Académique Documents

Professionnel Documents

Culture Documents

Section 6 B2H SOP

Transféré par

Dayaram SahCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Section 6 B2H SOP

Transféré par

Dayaram SahDroits d'auteur :

Formats disponibles

d l db d OoredooFTTx NationalBroadbandProject

FiberforBusiness

StandardOperationProcedure B2HConnectionsGuideBook

1

Standard Operation Procedure B2H Connections Guide Book

FiberForBusiness

Table Of Contents

Chapter1:B2HScenariosOverview

Ch t 2 P d f B2H i t ll ti

7.5:Stripping,leadingin,SplicingandFixingof

Fibers

TableOfContents

Chapter2:ProcedureforB2Hinstallation

Chapter3:CommunicationandSurvey

Chapter4:PreparationforB2H

Chapter5:StandardLayingofOutdoorOFC

5.1:SafetyEnvironmentDeployment

5 2 St d d D i

Fibers

7.6:PreparingofVerticalRisercable

7.7:PreparingofRisercable

7.8:Leadingin,splicingandFixingoffibers.

7.9:Exampleinstallations

7 10: Finishing

5.2:StandardDrawings

5.3:ImplementationPreparation

5.4:TransportingofCable

5.5:FixingCableDrum

5.6:ManholeOpening

5 7 D R di

7.10:Finishing

Chapter8:Standard Installation of Sub FAT3101

8.1:Plantheinstallationspace

8.2:Fixingonthewall

8.3:PreparingofVerticalRisercable

8 4: Leading in and Fixing of Riser Cable

5.7:DuctRoding

5.8:Makingtractionend

5.9:Layingthecable

Chapter6:StandardLayingofRiserandDropCable

6.1:TransportingandFixingofCableinside

Telecom Room

8.4:LeadinginandFixingofRiserCable

8.5:Leadingin,FixingandsplicingofDropfibers.

8.6:Splicingrequirementpercustomer

8.7:Additionalrecommendations

Chapter9:StandardLabeling

9 1 B2H Labeling solution

TelecomRoom

6.2:LayingofVerticalCable

6.3:LayingofDropCable

Chapter7:Standard Installation of FAT3201-24

and FAT3201-48 (direct drop fibers)

7.1:ProcedureofFATInstallation

9.1:B2HLabelingsolution

Chapter10:StandardISPinstallation

10.1:InstallationprocedureforSCS

10.2:StandardInstallationofATBandONT

Chapter11:StandardSplicing

11 1 S li i P d

7.2:InstallationofFATinthewall

7.3:PreparationofFeederCable

7.4:LeadinginandFixingofDropCables

11.1:SplicingProcedure

11.2:JointSplicingintheManhole

2

Chapter One

Business Lines B2H ScenariosOverview

3

FeasibilitySurvey y y

Beforestartinganyactivitywithimplementationinthebuilding,ensurethatthe

buildingwiringandinfrastructurecorrespondstooneofthefollowingscenarios.

Incaseofanydeviations refertoHuaweiSiteEngineer/AreaManagerforguidance.

4

DropcablesaredistributeddirectfromtheFAT3201 24(2

nd

Splitterwith16

Ports) (Each splitter up to 14 ONTs) Design populated scenario (To cater for some

1.B2HScenarios

1

st

Case

Ports)(Eachsplitter,upto14ONT s).Designpopulatedscenario(Tocaterforsome

Expansion).

X*Delnumber/CustomerReferenceNumber/ElectricityNumber

1 Case

of DELs 1,2,3,4 5,6,7,8 948 >48

2nd Floor

DirectDrop

Cables

Equipment 1ONTSupports 4Ports

(ONT8447)

2ONTSupports 4PortsEach

2*(ONT8447)

MA5612 nxMA5612

2ndFloor

1stFloor

GroundFloor

Basement

FAT320124(16)

(1Splitter)

Feeder

Cable Cable

5

Ifabuildinghas47floorsandeachfloorhas2connections,itispossible

to lay drop cables directly to FAT 24 provided that the size of the riser

2

nd

Case

1.B2HScenarios

tolaydropcablesdirectlytoFAT24providedthatthesizeoftheriser

conduithasenoughspacetoaccommodate814dropcables.

5th Fl

6thFloor

2 Case

DirectDrop

Cables

5thFloor

4thFloor

3th Floor 3thFloor

2ndFloor

1stFloor

Basement

GroundFloor

FAT 320124(16) FAT320124(16)

(1splitters)

Feeder

cable

6

DropcablesaredistributeddirectfromtheFAT3201 48(32)(2splitters,

up to 28 ONTs)

3

rd

Case

1.B2HScenarios

upto28ONTs)

3 Case

X*Delnumber/CustomerReferenceNumber/ElectricityNumber

of DELs 1,2,3,4 5,6,7,8 948 >48

Equipment 1ONTSupports 4Ports 2ONTSupports 4PortsEach M5612 nxMA5612

2ndFloor

DirectDrop

Cables

q p pp

(ONT8447)

pp

2*(ONT8447)

1stFloor

GroundFloor

Basement

FAT320148(32)

(2splitters)

Feeder

cable

7

IfDistancefromFATtothenecessaryflooristoolong,orriseris

t d ibl t S b FAT t d t th M i FAT i Ri 4

th

Case

1.B2HScenarios

congested,possibletouseSubFAT,connectedtotheMainFATviaRiser

Cable.

4 Case

of DELs 1,2,3,4 5,6,7,8 948 >48

Equipment 1 ONT Supports 4 Ports 2 ONT Supports 4 Ports Each M5612 n x MA5612

2ndFloor

DropCables

SubFAT3101

Equipment 1ONTSupports 4Ports

(ONT8447)

2ONTSupports 4PortsEach

2*(ONT8447)

M5612 nxMA5612

1stFloor

Vertical

RiserCables

p

DropCables

SubFAT3101

GroundFloor

Basement

Feeder

Cable

FAT320148

(2Splitters)

8

InthiscaseDropCablesaredistributedbySubFAT3101,eachSubFATis

fl ( fl )

5

th

Case

1.B2HScenarios

servicing2floors(upto6Onts perfloor).

3rd Floor

2ndFloor

3rdFloor

DropCables

1stFloor

DropCables

SubFAT3101

GroundFloor

VerticalRiser

Cables

SubFAT3101

Basement

Feeder

Cable

FAT320148

(2Splitters)

9

IncaseifoneSubFATisservicingmorethanonefloor:

ll fl f h fl h ld b d h b l

6

th

Case

1.B2HScenarios

3rdFloor

AllflatsfromthesamefloorshouldbeconnectedtothesameSubFATonly.

2ndFloor

SubFAT3101

1stFloor

GroundFloor

SubFAT3101

Basement

Feeder

Cable

10

TwoFAT320148iscombined,DropcablesaredistributedbySubFAT3101,each

7

th

Case

1.B2HScenario's

3rdFloor

FATisservicing2floors(7to12ONTsperfloor).

DropCables

S b FAT3101

2ndFloor

Vertical

RiserCables

SubFAT3101

Sub FAT3101

1stFloor

SubFAT3101

Sub FAT3101

GroundFloor

SubFAT3101

SubFAT3101

Basement

Feeder

FAT320148

(2Splitters)

Cable

FAT320148

(2Splitters)

11

IncaseifnumberofSubFATisequaltothenumberofsplittersandfreesplitterports

ll l bl bl d d f h fl

8

th

Case

1.B2HScenario's

arestillavailable,itispossibletousedirectdropsfromFATtotheSAME floor.

S b FAT3101

3rdFloor

2ndFloor

Sub FAT3101

SubFAT3101

1stFloor

Vertical

RiserCables

SubFAT3101

SubFAT3101

DirectDrop

Cables

GroundFloor

Feeder

FAT320148

(2Splitters)

FAT 320124

Cable

FAT3201 24

(1Splitters)

12

SimilarscenarioforsingleFAT320148.Wehave2splittersand2ofSub

FAT 2 S b FAT t i 24 d fib i A di t

9

th

Case

1.B2HScenario's

FAT.2xSubFATcancontain24dropfibersmaximum.Accordingto

Ooredoo businessrules,wecanconnect28Onts to2splitters.So,4

splitterportsstillfreeandcanbedistributedbydirectdrops(onlytothe

nearestfloor).

2ndFloor

SubFAT3101

1stFloor

Vertical

RiserCables

SubFAT3101

FAT 320148

DirectDrop

Cables

GroundFloor

Feeder

Cable

FAT3201 48

(2splitters)

13

Each case to be dealt with on a casebycase basis in agreement with Ooredoo Design Approval

10

th

Case

1.B2HScenario's

SubFAT3101

SubFAT3101 5thFloor

6thFloor

Idealscenario ifwehaveupto7ofSubFAT.In

thiscaseispossibletoterminateeachof24F

cable to dedicated splicing/termination tray

Eachcasetobedealtwithonacase by casebasisinagreementwithOoredooDesignApproval

SubFAT3101 4thFloor

cabletodedicatedsplicing/terminationtray.

Otherwiseweneedtosplitthecablesto

differenttrays.

2ndFloor

3rdFloor

22UCabinet,5Splitters,72ONTsMaximum.

SubFAT3101

SubFAT3101

GroundFloor

1stFloor

Vertical

RiserCables

SubFAT3101

SubFAT3101

Basement

Feeder

22UCabinet

Cable

14

22Ucabinet,6splitters,84connectionsmaximum.

11

th

Case

1.B2HScenario's

, p ,

SubFAT3101

SubFAT3101 5thFloor

6thFloor

Forabuildingwhichhas7184connections,

Install1x22Ucabinetwith6splitters.Use

double 2:16 splitter as the bottom splitter It is

SubFAT3101 4thFloor

double2:16splitterasthebottomsplitter.Itis

alsopossibletoterminateeachof24Fcableto

dedicatedsplicing/terminationtray.Otherwise

weneedtosplitthecablestodifferenttrays.

2ndFloor

3rdFloor SubFAT3101

SubFAT3101

GroundFloor

1stFloor

Vertical

RiserCables

SubFAT3101

SubFAT3101

Basement

Feeder

22UCabinet

cable

15

IncaseifnumberofONTsperfloorismorethan12 twoSubFATstobe

installed for each floor

12

th

Case

1.B2HScenario's

installedforeachfloor.

3rdFloor

Drop Cables

EachcasetobedealtwithonacasebycasebasisinagreementwithOoredooDesignApproval

2ndFloor

DropCables

SubFAT3101

SubFAT3101

SubFAT3101

SubFAT3101

1stFloor

SubFAT3101 SubFAT3101

GroundFloor

SubFAT3101 SubFAT3101

Basement

Vertical

RiserCables

Feeder

Cable

22UCabinet

(WallMounted)

16

Scenariowithtworisers,1324ONTsperfloor.

Each case to be dealt with on a casebycase basis in agreement with Ooredoo Design Approval

13

th

Case

1.B2HScenario's

3rdFloor

SubFAT3101

SubFAT3101

EachcasetobedealtwithonacasebycasebasisinagreementwithOoredooDesignApproval

SubFAT3101 SubFAT3101

2ndFloor

Ground Floor

1stFloor

SubFAT3101 SubFAT3101

GroundFloor

SubFAT3101 SubFAT3101

Riser2

Feeder

Cable

Riser1

22UCabinet

(WallMounted)

Basement

Cable

17

Scenariowithtworisers,712ONTsperfloor.

E h t b d lt ith b b i i t ith O d D i A l `

14

th

Case

1.B2HScenario's

3rd Floor

EachcasetobedealtwithonacasebycasebasisinagreementwithOoredooDesignApproval `

3rdFloor

SubFAT3101

SubFAT3101

2ndFloor

1stFloor

GroundFloor

SubFAT3101 SubFAT3101

Basement

Riser2

Feeder

Cable

Riser1

22UCabinet

(WallMounted)

Basement

18

B2HRestrictions

3rdFloor

SubFAT3101

2ndFloor

1stFloor

SubFAT3101

GroundFloor

Riser

Basement

Riser

Feeder

cable

22UCabinet

(WallMounted)

19

Chapter Two

ProcedureforBusinessLinesB2Hinstallation

20

2.1B2HBusinessLinesProcess

21

1.1

Preparation for B2H

Installation

Site Engineer A

1.2

Communicate with building

authorised person

/permission to work and

verify that survey is correct.

Site Engineer A

1.3

Confirm access to building

and that works can proceed

Site Engineer A

1.5

Lay the external cable from

designed J oint closure to

telecom room or specified

comms location inside the

building

OSP Work C

1.6

Prepare cable ends, arrange

inside of J oint Closure and

splice the fibers allocated to

the splitter/FAT from J oint

Closure location

OSP Splicing C

Start

B2H

1.4

Pre-installation Marketing

Circular 1 (Any Business

Day)

Site Engineer A

1.7

Install required quantity of main FAT s with

splitters in Comms. location or specified

location. Prepare the cable, lead-in and splice

the fibers.

1.8

Lay the vertical cable from

comms location to

designated locations where

Sub FATs are required

2.0

Install Sub FATs in the

designated locations on

each specified floor of the

building. Ensure all fire

stops replaced through all

risers where new cables

pass

2.1

Label all cables, FATs and

sub FATs as per agreed

B2HSOP

B2H B

1.9

When Blockage in conduit is

found, install

internal/external Conduit /

External Over-Head Cable.

Then lay Vertical cable

within same.

B2H, Splicing Team B,D

B2H B

pass.

B2H B

B2H B

B2H B

Start

ISP

2.2

Pre-installation Marketing Circular 2(Any Business Day)

2.3

Pre-installation resource /

Tool / Equipment check

2.4

Open the IDP and identify

the route to each customer

dwelling for the 2F drop

cable and Sub FAT if

present

ISP Installation Team A Site Engineer A

present.

ISP Installation

Team

A

2.9

Install Cat3 cable, Cat6

cables, RJ 45 sockets as

per business rules

2.8

Install ONT as per business

rules (refer to the attached

documentation) whenever

2.7

Leave required drop cable

length for splicing at Sub

FATs and ONT location

2.6

Lay the 2F drop cable from

Sub FAT to the location of

ONT as per business rules.

2.5

Rod the internal conduit and

pull in rope if necessary and

install the 2F drop cable and p

ISP Installation

Team

A

)

possible.

ISP Installation

Team

A

FATs and ONT location

ISP Installation

Team

A

p

ISP Installation

Team

A

2.10

Install power supply for ONT

b i l i

2.11

Splice both core of the 2F

2.12

Confirm continuity test of

sta t e d op cabe a d

SubFAT if present.

ISP Installation

Team

A

as per business rules using

qualified electrician and

following safe working

practices

Electrician A

p

cable to the pig tails in the

ONT cabinet / ATB, in the

sub FAT and splice core1

to the splitter and the spare

core2 to the pigtail for the

patch panel at the splitter

location

Splicing Teams D

y

each fibre from ONT

location to splitter location

using power meter and

confirm the CAT 6 and CAT

3 continuity test.

Splicing Teams D

2 13

2.2 B2H

Reference:NextPage

3

Test the existing services

Migration

Team

E

3.1

Migrate the services

Migration

Team

E

3.2

Confirm Work order with

call center

Migration

Team

E

3.3

Test ALL the services after

Migration

Migration

Team

E

3.4

Installation / Migration

Completion sign off.

Call centre to call customer

after 2 days and confirm

customer satisfaction

Migration

Team

E

2.13

Obtainsign off of Installation

completion report form and

ensure customer satisfaction

survey is completed before

leaving premises

Site Engineer A

22

Migration

2.3NamingConvention

SE+ISPInstallationTeam:A

1. InstallationofATB&ONT

cabinet/casing

2. Knowrouteofbuilding

3 Good English

B2HInstallationTeam:B

1. Installationofrisercable,

FATandsubFAT

2. Installationof2Fdrop

cable 3. GoodEnglish

communicationskills

cable.

3. Knowrouteofbuilding

4. SimpleEnglish

communicationskills

SplicingTeam:D

1. HaveexpertFusionsplicing

OSPInstallationTeam+OSP

SplicingTeam:C

capability.

2. SimpleEnglish

communicationskills.

3. Havegoodknowledgeof

healthandsafety.

1. Haveagood

understandingofOSPwork

2. HaveexpertFusionsplicing

capability.

3. Havegoodknowledgeof

healthandsafety

MigrationTeam:E

1. Provisioning&testingofall

services.

2. Troubleshootingcapability

3. HaveknowledgeofISP

installation

MigrationTeam:F

1. Haveprofessional

electricalcertification

2. Troubleshootingcapability

3. GoodEnglish

communication skills installation.

4. GoodEnglish

communicationskills.

communicationskills.

Huawei/OoredooisnotresponsibleforanyThirdParty

23

internalcabling.PleaserefertolocalITdepartment

relatingtoanyissue.

Chapter Three

Communication and Survey

24

3.1CommunicationandSurvey

SN Task Description Operator Duration

3.1 Communication and Survey CDG

1

3.1 Communication and Survey CDG

Procedure

1 Introduce oneself at the office reception. As shown in Picture 1

2 Show the ID card to the Customer;

3

Get the access signature from customer on new Ooredoo Authorisationforms.

(Picture 1) (Picture 1).

4 Converse with the customer according to the script (Ask for IT person if available)

5

Agree the location of ONT/ATB with the Customer and confirm the installation

scenario based on xxxxxx (power socket location).

6 Survey the ODP location (drop cable route) as Image 4 shown.

7 Validate the customer's data information with customer;

Note

1

If it is inconvenient for the Customer to give access there and then, ISP

coordinator will make an appointment with customer and record the appointment

time via Ooredoo Call Center.

Please agree with the customer that drillingof holes is allowedbefore anysuch

2

2

Please agree with the customer that drilling of holes is allowed before any such

work.

3

If customer does not allow ISP team to carry out installation then ISP coordinator

will note this into his report and quality sign off sheet, will request the customer to

sign the sheet for not allowing the installation and report back.

4 The workers should be in neat and clean Ooredoo uniformat all times.

Th k t b d t l t i db f th i it t (H i ill

5

The workers must be adequately trained before they visit customer;(Huawei will

provide the technical training & Ooredoo will provide the communication training)

6 The workers should take off shoes if needed;

7 Ooredoo will provide the Authority letter;

Tools

Cross

ODP

25

1 Iron wire push rod 2

Cross

screwdriver

3 Straight Screwdriver

Materials

1 Introduction letter 2 Work order 3 Authority letter

Chapter Four

PreparationforB2H

26

Preparation for B2H

SN Task Description Co-ordination Duration

4.1 Preparation for B2H A & B

Procedure Procedure

1 Refer to door knocking procedure for the building access

2

Refer to building survey report, familiarize yourself for all the works needed to

be done

Before start any activity, give a brief safety instruction for the working force.

3

y y, g y g

Check the uniform and their appearance and ensure cleanliness and

professionalism to upheld at all times

4

Politely speak to the building property manager, building owner or the security

guard regarding the installation

5 Inspect the building scenario and compare it with the building survey report.

6

If any mismatches found (different quantity of floors, cable routes, FAT

capacity and etc.) immediately report to Huawei site engineer.

Note

1 Ensure all PPE is in place

2 Ensure all the accreditation cards are available

3

4

Tools

See separate tool list

Requirements

1

Installation

Schedule

2

Building Survey

report

3 Way leaves form

Remember -

Think Safety - Work Safely

Schedule report

4 5 6

27

Chapter Five

Standard Laying of Outdoor OFC

28

Safety Environment

Deployment

SN Task Description Operator Duration

S f t i t

p y

5.1

Safety environment

deployment

A & C 10 Min

Procedure

1 Ensure All PPE is worn 1 Ensure All PPE is worn

2

3

Note

1

Always wear safety glasses, high visibility jerkins, suitable safety

Helmet and protective gloves.

2 Keep all food and beverages out of the work area.

3

Don't touch your eyes while working with fiber optic systems until

they have been washed thoroughly.

4

Tools

R d S f t

Safety glasses Hi-Vis Vest

Road Safety

Signs

Safety Helmets Safety foot wear Gloves

Materials

Remember -

1 2 3 Think Safety, Work Safely

29

Safety Environment Deployment

SN Task Description Operator Duration

5.1.1 Safety environment

deployment

A & C 10 Min

Procedure Procedure

1 Deploy road safety precaution:"Keep left-Right" (see pic 1)(Observance of

the sign is mandatory and drivers must pass on the side indicted). Care must

therefore be taken to ensure that drivers are not directed onto the footway by

unintentionally placing the sign the wrong way round. The sign is always

placed at the start of a temporary kerbed line taper and at other locations.)

1

2 Cones, Reflecting (see pic 2)(cones are used to delineate a temporary

kerbed line). For day and night work, they should be used in conjunction with

lamps. Road caution, a cone and a lamp being placed alternately around the

obstructions that will be removed before darkness. Only cones should be

used to guard the area. Where cones are placed at between 45and 90to

2

approaching traffic, they must be spaced 1.2m apart. Where cones are

placed in line of traffic ,they must be spaced 9m apart.

3 Lamps, Road caution (see pic 3)(lamps, road caution are used with

cones),reflecting to delineate a working area for night work, lamps being

place midwaybetweensuccessive cones The lamps remainin position place midway between successive cones. The lamps remain in position

during the day. Lamps are used on footways at night to warn pedestrians of

obstruction.

Note

1 Deploy all required SLG(Signing ,Lighting and Guarding ) as per traffic

requirements

3

2 You are responsible for your own safety, the safety of your workmates and

that of public.

3

4

Tools

1 C 2 L 3 Si f K l ft 1 Cones 2 Lamps 3 Sign for Keep left-

Right

30

Implementation Preparation

SN Task Description Operator Duration

5 2 Drawing Standard A & C 5 Min 5.2 Drawing Standard A & C 5 Min

Procedure

1 Legend details (see pic 1)

2 Layers by colour (see pic 2)

1

3 Duct details (see pic 4)

4 Update the duct details used in FAT section of design

5

66

Note

1 Always Used the Approved OSP As-built Drawing

2

2

3

3

Tools

1 2 3

2

3

4 5

Materials

1 Drawing 2 3

4 5 6

31

Implementation Preparation

SN Task Description Operator Duration

5.3

Implementation

Preparation

A & C 5mins

Preparation

Procedure

1 Refer to the cable route design to start installation

2

Cross Check the Actual Route on cable route design and ODF

design.

3

4

5

6

Note

1 Always Used the Approved OSP As-built Drawing

2

33

4

Tools

1 2 3 1 2 3

4 5

Materials

1

Cable route

design

2 3

4 5 6

32

Standard laying of Distribution O.F. cable SN Task Description Operator Duration

5.4 Transporting of Cable A & C 5mins

Procedure

1 Unload the O.F.cable drum from the truck (see pic 1)

2 Roll the cable tray to the place near the manhole.

1

3 Secure the working area and set up the materials and tools properly

4

Observe the safety standard precaution measurement when carrying

out the work

5

66

Note

1 Ensure proper PPE is used

2 Ensure stopping block is in place when off loading cable drum

3 Ensure off ramp is in place

2

3 Ensure off ramp is in place

4

5

6

Tools

1 2 3

4 5

Materials

1 Cable 2 3

4 5 6

33

Standard Laying of Distribution O.F. Cable

SN Task Description Operator Duration

5.5 Fixing Cable Drum A & C 15mins

Procedure Procedure

1 Fix the cable drum on drum hydraulic as pic 1.

2 Adjust the height of holder as the pic 2 shown.

3

Put a ground sheet underneath the cable drum to prevent any

scratches or damage to the cable

1

scratches or damage to the cable

4

5

6

NNote

1 Make sure the cable rolling direction is correct.

2

The drum hydraulic should be set up at safe distance from the open

manhole

2

3 Do not block door entry or customer access

Tools

1

Cable

hydraulics

2 PPE 3 Ground Sheet

4 5 4 5

Materials

1 Cable Drum 2 Cable 3

4 5 6

34

Standard Laying of Distribution O.F. Cable

SN Task Description Operator Duration

5.6 Manhole Opening A & C 5mins

Procedure

1

Deploy cones and warning tape around manhole(see pic 1), clean

manhole cover (see pic 2)

2

Open manhole with proper Ooredoo manhole key as the pic 3,4 and

5 shown. Always ensure gas detector is used when opening

manholes

2 1

manholes.

3 Check the detail design and choose the right duct as pic 6 shown.

4

If there is water, sundries or sand in manhole which will affect

implementation, need to clean out with bailer, shovel or other tools.

5

Note

1 Always bring detail design and diagram drawing with the team.

2 Use proper key for different manholes.

3 Not allowed to change the design on site.

4

3

4 When opening the cover of manhole, there should be two people.

5 Must use gas detector for all manholes.

Tools

1 Manhole keys 2 Bailer 3 Shovel 5

6

4 Gas Detector 5 Gloves 6 Brush

7 SLG 8 Cones

Materials

1 2 3

4 5 6

35

Standard Laying of Distribution O.F.

Cable

SN Task Description Operator Duration

5.7

Duct Roding

(No Rope or Rope

can not be used)

ABCDE 30mins

Procedure

1

Pay attention to the connector of PVC duct rod,one side is the

female,the other is the male.And then start duct rodding,as pic

1,2,3,4,5,6 and 7 shown.

2

Take the push rod from truck, and disjoin them as the pic 1,2

shown Then connector themone by one as the pic 3 Assemble 2 shown. Then, connector them one by one as the pic 3. Assemble

the tools near both of the manhole A and B at the same time,

3

Install the female connector on one side of the duct rod at manhole

A, and the male connector at manhole B. Use the tape to fix the

two connectors firmly(pic 4,5,6).

4

Lead the duct rod to the underground duct both of manhole A and

B at the same time until they are connectedin the duct (pic 7 8 9) B at the same time until they are connected in the duct.(pic 7,8,9)

5

Tie up the draw rope on the push rod, turn back the push rod to the

manhole until the rope is in the duct from manhole A to manhole B.

Note

1 Ensure proper PPE is used

22

3

4

5

66

Tools

1

Distance

measurer

2

Tools for

dredging

3 PVC Duct Rods

4 Gloves 5 PVC tape 6 Rope

Materials

Manhole A Manhole B

Distancemeasurer

Materials

1 Draw Rope 2

Ground

Sheet

3

4 5 6

Manhole A Manhole B

Duct X

Female Connetor

Male Connetor

36

Standard Laying of Distribution O.F. Cable

SN Task Description Operator Duration

5.8 Making traction end A & C 5mins

Procedure

1 Connect the Cable Grips and Cable Swivel as pic 1 shown.

2 Insert cable end into cable grips as pic 2 shown.

3 Wrap the cable and cable grips with tape (see pic 3).

1 2

4

Connect the cable Swivel and the pulling rope. splice the pulling

rope and wrap the splice rope with a PVC tape as pic 4,5

5

6

Note

3

Note

1

2

3

4

4

5

6

Tools

1 Cable Grips 2 Cable Swivel 3

5

1 Cable Grips 2 Cable Swivel 3

4 5

Materials

1 Tape 2 3

4 5 6

Connectto

O.F.cable

viaswivel

4 5 6

37

Standard Laying of Distribution O.F. Cable

SN Task Description Operator Duration

5.9 Laying the cable A & C 20mins

Procedure

1

Put the ground sheet on the ground between the cable drum

and the manhole (see pic 1).

2 Deploy the bellmouths at both sides of duct (see pic 2)

3 Fi a Rope G iding Roller near the manhole as the pic 3 sho n

1

2

3 Fix a Rope Guiding Roller near the manhole as the pic 3 shown.

4

In order to feed the cable into the duct in preparation for pulling

E.G. person at manhole A pulls the pulling rope slowly while

person at cable drum E.G. person at pic 4 feeds the cable into

the duct . Pull the cable accordingly.

5

After the cable is installed Leave maintenance loop of 8 meters

4

3 Manhole A

5

inside the splitter/joint manhole

6

Coil a loop of cable atleast 5 meters inside telecom room for

arranging and splicing purposes

7

Seal the duct entry point from the manhole and inside telecoms

room by using compound 16.

Note

RopeGuiding

Roller

Always adhere for the safety standard precaution measurement

Cable labeling should be in this format Approved format by

Ooredoo

(to be confirmed) Manhole B

6

(to be confirmed) Manhole B

Tools

1

Split Bell

mouths

2

Rope Guiding

Roller

3

Road safety

precaution

4 Ladder 5 ground sheet 6 Screw drivers

Materials

1 Cable 2 PVC tape 3

4 5 6

38

Chapter Six

StandardLayingofRiserandDropCable

39

Standard Laying of Vertical Cable

SN Task Description Operator Duration

6 1

Transporting and

fixing of cable

B Standard Laying of Vertical Cable 6.1

drum inside

telecom room

B

Procedure

1

Make sure that the cable drum is correctly positioned. See pic 1

as shown

1

2

3

4 NOTE 4 NOTE

Note

1 Ensure proper PPE

Make sure that the telecomroomhas enough space for the

2

Make sure that the telecom room has enough space for the

cable drum, If not take the cable drum outside telecom room

and proceed for the standard laying of the cable and ensure all

the safety precautions are taken

3

Tools

1 Cable Cutter 2

Ground

Sheets

3 Cable J acks

Materials

1 Cable Drum 2 Drop cable

40

Standard Laying of Vertical Cable

SN Task Description Operator Duration

6.2 Laying of Vertical Cable B

Procedure Procedure

1

Open the tray works safely and Identify the route of the riser

cable.(see pic 1)

2

Rod and Pull the vertical cable from the telecom room to the

next floor where the sub FAT is located. (see pic 2)

Keep a loop of cable for splicing inside the telecom room

1

3

(approximately 3 meters for main FAT) and to the designated

floor where the sub FAT is required (approximately 2 meters for

the sub FATs) (see pic 3)

4

Mark the vertical cable with a temporary label according to the

floor number where the sub FAT will be installed.

5

Tie up the vertical cable neatly in the existing tray works in the

2 3

5

p y g y

dry riser by using cable ties. (see pic 4)

6

Seal the duct entry point by using fire stopping compounds from

telecom and riser room. (see pic 5)

6 close the tray works safely. (see pic 6)

Note

4

1 The minimum bending radius of the fibre is 8 cm.

2

The cables should be routed neatly and together. Do NOT mix or twist

the cables up with the existing copper cables in the dry riser.

3 Label the cables as per Labeling SOP

Tools

1 Screw drivers 2

4 mm

cobra rod

3 Cutter

4 Ladder 5 6

Materials

6

5

1 12/24F cable 2 Cable ties 3 Insulation tape

4

Fire stopping

compound

5

Ground

Sheets

6

41

Standard Laying of Vertical Cable

SN Task Description Operator Duration

6.3

Laying of Drop

Cable

A

Procedure

1

Identify the primary telephone socket outlet in the customer

premises. (see pic 1)

2

Identify the route of the drop cable from installed FAT or sub-

FAT to inside customer premises

1 2

FAT to inside customer premises

3

Open the telephone socket and search if there is a pulling rope.

Push rod should be used if there is no pulling rope. (see pic 2)

4

Tie up the pulling rope and drop cable with PVC tape. (see pic

3)

5

Lay the drop cable from the installed FAT or Sub FAT to inside

5

y

customer premises

6

Keep a loop of cable inside the ONT cabinet (approximately 2

meters) and inside FAT or Sub FAT(approximately 2 meters)

for splicing

7

Mark each drop cable with a temporary cable and ensure its

aligned with the correct apartment and electricitynumber aligned with the correct apartment and electricity number

Note

1

Keep the maintenance loop safe and avoid unnecessary

bends.

2

Minimum bending radius of the drop cable shall be maintained

according to the cable specification.

Dropcable

3 4

3

Tools

1 Screw Drivers 2 Cutter 3 4mm rod

Materials

1 pulling rope 2 PVC Tape 3 Drop cable

4

Cable

Lubricant

5

Ground

Sheets

6

42

Chapter Seven

S d dI ll i f FAT3201 24 dFAT3201 48(di d fib ) Standard Installation of FAT3201-24 and FAT3201-48 (direct drop fibers)

43

SurveyInformation

BeforestartinganyB2HinstallationitisMANDATORYthatthepresitesurvey

informationformisrequested,studiedandapreimplementationsurveyis

carried out It is mandatory that you request the forms 2 weeks in advance of carriedout.Itismandatorythatyourequesttheforms2weeksinadvanceof

yourintendedinstallationdate.

Thisformwillprovidecontactdetailsforaccessintothebuilding.

WillprovideasuggestedsolutionforB2Hinstallation.

Willprovideaguidetothematerialrequirementsforinstallinginthebuilding.

Willgiveyouanopportunitytocompleteyourownpresitesurveytoconfirm

the information on the form is accurate theinformationontheformisaccurate.

Willgiveyouanopportunitytoarrangeforanyamendmentsandchangesto

materialandimplementationrequirements.

Willsupportyourplanandmakeyourteamsmoreefficient.

44

Standard Installation of FAT3201-24 and

FAT3201-48

SN Task Description Operator Duration

7.1

Procedure for FAT

installation

B

Feedercable

outlet

FAT320124

Dropcableinlet

The personnel in charge of installation and maintenance must be

trained and master the correct operating methods and safety

precautions before beginning of work. Ensure permission to work on premises

has been granted

Procedure

outlet

1 Check FAT and the accessories are fit for purposes

2 Check the space where the FATs will be installed.

3

The preferred installation location of FATs is nearby of Cable Trays , as close as

ibl t th i ti DP

Riser/Drop

cableinlet

Feeder

cableinlet

FAT3201 48

3

possible to the existing copper DP

4

5

If FAT is installed in Telecom room, the new cable tray is required, to link the FAT

with existing cable trays. In other cases 60 x 40 or 100 x 50 cable trunk, to provide

smooth banding radius, (not less than 80 mm)

FAT320148

Feedercableoutlet

Dropcableinlet

In case of combination of 2 FATs, vertical cascading

is preferable, to reduce the length and routes of

cable trays or cable trunks .

5

5

Note

1 Please make sure that the FATs are leveled properly by using spirit level

Riser/Drop

cableinlet

Feeder

cableinlet

2

Please make sure to keep clear the area of work from obstacles like :

decoration or any material that can be damaged due to work.

3

ALWAYS install the FAT-48 above the FAT-24 whenever 3 splitters are required

as Pic5

45

Standard Installation of FAT3201-24 and

FAT3201-48 (direct drop fibers)

SN Task Description Operator Duration

7.2

Installing of FAT in

the wall

B

1

Marker

Procedure

1

Determine the installation position. Use Cable avoidance tool to identify

the e istingser ices before drillingthe all ens re no ser ices in the all

Level

Installation

location

the existing services before drilling the wall ensure no services in the wall

2

Put a piece of ground sheet on the ground just under the

installation space to cover the floor/carpet from waste

material, dirt etc. as picture 2 shown;

3 Drill holes using a percussion drill as picture 3 shown;

2

3

8drillbit

Install the anchor bolts and remove the nut with washer. 4

4 5

Open the lower layer of FAT, then hang the case to the expansion bolts on

5

Note

42mm45mm

p y , g p

the wall, fasten the nuts.

5

For safety concern, at least two persons are required to install the case. One

person is to hold the case and the other person to fasten the nuts

b

ALWAYS check for other services BEFORE drilling any holes using a metal

detector and by using information from the Building in - charge.

46

Standard Installation of FAT3201-24 and

FAT3201-48

SN Task Description Operator Duration

7.3

Preparing of

Feeding cable

CD

Striptheoutdooropticalcableaccordingtotheactualscenario.MakesurethatcablewillfitinsideofFATwithfollowingrouting.

Procedure

1

FAT 3201-24 3 0

Fiber Tubes Route

Feeder

Pig Tails

FAT 3201-48

Fiber Tubes Route

Pig Tails

b

Feeder

47

Standard Installation of FAT3201-24 and

FAT3201-48

SN Task Description Operator Duration

7.3

Preparing of

Feeding cable

CD

Cascading of FAT 3201-48 and FAT 3201-24

Tube 1 Route

Pig Tails

Bridge between splitter

modules

Tube 2 Route

Pig Tails

b

Feeder

48

Standard Installation of FAT3201-24 and

FAT3201-48

SN Task Description Operator Duration

7.3

Preparing of

Feeding cable

CD

Cascading two of FAT 3201-48

Tube 1 Route

Pig Tails Pig Tails

Tube 2 Route

Bridge between splitter

modules

Note: In this situation a maximum of four Fibres will

be used One for each splitter.

Tube 2 Route

p

Two from the Red Tube and Two from the green

Tube

Pig Tails

Bridge between splitter

modules

b

Feeder

49

Standard Installation of FAT3201-24 and

FAT3201-48

SN Task Description Operator Duration

7.3

Preparing of

Feeding cable

CD

1 2

Dressthefiberloosetubesintoprotectivetube 1

3

Polishthesheathwhichisnearthestrippedpointusingthesand

paper

2

4

Procedure

3

wrapitwithinsulatingtape. 3

4

4

Remove the tower plug on the case. Cut a cable hole on the

tower plug based on the diameter of the optical cable.

Note

5 Insert and fix the Feeding optical cable.

6 Seal the cable inlet/outlet using insulating tape

6

Note

Thediameteroftheopticalcablemustbelessthan20mm. 1

2

Thestrippedlengthoftheopticalcabledependsonthecable

route.

55

When cutting the cable hole, please pay attention to the

different diameters mark on the tower plug .

3

50

Standard Installation of FAT3201-24 and

FAT3201-48

SN Task Description Operator Duration

7.4

LeadinginandFixing

ofDropCables

CD

Procedure

Lead in and fix the drop cable.

For FAT3201-24, the drop cable inside the FAT should

be 1600 mm in length.

1a 1b

Drop

Cable

C

g

For FAT3201-48, when the drop cable and distribution

optical cable are led into the bottom section, the drop

cable inside the FAT should be 2500 mm in length.

Arrangement of Drop Fibers must be done according to

figures 1-3, dependant of the Drop Fibers Entry point

location.

2

Drop Cable

Copex

Tube

1-a

Note: Labeling of Drop Fibers should be done

according to the Chapter of SOP B2H Labeling

Entry point is on top of FAT

1-b

Entry point is on the bottom of FAT. In this case

drop fibers MUST BE PROTECTED with Copex

tube or Cable Trunk.

2 Routes of drop fibers for FAT 3201-24

3

3 Routes of drop fibers for FAT 3201-48

b

51

Standard Installation of FAT3201-24 and

FAT3201-48

SN Task Description Operator Duration

7.5

Stripping,Leadingin,

splicingandFixingof

fibers.

CD

1 Arrange the loose tube and drop cables according to table

Procedure

Splicing Tray NO

Tray 1 (Bottom tray)

Side A

Feeder INPUT

Splitter input

Feeder output (if

di f FAT)

Side B

1

Specification of splicing tray module

1

Note:Dropfibers/loosetubesmustbewrappedwiththe

Stripthe optical fiber core with the lengthof 30mmandprepare to splice

Tray 2

Splitter outputs 0-3

Pigtails 1-4

cascading of FAT)

Drop Fibers 1-4

Tray 3

Splitter outputs 4-7

Pigtails 5-8

Drop Fibers 5-8

2 Strip the Drop Cables with the length of 950 mm

p / pp

insulationtapeandbefixedattheportsofthesplicingtray

withstraps.

3

Strip the optical fiber core with the length of 30 mm and prepare to splice

the optical fiber.

Tray 4

Splitter outputs 8-11

Pigtails 9-12

Drop Fibers 9-12

Tray 5

Splitter outputs 12-15

Pigtails 13-16

Drop Fibers 13-16

Tray 2- Tray 5 Side A Side B

Splicing

Bottom tray

Splicing

Side A Side B

Drop Fibers

Splitter

S li th fib di t Ch t 8 f SOP

Splitter outputs

4

Pig Tails

Splitter outputs

Insulation Tape

Insulationtape

b

Splice the fibers according to Chapter 8 of SOP.

Feeding input

Splitter outputs

4

Arrange fibers and protective heat shrinks inside of splicing tray. 5

52

Standard Installation of FAT3201-24 and

FAT3201-48

SN Task Description Operator Duration

7.6

Preparing of

Vertical Riser cable

CD

1

Before start any operation with Vertical

Riser cable, you should pay attention to

the Color Code Table (figure 1). the Color Code Table (figure 1).

2

Cores 1-12 have pure colors, cores 13-

24 have the same color coding as 1-12,

but with black marks, every 5 cm. (figure

2)

Note: Fiber number 20 has white mark

b

Note: Fiber number 20 has white mark

53

Standard Installation of FAT3201-24 and

FAT3201-48

SN Task Description Operator Duration

7.7

Preparing of Riser

cable

CD

1

Procedure

1

Route 2 - 1900 mm

(950 mm of spiral tube)

Route 3 - 2200 mm

(1250 mmof spiral tube)

StriptheRiserCablesto2.2moflengthfromtheEntryPoint. 1

Identifyfiberroutestoallocatedsplittermodulesaccordingly

totheRoutingTable.Dividefiberstodifferentbundles(8fiber

perbundle)Dressthebundlesintospiralprotectivetube.

2

Route 1 - 1550 mm

(600 mmof spiral tube)

(1250 mm of spiral tube)

3

WrapthejointingplaceofCablesheathandspiraltubeswith

insulatingtape.

4

LeadallcablesintotheFATandfixattheentrypointwith

CableStraps.

(600 mm of spiral tube)

Entry Point

2

3

4

b

54

Standard Installation of FAT3201-24 and

FAT3201-48

SN Task Description Operator Duration

7.8

Leadingin,splicing

andFixingoffibers.

CD

1 Arrange the bundles of riser cable according to the table

Procedure

Splicing Tray NO

Tray 1 (Bottom tray)

Side A

Feeder INPUT

Splitter input

Feeder output (if

di f FAT)

Side B

1

Specification of splicing tray module

1

Note:theendofprotectivespiraltubingmustbewrapped

Stripthe optical fiber core with the lengthof 30mmandprepare to splice

Tray 2

Splitter outputs 0-3

Pigtails 1-4

cascading of FAT)

Tray 3

Splitter outputs 4-7

Pigtails 5-8

2

Lead the bundles of riser cable into the splicing tray and fix with cable

straps.

p p g pp

withtheinsulationtapeandbefixedattheportsofthe

splicingtraywithstraps.

Fibers 1,3,5,7

Fibers 2,4,6,8

Fibers 9,11,13,15

Fibers 10,12,14,16

3

Strip the optical fiber core with the length of 30 mm and prepare to splice

the optical fiber.

Tray 4

Splitter outputs 8-11

Pigtails 9-12

Tray 5

Splitter outputs 12-15

Pigtails 13-16

Tray 2- Tray 5 Side A Side B

Fibers 17,19,21,23

Fibers 18,20,22,24

Fibers 1,3,5,7

Fibers 2,4,6,8

Splicing Splitter

Bottom tray

Splicing

Side A Side B

Pi T il

Drop Fibers

Insulationtape

Feeding input

Splitter outputs

Pig Tails

Splitter outputs

Insulation Tape

Splice the fibers according to Chapter 8 of SOP.

g p

4

Arrange fibers and protective heat shrinks inside of splicing tray. 5

55

Standard Installation of FAT3201-24 and

FAT3201-48

SN Task Description Operator Duration

7.9 Exampleinstallations CD

56

Standard Installation of FAT3201-24 and

FAT3201-48

SN Task Description Operator Duration

7.10 Finishing CD

1 Additional Informationandchecklist 1 Additional Information and check list

No Check list

1

Splitters are installed incorrect inside FATs and MUST be removed , rotated 180 degrees and re-installed

BEFORE any dressing in of Fibres takes place. If not , the dressing in is not to SOP and will have to be re-done

2 Is the optical cable properly fixed?

3

Is the optical fiber neatly routed and fixed (with optical fiber fastener)?

4

Is the optical fiber routing correct?

5

Fibre A, Fibre 1 or the blue core will ALWAYS be spliced to the Ooredoo network.

Fibre B Fibre 2 or the orange core will ALWAYS be spliced to the Pig tail for the 2

nd

service provider Fibre B, Fibre 2 or the orange core will ALWAYS be spliced to the Pig tail for the 2 service provider.

6

Splicers MUST follow the colour code for the riser cable.

Example:

Customer for port 00 will have the Blue and Orange cores Blue is Ooredoo, Orange is 2

nd

service provider.

Customer for port 06 will have the Blue and Orange cores with black dashes Blue/black is Ooredoo and

Orange/black is 2

nd

service provider.

Blue & Blue/black, Orange & Orange/black etc IS NOT the colour code and MUST NOT be followed.

7

Maximum number of ports allocated per splitter is 14. (00-13) If ports 14/15 are required to be used permission

MUST be requested from Ooredoo BEFORE using these ports.

8

If an additional splitter is required due to more customers identified than on the survey, a DCR MUST be

submitted through normal procedures.

9

Has the Labeling SOP been followed 100% - This is a MUST DO task and is critical.

10

Does the pigtail storage meet the requirement for the bending radius and is fixed (with roll protection tube)?

11

Does the door open and close with ease?

12

Is the earthing good (if OF cables have a metal element)?

13

Has the Allen bolt been tightened properly and the Patch panel door been locked

13

Has the Allen bolt been tightened properly and the Patch panel door been locked

14

All keys for FAT-24 & FAT-48 are universal One fits all.

15

FAT patch panel door access keys must be handed to Ooredoo

16

Implementation details for each building installation must be recorded for future maintenance purposes.

57

Chapter Eight

S d dI ll i f S b FAT3101 Standard Installation of Sub FAT3101

58

Standard Installation of Sub FAT3101

SN Task Description Operator Duration

8.1

Plan the

installation space

CD

The personnel in charge of installation and maintenance must be trained and master the correct operating

methods and safety precautions before beginning of work. Ensure permission to work at premises has been granted

ExteriorandStructureoftheCase

Splicing information Splicing area

Procedure

1

Check the quality of FATs and the

accessories

Splicinginformation Splicingarea

2

Check the space where the FATs will be

installed.

3

The preferred installation location of FATs is

on top of existing copper IDP

Opticalcablestrippingandfixingarea

Note

1 Please make sure that the FATs are leveled properly by using spirit level

2

Please make sure to keep clear the area of work from obstacles like :

decoration or any material that can be damaged due to work. y g

SubFAT has 2 kinds: 12F and 18F. 12F subFAT can accommodate a maximum of 9

customers 3 trays 3 customers per tray 6 splices per tray 2 splices per

customer. 18F subFAT can accommodate a maximum of 12 customers 4 trays 3

customers per tray 6 splices per tray 2 splices per customer

3

59

Standard Installation of Sub FAT3101

SN Task Description Operator Duration

8.2 Fixing on the wall CD

Marker

Wall

Level

1

Determine the installation position. Use Cable avoidance tool to identify

the e istingser ices before drillingthe all Ens re no ser ices in the all

Procedure

1

Mountinghole

Template

the existing services before drilling the wall Ensure no services in the wall

2

Put a piece of plastic sheet on the ground just under

the installation space to cover the floor/carpet from

waste material, dirt etc. as picture 2 shown;

3 D ill h l i i d ill i 3 h

2 3

8drillbit

Flatwasher

3 Drill holes using a percussion drill as picture 3 shown;

4 5

Nut

Coneheadbolt

42mm45mm

Install the anchor bolts. 4

Open the lower layer of FAT, then hang the

case to the expansion bolts on the wall,

fasten the nuts.

5

b

60

Standard Installation of Sub FAT3101

SN Task Description Operator Duration

8.3

Preparing of

Vertical Riser cable

CD

1

Before the start any operation with

Vertical Riser cable, you should pay

attention to the Color Code Table (figure

1) 1).

2

Cores 1-12 have pure colors, cores 13-

24 have the same color coding as 1-12,

but with black marks, every 5 cm. (figure

2)

Note: Fiber number 20 has white mark

b

Note: Fiber number 20 has white mark

61

Standard Installation of Sub FAT3101

SN Task Description Operator Duration

8.3

Preparing of Riser

cable

CD

Procedure

1

Striptheopticalcable.UsingIndustrystandardstrippers&

cleansingwipes

1

Dressthefibersintospiralprotectiontube,6fiberspertube. 3

2

Prepare4piecesofspiralprotectiontube,55cmlength 2

4

WrapthejointingplaceofCablesheathandspiraltubeswith

insulatingtape.

5 CablenowreadyforthefixinginsideofSubFAT

3

4

b

5

62

Standard Installation of Sub FAT3101

SN Task Description Operator Duration

8.4

LeadinginandFixing

ofRiserCable

CD

1 Lead in and fix the Vertical Riser optical cable.

2 Wrapthe endof eachspiral tube with insulatingtape 2-3layers

Procedure

2 Wrap the end of each spiral tube with insulating tape, 2-3 layers.

3

Insert the spiral tube with fibers 1-6 into the splicing tray 1 and fix

with cable ties.

1 2

4

Coil the fibers inside of the splicing tray and fix end of the bundle

withpiece of insulatingtape

N t

3

with piece of insulating tape

5 Repeat item 3 and 4 for the rest of splicing trays.

Note

4

Arrangement of fibers inside of splicing

trays must be done in order to the

following table

Tray 1

4

Fiber 1 to 6

Tray 2 Fiber 7 to 12

Tray3 Fiber 13to 18

b

5

Tray 3 Fiber 13 to 18

Tray 4 Fiber 19 to 24

63

Standard Installation of Sub FAT3101

SN Task Description Operator Duration

8.5

Leadingin,Fixingand

splicingofDrop

fibers.

CD

1 2 3

Labels Labels

Procedure

4

Specification of splicing tray module

M3flatheadscrewdriver

1

Confirmthenumberoftheleadinginflatdropcables,andpiercethecable

leadinginholesofthesamenumber.

3

Lead in the flat drop cable into the splicing tray 1, strip and fix with the straps at

2

Leadintheflatdropcable fromthecableleadinginholeatthebottomofthe

fiberaccessterminal.

RunDropFibersthroughthelabelingrings,accordingtothelabelingrules.

Splicing Tray NO

Side A (Riser

Cable)

Tray 1 Fiber 1-6

Side B (Drop

Cables)

Drop Fibers 1-3

p p g y

Tray 2 Fiber 7-12 Drop Fibers 4-6

Tray3 Fiber 13 18 DropFibers 7 9

3

Leadintheflatdropcableintothesplicingtray1,stripandfixwiththestrapsat

theentrypoint.

Splicethefibersaccordingtothetable,arrangefibersandprotectiveheat

shrinksinsideofsplicingtray

4

Repeattheitem2,3and4fortherestofsplicingtrays.Fixdropfiberswiththe

strapsatFATd/fiberentrypoint.

5

Side A Side B

Tray 3 Fiber 13-18 Drop Fibers 7-9

Tray 4 Fiber 19-24 Drop Fibers 10-12

Splicing

5

Straps

b

Feeding input Drop Fibers

64

Standard Installation of subFAT 3101

SN Task Description Operator Duration

8.6

Splicingrequirement

percustomer

CD

65

Standard Installation of Sub FAT3101

SN Task Description Operator Duration

8.7

Additional

recommendations

CD

1

Position of FAT must be as close as possible to the existing

copper IDP or to existing cable tray/cable trunk.

1

2

All visible vertical riser cable and drop fibers must be

protected with cable trunk or Copex tube

No Item

1 Are all the bolts tightened?

2 Is the optical cable properly fixed?

3

Is the optical fiber neatly routed and fixed (with optical fiber

fastener)?

4

Is the optical fiber routing correct?

2

p g

5

Does the door open and close with ease?

6

7

8

b

66

Chapter Nine

StandardLabeling

67

B2HLabeling

Key Elements KeyElements

Inordertorepresentthebestinquality,serviceandperformance,

FATs subFATs and MDUs should have clear easy to read easy to FAT ssubFAT sandMDUsshouldhaveclear,easytoread,easyto

understandprofessionallabelingsystemthatshouldnotbeabletobe

removed,abradeorfadeinashortperiodoftimebyusingthecorrect

toolsandmaterialsasstatedintheLabelingSOP.

AccordinglylabelingMUSTbedoneaspertheagreedsolutionwith

Ooredoo

68

B2HLabeling

FATwithSplitter(s)&FeederCable p ( )

FAT320148

(2splitters)

FAT320124

(1splitter)

FAT320124and320148aretobelabeled

ontheoutsidewithfeedercableand

splitterinformation

FAT320124Example:KRG/1/F1

Explanation:Area/Cable/buildingsplitter

FAT320148Example:KRC/1/F1F2

Explanation:Area/Cable/buildingsplitters

KRC/1/J17F1/12F(1)

FeedercablesaretobelabeledasOSPandnumberinbracketsdenotes

howmanysplittersinthebuilding

Example:KRC/1/J17F1/12F(3)Explanation:Area/cable/jointBuildingsplitter/cablesize/Totalsplitters

KRC/1/J17F1/12F(2)

69

FAT&subFATLabeling

70

B2HLabelingOverview

labelinginFATandsubFAT g

Labeltherisercablewithdetailsasshown

inPic1.

1

2Fibredropcabletobelabeledwith

splitterandportdetailsinsideeachFATas

showninPic1.

F1/01

Note:IncaseofSubFAT,onlySplitterport

Noisrequired

00,01,02etcistherecommendedmethod.

F1/01

01

2

01

A/PP2/00

/121A

71

B2HLabelingOverview

SubFATCustomerRoutingInformationforODF&22UScenario g

FAT310112/18

(12F/24Fsplices)

1 2A/PP2/2

1 3 4

ODF:A/PP2/1(24)

F1/00/SED

5 6

7 8

2 9 10

11 12

13 14

3 15 16

17 18

19 20

4 21 22

23 24

Customerinformationlabelinside

subFATtobeshownHorizontally.

SubFATODFterminationAddress

/ / ( )

SparecoreODFAddress

Example:F1/00/E4532889

Explanation:buildingsplitter/port

number/Electricitynumber

Example:A/PP2/1(24)

Explanation:TerminationBlock/Patch

Panel/FirstPatchPanelPort(numberof

terminatedfibers)

Example:A/PP2/2

Explanation:TerminationBlock/Patch

Panel/FirstPatchPanelPort

72

B2HLabelingOverview

SubFATCustomerRoutingInformationforFATScenario&RiserCable g

FAT310112/18

(12F/24Fsplices)

1 2B/1

1 3 4

FAT:B/F3/0011(24)

F3/00/SED

1 3 4

5 6

7 8

2 9 10

11 12

13 14

3 15 16

17 18

19 20

4 21 22

23 24

ProvidelabeltagonrisercabletoeachsubFAT

SubFAT FATterminationAddress

Example:B/F3/00 11(24)

Explanation:TerminationBlock/

Splitteroutputport.used/of

terminated fibres

Example:B/1

Explanation:Termination

Block/FATPigtail

SpareCoreAddress

ExampleFAT320124/48scenario:A/F3/00/121/AExplanation:TerminationBlock /Buildingsplitter /firstsplitterport used/totalnumberofsplitter

portsusedFloor /subFATcode

ExampleODFCabinetScenario:A/PP2/1/121/AExplanation:TerminationBlock/PP/firstPPport//totalnumberofPPportsFloor /subFATcode

terminatedfibres

73

B2HLabelingOverview

SubFAT&RiserCable

Splicinginformationlabelinside

subFATtobeshownHorizontally

FAT310112/18

(12F/24Fsplices)

FAT310112/18

(12F/24Fsplices)

Providelabelsonrisercable

from1

st

subFATto2

nd

subFAT.

3

E l f ODF E l f FAT3201 ExampleforODF

cabinetscenario:

ExampleforFAT3201

24/48scenario:

SubFATtobelabeledontheoutsideofthe

subFATasshowndisplayingfloornumber

d b FAT d i i d

2/A 2/B

SubFATtobenumberedperfloorfroma

clockwisedirectionaseachfloorisentered

fromeithertheliftorthestairs

andsubFATdesignationcode

74

IdentifyingandlabelingsubFATsandsubFATportallocation

subFAT labeling

03 04

First Floor

Note: No matter which location you enter the

floor the first subFAT will be the first one on

your left from where you enter the floor.

1 is floor #A is subFAT A etc

If you have more than one entry onto a floor,

subFAT

subFAT

02

choose the left side of the building from the

ground floor entrance as your starting point.

1/A

1/B Clockwise Direction

01

Lift or Stairs

First Floor

Port allocation

00

2/01 1/00 3/02

4/03 5/04

Clockwise Direction

Note: If there are no numbers on the doors of

each apartment then follow the same

instruction as for subFAT labeling and allocate

accordingly.

If the apartments have numbers then follow the

numbers regardless of sequence.

E l If A t t F1/1i it lift

4/03 5/04

subFAT

1/A

subFAT

1/B

Lift or Stairs

Example: If Apartment F1/1 is opposite lift or

stair entrance and apartments 2 & 3 are either

side (as shown) then you will still allocate ports

to the apartment number and not in a

clockwise direction from Apartment 1.

6/05

7/06

9/08 8/07

Existing

Ooredoo

access panel

SubFAT Clockwise Direction

9/08 8/07

75

B2HLabelingOverview

labelinginATB&ONTCabinet g

Placeroutinginformationoninsideof

inspectioncoverofONTCabinet

Placeroutinginformationon

insideofinspectioncoverofATB

ForODFCabinetScenario

ATB co er

KRC/1/F1/00

A/PP2/2

COName/Cable /Splitter

/Splitterport

ATBcover

ONTcabinetcover

A/PP2/2

KRC/1/F1/00

A/PP2/2

SpareFiberODFterminationAddress

(TerminationBlock /PP/PPport )

ForFAT320124/48Scenario

ATBcover

ONTCabinetcover

KRC/1/F1/00

A/1

COName/Cable /Splitter

/Splitterport

KRC/1/F1/00

A/1

SpareFiberFATterminationAddress

(TerminationBlock/PPPort)

76

A

77

78

79

80

Standard Labeling of FAT, sub FAT, 22U and

42U cabinet

SN Task Description Operator Duration

9.9 Labeling D

No Check list

Additional Information and check list 1

1

Labeling SOP MUST be followed 100% - This is critical

2 Labeling is required to be 100% accurate for providing information for 2

nd

service

provider by Ooredoo

3

Existing labeling inside the subFAT is wrong (Vertical) and must be changed.

3

g g g ( ) g

4

ALL routing information is to be entered horizontally inside the subFAT. (See slide

68)

5

Alternative labeling template is available from the Processes, procedures and

SOPs team. (See Slide 68)

6

SubFAT labeling follows the floor level and locations in a clockwise direction

from the left as you enter each floor. From the lift or stairs.

Example: G/A Ground floor subFAT A. 2/B 2

nd

Floor subFAT B

81

Chapter Ten

StandardISPinstallation

82

Installation of Structured

Cabling System

SN Task Description Operator Duration

10.1-a

Installation procedure for

SCS

AB

Procedure

1 Rod the section from location a to b

2 Prepare CAT6 (see pic 1)

1

3 Tie up the push rod and CAT6 with tape(see pic 2)

4 One worker pulls the push rod from location B (see pic 3)

5 One worker should feed in the cat6 from location A(see pic 3 and 4)

2

NOTE

1

Pulling of cat 6 must be in one direction

22

3

4

Tools

LocationB

3

1 4mm rod 2

Cross

screwdriver

3 Gloves

4 5 6

Materials

LocationA

4

1 CAT6 2 ground sheet 3 Tape

4 5 6

83

Installation of Structured

Cabling System

SN Task Description Operator Duration

10.1-b

Installation procedure for

SCS

AB

Procedure

1

If the location A doesn't connect to B directly, we should open the intermediate

box between location A and B as pic 1 shown.

2 Lay the push rod from location B to intermediate ,and then to location A;

C f

1

location

Intermediate

l ti B

3 Lay the CAT6 from location A to intermediate ,and then to location B;

4

Note

1 There may be multiple access holes in any cable run

location

A

locationB

1 There may be multiple access holes in any cable run

2

If there is no existing internal conduit, trunking should be installed with the

permission of the customer.

3

4

I di

4

Tools

1 4mm rod 2 Gloves 3 Cross screwdrivers

4 5 6

Intermediate

Materials

1 CAT6 2 Ground sheet 3

Insulating Tape

4 5 6

84

StandardInstallationofATBandONT

Refer to Section 5 Chapter 8

85

Chapter Eleven

StandardSplicing

86

Standard Splicing Process

SN

Task Description Operator Duration

11.1 Splicing procedure

Splicing

technician

15 Minutes

Procedure Procedure

1 Arrange the drop cable inside ONT cabinet and splicing tray

2

Strip the optical fiber cable sheathing, expose the bare fibres and then

install the splice protection sleeve. See Pic 1.

3 Strip, cleave, clean and splice both optical fibres. See Pic's 2 - 5

4

After the splicing is complete and passes the check, heat shrink the

protection tube. Insert the splice protection sleeve into the fixing base of

Spliceprotection

sleeve

0.25Optical

fiber

0.25

Opticalfiber

1

p p p g

the splicing tray to protect the splicing point. See Pic 6.

5

Put the splicing information according to the coding standard approved by

Ooredoo

6 Arrange the spliced fibres in the fibre management tray

7

Note

2

3

1

All route cables from the same splitters to be labeled firmly as per the

labeling standard approved by Ooredoo

2

Labeling inside ATB to be confirmed

3

Isopropyl alcohol and lint free cloth MUST be used for all splicing

ti

4 5

3

operations.

4

Tools

1

Cable Sheath

Cutter

2

Cable(Tube)

Cutter

3

Isopropyl alchohol and lint free

cloth

4 Fusion splicer 5 Fibre Cleaver 6 Sharps box

7 S li i t l 8 S i 9 b ff t i

6 7

7 Splicing tools 8 Scissors 9 buffer stripper

10 11 12

13 14 15

Materials

1

Splice protection

sleeve

2

soft ground

tube

3 Cable tie

sleeve tube

4 Ground sheet 5 6

87

Splicing from the Splitter or joint

SN

Task Description Operator Duration

11.2

J oint Splicing in the

Manhole

Splicing

technician

30 minutes

Procedure

1 Open the closure inside an air conditioned splicing vehicle or splicing tent

2 Label th drop cable outside the closure with the port number allocated.

3 Prepare, lead-in and fix the drop cable into the closure.

4 St i l l d li th ti l fib

1

4 Strip, cleave, clean and splice the optical fibers.

5 Arrange the spliced fibres in the splicing tray or cassette.

6

Update the fiber label according the coding standard for the drop cable.

See Pic 2.

7

close and replace the closure fixing it to the wall of the manhole using the

bracket provided and arranging the cables neatly to OSP specifications. p g g y p

8 Clean the site

Note

1 A vehicle or tent must be used when opening closures.

2 The detailed splicing procedure is the same with OSP splicing;

2

3

Fibre shards after cleaving are dangerous and must be disposed of

properly.

Tools

1 S d i 2 Di l li 3 Fib t i 1 Screwdriver 2 Diagonal pliers 3 Fibre stripper

4

Adjustable

wrench

5

Black sealing

tape

6 Cable (Tube) Cutter

7

Cable Sheath

Cutter

8 Fusion splicer 9

Isopropyl alchohol and lint free

cloth

10 Fibre Cleaver 11 Sharps Box 12 Splicing tools

88

Chapter 12 p

BusinessLines Migration

89

Migration

SN Task Description Operator Duration

g

12.1

Preparation for

migration

Co-ordinator 1 hour

Procedure

1 Run off the work orders from CRM

2 Confirm appointments with the customers

3

Confirm number and types of existing services

i th k d b CRM D t b

3

in the work order by CRM Database

4

Confirm existing services are working in the

premises,

5 Issue work orders to Supervisor.

6 Plan the work in advance.

Note

Exchange D-Side DP-Pairs DP No CAB No. Telephone Customer Name Status Electricity Equipment

Installatio

n

1 ONT

KTR 256 2 3267 69 44878308

CONSULTANT

LEGAL

CONSULTATI

ON &

ARBI TRATI ON OSUB 141658

E3_008-

127

1 ONT ,

1Drop

Cable 4

ports

(8447) ,

CONSULTANT

1 port

KTR 287 5 3267 69 44873938

LEGAL

CONSULTATI

ON &

ARBI TRATI ON OSUB 141658

E3_008-

1328

1 port

overthe

splitter

KTR 294 9 3267 69 44873877

CONSULTANT

LEGAL

CONSULTATI

ON &

ARBI TRATI ON OSUB 141658

E3_008-

1672

EASTERN

GA LAXY

TRA DI NG & SX 10.10.

1 ONT ,

1Drop

Cable 4

No Shahry

Subscriptio

n

KTR 224 21 3267 69 44869159

G &

CONT. CO.

W.L.L. OSUB 141657

S _ 0 0

19.148:29

44-0-29-1

Cable 4

ports

(8447) ,

KTR 295 10 3267 69 44869154

EASTERN

GA LAXY

TRA DI NG &

CONT. CO.

W.L.L. OSUB 141657

SX_10.10.

19.148:29

44-1-7-29

1port

overthe

splitter

Shahry

Subscriptio

n

90

From this point onwards, you should follow:

Migration SOP guidebook (Section 9) to continue with

Migration

91

Vous aimerez peut-être aussi

- Master Plan StepDocument43 pagesMaster Plan Stepnailclipperla100% (1)

- Fiber Distributed Data Interface [FDDI] Technology ReportD'EverandFiber Distributed Data Interface [FDDI] Technology ReportÉvaluation : 5 sur 5 étoiles5/5 (1)

- WDM Technologies: Passive Optical ComponentsD'EverandWDM Technologies: Passive Optical ComponentsAchyut K. DuttaPas encore d'évaluation

- Optec Catalogue PDFDocument98 pagesOptec Catalogue PDFVijay Lakshmipathy0% (1)

- Fiber Optic CommunicationDocument4 pagesFiber Optic Communicationeaglett100% (1)

- HOW GPON WorkDocument13 pagesHOW GPON WorkHarsh Zaveri100% (1)

- 12.5U Central MSAN - 2 Management and Switching Cards PlusDocument2 pages12.5U Central MSAN - 2 Management and Switching Cards PluswirelesssoulPas encore d'évaluation

- Engineering Instructions - FTTH House WiringDocument18 pagesEngineering Instructions - FTTH House WiringReena SharmaPas encore d'évaluation

- Ason/Gmpls: Development and Deployment: Young Lee Huawei, USADocument25 pagesAson/Gmpls: Development and Deployment: Young Lee Huawei, USA7kkhsPas encore d'évaluation

- Televes OLT512 Optical Line TerminalDocument1 pageTeleves OLT512 Optical Line TerminalBastian AtenasPas encore d'évaluation

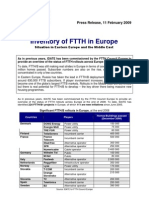

- Inventory of FTTH in Europe: Press Release, 11 February 2009Document4 pagesInventory of FTTH in Europe: Press Release, 11 February 2009nitsuiPas encore d'évaluation

- FTTX Solutions BrochureDocument12 pagesFTTX Solutions BrochureWalter R. SchulzPas encore d'évaluation

- TM 2G3G4G Hardware Installation Guide V1.6 PDFDocument150 pagesTM 2G3G4G Hardware Installation Guide V1.6 PDFjacobus_louw4329Pas encore d'évaluation

- FTTX Solutions: Mini Fiber Distribution Hub 3000Document5 pagesFTTX Solutions: Mini Fiber Distribution Hub 3000julianPas encore d'évaluation

- FTTH Accessories PDFDocument10 pagesFTTH Accessories PDFdannyalcivarPas encore d'évaluation

- FTTH SCTE May2010Document92 pagesFTTH SCTE May2010Mustapha BrahimPas encore d'évaluation

- Gigabit Passive Optical Network: Ii. Theory A. FTTHDocument4 pagesGigabit Passive Optical Network: Ii. Theory A. FTTHarif100% (1)

- Opt Ic3Document137 pagesOpt Ic3Anonymous bpf0OZSd9Pas encore d'évaluation

- Test FTTHDocument23 pagesTest FTTHSanjeev KoulPas encore d'évaluation

- Telecommunication PosterDocument3 pagesTelecommunication PosterWan HaziqPas encore d'évaluation

- TransmissionDocument32 pagesTransmissionahmad7160Pas encore d'évaluation

- Smartax Ma5801: Optimized Lightweight Olt For Rapid Network ConstructionDocument2 pagesSmartax Ma5801: Optimized Lightweight Olt For Rapid Network ConstructionBuratPas encore d'évaluation

- FTTH ProfileDocument28 pagesFTTH Profilesandeepmishra100% (1)

- Signaling in Telecommunication NetworksD'EverandSignaling in Telecommunication NetworksÉvaluation : 4 sur 5 étoiles4/5 (1)

- GPON - FundamentalsDocument18 pagesGPON - FundamentalsMuhammad Sharif Janjua0% (1)

- CFHP Course OutlineDocument4 pagesCFHP Course OutlineJuan Salvador JVPas encore d'évaluation

- FTTXDocument23 pagesFTTXSamir LaliliPas encore d'évaluation

- Gpon Vs EponDocument17 pagesGpon Vs Eponkflim100% (1)

- OFT - Presentation For Newroz Access Network (OSP Part)Document35 pagesOFT - Presentation For Newroz Access Network (OSP Part)dsfghedfhgPas encore d'évaluation

- GP Power System OverviewDocument36 pagesGP Power System OverviewMd.Bellal HossainPas encore d'évaluation

- Thomas Martin Fiber To The HomeDocument56 pagesThomas Martin Fiber To The HomeBayu Bentar KumbaraPas encore d'évaluation

- Fiber Optics ReviewerDocument16 pagesFiber Optics Reviewersupermax23Pas encore d'évaluation

- Colorless and Directionless Multi-Degree ROADMDocument5 pagesColorless and Directionless Multi-Degree ROADMKirandip Singh100% (1)

- FTTH PDFDocument20 pagesFTTH PDFasmaa dinePas encore d'évaluation

- Apsfl Brochure Web PurposeDocument16 pagesApsfl Brochure Web PurposeBharath CNWPas encore d'évaluation

- OSP DataDocument6 pagesOSP DataHemanth KumarPas encore d'évaluation

- Otu 8000 Optical Test Unit Data Sheets enDocument2 pagesOtu 8000 Optical Test Unit Data Sheets enSalahuddin MughalPas encore d'évaluation

- Optical Network Monitoring System Onmsi Ensures Municipality Fiber Network Availability Case StudiesDocument2 pagesOptical Network Monitoring System Onmsi Ensures Municipality Fiber Network Availability Case StudiesgagaPas encore d'évaluation

- Optera Metro: The Optical ConnectionDocument24 pagesOptera Metro: The Optical ConnectionBrenton Grinnell BrownellPas encore d'évaluation

- DWDM Impairments Optical Transport Networks (OTN) : Linear EffectsDocument1 pageDWDM Impairments Optical Transport Networks (OTN) : Linear Effectskapil dev pandeyPas encore d'évaluation

- CFHP Course OutlineDocument4 pagesCFHP Course OutlineDrJennifer LoboPas encore d'évaluation

- LTE/LTE A Interference Coordination For FemtocellsDocument98 pagesLTE/LTE A Interference Coordination For FemtocellsRoy Naldo Nathaniel SihotangPas encore d'évaluation