Académique Documents

Professionnel Documents

Culture Documents

Delphi Manual Requirements

Transféré par

abraham_ginTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Delphi Manual Requirements

Transféré par

abraham_ginDroits d'auteur :

Formats disponibles

DELPHI GLOBAL

SUPPLIER GUIDELINES

Revised 24 November, 2003

The following additional provisions shall be applicable to all business with Delphi. The

terms of this document shall be construed, to the extent reasonable, to be in addition to

and cumulative to the General Terms and Conditions as defined in Attachment C the

General Terms. In the event of any conflict between any terms in this document and the

General Terms, the General Terms shall govern.

Page 1 (Revised 10/31/03)

Table of Contents

SUBJECT SECTION PAGE

ADDITIONAL PROVISIONS 1.0 3

EXCELLENCE 1.1 3

QUALITY 1.2 4

PRICING / PAYMENT 1.3 8

PRODUCTION CONTROL & LOGISTICS 1.4 10

SPECIFICATION 10949001 1.5 14

ENGINEERING 1.6 14

CHANGE APPROVAL 1.7 17

PROPERTY RIGHTS 1.8 18

GENERAL INFORMATION 1.9 18

PROTOTYPE PARTS PROVISIONS 1.10 19

TOOL INVENTORY / DISPOSAL 1.11 20

ATTACHMENTS: Attachment Letter

SUPPLIER SUGGESTION PROGRAM A

VALUE STREAM MAP EXAMPLE B

GENERAL TERMS AND CONDITIONS C

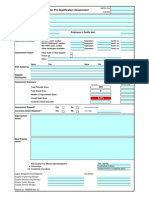

GENERAL FORMS: FORM # (if applicable)

FIRE AND SECURITY SURVEY

SUPPLIER CHANGE REQUEST / REVIEW FORM

SUPPLIER SUGGESTION PROGRAM FORM

ELECTRONIC FUNDS TRANSFER (EFT)

FOREIGN RECEIVING REPORT - example

FRM 6889

PIECE PRICE BREAKDOWN FORM & INSTRUCTIONS

TOOLING COST DETAIL BREAKDOWN FORM &

INSTRUCTIONS

SUPPLIER PACKAGING INFORMATION FORM

Page 2 (Revised 10/31/03)

1.0 ADDITIONAL PROVISIONS

1.1 EXCELLENCE

Commitment to Excellence

In direct support of Delphis commitment to excellence and desire to exceed our

customers expectations, it is expected that our suppliers work toward exceeding the

expectations and requirements of the Delphi Global Supplier Guidelines.

Excellence means perfection in all that you do: Perfect planning, perfect execution,

perfect communications, and perfect parts. This is demonstrated through consistent

delivery of quality products to Delphi and our customers. Our suppliers are expected

to have zero incidents and zero disruptions, provide products with zero defectives,

and have flawless delivery performance and on time responsiveness to issues.

Suppliers must have a philosophy of total quality commitment, with subsequent

planning and actions, that drive for perfection. This commitment starts with top

leadership and is driven through all levels and aspects of their operations.

Suppliers should have in place First Time Quality tracking methods, with appropriate

alarms and actions defined. This data should be utilized to continue to drive

continuous improvement in their processes and operations.

Excellence in the Relationship

All Delphi employees must conduct their business activities with suppliers

exhibiting the highest ethical standards. Such conduct enables Delphi to have

mutually beneficial relationships with its suppliers and thus provide competitive

advantage to Delphi.

If a Delphi Customer/Employee solicits a gift or favor from your company, the

request is to be tactfully declined. The solicitation of gifts from suppliers by Delphi

Employees is strictly prohibited. In the event a Delphi Employee does solicit a gift

from your company, the Delphi Ethics Line should be notified. The phone numbers

for the ethics line are as follows:

US, Canada, and Portions of Mexico: 1-888-679-8848

Mexico 01-800-288-2872-888-679-8848

Brazil: 00-XX*-1-881-679-8848 *Codigo da operadora

Argentina 0800-555-4288-888-679-8848

Page 3 (Revised 10/31/03)

1.2 QUALITY

Quality System Requirement

Suppliers are expected to implement a robust Quality Management System (QMS)

that promotes defect free products through prevention, monitoring, and ongoing

improvement.

Delphi prefers certification to ISO/TS 16949:2002 for its suppliers but will accept

certification to ISO9001: 2000 in conjunction with Delphi specific requirements as a

minimum for supplier selection and meeting TS section 7.4.1.2, supplier quality

management system development. All suppliers that manufacture direct product or

materials must comply with these requirements by June 1, 2004. Delphi strongly

encourages its suppliers to become certified to ISO/TS16949: 2002 and may

strategically require TS certification in the future. Suppliers to Delphi Product &

Service Solutions (DPSS) should contact the appropriate DPSS SQ contact for

specific requirements.

Suppliers registered to ISO or TS must notify Delphi of certificates being revoked or

placed on probation. Suppliers must also notify Delphi if they plan to change

registrars.

Suppliers must provide the Delphi Buyer a copy of the registration certificate for any

amendments or renewals to the quality management system certification.

Suppliers should reference current Automotive Industry Action Group (AIAG)

manuals for Advanced Part Quality Planning (APQP), Production Part Approval

Process (PPAP), Measurement System Analysis (MSA), Failure Mode and Effects

Analysis (FMEA)*, QS9000 and ISO/TS16949: 2002.

Suppliers to Delphi that are certified to QS9000 are authorized to use the Delphi

Potential Supplier Assessment Appendix 26 or other QS or TS based assessment for

sub-supplier evaluations to meet C9 of the QS9000 Sanctioned Interpretations,

7/1/02. This authorization is in effect until the June 1, 2004 compliance date as stated

above.

* Notes:

When developing PFMEAs for production parts or material supplied to Delphi,

the Delphi rating tables for severity, occurrence, and detection shall be used

in place of the rating tables referenced in AIAG FMEA 3

rd

edition.

Potential Failure modes with a severity of 7 or greater must have either an

occurrence of 1 or a detection of 5 (see Delphi PFMEA rating tables-APQP

Forms.xls).

Page 4 (Revised 10/31/03)

Managing Supply Chain

Suppliers are expected to ensure the quality and capacity of materials and component

parts coming from their sub-suppliers through supplier selection and on-going

monitoring. Suppliers are responsible for ensuring that sub-suppliers develop a

quality management system that facilitates defect prevention, monitoring, and

improvement.

Supplier Performance Development Process (SPDP)

Delphis process for managing suppliers quality is the SPDP process. SPDP

contains the major activities for Advanced Quality planning and production. The

supplier specific SPDP tasks and accompanying appendices are itemized below:

APQP

Technical Review

- Appendix 3- Required Quality Information

Feasibility Letter

- Appendix 5- Team Feasibility Commitment

Supplier Assessment

- Appendix 26- Potential Supplier Assessment

- Appendix 27- On Site Assessment

Timing Charts & Open Issues List

- Appendix 8- APQP Open Issues List

- Appendix 9- APQP Timing Chart

DFMEA

Design Review

Gage Review

Process Flow

- Appendix 13_2- PFD Flowchart

PFMEA* (see notes above)

- Appendix 13_3- FMEA Form

- APQP Forms (tables)

Control Plan

Program Reviews

Proactive Containment

- Early Production

- Provisional

PPAP

Run at Rate

- Appendix 14- Run at Rate Plan

- Appendix 15- Run at Rate Worksheets

Lessons Learned

Production Cycle

Problem Tracking

- Appendix 31_1- SQAP

- Appendix 31_2- Gate Chart

Supplier Requested Change Process

- Appendix 32_1- Supplier Change

Request/Review (SCRR) Instructions

- Appendix 32_2- Supplier Change

Request/Review Form

Production Process Audit

- Appendix 39- Production Process Review

PRR

Utilizing the 5 why analysis technique

- Appendix 41- 5 Why Analysis Chart

- Appendix 42- 5 Why Problem Solving

Process Instructions

Reactive Containment

- Problem Report

- Controlled Shipping

Page 5 (Revised 10/31/03)

In order to work with suppliers via the SPDP process, we will need access to

suppliers facilities and appropriate documents. In some cases, this may require

access to sub-tiers facilities and documents.

Suppliers Involvement prior to Sourcing

In preparation of the RFQ, please submit a Team Feasibility Commitment Form,

(see SPDP Appendix 5).

You also may be asked to submit the Required Quality Information Letter (see

SPDP Appendix 3) and requested to participate in a Technical Review with Delphi

Personnel.

You may be requested to participate in a Supplier Assessment with Delphi Personnel

(see SPDP Appendix 26 or 27).

After you have been named the supplier:

Suppliers must participate in and meet APQP requirements for all new parts. You

will receive specific instructions from your Supplier Quality Engineer. These

requirements are further detailed in SPDP and the AIAG APQP manual.

The following are some of the key requirements:

Participate in Program Reviews

Participate in Design Reviews

Provide and maintain Timing Charts and Open Issues tracking lists

Provide and maintain DFMEA

Provide and maintain Process Flow, PFMEA*(see notes above) and Process

Control Plan(s)

Perform and provide Measurement System Analysis/Gage Reviews

Provide an Early Production Containment and Pre Launch control plan

Complete Part Certification (PPAP) requirements, prior to shipment of initial

production. ---please follow 3

rd

edition of AIAG PPAP requirements

Perform and pass Run at Rate

For APQP, suppliers are expected to meet program timing, keep commitment dates,

and support early builds and pre-launch requirements.

All communications/documents must be in English, unless there is prior agreement.

Performance Monitoring

Delphi will track supplier quality performance; including the following: Defective

parts per million, number of disruptions, overall responsiveness, Problem Reports,

Controlled Shipping status, and program execution.

Page 6 (Revised 10/31/03)

Suppliers will be requested to complete and update a Supplier Quality Action Plan

for communications back to Delphi on problem resolution, actions and timetable.

Change Management

Suppliers will not make any changes without prior written notification and approval

from Delphi. Changes should be communicated through the SPDP Supplier

Suggested Change Process. (Appendix 32_2- Supplier Change Request/Review form) These

include changes to part design, material, sub-tier supplier, manufacturing location or

process. (Reference AIAG PPAP, 3

rd

edition.)

Improvement and Development Management

When necessary, Delphi will provide suppliers with tools and expertise for

improvement activities. Two tools suppliers should utilize are a Production Process

Review and Value Stream Mapping.

Problem Reporting & Resolution

When a problem does occur, we expect our suppliers to immediately put their

operations in containment and to protect Delphi or Delphis customers from receiving

any defective material.

Suppliers will receive a Problem Case from Delphi for documenting corrective

action plans

Suppliers are expected to have on-line access to our PRR system to receive copies of

problem cases from Delphi, unless prior arrangement has been made through

Purchasing. Suppliers need to register with Covisint, which will be hosting the

Problem Solver application, when contacted.

Suppliers are expected to monitor and respond to all PRRs issued by Delphi. The

initial response to a problem (essentially the containment plan) is due within 24

hours. Final response, (with verified root cause analysis), is due within 15 calendar

days, unless additional time has been requested and approved.

Suppliers will be requested to complete a 5-Why Analysis as a means of ascertaining

root cause analysis and verification.

Although the PRR system is a communication tool for reporting and resolving

problems and should be freely used for this purpose, it is expected that suppliers work

toward reducing their number of PRRs over time. Repeat PRRs of the same

problem and lack of a response to a PRR or resolving the issue is not acceptable.

Page 7 (Revised 10/31/03)

Suppliers have financial responsibilities for non-conforming materials and their

effects, which may include warranty issues and cost recoveries for sorting, re-work,

scrap, premium transportation and other related types of charges incurred at Delphi or

by our OEM customer. Cost recovery will be communicated with a PRR and through

a cost recovery notice in the Covisint Problem Solver system. Suppliers must

respond to the cost recovery notices within 15 days.

For some problems, Delphi may place a supplier in Controlled Shipping Level I or

Level II, at the suppliers expense, as a further means to ensure that no defective

parts reach Delphi or Delphis customer. Use of these levels of containment depends

on the severity of the problem and the suppliers actions to correct it. Suppliers placed

on Controlled Shipping Level II must inform their registrar of this activity and action

plans for improvement. Delphi may also send a copy of Control Shipping

correspondence to the suppliers registrar.

1.3 PRICING / PAYMENT

Pricing

Suppliers will be expected to be globally competitive, which will be benchmarked by

Delphi buyers.

When requested by the Delphi buyer, suppliers will complete the Piece Price

Breakdown Form and the Tooling Cost Detail Breakdown Form and submit with the

suppliers response to the Request for Quote. These forms and instructions are

available on www.delphi.com.

All quotations must include a separate itemized price for 1.) expendable packaging

and 2.) returnable packaging; when specified.

Suppliers are expected to have a continuous cost reduction improvement process in

order to manage their costs.

With this in place, it is expected that that increased costs are not passed on to the

customer.

In addition, suppliers are expected to work with Delphi buyers toward annual price

reductions, via long-term and lifetime contracts.

Suppliers should actively participate with buyers in the suggestion process

(Attachment A and Supplier Suggestion Program Form are available on

www.delphi.com), bringing forward ideas that would improve both product quality

and cost.

When required, Delphi can provide assistance in cost reduction issues, through

various workshops. Contact your buyer.

Page 8 (Revised 10/31/03)

Suppliers who provide prototype/pre-production part requirements are expected to

provide those at normal production pricing

Suppliers will provide service parts at full production volume prices.

Delphi will not accept quotations with minimum order quantities. (Reasonable

exceptions will be reviewed.)

Currency

It is Delphis policy that all prices and payments should be in the Delphi buyers local

currency. The Delphi buyers local currency is defined as the currency of the country

in which Delphi sells the final product to the customer.

Suppliers should quote in the currency requested by the Delphi buyer. For exceptions

to this policy contact Delphi.

Payment

Delphis standard payment term is MNS-2. MNS-2 establishes the minimum payment

term as the 2

nd

day of the 2

nd

month (on average) following receipt of goods or

receipt date of services.

For North America, new suppliers will complete an Enterprise Activities Group

(EAG) Disbursement Services Enrollment package. (see Payment Agreement

Form) This is required only prior to issuing first payment or if remit name, address

or Ship From Duns number changes. Payments cannot be issued until the following

documented remittance information is provided to the EAG Disbursement Services:

For other regions, contact the Delphi buyer.

The Foreign Receiving Report or FRR (see form FRM 6889 or equal) is the official

document that must be used by supplier receiving locations to document that material

has been received under a Delphi Purchase Order at their respective locations. The

FRR will be provided by Delphi and is to be completed by the receiving location and

returned to Delphi to input receipts, which will generate payment to the supplier. The

FRR is very critical in a system that is invoiceless and relies upon receipts as the

trigger for payment. Instructions on how to complete and return Foreign Receiving

Reports can be obtained by contacting Delphi.

Page 9 (Revised 10/31/03)

1.4 PRODUCTION CONTROL & LOGISTICS

Lean

Lean manufacturing is the balanced use of people, equipment and material that gives

the lowest lifecycle cost. Lean thinking looks to eliminate all waste. Delphi, through

the Delphi Manufacturing System (DMS), is expanding this concept beyond our

factory floors to our suppliers. In order to become a Lean Enterprise through the

complete value chain the following items are required from suppliers:

Value Stream Map: The supplier who is awarded the production business

may be required to include an internal and external value stream map. An

example of a value stream map is included (see Attachment B). It is

expected that the supplier highlight the potential areas on the map where

the material pipeline can be optimized.

Delphi encourages suppliers to obtain value stream mapping training.

Delphi Specific value stream mapping training may be available in the

future. Please periodically check the supplier page of www.delphi.com for

further details.

Labels

For all Delphi destinations in North America, all materials must be identified in

compliance with Delphi Shipping/Parts Identification Label Standard. This specifies

that information is printed in human readable characters and bar code symbols and

defines the size and format the labels should follow. A sample or facsimile of your

label must be provided with your Part Certification package. For destinations in other

regions of the world, Delphi will provide you with the labeling specification for that

region.

For Delphi destinations in Europe, materials must be labeled according to Odette

standards. Reference Supplier Label Specifications-Europe Only. For other

regions of the world, Delphi will provide you with the labeling specification for that

region.

Every container in a shipment must be labeled, according to the label standard

Any special label requirements will be communicated as required.

Suppliers will label part containers according to Delphi divisional standards with up-

to-date dock and delivery location (DLOC).

Shipping containers must be identified with the materials appropriate "COUNTRY

OF ORIGIN".

Page 10 (Revised 10/31/03)

A legible packing slip or SPSSL (supplier pull signal summary list) must be affixed

next to the master label when skid packed and next to the container label if the

shipment is a single container.

One purchase order per packing slip (may include multiple P/N's).

One packing slip per skid of material.

Each packing slip (or SPSSL) shall contain the following information:

Part Number/Revision Total Quantity

Unique load identifier (i.e. bill of

lading number)

PRO Number

# of Containers Quantity per Pack

Weight Supplier Number

Deliver to Location

Invoice Number Pull Signal Number

Carrier (SCAC Code) PO Number or Release No.

Packaging

The packaging function plays a key role in supporting lean manufacturing. Suppliers

packaging must comply with the Delphi Packaging Manual. See Engineering 1.6

Packaging Expectations.

Scheduling

Delphi requires suppliers to be EDI (Electronic Data Interchange) capable.

Current EDI standards are UN/EDIFACT version D97.A.

Messages Suppliers must have the ability to electronically receive

forecasts (DELFOR), and schedules (DELJIT) as well as transmit

Advance Shipment Notifications (DESADV).

The only authorization for the shipment and invoice of product is a shipment

authorization, pull signal, or authorization from a Delphi facility to ship to a

minimum/maximum inventory level.

Fabrication Authorization terms will be 2 weeks and Material Authorization will be 2

additional weeks for a total of 4 weeks

All information beyond 4 weeks is for planning purposes only. Exceptions to these

terms must be agreed upon during the quoting process.

Page 11 (Revised 10/31/03)

Delphi will establish the shipping frequency for each production part, but the supplier

must have the ability to ship daily at a minimum. Supplier must ship to the exact

quantities, dates, and times specified on the release: no over, under, early or late

shipments and no freedom of the week delivery. All Delphi schedules will be in

standard pack quantities in the smallest approved standard pack container. Suppliers

must have shipping capability that matches the Delphi receiving plants normal

production schedule.

Advance Shipment Notifications (ASN) will be sent electronically at the time of

shipment. At the time of pick up, the supplier must allow the authorized carriers

driver to check the standard pack quantities against the scheduled quantities.

Overshipments will not be accepted.

If for any reason the supplier is unable to meet the schedules communicated, it is the

responsibility of the supplier to notify proper Delphi personnel immediately and

receive authorization for the undershipment. Suppliers will make up all

undershipments via supplier paid premium transportation on Delphi authorized

carriers to meet the originally scheduled destination window.

Supplier caused premium transportation or transportation costs for material returned

due to over shipment will be paid by the supplier.

Suppliers will use authorized carriers for all modes of transportation, including

supplier fault premium transportation. Excess transportation costs incurred; as a result

of using incorrect carriers will be debited from the suppliers account.

If Delphis and/or its customers production is interrupted by the failure of the

supplier to deliver contracted goods within the terms of the contract, all costs that are

incurred by Delphi and/or its customers will be the sole responsibility of the supplier.

Transportation

Routing instructions will be provided by Delphi for all suppliers who ship under

collect freight terms.

All shipments must be made by normal mode at the prescribed ship window time on

the Delphi authorized carrier, unless otherwise specified by Delphi.

Shipments will be made in the approved standard pack container. Suppliers must be

able to ship mixed part numbers on a pallet as defined in the Delphi Global Supplier

Packaging Manual.

Premium freight to be paid by Delphi must have an assigned Premium Transportation

Authorization (PTA) number, issued by the receiving location and appearing on the

bill of lading; and, if transportation is paid by the supplier, on the invoice.

Page 12 (Revised 10/31/03)

For domestic shipments, material ownership and freight terms for all material

received by Delphi are FOB Destination, freight collect (FOB Destination FC) unless

otherwise agreed to by Delphi Purchasing, Delphi Production Control & Logistics

and the supplier. The applicable terms and conditions will be defined in a separate

contract. Delphi will assume liability for insurance on the in transit material as

Delphi is specifying the carrier. In the event the carrier is supplier owned, the

insurance liability will rest with the supplier.

For international shipments, material ownership and freight terms for all material

received by Delphi are Title Transfer Our Plant, FCA Origin 2000 INCOTERMS

(FCA Origin TTOP) unless otherwise agreed to by Delphi Purchasing, Delphi

Production Control & Logistics and the supplier. If required, offshore suppliers will

be responsible for the transfer of parts to small lot containers prior to delivery to the

Delphi receiving plant. Delphi will not carry any inventory cost associated with this

process. The applicable terms and conditions will be defined in a separate contract.

For international shipments, advanced forwarder information and customs

documentation must be generated by the supplier on time and to Delphi

specifications.

Capacity

The capacity information provided with the quote should reflect the available daily

capacity and your operating plan (hrs. /day, days/week). The operating plan should

meet the weekly volume requirement and current model service requirement and

should be 100 hours per week or less. The buyer should be notified and approve of

any operating plan using more than 100 hours per week.

Suppliers must have capability to provide 15% above the quoted volume without

additional investment from Delphi Automotive.

Lead Time

The shipment lead-time will be quoted in calendar days and should quantify the time

from receipt of order to ship availability. Steady state lead-time (when schedule

and/or forecast is routinely available) is 10 days or less. Exceptions to this lead-time

requirement must be approved by Delphi.

Past Model Service

Suppliers must maintain the ability to provide parts to Delphi for 15 years after the

last active model year to satisfy service requirements, unless otherwise stated.

Page 13 (Revised 10/31/03)

1.5 DELPHI SUBSTANCES OF CONCERN AND RECYCLED SPECIFICATION

10949001

Delphi has posted a copy of the Delphi Substances of Concern and Recycled

Specification 10949001 on the Delphi website, www.delphi.com. This specification

supercedes C-1000 and GM1000M on all Delphi prints. This specification will

become part of the standard drawing template and compliance to Delphi 10949001 is

mandatory.

Suppliers must review Specification 10949001 that is on the Delphi website and

comply with all requirements.

1.6 ENGINEERING

General

Suppliers are expected to maintain confidentiality of development activities.

Suppliers should communicate technology development activities and new

technology ideas to Delphi.

Suppliers should ensure that engineering contacts are in place and available to Delphi

personnel.

Product Expectations

Suppliers should utilize electronic print file formats.

For molded parts, all product definition will be communicated in 3D Solid model

Unigraphics native language file format.

Suppliers will work with Delphi to continue to develop appropriate C4 capability.

Suppliers must provide Certificates of Origin and Manufacturers Affidavit.

Data Collaboration Policy

Delphi mechanical design departments 3D CAD data and drawings exchange with

suppliers will only be in the Native CAD format. Exceptions will be at Delphis

discretion

Requests for quotation will indicate the 3D CAD format of the design. If a supplier

must rely on data translations, the supplier will obtain and verify those translations at

its own expense.

Page 14 (Revised 10/31/03)

Material Expectations

Suppliers will provide samples, testing, environmental and MSDS (Material Safety

Data Sheet) information in the timeframe requested.

Suppliers should be able to provide same material on a global basis, if requested

Packaging Expectations

Suppliers must provide packaging in accordance with the Delphi Global Supplier

Packaging Manual (DAS-GSPM). Any deviation from the guideline must be

directed to the Delphi buyer and approved by Delphi.

Suppliers can access the manual on Delphis website, www.delphi.com. The manual

is located under Suppliers Standards on the site.

The Supplier Packaging Information Form, (DAS-SPI) must be submitted by the

supplier at the time of quote and/or to communicate a packaging change for a current

part. The form is located on www.delphi.com and is found as attachment B in the

packaging manual.

Packaging material costs associated with meeting packaging requirements must be

provided as part of the quotation. All quotations must include a separate itemized

price for 1) expendable packaging and 2) returnable packaging.

The supplier may receive packaging specifications and/or special requirements with

the quote package. When definition is provided, the supplier must quote to the

packaging specifications provided. If definition on a returnable container is provided,

the supplier must quote an expendable back up container of the same standard pack

quantity and dimensions.

If packaging definition is not provided by Delphi within the request for quote, the

supplier should follow the decision process for container rightsizing found in the

DAS-GSPM. Manually handled containers should be considered mainstream. The

Standard Container Listing provides a menu of the containers that should be used.

(see attachment A in the DAS-GSPM)

The overall responsibility for the design of the packaging system and the quality of

the part remains with the supplier.

When expendable packaging is used, half-slotted cartons and full layer pads are

considered mainstream. When regular slotted cartons are used, perforated tear away

tabs will be incorporated. Handholds will be used with all expendable containers.

Ergonomic guidelines must be followed. The weight limit of containers may be

specified in your quote package. If no weight limit is specified, the weight of any

manually handled container cannot exceed 40 pounds (18 kilograms).

Page 15 (Revised 10/31/03)

Containers must meet all current International and governmental regulations. (i.e.

NAFTA requirements)

The packaging system must ensure part integrity during transportation and subsequent

handling and storage through point of use. For this reason, the supplier should

develop methods to test the pack design under simulated real life conditions.

Suppliers must provide Delphi with validation results and testing documentation as

required. (reference testing and validation section in the DAS-GPSM)

The product must be properly oriented for part presentation to the operator.

No price increases will be granted to correct defective and /or nonconforming

packaging. Suppliers will provide packaging samples, when requested. In all cases,

the supplier must receive packaging approval prior to start of production.

Delphi will control the ownership of all returnable container systems.

Suppliers contracted to ship directly to Delphis customers must meet the customer's

packaging requirements. The requirements may differ from DAS-GSPM, but the

Supplier Packaging Information form must be included with the quote.

Standard packs must not exceed one-tenth of a days usage unless otherwise specified

by Delphi.

Once the standard pack and container has been established, it must be adhered to.

Any changes or deviations from the authorized standard pack and container must be

requested through and agreed to by Delphi Production Control & Logistics prior to

making the change.

Optimum order quantities may be requested by Delphi for effective skid stacking for

transportation

All packaging materials should be recyclable, reusable or returnable.

When shipping parts from one country to another country, the supplier must comply

with regulations regarding Non-Manufactured Wood Packing (NMWP) materials.

Wood pallets and other packing materials made entirely or partially of coniferous

wood must be treated and marked in accordance to the measures set forth by the

receiving country or international union. While current regulations exempt non-

coniferous NMWP materials from specialized treatment or markings, Delphi has

chosen to require one of the three following marking alternatives to identify non-

coniferous materials. (1) Mark all non-coniferous materials with appropriate

markings. The recommended markings can be referenced at the following web site:

http://www.aphis.usda.gov/ppq/swp/eunmwp.html. The size of the mark may vary due to the

nature of the product, but must be legible. In the case where the wood material is not

visible and part of a higher assembly, the higher assembly must be marked or labeled

to indicate compliance. (2) Indicate on the commercial invoice that all NMWP

materials are non-coniferous. (3) Provide a letter of certification to the freight

Page 16 (Revised 10/31/03)

forwarder stating that products are packaged with NMWP materials made from 100%

non-coniferous wood.

Suppliers will be responsible for cleaning returnable containers and dunnage,

removing labels and sorting for damage. Suppliers are also responsible for

maintaining inventory counts on returnable containers and maintaining a sufficient

supply of expendable backup material for emergency situations. Back up packs must

have the same pack dimensions, pack quantities and part orientation as the returnable

container.

The packaging will be of sufficient strength to allow full transportation utilization (no

special loading or stacking instructions).

Equipment

Suppliers equipment should meet industry quality; maintenance, safety, changeover

and production yield requirements.

Tools

If tooling is to be paid by Delphi, suppliers will be paid for tooling contingent on full

PPAP approval.

Maintenance, refurbishment and replacement of Delphi-owned tooling are the

responsibility of the supplier.

If the supplier is tool design responsible, then reproducible tooling prints must be

completed by supplier within 6 weeks after PPAP approval on all new program tools,

tools undergoing an engineering change, and current tools that are revised. Supplier,

upon request from Delphi, must provide reproducible tooling prints for existing tools.

1.7 CHANGE APPROVAL

Any changes including but not limited to process, design, component, packaging,

component suppliers, or facilities, must be communicated to and receive written

authorization from Delphi prior to implementation. Please reference Supplier

Suggested Change process as part of the SPDP requirements on page six of these

guidelines. The Supplier Change Request/Review (SCRR) form and instructions are

located on with these guidelines on www.delphi.com.

Page 17 (Revised 10/31/03)

1.8 PROPERTY RIGHTS

This section on Property Rights applies when Delphi pays a direct charge for

engineering and development, even if those charges are amortized into the unit cost.

Supplier agrees that all designs, drawings, processes, compositions, software, mask

works or other technical information made and furnished by supplier for each contract

(including all rights to patents, trademarks, copyrights, mask works, trade secrets, and

other proprietary information pertaining to the same) shall be the sole and exclusive

property of Delphi (unless specifically agreed to otherwise in writing) and that

supplier shall protect same against disclosures to third parties.

Supplier agrees that, as to all inventions and improvements in such designs, drawings,

processes, compositions of material, specifications, software, or other technical

information or all creations in such mask works made and furnished by supplier for

each contract, supplier will promptly identify and disclose such inventions,

improvements and creations to Delphi, upon request of Delphi, execute or obtain the

execution of any papers as may be necessary to perfect ownership of the same in

Delphi or as may be necessary in the acquirement, maintenance, or enforcement of

any patent, trademark, copyright, trade secret, mask work right or other proprietary

right pertaining to the same.

On programs deemed confidential by Delphi, supplier agrees to require supplier's

employees assigned to perform work for Delphi to sign Delphis standard

"Intellectual Property Rights Agreement". Supplier further agrees to maintain such

signed agreements on file for a period of five (5) years after the completion of work

under the applicable contract, and, at Delphi's request at any time before the end of

that five (5) year period, to deliver any or all such signed agreements to Delphi.

1.9 GENERAL INFORMATION

Duns Code - Supplier must provide authentic Dun and Bradstreet (Duns Code)

identification number to Delphi for each specific "Manufacturing Plant" address

as well as the primary sales office.

24-Hour Contact - Supplier must provide 24-hour service by providing contact

names and phone numbers where they can be contacted during off-hours, and

weekends.

Routine Contact - A regular contact point must be established and available

during all operating hours of the receiving location.

Emergency Contact - The supply location must provide and maintain a

communication matrix for the receiving location to use, should extraordinary

situations occur. This includes emergency contact capability during unscheduled

Page 18 (Revised 10/31/03)

work hours and organizational structure for resolution of any delivery, quality or

unresolved issues.

Language - All international contacts must be proficient in reading, writing, and

speaking English.

Suppliers Planned Down Time - Supplier must provide annually a listing of

planned Plant down time for holidays, vacations, etc. to Delphi.

Union affiliation and contract expiration If the supplier is unionized, they

must provide the union affiliation and contract expiration date to the buyer.

Suppliers are expected to manage these situations, and notify Delphi of pending

issues that could lead impact delivery.

Inquiries - All suppliers must respond to all inquires in writing or via E-mail on

or before the due date stated on the inquiry. All quotes must be prepared using

Delphi Automotive forms as provided.

Fire and Security Survey- All suppliers are expected to be compliance with local

fire and security regulations. In addition, all suppliers are expected to complete

the Fire and Security Survey and have it available upon the request of the buyer.

Definition of Supplier Business Sites to Delphi-All suppliers are required to

advise Delphi of the following Business Sites when quoting Delphi components.

QA-Quotation Site (where RFQs should be sent)

CA-Contract Site (where Production Contracts or Purchase

Orders should be sent)

FA-Forecast/Release Site (where DELFOR or 830 transmission

should be sent)

OA-Ship from site (where DELJIT or 862 transmission should

be sent)

GS-Manufacturing Site (where parts are manufactured and

where PPAP will be performed)

1.10 PROTOTYPE PARTS PROVISIONS

Delivery date(s) for samples of prototype components shall be established by

Delphi and noted on the purchase order. The delivery date(s) reflect the date(s)

parts are to be received at Delphis dock.

All prototype components must be clearly identified as such noting the Delphi

part number (i.e.: PE0, EX, MX, or a production number) and have a current

revision level. These parts are to be delivered as noted on the purchase order.

All prototype shipments must include the blue label Prototype Parts.

The Supplier shall submit inspection reports with sample delivery. Upon request

of the Delphi buyer, Prototype Parts Submission (i.e.: GP-11) must be submitted.

Page 19 (Revised 10/31/03)

Page 20 (Revised 10/31/03)

If review of the inspection report indicates that the parts do not agree with the

prints or examination of the parts discloses an unsatisfactory condition not

covered by the report, it shall be the suppliers responsibility to resolve all

discrepancies with the Delphi Product Design Engineer. This needs to be

communicated in writing to the Delphi buyer.

If resolution of the discrepancy results in a tooling, material or processing

change, the supplier will correct the situation (at the supplier's expense) and re-

submit an inspection report on the revised parts. This needs to be communicated

in writing to the Delphi buyer.

1.11 TOOL INVENTORY/DISPOSAL

The supplier shall furnish a tool inventory of all Delphi-owned tools (active and

inactive) in the suppliers possession. The tool inventory must be submitted to

the Delphi buyer annually by January 31. The inventory must contain the

following information for each Delphi-owned tool:

Tool part number(s) (typed in numerical order)

o Current tool revision

o Description

o Date parts last ordered

o Total cost of tool

o Quantity of parts produced from tool

o Remaining tool life

o Indicate previous part number if tool has been changed to

produce a new part number

o Delphi Design Engineer name

Delphi will determine the disposition of all Delphi-owned tooling and such

disposition shall be communicated to the supplier in writing by Delphi with a

formal letter and with a Return Material Authorization

Vous aimerez peut-être aussi

- Delphi CSRDocument32 pagesDelphi CSRecemericPas encore d'évaluation

- Supplier Quality ManualDocument29 pagesSupplier Quality Manualppanambo100% (2)

- Littelfuse Supplier Production Part Approval Process (PPAP) ManualDocument44 pagesLittelfuse Supplier Production Part Approval Process (PPAP) ManualIvanPas encore d'évaluation

- Delphi Technologies Customer Specific Requirements for ISO 9001 and IATF16949Document15 pagesDelphi Technologies Customer Specific Requirements for ISO 9001 and IATF16949Ram100% (1)

- Delphi Technologies Aftermarket Customer Specific RequirementsDocument12 pagesDelphi Technologies Aftermarket Customer Specific RequirementssrinivignaPas encore d'évaluation

- SPDP Tasks OverviewDocument8 pagesSPDP Tasks OverviewAndres TorresPas encore d'évaluation

- GSQMDocument48 pagesGSQMisolongPas encore d'évaluation

- TRW Automotive Global Supplier Quality ManualDocument48 pagesTRW Automotive Global Supplier Quality ManualJuan José Viñas Méndez50% (2)

- Magna Supplier Quality Requirements Manual Rev2Document25 pagesMagna Supplier Quality Requirements Manual Rev2marco07100% (1)

- SAQP Elements OverviewDocument38 pagesSAQP Elements OverviewBoštjan Dokl MenihPas encore d'évaluation

- Magna Supplier Quality Requirements Manual Rev2 PDFDocument25 pagesMagna Supplier Quality Requirements Manual Rev2 PDFJoe HosnyPas encore d'évaluation

- PPAPDocument7 pagesPPAPsunnysunsationPas encore d'évaluation

- Supplier Quality Manual-PWSIL - Rev. 01 Dt.20-12-2017Document21 pagesSupplier Quality Manual-PWSIL - Rev. 01 Dt.20-12-2017ilayaraja MKPas encore d'évaluation

- VITEC Supplier Requirements Manual SummaryDocument38 pagesVITEC Supplier Requirements Manual SummaryJesus SanchezPas encore d'évaluation

- GSQMDocument48 pagesGSQMSanthanu rajPas encore d'évaluation

- GTC Annex 1 Quality Requirements R3 Eng 180501 01Document9 pagesGTC Annex 1 Quality Requirements R3 Eng 180501 01Chiheb GPas encore d'évaluation

- AC7109 Rev D - Nadcap Audit Criteria For Coatings (To Be Used On or AFTER 18-Aug-13)Document9 pagesAC7109 Rev D - Nadcap Audit Criteria For Coatings (To Be Used On or AFTER 18-Aug-13)Ravi Kumar100% (1)

- Autocar Ppap Requirements Rev 5Document17 pagesAutocar Ppap Requirements Rev 5man hoPas encore d'évaluation

- FNGP Supplier Manual Rev9 10-1-2007Document21 pagesFNGP Supplier Manual Rev9 10-1-2007davidalejandrotorresPas encore d'évaluation

- Production Part Approval Process (Ppap)Document20 pagesProduction Part Approval Process (Ppap)Primoz Cermelj100% (1)

- CFUSA Supplier HandbookDocument24 pagesCFUSA Supplier HandbookBrenda GillPas encore d'évaluation

- Apqp PpapDocument50 pagesApqp PpapEvandro Ribeiro50% (2)

- PPAPDocument16 pagesPPAPRohit JanardananPas encore d'évaluation

- TRW Automotive - 223a6 PDFDocument48 pagesTRW Automotive - 223a6 PDFHari HaranPas encore d'évaluation

- Quality PlanDocument9 pagesQuality PlanمحمودالوصيفPas encore d'évaluation

- F1021 PPAP Check List Instructions 04JN18Document9 pagesF1021 PPAP Check List Instructions 04JN18Sharmad TamhanePas encore d'évaluation

- Cqi 11Document73 pagesCqi 11dwimukh360Pas encore d'évaluation

- 1 - APCB Customer Specific Requirements Fourth Revision - 11122019Document7 pages1 - APCB Customer Specific Requirements Fourth Revision - 11122019Trivesh SharmaPas encore d'évaluation

- ISO 9001:2008 and AS9100 Rev. C: Supplier Quality ManualDocument9 pagesISO 9001:2008 and AS9100 Rev. C: Supplier Quality ManualAbd ZouhierPas encore d'évaluation

- Achieve Quality Goals with Supplier ManualDocument39 pagesAchieve Quality Goals with Supplier ManualJuan Egara100% (1)

- Supplier Quality Manual - Edition 3 - April 2010Document14 pagesSupplier Quality Manual - Edition 3 - April 2010sosobigmanPas encore d'évaluation

- APQP Guide for SuppliersDocument19 pagesAPQP Guide for SuppliersrjzepfelPas encore d'évaluation

- Renault CSR - September 2011Document3 pagesRenault CSR - September 2011lostris234Pas encore d'évaluation

- Global Supplier Quality Manual: Revision 5Document14 pagesGlobal Supplier Quality Manual: Revision 5Avinash SilimkarPas encore d'évaluation

- DOP2000 PRC 001-0-03 Supplier PerformanceDocument18 pagesDOP2000 PRC 001-0-03 Supplier PerformancefgfPas encore d'évaluation

- Intro To APQP On Site PPAP TrainingDocument240 pagesIntro To APQP On Site PPAP Trainingalexrferreira100% (3)

- Global Supplier Quality Manual 02-18-2020Document13 pagesGlobal Supplier Quality Manual 02-18-2020Emre TekinPas encore d'évaluation

- Nexteer PPAP Process Checklist / Sign Off Sheet InstructionsDocument7 pagesNexteer PPAP Process Checklist / Sign Off Sheet Instructionscong daPas encore d'évaluation

- Supplier Quality Requirements: Key Elements Procedures # 2Document14 pagesSupplier Quality Requirements: Key Elements Procedures # 2Juan DavidPas encore d'évaluation

- ChryslerDocument117 pagesChryslerdokser29100% (1)

- Customer Specific Requirements DelphiDocument32 pagesCustomer Specific Requirements DelphiilkaytradeePas encore d'évaluation

- Supplier Parts Quality ManualDocument41 pagesSupplier Parts Quality Manualkyu999950% (2)

- PPAP Process Checklist / Sign Off Sheet InstructionsDocument7 pagesPPAP Process Checklist / Sign Off Sheet InstructionsSharmad TamhanePas encore d'évaluation

- AIAG IAOB ChangesDocument44 pagesAIAG IAOB ChangesKrishna Mohan T.RPas encore d'évaluation

- 01 Supplier Pre-Qualification AssessmentDocument18 pages01 Supplier Pre-Qualification AssessmentChinh Lê Đình100% (1)

- Iso/ts 16949: 2009Document117 pagesIso/ts 16949: 2009Vijay K SharmaPas encore d'évaluation

- MazegetDocument73 pagesMazegetwatnaPas encore d'évaluation

- IAQG 9120:2009 Revision Overview: Prepared by IAQG 9120 TeamDocument24 pagesIAQG 9120:2009 Revision Overview: Prepared by IAQG 9120 TeamYogita NarangPas encore d'évaluation

- Cobasys Supplier Quality ManualDocument31 pagesCobasys Supplier Quality Manualwilsonmiccoli100% (1)

- Guide To Product AcceptanceDocument15 pagesGuide To Product Acceptancepbartlett1977Pas encore d'évaluation

- Seminar PPAPDocument17 pagesSeminar PPAPSumit BedekarPas encore d'évaluation

- Ford SpecificDocument7 pagesFord SpecificJulio ChagoyaPas encore d'évaluation

- Customer-Specific Requirements: For Use With ISO/TS 16949 Second Edition March 2012Document4 pagesCustomer-Specific Requirements: For Use With ISO/TS 16949 Second Edition March 2012befoaPas encore d'évaluation

- IATF 16949:2016 Audit Guide and Checklist 2nd EditionD'EverandIATF 16949:2016 Audit Guide and Checklist 2nd EditionÉvaluation : 4.5 sur 5 étoiles4.5/5 (10)

- Successful Instrumentation and Control Systems Design, Second EditionD'EverandSuccessful Instrumentation and Control Systems Design, Second EditionÉvaluation : 4.5 sur 5 étoiles4.5/5 (10)

- Conversion Formulas ADocument14 pagesConversion Formulas Aabraham_ginPas encore d'évaluation

- Chrysler StandardDocument25 pagesChrysler Standardabraham_ginPas encore d'évaluation

- Basic HydraulicsDocument916 pagesBasic Hydraulicsabraham_ginPas encore d'évaluation

- Main Causes For HysteresisDocument2 pagesMain Causes For Hysteresisabraham_ginPas encore d'évaluation

- Control of Porosity of AlumnumDocument9 pagesControl of Porosity of Alumnumabraham_ginPas encore d'évaluation

- Main Causes For HysteresisDocument2 pagesMain Causes For Hysteresisabraham_ginPas encore d'évaluation

- Control of Porosity of AlumnumDocument9 pagesControl of Porosity of Alumnumabraham_ginPas encore d'évaluation

- Gas Can TestsDocument15 pagesGas Can Testsabraham_ginPas encore d'évaluation

- Chrysler StandardDocument25 pagesChrysler Standardabraham_ginPas encore d'évaluation

- 3 5 Valve ManifoldDocument28 pages3 5 Valve Manifoldabraham_ginPas encore d'évaluation

- Trivalent Yellow Chromate PresentationDocument29 pagesTrivalent Yellow Chromate Presentationabraham_ginPas encore d'évaluation

- Units, Dimensions & Conversion Factors: Fundamental DerivedDocument5 pagesUnits, Dimensions & Conversion Factors: Fundamental Derivedabraham_ginPas encore d'évaluation

- Lord Kuthumi UnifiedTwinFlameGrid Bali2013 Ubud 5 Part11 StGermain 24-04-2013Document6 pagesLord Kuthumi UnifiedTwinFlameGrid Bali2013 Ubud 5 Part11 StGermain 24-04-2013Meaghan MathewsPas encore d'évaluation

- Case 50Document4 pagesCase 50Phan Tuan AnhPas encore d'évaluation

- Employee Separation Types and ReasonsDocument39 pagesEmployee Separation Types and ReasonsHarsh GargPas encore d'évaluation

- Versova Koliwada': Introd U C T I OnDocument4 pagesVersova Koliwada': Introd U C T I OnNikunj Dwivedi100% (1)

- Hamilton EssayDocument4 pagesHamilton Essayapi-463125709Pas encore d'évaluation

- People v. Romorosa y OstoyDocument12 pagesPeople v. Romorosa y OstoyArjay ElnasPas encore d'évaluation

- The Legend of Lam-ang: How a Boy Avenged His Father and Won His BrideDocument3 pagesThe Legend of Lam-ang: How a Boy Avenged His Father and Won His Brideazyl76% (29)

- Introduction To Contemporary World: Alan C. Denate Maed Social Science, LPTDocument19 pagesIntroduction To Contemporary World: Alan C. Denate Maed Social Science, LPTLorlie GolezPas encore d'évaluation

- Electronic Green Journal: TitleDocument3 pagesElectronic Green Journal: TitleFelix TitanPas encore d'évaluation

- Trivandrum District IT Quiz Questions and Answers 2016 - IT Quiz PDFDocument12 pagesTrivandrum District IT Quiz Questions and Answers 2016 - IT Quiz PDFABINPas encore d'évaluation

- 721-1002-000 Ad 0Document124 pages721-1002-000 Ad 0rashmi mPas encore d'évaluation

- PMT Machines LTD Inspection and Test Plan For Bogie Frame FabricationDocument6 pagesPMT Machines LTD Inspection and Test Plan For Bogie Frame FabricationAMIT SHAHPas encore d'évaluation

- Network Marketing - Money and Reward BrochureDocument24 pagesNetwork Marketing - Money and Reward BrochureMunkhbold ShagdarPas encore d'évaluation

- Taxation of XYZ Ltd for 2020Document2 pagesTaxation of XYZ Ltd for 2020zhart1921Pas encore d'évaluation

- Property Accountant Manager in Kelowna BC Resume Frank OhlinDocument3 pagesProperty Accountant Manager in Kelowna BC Resume Frank OhlinFrankOhlinPas encore d'évaluation

- BGAS-CSWIP 10 Year Re-Certification Form (Overseas) No LogbookDocument7 pagesBGAS-CSWIP 10 Year Re-Certification Form (Overseas) No LogbookMedel Cay De CastroPas encore d'évaluation

- Business LawDocument4 pagesBusiness LawMelissa Kayla ManiulitPas encore d'évaluation

- CallClerk User GuideDocument94 pagesCallClerk User GuiderrjlPas encore d'évaluation

- Agent of The ShroudDocument25 pagesAgent of The ShroudKoen Van OostPas encore d'évaluation

- KSDL RameshDocument10 pagesKSDL RameshRamesh KumarPas encore d'évaluation

- 0500 w16 Ms 13Document9 pages0500 w16 Ms 13Mohammed MaGdyPas encore d'évaluation

- Encyclopædia Americana - Vol II PDFDocument620 pagesEncyclopædia Americana - Vol II PDFRodrigo SilvaPas encore d'évaluation

- CIA AirlinesLaosDocument36 pagesCIA AirlinesLaosMey SamedyPas encore d'évaluation

- The Slow Frog An Intraday Trading Strategy: A Rules Based Intra-Day Trading Strategy (Ver 1.0)Document17 pagesThe Slow Frog An Intraday Trading Strategy: A Rules Based Intra-Day Trading Strategy (Ver 1.0)ticman123Pas encore d'évaluation

- Summary of Kamban's RamayanaDocument4 pagesSummary of Kamban's RamayanaRaj VenugopalPas encore d'évaluation

- Daddy's ChairDocument29 pagesDaddy's Chairambrosial_nectarPas encore d'évaluation

- Quiz 2Document2 pagesQuiz 2claire juarezPas encore d'évaluation

- MKT201 Term PaperDocument8 pagesMKT201 Term PaperSumaiyaNoorPas encore d'évaluation

- Engineering Economy 2ed Edition: January 2018Document12 pagesEngineering Economy 2ed Edition: January 2018anup chauhanPas encore d'évaluation

- Todd Pace Court DocketDocument12 pagesTodd Pace Court DocketKUTV2NewsPas encore d'évaluation