Académique Documents

Professionnel Documents

Culture Documents

Ochure ulstEIN

Transféré par

bernardinodinoTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Ochure ulstEIN

Transféré par

bernardinodinoDroits d'auteur :

Formats disponibles

Increased operational window

Lower fuel consumption

Reduced emissions

Safer workplace

Increased volume

Improved comfort

WWW.ULSTEINGROUP.COM

X-BOW

HULL LINE DESIGN

X-BOW

- GENERAL DESCRIPTION

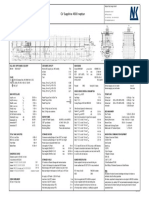

PRINCIPAL CHARACTERISTICS

A novel hull shape with a redistributed foreship volume and substantially reduced fare

A raised foreship, which normally incorporates accommodation

OPTIMISED HULL SHAPE

The shape of the hull has been optimised with a view to high

top speeds, low resistance and reduced fuel consumption. Great

emphasis has been placed on the crews safety and comfort.

X-BOW

BENEFITS

An X-BOW

vessel is characterised by its slender hull water line

and a smoother volume distribution in the foreship. The many

benefts of the X-BOW

hull line design have been documented

through tank tests performed by recognised maritime institutions

and feedback from the owners and users of vessels with X-BOW

:

EFFICIENCY AND ENVIRONMENT

- Signifcantly more energy-efcient shape in waves

- Higher transit speed

- Reduced power consumption

- Improved fuel efciency

- Reduced emissions

- Increased operational time

- Increased schedule-keeping

SAFETY AND COMFORT

- Elimination of slamming and bow impact

- Soft entry in waves

- Less spray

- Low acceleration levels

- Reduced vibration levels

- Increased comfort and available crew rest time

- Safer workplace due to smoother motions

and protection provided by hull

INTRODUCING A NEW BOW

At the beginning of the new millennium, ULSTEIN started a design

innovation project challenging traditional solutions and conventions.

Drawing on decades of ship design experience, a new bow concept

slowly emerged on paper. By introducing a larger and smoother

volume distribution in the foreship, which allows for submersion,

combined with a sharper bow shape, the typical challenges of

conventional bow shapes were solved. Preliminary sketches of a

vessel with the new, backward-sloping bow were presented in a

company magazine.

VISION POSSIBLE

Bourbon Ofshore Norway believed in the new bow concept and worked

closely with ULSTEIN on the development of the frst vessel design

with the X-BOW

hull line design - an anchor handling tug supply vessel

(AHTS) of the AX104 type - launched in 2005. The frst vessel of this

type, Bourbon Orca, was delivered in 2006 and received a number

of awards, including the Norwegian Design Councils design award,

the Engineering Feat of the Year, and Ofshore Support Journals and

Skipsrevyens Ship of the Year Awards. Other vessel designs with the

X-BOW

hull line design have since received similar distinctions.

FROM VISION TO WORLDWIDE REALITY

Since the new bow concept was frst launched, it has been in

demand, and today over 40 ULSTEIN vessels with the X-BOW

hull

line design have been delivered or are under construction world-

wide. The frst X-BOW

designs were for AHTS and platform supply

vessels, but it has later been introduced on construction, rescue,

and seismic vessels, as well as into the heavy ofshore and short-sea

shipping segments.

Seismic vessel Oceanic Vega delivered in 2010 is one of the over 20

vessels with the X-BOW

hull line design already in operation.

The anchor handling tug supply vessel Bourbon Orca was delivered in

2006 and received numerous awards for engineering and innovation.

Crew feedback has been very positive, including on the X-BOW

vessels ability to maintain higher speed in rough sea conditions and thereby

increasing operational time, and on the softer movements and the absence of slamming, which provide increased comfort and a safer work

environment for the crew.

The X-BOW

is a backward-sloping bow that starts at the

extreme front of the vessel. This allows for the sharpest possible

bow shape.

Result: A continuous and sharp bow shape, which smoothly

divides both waves and calm water. Increased volume above and

up front allows the vessel to efciently respond to large waves.

A conventional bow has a forward-sloping bow shape that starts

at the extreme front of the vessel and drops down and back. The

actual start of the bow at the waterline is moved back, and the bow

shape at the start of the waterline is less sharp.

Result: A bow that pushes the waves down and forward - this

absorption of energy slows the vessel.

The photos above show comparison testing of an ofshore vessel with X-BOW

hull line design and an equivalent ofshore vessel with a

conventional bow. The wave height is 2.8 metres, with a wave period of 10.5 seconds and a speed of 15 knots.

SPEED LOSS IN WAVES

The table below shows the attainable speed and the speed loss

in waves for a container vessel with the X-BOW

hull line design

compared to an equivalent vessel with a conventional bow. The

performed tests indicate that the X-BOW

hull line design ofers a

signifcant speed advantage in sea states most probable on a North

Atlantic trade route, where waves are expected to be above 2.5

metres 74% of the time. The X-BOW

has an average improvement in

speed loss of 19% in the 2.5-10.0 metre wave height range.

The photo above left shows the X-BOW

vessel. With a sharp hull

shape, there is no spray and there is a soft entry into the waves. As

the waves are parted efciently, wave energy transfer is minimised.

This means that speed losses are reduced.

FUEL CONSUMPTION

An independent maritime institution has performed a comparison

study between a short sea container vessel with X-BOW

hull

line design and an equivalent container vessel with a conventional

bow under expected service conditions. With a design speed of

18 knots, the diference in fuel consumption is shown in the chart

below. Results show 7-16% fuel reduction, depending on ship

speed and sea state.

The photo above right shows the vessel with a conventional bow. With

a blunt hull shape, there is spray generation, high bow impact and

slamming. The waves are pushed forward and wave energy is moved

against the hull. This makes for greater speed losses.

X-BOW

- CONCEPT COMPARISON

SPIRIT OF INNOVATION CONTACTS

ULSTEIN DESIGN &

SOLUTIONS AS

P. O. Box 278

NO-6067 Ulsteinvik

Norway

Tel.: +47 7000 8000

ULSTEIN ofers a broad range of ship designs

for demanding operations. We design with a

focus on the environment, cost-efciency,

reliability and total life-cycle cost. We ofer

ship design packages to the international

market with an emphasis on ofshore support,

heavy ofshore, and shortsea vessels. Vessels

designed by ULSTEIN are built at shipyards

world-wide.

WWW.ULSTEINGROUP.COM

The X-BOW

hull line design is patented in Norway (reg. no. 324744), Russia (reg. no. 2374120), Singapore (reg. no. 135279 (WO/2006/096066)),

Ukraine (reg. no. 95070), USA (reg. no. 7,658,159) and Vietnam (reg. no. 8437). Patent is pending in Brazil, China, Europe (EPA), Hong Kong and India.

TURNING VISIONS INTO REALITY

2

0

M

a

y

2

0

1

1

ULSTEIN SEA OF

SOLUTIONS B.V.

Churchillsingel 432-446

3137 XB Vlaardingen

Netherlands

Tel.: +31 10 475 00 11

ULSTEIN ES-CAD

MHENDISLIK DENIZCILIK

SAN. VE TIC. AS

Zmrtevler Mah.

Hanimeli Cad. 2/1

Maltepe 34852 Istanbul

Turkey

Tel.: +902 16 458 7100

ULSTEIN DESIGN COMPANIES

ULSTEIN DESIGN & SOLUTIONS

Ulstein Design & Solutions in Ulsteinvik, Norway, focuses on

product development and ofers ship designs, engineering

services and ship equipment packages to the international

market, with an emphasis on the ofshore support segment

(platform supply, anchor handling tug supply, seismic research,

and construction vessels).

ULSTEIN SEA OF SOLUTIONS

Ulstein Sea of Solutions in Vlaardingen, the Netherlands,

specialises in the design of heavy ofshore vessels, including

pipelay vessels, drillships, heavy lift vessels and ofshore

construction vessels. In addition, the company designs ships and

equipment for the ofshore wind market. The company develops

projects for operators, contractors and shipowners.

ULSTEIN ES-CAD

Ulstein Es-Cad in Istanbul, Turkey, develops designs for shortsea

vessels, including ro-ro, container, dry cargo, and liquid carriers.

Vous aimerez peut-être aussi

- ULSTEIN X-BOWlrDocument4 pagesULSTEIN X-BOWlrfuertesPas encore d'évaluation

- Offshore Support VesselsDocument7 pagesOffshore Support VesselsCriss MadPas encore d'évaluation

- X-Bow & X-Stern Hull Lines: Studies, Documentation and ExperiencesDocument11 pagesX-Bow & X-Stern Hull Lines: Studies, Documentation and ExperiencesjasanuPas encore d'évaluation

- Steerprop Innovative Propulsion SolutionsDocument21 pagesSteerprop Innovative Propulsion SolutionsMaurizio BernasconiPas encore d'évaluation

- Gragen - Offshore IndustryDocument30 pagesGragen - Offshore Industrywaleedyehia100% (1)

- Vietshipping 2008Document22 pagesVietshipping 2008minus89aspire100% (1)

- 2x WLSV - Specification Rev 0Document69 pages2x WLSV - Specification Rev 0pal_malayPas encore d'évaluation

- High Speed 4Document3 pagesHigh Speed 4littelPas encore d'évaluation

- Gpa 654 PSV SeriesDocument6 pagesGpa 654 PSV Serieszpoker49417Pas encore d'évaluation

- Rolls Royce Insights 2018 Issue 32Document48 pagesRolls Royce Insights 2018 Issue 32Vladimir V. HaltakovPas encore d'évaluation

- EnquiryDocument24 pagesEnquirySarath PurushothamanPas encore d'évaluation

- The Demise of EL FARO - A Wake Up Call For The World Merchant MarineDocument18 pagesThe Demise of EL FARO - A Wake Up Call For The World Merchant Marineshakeer tPas encore d'évaluation

- VSP para Buques de Offshore PDFDocument6 pagesVSP para Buques de Offshore PDFrrcardoso230Pas encore d'évaluation

- Shippaxguide16: Extract From The Annual Publication Shippax Guide 16. Presentation of ACL's ATLANTIC STARDocument68 pagesShippaxguide16: Extract From The Annual Publication Shippax Guide 16. Presentation of ACL's ATLANTIC STARЕгор Лядов100% (1)

- MAIBInvReport-22 2015Document37 pagesMAIBInvReport-22 2015Adrian Ovidiu VulcanPas encore d'évaluation

- Alibi 54 Detailled SpecificationsDocument14 pagesAlibi 54 Detailled SpecificationsFernando MarinhoPas encore d'évaluation

- Skandi ArcticDocument4 pagesSkandi ArcticnebulaequinoxPas encore d'évaluation

- Parsifal 2263Document2 pagesParsifal 2263maritim2k16Pas encore d'évaluation

- Saipem 3000Document8 pagesSaipem 3000Nkechi KokoPas encore d'évaluation

- Schemas Alphatron Principe Instru Navigtableau de Bord - 3923714 - 1 - A) - 1 PDFDocument54 pagesSchemas Alphatron Principe Instru Navigtableau de Bord - 3923714 - 1 - A) - 1 PDFakrealphonsePas encore d'évaluation

- Platform Supply Vessel Data Part 1Document18 pagesPlatform Supply Vessel Data Part 1api-231764268Pas encore d'évaluation

- Brief Presentation of Ut-Design UT 739 L: Multifunctional, Deep Water Anchor Handling, Tug, Supply and Service VesselDocument32 pagesBrief Presentation of Ut-Design UT 739 L: Multifunctional, Deep Water Anchor Handling, Tug, Supply and Service VesselCinthia Lidia Hidrogo PaulinoPas encore d'évaluation

- 2013.12-Emma Maersk ER FloodingDocument58 pages2013.12-Emma Maersk ER FloodingLokesh RavichandiranPas encore d'évaluation

- The Report June 2020 Issue 92Document112 pagesThe Report June 2020 Issue 92anacondamarinePas encore d'évaluation

- 2019 Fairplayer FactsheetDocument4 pages2019 Fairplayer Factsheetnoorul786Pas encore d'évaluation

- Supertanker - Knock Nevis: Seawise Giant, Happy Giant, and Jahre VikingDocument16 pagesSupertanker - Knock Nevis: Seawise Giant, Happy Giant, and Jahre Vikingsan0zPas encore d'évaluation

- SeaBoats ID1558 PDFDocument6 pagesSeaBoats ID1558 PDFSonyPas encore d'évaluation

- Marine Products Systems CatalogueDocument97 pagesMarine Products Systems CatalogueJhonnatan Quispe Franco100% (1)

- Propulsion of Offshore Support VesselsDocument8 pagesPropulsion of Offshore Support VesselsPatrick Araujo RamalhoPas encore d'évaluation

- Effect of The Moonpool On The Total Resistance of A DrillshipDocument66 pagesEffect of The Moonpool On The Total Resistance of A DrillshipNitin ShindePas encore d'évaluation

- 3559Document24 pages3559ldigasPas encore d'évaluation

- CLT SMM2014 PresentationDocument29 pagesCLT SMM2014 PresentationEmine DağPas encore d'évaluation

- Commodore RS Vasan IN (Retd) Head, Strategy and Security Studies Center For Asia Studies, ChennaiDocument72 pagesCommodore RS Vasan IN (Retd) Head, Strategy and Security Studies Center For Asia Studies, ChennaiJacob ThomasPas encore d'évaluation

- 2021 05 01 - SeawaysDocument40 pages2021 05 01 - SeawaysMuhammad100% (1)

- APAC Report Issue 231 Mid-May 2023 PDFDocument22 pagesAPAC Report Issue 231 Mid-May 2023 PDFMohammad AnnasPas encore d'évaluation

- Seaway - Alfa Lift-300dpi - Pdf.downloadasset PDFDocument2 pagesSeaway - Alfa Lift-300dpi - Pdf.downloadasset PDFДимаPas encore d'évaluation

- SLS301 (Launched On 08.05.2015)Document20 pagesSLS301 (Launched On 08.05.2015)a.msPas encore d'évaluation

- Significant Ships 2014Document116 pagesSignificant Ships 2014Marcel SchmalPas encore d'évaluation

- The Platou Report 2013Document58 pagesThe Platou Report 2013VizziniPas encore d'évaluation

- SurfaceDocument10 pagesSurfaceManoj Kumar BisoyiPas encore d'évaluation

- The Report September 2020Document112 pagesThe Report September 2020anacondamarinePas encore d'évaluation

- Profile View: General Arrangement 02 June 2015 33M Passenger CatamaranDocument1 pageProfile View: General Arrangement 02 June 2015 33M Passenger Catamaranritik khandelwalPas encore d'évaluation

- Ships 2017: SignificantDocument85 pagesShips 2017: SignificantFilipe Lima100% (1)

- Luciano Federico L Brochure PDFDocument4 pagesLuciano Federico L Brochure PDFbft23Pas encore d'évaluation

- Steer PropDocument8 pagesSteer Propfabiorr75Pas encore d'évaluation

- Zhejiang Honxin ShipyardDocument12 pagesZhejiang Honxin ShipyardLegend Anbu0% (1)

- Data Sheet CV-Sapphire PDFDocument1 pageData Sheet CV-Sapphire PDFthehoang12310Pas encore d'évaluation

- Global Maritime Design Services Brochure 2013Document9 pagesGlobal Maritime Design Services Brochure 2013NavalArchitecturePas encore d'évaluation

- SCHOTTEL - SRP Retractable ThrusterDocument1 pageSCHOTTEL - SRP Retractable Thrusterpratee_bharatiPas encore d'évaluation

- Expeditions: The Next Generation in Catamaran DesignDocument1 pageExpeditions: The Next Generation in Catamaran DesignEman AgiusPas encore d'évaluation

- AluminumNow HSVDocument35 pagesAluminumNow HSVbkm dizaynPas encore d'évaluation

- Fast Ferry Brochure WebDocument11 pagesFast Ferry Brochure WebNico LomibaoPas encore d'évaluation

- SeaBoats ID1127Document14 pagesSeaBoats ID1127nipper7Pas encore d'évaluation

- Product Sheet Partly Open Top Conro Vessel Atlantic Star PDFDocument2 pagesProduct Sheet Partly Open Top Conro Vessel Atlantic Star PDFЕгор ЛядовPas encore d'évaluation

- Ship SizesDocument5 pagesShip SizesJeesonAntonyPas encore d'évaluation

- Schat-Harding Group PresentationDocument44 pagesSchat-Harding Group Presentationbaaziz2015100% (1)

- Nexans Norway As M/V Elektron Annual DP Trials 6 September 2009Document50 pagesNexans Norway As M/V Elektron Annual DP Trials 6 September 2009Ramon Teixeira DiasPas encore d'évaluation

- Ropax and Cruise-Ferry ServicesDocument12 pagesRopax and Cruise-Ferry ServicessilidiriPas encore d'évaluation

- Anchor Handling Tug SupplyDocument12 pagesAnchor Handling Tug Supplyapi-231764268Pas encore d'évaluation

- Us Navy Selects Ion Track S Vaportracer To Fight Terrorism, Improve Force ProtectionDocument2 pagesUs Navy Selects Ion Track S Vaportracer To Fight Terrorism, Improve Force ProtectionbernardinodinoPas encore d'évaluation

- Advisory: What Should You Do?Document1 pageAdvisory: What Should You Do?bernardinodinoPas encore d'évaluation

- Explosives-Detection Systems: Configuration Management and Performance Verification ofDocument20 pagesExplosives-Detection Systems: Configuration Management and Performance Verification ofbernardinodinoPas encore d'évaluation

- Republic of The Marshall Islands Office of The Maritime AdministratorDocument5 pagesRepublic of The Marshall Islands Office of The Maritime AdministratorbernardinodinoPas encore d'évaluation

- Explosives Sampling SystemDocument2 pagesExplosives Sampling SystembernardinodinoPas encore d'évaluation

- ISPS Clause For Voyage Charter PartiesDocument3 pagesISPS Clause For Voyage Charter PartiesbernardinodinoPas encore d'évaluation

- 2000 - NIJ - A Guide For Explosion and Bombing Scene InvestigationDocument64 pages2000 - NIJ - A Guide For Explosion and Bombing Scene Investigationfaradio2100% (2)

- Propulsion Systems For Future LNG CarriersDocument4 pagesPropulsion Systems For Future LNG CarriersbernardinodinoPas encore d'évaluation

- Equipos Automaticos de Deteccion de ExplosivosDocument12 pagesEquipos Automaticos de Deteccion de ExplosivosbernardinodinoPas encore d'évaluation

- Ship's Ballast ConventionDocument5 pagesShip's Ballast ConventionbernardinodinoPas encore d'évaluation

- 112 LNG Propulsion GuideDocument74 pages112 LNG Propulsion Guidebernardinodino100% (1)

- World S First Large Size: LNG Carrier With Electric PropulsionDocument2 pagesWorld S First Large Size: LNG Carrier With Electric PropulsionbernardinodinoPas encore d'évaluation

- LNGDocument2 pagesLNGbernardinodinoPas encore d'évaluation

- Gastech: Kazuaki YuasaDocument16 pagesGastech: Kazuaki YuasabernardinodinoPas encore d'évaluation

- SIGTTO BookletDocument6 pagesSIGTTO BookletbernardinodinoPas encore d'évaluation

- Facts FellowSHIP and Viking Lady2Document2 pagesFacts FellowSHIP and Viking Lady2bernardinodinoPas encore d'évaluation

- ECDIS Certifcate For OfficersDocument2 pagesECDIS Certifcate For OfficersbernardinodinoPas encore d'évaluation

- Maritimenewzealand Accidente RenaDocument20 pagesMaritimenewzealand Accidente RenabernardinodinoPas encore d'évaluation

- Freefall Lifeboats: in Maritime EquipmentDocument4 pagesFreefall Lifeboats: in Maritime Equipmentbernardinodino100% (1)

- Good Practice: Enclosed Lifeboat LaunchingDocument20 pagesGood Practice: Enclosed Lifeboat Launchingbernardinodino0% (1)

- Manoeuvring BookletDocument29 pagesManoeuvring Bookletbernardinodino100% (1)

- Worksheet23 MaritimeDocument2 pagesWorksheet23 MaritimebernardinodinoPas encore d'évaluation

- Post OPA-90 Vessel Oil Transfer Spill Prevention: The Effectiveness of Coast Guard EnforcementDocument22 pagesPost OPA-90 Vessel Oil Transfer Spill Prevention: The Effectiveness of Coast Guard EnforcementbernardinodinoPas encore d'évaluation

- Brochure FDP - EG 16.08.2021-1-2-2Document3 pagesBrochure FDP - EG 16.08.2021-1-2-2sri sivaPas encore d'évaluation

- TIL 1881 Network Security TIL For Mark VI Controller Platform PDFDocument11 pagesTIL 1881 Network Security TIL For Mark VI Controller Platform PDFManuel L LombarderoPas encore d'évaluation

- Chip DielDocument45 pagesChip DielJUANCANEXTPas encore d'évaluation

- Brochure sp761lfDocument10 pagesBrochure sp761lfkathy fernandezPas encore d'évaluation

- L18 PDFDocument8 pagesL18 PDFrashmi sahooPas encore d'évaluation

- A New Finite Element Based On The Strain Approach For Linear and Dynamic AnalysisDocument6 pagesA New Finite Element Based On The Strain Approach For Linear and Dynamic AnalysisHako KhechaiPas encore d'évaluation

- Status Profile Creation and Assignment To An Order Type in SAP PPDocument7 pagesStatus Profile Creation and Assignment To An Order Type in SAP PPHemant UNICHEMLLPPas encore d'évaluation

- EM000039Rev1 PDFDocument1 pageEM000039Rev1 PDFGustavo RiveraPas encore d'évaluation

- The Importance of Subscale Jet Engine TestingDocument8 pagesThe Importance of Subscale Jet Engine TestingKKayPas encore d'évaluation

- Strength of Materials Basics and Equations - Mechanics of Materials - Engineers EdgeDocument6 pagesStrength of Materials Basics and Equations - Mechanics of Materials - Engineers EdgeansarPas encore d'évaluation

- Unistream-Installation Operation & MaintenanceDocument24 pagesUnistream-Installation Operation & MaintenanceJoanna Lauer-TrąbczyńskaPas encore d'évaluation

- 4 MPM Scope - OutputDocument45 pages4 MPM Scope - OutputSajid Ali MaariPas encore d'évaluation

- SAP Hybris Thinking Outside The Box. PART 1Document18 pagesSAP Hybris Thinking Outside The Box. PART 1Rauf AlievPas encore d'évaluation

- 12.5 Worksheet: Direct VariationDocument4 pages12.5 Worksheet: Direct VariationMarian NeldPas encore d'évaluation

- Bloomberg - Transport - SecurityDocument13 pagesBloomberg - Transport - SecurityFernandoPas encore d'évaluation

- cjv30 Maintenance V10a PDFDocument101 pagescjv30 Maintenance V10a PDFEdu100% (1)

- Exterior Perspective 1: PasuquinDocument1 pageExterior Perspective 1: Pasuquinjay-ar barangayPas encore d'évaluation

- Alloc 150 DMDocument301 pagesAlloc 150 DMSheik Mohamed ImranPas encore d'évaluation

- Language Processing System:-: CompilerDocument6 pagesLanguage Processing System:-: CompilerRenganathan rameshPas encore d'évaluation

- Testing Report For Pressure Relief Valves: Petrofac International (UAE) LLCDocument1 pageTesting Report For Pressure Relief Valves: Petrofac International (UAE) LLCmurthy challapalliPas encore d'évaluation

- GFF (T) ... MenglischNANNI (DMG-39 25.11.05) PDFDocument38 pagesGFF (T) ... MenglischNANNI (DMG-39 25.11.05) PDFjuricic2100% (2)

- En Privacy The Best Reseller SMM Panel, Cheap SEO and PR - MRPOPULARDocument4 pagesEn Privacy The Best Reseller SMM Panel, Cheap SEO and PR - MRPOPULARZhenyuan LiPas encore d'évaluation

- Logcat 1693362990178Document33 pagesLogcat 1693362990178MarsPas encore d'évaluation

- Activa NewDocument160 pagesActiva NewSiddharth Jain100% (1)

- OTM Reports FTI Training ManualDocument78 pagesOTM Reports FTI Training ManualAquib Khan100% (2)

- MOTOR Brushless ss2814 Xiii 1000kvDocument1 pageMOTOR Brushless ss2814 Xiii 1000kvsalah eddinePas encore d'évaluation

- Cinegy User ManualDocument253 pagesCinegy User ManualNizamuddin KaziPas encore d'évaluation

- Technical Data For Elevator Buckets - Bucket ElevatorDocument1 pageTechnical Data For Elevator Buckets - Bucket ElevatorFitra VertikalPas encore d'évaluation

- Viewnet Diy PricelistDocument2 pagesViewnet Diy PricelistKhay SaadPas encore d'évaluation

- CFJV00198BDocument360 pagesCFJV00198BCheongPas encore d'évaluation