Académique Documents

Professionnel Documents

Culture Documents

MPH

Transféré par

DANIZACHDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

MPH

Transféré par

DANIZACHDroits d'auteur :

Formats disponibles

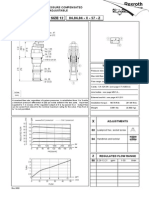

COMBINED SCREW-WASHER

COVER

VISUAL

ELECTRICAL

INDICATOR

OPTIONS

INSERT

HIGH EFFICIENCY

ELEMENT WITH HIGH

DIRT HOLDING CAPACITY

O-RING

PRE FILTRATION

MAGNET

BYPASS SPRING

PRESSURE DIE

CAST ALUMINIUM

New

absolute filter elements

independently tested

in the following Institutes:

MPH

MPH and MPI series filters are designed for return-

line applications and provide various installation

applications. The filters are installed semi-

immersed or totally immersed into a reservoir. The

filtration flow is from inside to outside of the filter

element which ensures that all the contaminant is

collected inside the element itself avoiding contact

with the reservoir oil during element change. The

combination of magnetic pre-filtration and high fil-

tration efficiency results in a cost effective and ver-

satile filtration series.

The high flow rapid response bypass valves are a

standard feature with this range of filters.

The MPH 100 series are available with an option of

an air filter.

The MPH-MPI 250, 630, 850 series can be speci-

fied with dual inlet ports.

MPH-MPI filters within this range are suitable for

flow rates up to 550 gpm.

MPH-MPI series are specifically designed for

heavy duty mobile machinery and process plant

applications.

D e s c r i p t i o n

MPH-MPI 02050/7.99/USA

2

UNI EN ISO 9001

N 037/98

O-RING

TANK SEAL

MPH-MPI STEEL

DIFFUSER

Element material

Nominal filtration

Inorganic microfiber with acrylic support

ASeries

Resin - impregnated paper

PSeries

End caps:

Nylon

Support tube:

Galvanized steel

New improved 200

filter elements with

greater efficiency and

increased dirt holding

capacity

Support frames:

Galvanized steel with an epoxy coating

Contamination retention

as per ISO 4572: Multi-pass test.

Materials

Filtering area

Filter elements

Filtering area

Filter elements

Square wire mesh (filtration degree is defined in microns by the

maximum diameter of a sphere corresponding to the mesh size)

MSeries

Element material

Absolute filtration

MP Fi l tri - Fi l trati on technol ogy

3

P

(psi)

2

(50%)

20

(95%)

75

(98,7%)

2 10 20

200

(99,5%)

Dimensions for

(m) values

Filter

elements

A06

A10

A25

3

13

3

6

19

4,6

7,8

22

6

10

25

> 2.000

200

> 1,5

>10.000

>10.000

> 35

100

100

100

8

1,5

Filtration ratios

N.B. Other materials giving different degrees of filtration are available on request.

Values in sq. in

Type MR

A06

A10/A25

100-1

130.2

130.2

100-2

194.5

194.5

100-3

265

265

100-4

406.1

406.1

250-1

434

434

250-2

604.5

604.5

250-3

844.8

844.8

250-4

1550

1550

Values in sq. in

Type MR

A06

A10/A25

630-1

860.3

860.3

630-2

1210.6

1210.6

630-3

1650.8

1650.8

630-4

2031

2031

850-1

2852

2852

850-2

4774

4774

850-3

7208

7208

850-4

9564

9564

Values in sq. in

Type MR

P10/P25

M25

M60

M90

100-1

202

96.1

96.1

96.1

100-2

279

127.1

127.1

127.1

100-3

409.2

194.5

194.5

194.5

100-4

589

284

284

284

250-1

543

176

176

176

250-2

744

244.1

244.1

244.1

250-3

1023

340

340

340

250-4

1845

620

620

620

Values in sq. in

Type MR

P10/P25

M25

M60

M90

630-1

1039

345.4

345.4

345.4

630-2

1457

484.2

484.2

484.2

630-3

1953

657.8

657.8

657.8

630-4

2403

810.6

810.6

810.6

850-1

3440

1028

1028

1028

850-2

5775

1721

1721

1721

850-3

8683.1

2527

2527

2527

850-4

11550.6

3444.3

3444.3

3444.3

Filter element:

ISO 2941 - Verification of collapse/burst resistance.

ISO 2942 - Verification of fabrication integrity and determination

of the first bubble point.

ISO 2943 - Verification of material compatibility with fluids.

ISO 3723 - Method for end load test.

ISO 3724 - Verification of flow fatigue characteristics.

ISO 3968 - Evaluation of pressure drop versus flow characteristics.

ISO 4572 - Multi-pass method for evaluating filtration per formance.

MP Filter elements - Conform to the following

ISO standards

External wire mesh

Microfiber filtration media

Internal wire mesh

Inner support

tube

External support media

Internal support media

A Series

Inorganic microfiber

water - glycol

(types HFC as per ISO 6743/4)

V Series

Viton compatible with synthetic fluids

(types HS-HFDR-HFDS-HFDU as per ISO 6743/4)

Bypass valve

Seals

A Series: Nitrile (Buna-N)

V Series: Viton

Filter head and bowls

compatible for use with:

mineral oils

(types HH-HL-HM-HR-HV-HG as per ISO 6743/4)

water-based emulsions

(types HFAE-HFAS as per ISO 6743/4)

synthetic fluids

(types HS-HFDR-HFDS-HFDU as per ISO 6743/4)

water-glycol

(types HFC as per ISO 6743/4)

Ask for anodised version

VT Series with bypass 12 psi setting

VR Series with bypass 25 psi setting

V1 Series (MPH 850, only)

Visual indicator

Color coded pressure gauge scale 0-15 psi

Color coded pressure gauge scale 0-30 psi

Collapse pressure

filter elements

M P F i l t r i - S p e c i f i c a t i o n

145 psi

From -13F to 230F

For temperatures outside this range, please

consult our Sales and Network Organization

Working

temperature

Fatigue test: a filter body subjected to

pressure impulses from 0 to 145 psi will

withstand 1.000.000 cycles

Pressure filter

body

Maximum working pressure up to 145 psi

Test pressure: 217.5 psi

Minimum burst pressure: 435 psi

B: 2 psi 10%

C: 25 psi 10%

Bypass valve, differential opening pressure:

Bypass valve

Calibration pressure

at a pressure of 15 psi 10%

(with bypass 25 psi setting)

at a pressure of 8.7 psi 10%

(with bypass 12 psi setting)

Description:

MPH series filters are fitted with

indicators switching

Types of indicators

Materials

Pressure die cast aluminium

Cover

MPH 100 Nylon

MPH 250-630 Aluminium

MPH 850 Steel

Steel

Head

Electrical indicator

Operational information:

Max voltage: 48 Vac 5060 Hz

Max current: 0.5 A resistive, 0.2 A inductive.

With bypass 12 psi

EQ Series: Pressure switch with N.O. contacts

EB Series: Pressure switch with N.C. contacts

With bypass 25 psi

ER Series: Pressure switch with N.O. contacts

EC Series: Pressure switch with N.C. contacts

Compatibility

with fluids

Brass

Steel

Diffuser

Indicator

Seals

A Series

Nitrile (Buna-N) compatible with mineral oils

(types HH-HL-HM-HR-HV-HG as per ISO 6743/4)

water - based emulsions

(types HFAE-HFAS as per ISO 6743/4)

Filter elements

As per ISO 2943; suitable for mineral oils

(types HH-HL-HM-HR-HV-HG as per ISO 6743/4)

synthetic fluids (A and M series only)

(types HS-HFDR-HFDS-HFDU as per ISO 6743/4)

For water-based emulsions (types HFAE-HFAS

as per ISO 6743/4) and fluids other than

those mentioned, please consult our Sales

and Network Organization.

4

Filter body:

S e l e c t i o n

& i n s t a l l a t i o n i n f o r m a t i o n

Filter elements

types

A Series P Series

Nominal cellulose impregnated

paper media, available in 10

and 25 micron.

Example - P10 or P25

M Series

Metal mesh media, available in

25, 60, and 90 micron.

Example - M25, M60 or M90.

Please refer to individual pressure drop curves to obtain filter assembly pressure drop information

The following filter sizing recommendations are based using a mineral oil fluid at 150 SUS with a maximum total filter assembly (housing

and filter element) pressure drop of 30% of the filter condition indicator 5.8 psi (bypass type C)

MPH SERIES 100 SIZE

5

Thread

connections

2.67

3.03

1.02

3.38

2.83

0.35

3.46 min

Mounting Pattern

Only with air breather

With air breather

Without air breather

3.54 max

4.25 2.32

5/16UNC

2.79

2

.

1

2

A

4

.

5

6

4

.

5

6

0

.

7

8

R

0

.

4

5

3.15

D VERSION O VERSION

4.37

H

4

3

.

8

1

H

1

H

2

H

3

F

I

L

T

E

R

E

L

E

M

E

N

T

L

E

N

G

T

H

0

.

4

7

3

.

1

5

1

.

2

6

1

.

5

7

MPH 100

Type

G1

G2

G3

G4

G5

G6

G7

G8

G9

A

3/4 BSP

1 BSP

1 1/4 BSP

3/4 NPT

1 NPT

1 1/4 NPT

SAE 12 - 1 1/6 - 12 UN

SAE 16 - 1 5/16 - 12 UN

SAE 20 - 1 5/8 - 12 UN

* Flow rates with 150 SUS fluid

** Weight including filter element and diffuser

Filter

assembly

Flow rate

gpm

*

Bowl

length

Port size

BSP/NPT/SAE

Weight

lb

**

A06

A10

A25

P10

A06

A10

A25

P10

A06

A10

A25

P10

A06

A10

A25

P10

7.1

9.2

26.4

21.1

9.2

10.5

29

26.4

14.5

19.8

42.2

34.3

18.5

27.8

58.1

50.2

1

2

3

4

3/4

3/4

1

1 1/4

2.2

2.64

2.86

3.3

G

1/8 BSP

1/8 BSP

1/8 BSP

1/8 NPT

1/8 NPT

1/8 NPT

1/8 NPT

1/8 NPT

1/8 NPT

Type

1

2

3

4

H1

7

7

8.97

12.91

H2

4.17

5.9

7.87

11.81

H3

5.04

6.77

8.74

12.67

H4

7.48

9.05

11.02

14.96

Lengths

Absolute inorganic microfibre

filtration media, available in

6, 10 and 25 micron

Example - A06, A10 or A25

G

1

.

2

2

2.20

Pg 0.27

1

.

1

8

1.69

1.34

1.57

A/F.24(mm)

A/F.14(mm)

1

/

8

N

P

T

1

/

8

N

P

T

Housing pressure drop curve

3

2

1

0

Flow rate gpm

p

p

s

i

0 12 24 36 48 60

3/4

1

1 1/4

S e l e c t i o n

& i n s t a l l a t i o n i n f o r m a t i o n

6

MPH SERIES 250 SIZE

MPH 250

* Flow rates with 150 SUS fluid

** Weight including filter element and diffuser

Filter

assembly

Flow rate

gpm

*

Bowl

length

Port size

BSP/NPT/SAE

Weight

lb

**

A06

A10

A25

P10

A06

A10

A25

P10

A06

A10

A25

P10

A06

A10

A25

P10

26.4

30.4

52.8

47.5

32

42.2

58.1

52.8

45

54.1

74

68.6

79.2

95

132

118

1

2

3

4

1 1/2

1 1/2

1 1/2

1 1/2

8.6

1 port

9.5

2 ports

9

1 port

9.9

2 ports

10.1

1 port

11

2 ports

10.5

1 port

11.5

2 ports

Please refer to individual pressure drop curves to obtain filter assembly pressure drop information

The following filter sizing recommendations are based using a mineral oil fluid at 150 SUS with a maximum total filter assembly (housing

and filter element) pressure drop of 30% of the filter condition indicator 5.8 psi (bypass type C)

Thread

connections

Flange

connections

(1 port)

Flange

connections

(2 ports)

F

I

L

T

E

R

E

L

E

M

E

N

T

L

E

N

G

T

H

H

3

H

2

H

1

1

.

6

5

0

.

4

7

H

4

4

.

3

3

3.54

G

5.19

5.11

4.17

5.9 5.9

90

0

.

4

3

6

.

8

9

5

.

2

9

+

0

.

0

2

3

/

8

U

N

C

6

.

8

9

P

O

R

T

B

P

O

R

T

A

D VERSION O VERSION

3

.

5

4

5

.

9

5

.

9

A

3.54

+

0

.

0

4

Type

G1

G2

G3

G4

G5

G6

G7

G8

Port A

1 1/2 BSP

1 1/2 BSP

Not available

1 1/2 NPT

1 1/2 NPT

Not available

SAE 24 - 1 7/8 - 12 UN

SAE 24 - 1 7/8 - 12 UN

Port B

Not available

1 1/4 BSP

--------

Not available

1 1/4 NPT

--------

Not available

SAE 20 - 1 5/8 - 12 UN

G

1/8 BSP

1/8 BSP

--------

1/8 NPT

1/8 NPT

--------

1/8 NPT

1/8 NPT

Type

F1

F3

A

1 1/2 SAE - 3000 PSI/M

1 1/2 SAE - 3000 PSI/UNC

E

M12

1/2 UNC

D

14.06

14.06

C

2.75

2.75

Type

F2

F4

Port A/B

A:1 1/2 SAE - 3000 PSI/M

B:1 1/4 SAE - 3000 PSI/M

A:1 1/2 SAE - 3000 PSI/UNC

B:1 1/4 SAE - 3000 PSI/UNC

E

M12

M10

1/2 UNC

3/8 UNC

D

14.06

11.88

14.06

11.88

C

2.75

2.31

2.75

2.31

Type

1

2

3

4

H1

9.44

9.44

12.2

20.27

H2

5.51

7.48

10.23

18.3

H3

6.89

8.86

11.61

19.69

H4

10.24

12.20

14.96

22.83

Lengths

Mounting Pattern

E

C

D

1

.

2

2

2.20

Pg 0.27

1

.

1

8

1.69

1.34

1.57

A/F.24(mm)

A/F.14(mm)

1

/

8

N

P

T

1

/

8

N

P

T

Housing pressure drop curve

3

2

1

0

Flow rate gpm

p

p

s

i

0 32 64

*

96 128 160

1 1/2

S e l e c t i o n

& i n s t a l l a t i o n i n f o r m a t i o n

7

Type H1 H2 H3 H4

1 8.26

11.41

15.35

2

3

18.81

11

14.17

18.1

21.65

10.23

13.38

17.32

20.86

13.78

16.93

20.86

24.41 4

Lengths

Filter

assembly

Flow rate

gpm

*

Bowl

length

Port size

BSP/NPT/SAE

Weight

lb

**

1

2 1/2

2 1/2

2 1/2

2 1/2

2

3

4

* Flow rates with 150 SUS fluid

** Weight including filter element and diffuser

MPH SERIES 630 SIZE

MPH 630

Please refer to individual pressure drop curves to obtain filter assembly pressure drop information

The following filter sizing recommendations are based using a mineral oil fluid at 150 SUS with a maximum total filter assembly (housing

and filter element) pressure drop of 30% of the filter condition indicator 5.8 psi (bypass type C)

F

I

L

T

E

R

E

L

E

M

E

N

T

L

E

N

G

T

H

H

3

H

2

H

1

2

.

1

6

0

.

5

5

H

4

5

.

5

1

4.33

6.49

6.41

4.96

7.16

0

.

4

3

8

.

4

6

P

O

R

T

B

P

O

R

T

A

D VERSION O VERSION

4

.

3

3

7

.

1

6

4.33

Flange connections (1 port)

Flange connections (2 ports)

Type

F1

F3

A

2 1/2 SAE - 3000 PSI/M

2 1/2 SAE - 3000 PSI/UNC

E

M12

1/2 UNC

D

2

2

C

3.54

3.54

Type

F2

F4

Port A/B

A: 2 1/2 SAE - 3000 PSI/M

B: 2 SAE - 3000 PSI/M

A: 2 1/2 SAE - 3000 PSI/UNC

B: 2 SAE - 3000 PSI/UNC

E

M12

M12

1/2 UNC

1/2 UNC

G

1/8 BSP

1/8 NPT

G

1/8 BSP

1/8 NPT

D

2

1.68

2

1.68

C

3.54

3.06

3.54

3.06

G

58

84.5

132

85

66

105.6

158.4

116.2

74

116.2

237.6

142.6

86

126.8

264

211.2

A06

A10

A25

P10

A06

A10

A25

P10

A06

A10

A25

P10

A06

A10

A25

P10

7.16

7

.

1

6

A

90

8

.

4

6

6

.

5

5

+

0

.

0

2

3

/

8

U

N

C

+

0

.

0

4

Mounting Pattern

E

C

D

1

.

2

2

2.20

Pg 0.27

1

.

1

8

1.69

1.34

1.57

A/F.24(mm)

A/F.14(mm)

1

/

8

N

P

T

1

/

8

N

P

T

18

19.1

19.8

20.9

Housing pressure drop curve

3

2

1

0

Flow rate gpm

p

p

s

i

0 64 128 192 256 320

2 1/2

S e l e c t i o n

& i n s t a l l a t i o n i n f o r m a t i o n

8

Type H1 H2 H3 H4

1 12.99

21.45

32.48

2

3

42.91

16.53

25

36.02

46.45

15.27

23.74

34.76

45.19

20.47

29.13

40.15

50.78 4

Lengths

Filter

assembly

Flow

rate

gpm

Bowl

length

Port size

BSP/NPT/SAE

Weight

lb

**

118.8

171.6

264

211.2

185

264

396

264

225

317

462

396

264

396

554.4

475.2

A06

A10

A25

P10

A06

A10

A25

P10

A06

A10

A25

P10

A06

A10

A25

P10

1

4

4

4

4

2

3

4

81.4

74.8

66

* Flow rates with 150 SUS fluid

** Weight including filter element and diffuser

MPH SERIES 850 SIZE

MPH 850

Please refer to individual pressure drop curves to obtain filter assembly pressure drop information

The following filter sizing recommendations are based using a mineral oil fluid at 150 SUS with a maximum total filter assembly (housing

and filter element) pressure drop of 30% of the filter condition indicator 5.8 psi (bypass type C)

Type Port A/B E G

1/8 BSP

1/8 NPT

F1

M16

D

2.43

C

4.26 B: 3 SAE - 3000 PSI/M

A: DN 100 PN 10/16

F2

5/8 UNC 2.43 4.18 B: 3 SAE - 3000 PSI/UNC

A: DN 100 PN 10/16

D VERSION

8.26

9.72

9.84

C

D

E

1

2

.

6

9

.

9

0

+

0

.0

2

G

7.99

1

1

.

6

1

4

5

22 30

7.08

0

.7

8.66

3

.

9

3

4

5

22 30

7

/

1

6

U

N

C

8.26

H

4

2

.

9

9

0

.

5

9

H

3

H

1

P

O

R

T

B

PORT B

3 SAE 3000 PSI

PORT A

DN 100 PN 10/16

UNI 2223

P

O

R

T

A

7

.

2

4

9

.

8

4

H

2

F

I

L

T

E

R

E

L

E

M

E

N

T

L

E

N

G

T

H

+

0

.0

4

Flange connections

O VERSION

Mounting Pattern

1

.

0

2

1.57

1.18

A/F 14 (mm)

1/8 NPT 1/8 NPT

Pg 0.27

2

.

2

1

.

6

9

1.22 90.2

Housing pressure drop curve

3

2

1

0

Flow rate gpm

p

p

s

i

0 110 220 330 440 550

4

Customer requires a 66 gpm filter assembly (with bypass valve setting at 5.8 psi type C)

Mineral oil fluid: 230 SUS at 104F

A25 - 25 micron absolute filtration

Selection :

Housing pressure drop - MPH 250-3 with 66 gpm p = 0.38 psi (see curve on page 6)

Filter element pressure drop (brochure viscosity) - MR 250-3 A25 with 66 gpm p = 3.25 psi (see curve on page 10)

Filter element pressure drop (working viscosity) - With 230 SUS p

1

= 3.25 x (230/150) = 4.98 psi

Filter assembly pressure drop p Total = p Housing + p

1

Filter element = 0.38 + 4.98 = 5.36 psi*

{

Acceptable pressure drop value,

as per our recommendations

The curves were obtained using a mineral oil with a density of 0,86.

The p varies proportionally to the density.

General

Pressure drop versus flow rate curve information for both housing and filter elements is in accordance with ISO 3968

Filter assembly pressure drop - p Total = p Housing + p Filter element

Housing pressure drop - The housing pressure drop is proportional to the fluid density

Filter element pressure drop - Filter element pressure drop is proportional to kinematic viscosity therefore always check the

fluid operating temperature and fluid type to obtain the working viscosity according to the following formula:

P r e s s u r e d r o p i n f o r ma t i o n

Fi l ter assembl y si zi ng exampl e

By pas s v al v es pr es s ur e dr op

9

Brochure viscosity 150 SUS

p

1

Filter element = (working viscosity/brochure viscosity) x p filter element

MPH 100

45

30

15

0

9 0 18 27 36

Flow rate gpm

p

p

s

i

25 psi

12 psi

MPH 250

45

30

15

0

16 0 32 48 64

Flow rate gpm

p

p

s

i

25 psi

12 psi

MPH 630

45

30

15

0

35 0 70 105 140

Flow rate gpm

p

p

s

i

The curves were obtained using a mineral oil with a kinematic viscosity of 150 SUS.

The p varies proportionally to the fluid kinematic viscosity.

F i l t e r e l e me n t s - A Se r i e s -

10

*

Example: See page 9

15

10

5

0

10 0 20 30 40

p

p

s

i

MR 100 - 1 A...

Flow rate gpm

A06 A10

A25

15

10

5

0

20 0 40 60 80

p

p

s

i

MR 100 - 4 A...

Flow rate gpm

A06 A10

A25

15

10

5

0

40 0 80 120 160

p

p

s

i

MR 250 - 3 A...

Flow rate gpm

A06

A10

A25

15

10

5

0

40 0 80 120 160

p

p

s

i

MR 630 - 2 A...

Flow rate gpm

A06

A10

A25

15

10

5

0

100 0 200 300 400

p

p

s

i

MR 850 - 1 A...

Flow rate gpm

A06

A10

A25

15

10

5

0

137,5 0 275 412,5 550

p

p

s

i

MR 850 - 4 A...

Flow rate gpm

A06

A10

A25

15

10

5

0

120 0 240 360 480

p

p

s

i

MR 850 - 2 A...

Flow rate gpm

A06

A10

A25

15

10

5

0

137,5 0 275 412,5 550

p

p

s

i

MR 850 - 3 A...

Flow rate gpm

A06

A10

A25

15

10

5

0

80 0 160 240 320

p

p

s

i

MR 630 - 3 A...

Flow rate gpm

A06 A10

A25

15

10

5

0

80 0 160 240 320

p

p

s

i

MR 630 - 4 A...

Flow rate gpm

A06

A10

A25

15

10

5

0

40 0 80 120 160

p

p

s

i

MR 250 - 4 A...

Flow rate gpm

A06

A10

A25

15

10

5

0

40 0 80 120 160

p

p

s

i

MR 630 - 1 A...

Flow rate gpm

A06

A10

A25

15

10

5

0

20 0 40 60 80

p

p

s

i

MR 250 - 1 A...

Flow rate gpm

A06

A10

A25

15

10

5

0

20 0 40 60 80

p

p

s

i

MR 250 - 2 A...

Flow rate gpm

A06

A10

A25

15

10

5

0

10 0 20 30 40

p

p

s

i

MR 100 - 2 A...

Flow rate gpm

A06 A10

A25

15

10

5

0

20 0 40 60 80

p

p

s

i

MR 100 - 3 A...

Flow rate gpm

A06 A10

A25

*

The curves were obtained using a mineral oil with a kinematic viscosity of 150 SUS.

The p varies proportionally to the fluid kinematic viscosity.

For the metal mesh filter elements curves (M series),

please consult our Sales and Network Organization

F i l t e r e l e me n t s - P Se r i e s -

11

6

4

2

0

10 0 20 30 40

p

p

s

i

MR 100 - 1 P...

Flow rate gpm

P10

P25

6

4

2

0

10 0 20 30 40

p

p

s

i

MR 100 - 2 P...

Flow rate gpm

P10

P25

6

4

2

0

20 0 40 60 80

p

p

s

i

MR 100 - 3 P...

Flow rate gpm

P10

P25

6

4

2

0

20 0 40 60 80

p

p

s

i

MR 100 - 4P...N

Flow rate gpm

P10

P25

6

4

2

0

20 0 40 60 80

p

p

s

i

MR 250 - 1P...N

Flow rate gpm

P10

P25

6

4

2

0

20 0 40 60 80

p

p

s

i

MR 250 - 2P...N

Flow rate gpm

P10

P25

6

4

2

0

40 0 80 120 160

p

p

s

i

MR 250 - 3P...N

Flow rate gpm

P10

P25

6

4

2

0

40 0 80 120 160

p

p

s

i

MR 250 - 4P...N

Flow rate gpm

P10

P25

6

4

2

0

40 0 80 120 160

p

p

s

i

MR 630 - 1P...N

Flow rate gpm

P10

P25

6

4

2

0

40 0 80 120 160

p

p

s

i

MR 630 - 2P...N

Flow rate gpm

P10

P25

6

4

2

0

80 0 160 240 320

p

p

s

i

MR 630 - 3P...N

Flow rate gpm

P10

P25

6

4

2

0

80 0 160 240 320

p

p

s

i

MR 630 - 4P...N

Flow rate gpm

P10

P25

6

4

2

0

100 0 200 300 400

p

p

s

i

MR 850 - 1P...N

Flow rate gpm

P10

P25

6

4

2

0

120 0 240 360 480

p

p

s

i

MR 850 - 2P...N

Flow rate gpm

P10

P25

6

4

2

0

137,5 0 275 412,5 550

p

p

s

i

MR 850 - 3P...N

Flow rate gpm

P10

P25

6

4

2

0

137,5 0 275 412,5 550

p

p

s

i

MR 850 - 4P...N

Flow rate gpm

P10

P25

MPI Fi l t er s

Appl i cat i ons

Example of application

12

D2

D4

D7

D6

D8

D9 + 0,001

H

1

H

8

H

7

H

2

H

3

H

6

H

4

4

5

0

,

8

0

,

8

1

,

6

1

5

H

5

D5

D3

D1

Type

100-1 9.64

H1

4.17

H2

7.08

H3

0.15

H4

0.47

H5

0.09

H6

1.77

H7

4.72

D1

3.42

D2

0.78

D3

2.83

D4

3.50

D5

3.46

D6

3.25

D7

2.99

D8

4.33

100-2 9.64 5.9 8.81

100-3 11.61 7.87 10.78

100-4 11.55 11.81 14.72

250-1 12.08 5.51 9.84

0.19 0.59 0.09 3.07 6.10 4.94 0.98 4.17 5.19 4.96 4.86 4.60 5.71

250-2 12.08 7.48 11.81

250-3 14.84 10.23 14.57

250-4 22.91 18.3 22.71

630-1 13.97 8.26 13.42

0.19 0.7 0.09 3.93 7.28 5.91 0.98 4.96 6.50 5.94 5.87 5.47 7.01

630-2 17.52 11.41 16.57

630-3 22.45 11.35 20.51

630-4 25 18.82 23.97

850-1 20.88 12.99 20.27

0.23 0.78 0.09 5.51

3.15

H8

3.54

4.33

9.85 10.24 9.06 1.57 7.99 9.64 9.10 8.84 8.54 9.86

850-2 29.35 21.45 28.74

850-3 40.37 32.48 38.76

850-4 50.8 42.91 50.19

D9

Tank internal plate without diffuser

Tank internal plate with diffuser

Trim

13

Not es

O r d e r i n g i n f o r m a t i o n

R e p l a c e m e n t e l e m e n t

MPI

MR

14

A Nitrile (Buna-N)

V Viton

Seals

Models

O Without diffuser

D With diffuser

B Setting: 12 psi

C Setting: 25 psi

100

250

630

850

Nominal sizes

Lengths

Integral bypass valve

A06

A10 Inorganic microfiber Bx 200

A25

P10

Resin-impregnated paper Bx 2

P25

M25

M60 Square wire mesh

M90

Filter elements

MPH 100 = 1,2,3,4

MPH 250 = 1,2,3,4

MPH 630 = 1,2,3,4

MPH 850 = 1,2,3,4

15

A06

A10 Inorganic microfiber Bx 200

A25

P10

Resin-impregnated paper Bx 2

P25

M25

M60 Square wire mesh

M90

Filter elements

MP Filtri - Filtration products will only be guaranteed if original MP Filtri replacement elements and spares are used

Data hold in this pubblication are given only for indicative purposes. MP Filtri reserves to introduce

modifications to described items in every moment either for technical or commercial reasons. Copyright reserved.

A Nitrile (Buna-N)

V Viton

B Setting: 12 psi

C Setting: 25 psi

850 630 250 100

G1

3/4 BSP 1 1/2 BSP ===== =====

G2

1 BSP

1 1/2 BSP

1 1/4 BSP

===== =====

G3

1 1/4 BSP ===== ===== =====

G4

3/4 NPT 1 1/2 NPT ===== =====

G5

1 NPT

1 1/2 NPT

1 1/4 NPT

===== =====

G6

1 1/4 NPT ===== ===== =====

G7

SAE 12 SAE 24 ===== =====

G8

SAE 16

SAE 24

SAE 20

===== =====

F1

(M)

F2

(M)

=====

=====

1 1/2 SAE

1 1/2 SAE

1 1/4 SAE

2 1/2 SAE

2 1/2 SAE

2 SAE

DN 100 PN 10/16

3 SAE

=====

=====

=====

1 1/2 SAE

1 1/2 SAE

1 1/4 SAE

2 1/2 SAE

2 1/2 SAE

2 SAE

DN 100 PN 10/16

3 SAE

=====

G9

SAE 20 ===== ===== =====

O r d e r i n g i n f o r m a t i o n

R e p l a c e m e n t e l e m e n t

MPH

MR

100

250

630

850

Nominal sizes

Lengths

Ports option

Seals

S Without air breather

C With 10 m air breather (100 series only)

M With 40 m air breather (100 series only)

Air breather

Integral bypass valve

Type

Models

O Without diffuser

D With diffuser

F3

(UNC)

F4

(UNC)

MPH 250, G2-G5-G8 options have double port connection.

MPH 250-630, F2-F4 options have double port connection.

MPH 850 options, only available with double port connection.

S With threaded hole only

T With plug

VT Visual (setting at 8.7 psi)

VR Visual (setting at 15 psi)

V1 Visual MPH 850 only (setting at 15 psi)

EQ Electrical: N.O.contacts (setting at 8.7 psi)

EB Electrical: N.C.contacts (setting at 8.7 psi)

ER Electrical: N.O.contacts (setting at 15 psi)

EC Electrical: N.C.contacts (setting at 15 psi)

Filter condition indicator

3

0

0

0

P

S

I

MPH 100 = 1,2,3,4

MPH 250 = 1,2,3,4

MPH 630 = 1,2,3,4

MPH 850 = 1,2,3,4

Head Quarter :

MP FILTRI S.p.A. Italy

Via Matteotti, 2

20060 Pessano con Bornago (Milano) Italy

Tel. ++39.02/95703.1

Fax ++39.02/95741497-95740188

email: sales@mpfiltri.com

http://www.mpfiltri.com

GREAT BRITAIN

MP FILTRI U.K. Ltd.

Bourton Industrial Park

Bourton on the Water

Gloucestershire GL54 2HQ UK

Phone: 01451-822522

Fax: 01451-822282

email: sales@mpfiltri.co.uk

http://www.mpfiltri.co.uk

GERMANY

MP FILTRI D GmbH

Am Wasserturm 5

D-66265 Heusweiler/Holz

Phone: 06806/85022-0

Fax: 06806/85022-18

email: mpfiltrink@aol.com

U.S.A.:

MP FILTRI U.S.A. Inc.

1256C Oakbrook Drive - Norcross,

Georgia - U.S.A. 30093

Phone: 770-263-0090

Fax: 770-242-4069

email: mpusasales@aol.com

CANADA:

MP FILTRI CANADA Inc.

210 Jacob Keffer Parkway Concord,

Ontario Canada L4K 4W3

Phone: 905-303-1369

Fax: 905-303-7256

email: mail@mpfiltricanada.com

http://www.mpfiltricanada.com

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Nema Chart 04Document1 pageNema Chart 04zguy360Pas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Series 34Document10 pagesSeries 34DANIZACHPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- 305 TransmissionDocument2 pages305 TransmissionDANIZACHPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Baldor MotorsDocument124 pagesBaldor Motorsangel_basualdoPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Single and double acting hydraulic cylinders specificationsDocument1 pageSingle and double acting hydraulic cylinders specificationsDANIZACHPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Hsr-300e - CC PATINES LINEALES THKDocument26 pagesHsr-300e - CC PATINES LINEALES THKDANIZACHPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Check d180 - HR KRDocument4 pagesCheck d180 - HR KRDANIZACHPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Valvula de Acc Manual - E150Document4 pagesValvula de Acc Manual - E150DANIZACHPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Valvula Tn10 - Dke E025Document4 pagesValvula Tn10 - Dke E025DANIZACHPas encore d'évaluation

- En - b1 - 070 PATINES LINEALESDocument2 pagesEn - b1 - 070 PATINES LINEALESDANIZACHPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Valve configuration and solenoid directional valvesDocument8 pagesValve configuration and solenoid directional valvesFabinhoTowerPas encore d'évaluation

- Catalogo Componentes 2007Document39 pagesCatalogo Componentes 2007DANIZACHPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Alivio - d120 - HM - KMDocument4 pagesAlivio - d120 - HM - KMDANIZACHPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Check en Linea - c406Document2 pagesCheck en Linea - c406DANIZACHPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- Sun - Hydraulics CatalogDocument44 pagesSun - Hydraulics CatalogAndreea75% (4)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Allround Line Floor 100 250kNDocument4 pagesAllround Line Floor 100 250kNDANIZACHPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Gear flow dividers technical specifications and application guideDocument20 pagesGear flow dividers technical specifications and application guideDANIZACHPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- Pump Polaris SeriesDocument47 pagesPump Polaris SeriesDANIZACHPas encore d'évaluation

- Pump KappaDocument112 pagesPump KappaDANIZACHPas encore d'évaluation

- 4 - Way Directional Control Valve "HPV4": FeaturesDocument2 pages4 - Way Directional Control Valve "HPV4": FeaturesDANIZACHPas encore d'évaluation

- Aloy High Pressure Filters 20 BarDocument2 pagesAloy High Pressure Filters 20 BarDANIZACHPas encore d'évaluation

- Pump Magnun SeriesDocument63 pagesPump Magnun SeriesDANIZACHPas encore d'évaluation

- Baldor MotorsDocument124 pagesBaldor Motorsangel_basualdoPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Basic Training: Motors, Gears & DrivesDocument80 pagesBasic Training: Motors, Gears & DrivesDANIZACH50% (2)

- 742Document52 pages742DANIZACHPas encore d'évaluation

- 742Document52 pages742DANIZACHPas encore d'évaluation

- Absorb Shock and Reduce Vibration with Flexible Grid CouplingsDocument18 pagesAbsorb Shock and Reduce Vibration with Flexible Grid CouplingsRafo Vega GuerovichPas encore d'évaluation

- Re26892 2003-02Document10 pagesRe26892 2003-02DANIZACHPas encore d'évaluation

- 040404X57ZDocument1 page040404X57ZDANIZACHPas encore d'évaluation

- Calculator For SW Density Changes - Effect of List On Ships DraftDocument3 pagesCalculator For SW Density Changes - Effect of List On Ships DraftHein Thurein KyawPas encore d'évaluation

- ElectrochemistryDocument24 pagesElectrochemistryZainul AbedeenPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Project Cash FlowsDocument2 pagesProject Cash FlowsAdarsh Chhajed20% (5)

- The Ultimate Life GuideDocument12 pagesThe Ultimate Life GuideNLPCoachingPas encore d'évaluation

- Being and Nothingness The Look SartreDocument3 pagesBeing and Nothingness The Look Sartremaximomore50% (4)

- Welding Defects and AcceptanceDocument76 pagesWelding Defects and Acceptancearavindan100% (1)

- ArduinoDocument15 pagesArduinoAlvarez TomasPas encore d'évaluation

- ASSIGNMENTDocument10 pagesASSIGNMENTKoleen Lopez ÜPas encore d'évaluation

- Verbal ReasoningDocument8 pagesVerbal ReasoningyasirPas encore d'évaluation

- Evolis User ManualDocument28 pagesEvolis User ManualIonmadalin1000Pas encore d'évaluation

- Durango GS 6-7 Helitack OutreachDocument4 pagesDurango GS 6-7 Helitack OutreachdcgmPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Equations 2Document8 pagesEquations 2Patrick ValdezPas encore d'évaluation

- Mic ProjectDocument12 pagesMic Projectsarthakjoshi012Pas encore d'évaluation

- Engineering Aspects of Food Emulsification and HomogenizationDocument325 pagesEngineering Aspects of Food Emulsification and Homogenizationfurkanturker61Pas encore d'évaluation

- Iso 1924 2 2008Document11 pagesIso 1924 2 2008Pawan Kumar SahaPas encore d'évaluation

- Heat Exchanger Design and Drawing FundamentalsDocument11 pagesHeat Exchanger Design and Drawing Fundamentalsjeevanantham 5846Pas encore d'évaluation

- Meditations on Ancient Astrology Principles from Brihat Parashari HorāDocument87 pagesMeditations on Ancient Astrology Principles from Brihat Parashari HorāPrasanna KumarPas encore d'évaluation

- Prob Stats Module 4 2Document80 pagesProb Stats Module 4 2AMRIT RANJANPas encore d'évaluation

- Operational Transconductance Amplifier ThesisDocument6 pagesOperational Transconductance Amplifier ThesislaurahallportlandPas encore d'évaluation

- Ratana Outdoor FurnitureDocument107 pagesRatana Outdoor FurnitureNova TechiePas encore d'évaluation

- CodigosDocument73 pagesCodigosEnzo Miguel Sarabia MontesPas encore d'évaluation

- Indo American Journal of Pharmaceutical Research (India)Document4 pagesIndo American Journal of Pharmaceutical Research (India)Pharmacy2011journalsPas encore d'évaluation

- A7670 Series Hardware Design v1.03Document69 pagesA7670 Series Hardware Design v1.03Phạm NamPas encore d'évaluation

- Railway Electrification Projects Budget 2019-20Document9 pagesRailway Electrification Projects Budget 2019-20Muhammad Meraj AlamPas encore d'évaluation

- WPS Ernicu 7 R1 3 6 PDFDocument4 pagesWPS Ernicu 7 R1 3 6 PDFandresPas encore d'évaluation

- BS 7941-1-2006Document20 pagesBS 7941-1-2006Willy AryansahPas encore d'évaluation

- Chocolate - Useful Physical ConstantsDocument2 pagesChocolate - Useful Physical ConstantsJuan CPas encore d'évaluation

- Technical Data Speedmaster CX 104Document2 pagesTechnical Data Speedmaster CX 104Vinh Lê HữuPas encore d'évaluation

- Volvo g900 Modelos PDFDocument952 pagesVolvo g900 Modelos PDFAdrianDumescu100% (3)

- Alternator NotesDocument24 pagesAlternator Notesarunima arunimaPas encore d'évaluation