas encore d'évaluation

- 4 Assembly Points Locations Location LandmarkDocument1 page4 Assembly Points Locations Location LandmarkVijayakumar KarunanidhiPas encore d'évaluation

- Inspection Report (DNRD - Blue Camel)Document2 pagesInspection Report (DNRD - Blue Camel)Vijayakumar KarunanidhiPas encore d'évaluation

- Inspection Report 4.0 (PRM)Document2 pagesInspection Report 4.0 (PRM)Vijayakumar KarunanidhiPas encore d'évaluation

- Inspection Report (NEC TV Installation - Darwish)Document2 pagesInspection Report (NEC TV Installation - Darwish)Vijayakumar KarunanidhiPas encore d'évaluation

- Inspection Report (API Operations Centre - GBM)Document2 pagesInspection Report (API Operations Centre - GBM)Vijayakumar KarunanidhiPas encore d'évaluation

- 126657-APM Glass Removal Con ADocument5 pages126657-APM Glass Removal Con AVijayakumar KarunanidhiPas encore d'évaluation

- Inspection Report (Jones The Grocer Outlet - Fusion)Document1 pageInspection Report (Jones The Grocer Outlet - Fusion)Vijayakumar KarunanidhiPas encore d'évaluation

- Technical Submital Form - Du PontDocument1 pageTechnical Submital Form - Du PontVijayakumar KarunanidhiPas encore d'évaluation

- LF Refirdgerator001Document3 pagesLF Refirdgerator001Vijayakumar KarunanidhiPas encore d'évaluation

- 126654-Network Cabling DNRDDocument4 pages126654-Network Cabling DNRDVijayakumar KarunanidhiPas encore d'évaluation

- Parking Bay Con DDocument3 pagesParking Bay Con DVijayakumar KarunanidhiPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- FFSA BriefDocument4 pagesFFSA Briefcontactnandu7415Pas encore d'évaluation

- Urethyn HG 0 - Pi - (Gb-En)Document2 pagesUrethyn HG 0 - Pi - (Gb-En)CriVe OffePas encore d'évaluation

- Hydraulic Eaton Vickers VQ Vane Pump: Intra-Vane Mechanism FeaturesDocument7 pagesHydraulic Eaton Vickers VQ Vane Pump: Intra-Vane Mechanism FeaturesMiguel VlntìnPas encore d'évaluation

- Aircraft Wires and CablesDocument226 pagesAircraft Wires and Cablesjohn Bronson100% (1)

- ASTM 6365 - 99 - Spark TestDocument4 pagesASTM 6365 - 99 - Spark Testjudith_ayala_10Pas encore d'évaluation

- Good Practices and Innovations in Public Governance United Nations Public Service Awards Winners, 2012-2013Document254 pagesGood Practices and Innovations in Public Governance United Nations Public Service Awards Winners, 2012-2013Adriana Alberti UN100% (1)

- Lecture 1 - Course IntroductionDocument46 pagesLecture 1 - Course IntroductionRifaqat ZaheerPas encore d'évaluation

- Python Setup and Usage: Release 2.7.8Document57 pagesPython Setup and Usage: Release 2.7.8dingko_34Pas encore d'évaluation

- RoundingDocument65 pagesRoundingSourav Kumar100% (1)

- Sharp BP30C25 - Installation ManualDocument58 pagesSharp BP30C25 - Installation ManualSathish SukumaranPas encore d'évaluation

- Rules For Building and Classing Marine Vessels 2022 - Part 5C, Specific Vessel Types (Chapters 1-6)Document1 087 pagesRules For Building and Classing Marine Vessels 2022 - Part 5C, Specific Vessel Types (Chapters 1-6)Muhammad Rifqi ZulfahmiPas encore d'évaluation

- Massey Ferguson 8570 COMBINE Parts Catalogue ManualDocument22 pagesMassey Ferguson 8570 COMBINE Parts Catalogue ManualdidkskmdmdmPas encore d'évaluation

- Summer Practice Report Format For CeDocument8 pagesSummer Practice Report Format For CesohrabPas encore d'évaluation

- E-Content #03 (RSR) Thesis and Research Paper Writing - A BriefDocument2 pagesE-Content #03 (RSR) Thesis and Research Paper Writing - A Briefaravind mouryaPas encore d'évaluation

- VancouverDocument11 pagesVancouverAndi Firman MubarakPas encore d'évaluation

- Sec 1038Document4 pagesSec 1038Lauren BowenPas encore d'évaluation

- Award Report TemplateDocument3 pagesAward Report Templatechriscivil12Pas encore d'évaluation

- How To Choose Circuit Breakers For Electric MotorsDocument2 pagesHow To Choose Circuit Breakers For Electric Motorsحسن التميميPas encore d'évaluation

- No More FTP White PaperDocument11 pagesNo More FTP White PaperrlogiePas encore d'évaluation

- RC Design EC2 v1.9Document64 pagesRC Design EC2 v1.9mohammed alebiedPas encore d'évaluation

- Expansion JointsDocument29 pagesExpansion Jointsvarma101100% (1)

- Ogm 25Document1 pageOgm 25azimsabudinPas encore d'évaluation

- Cve 240-Assignment 5 - Chapter 4Document3 pagesCve 240-Assignment 5 - Chapter 4Ehab Wilson0% (1)

- Introduction To Politics SyllabusDocument10 pagesIntroduction To Politics SyllabusJoey BeetzPas encore d'évaluation

- Philips New Pricelist July 2022Document3 pagesPhilips New Pricelist July 2022PravinPas encore d'évaluation

- のわる式証明写真メーカー|PicrewDocument1 pageのわる式証明写真メーカー|PicrewpapafritarancheraPas encore d'évaluation

- FM 5-102 - CountermobilityDocument220 pagesFM 5-102 - CountermobilitySurvivIt100% (2)

- Transmision Q7 0C8 PDFDocument139 pagesTransmision Q7 0C8 PDFAlberto Morillas PueblaPas encore d'évaluation

- Three-Phase Induction MotorsDocument32 pagesThree-Phase Induction MotorsDimitriu CarmenPas encore d'évaluation

- Upgrading A P - SupplyDocument7 pagesUpgrading A P - SupplyDrift GeePas encore d'évaluation