Académique Documents

Professionnel Documents

Culture Documents

BP Anbauwerkzeuge

Transféré par

Márk Ferdinánd FischerDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

BP Anbauwerkzeuge

Transféré par

Márk Ferdinánd FischerDroits d'auteur :

Formats disponibles

The Liebherr

Working Tools

2

Tool-System for a

variety of jobs

Liebherr working tools for excavators were designed as problem solvers for the most varied

applications. The carefully balanced program ranges from standard buckets for digging and

loading of loosened material to buckets for heavy-duty jobs in the mining industry with extreme

break-out forces and high wear and tear. Equipped with effective, to the relating ground match-

ing teeth the Liebherr digging tools provide a maximum productivity and longevity.

Performance

Liebherr digging tools are particularly productive excavator components at

the very latest technological level. Special bucket shapes, permit maximum

transmission of power, provide the best penetration- and outstanding dig-

ging characteristics. Optimized bucket capacities and improved heap-cones

provide the best turn-over performance.

Reliability

Liebherr digging tools are in-house designed and manufactured. Specic

material selection, specialized heat treatment and lowest machining toler-

ances are utilized in order to achieve the especially toughness and the high

longevity. The convincing result: outstanding dependability under the most

severe job conditions.

Comfort

The careful and precise calibration of bucket shape and tooth selection

provides the ideal digging tool for each job. The proven and reliable quick-

change system LIKUFIX permits the split-second, safe exchange of me-

chanical and hydraulic attaching tools by the press of a button from the cab.

LIKUFIX attaching tools also work on hydraulic excavators with Liebherr

quick change adapters without LIKUFIX - that means full exibility and high

comfort in every situation.

Efficiency

Liebherr digging tools provide a maximum of protability. The Liebherr quick

change systems increase productivity especially in applications with varying

attaching tools. The 24/7 availability of wear parts and the easy exchange

procedure safe time and money as well. Because of the modular design, the

change systems and tools are very suitable for future tasks.

3

Tool-System for a

variety of jobs

4

Bucket options

Whether loose dirt, abrasive material or hard rock quality and effectiveness of every

excavator job are affected by the targeted selection of the suitable bucket. Therefore,

Liebherr has designed a wide range of bucket options, which are especially suitable for an

applicable job due to the shape, material selection and technical ttings. Practical experi-

ence and continued attention to product development assure that Liebherr buckets are

always state-of-the-art technology.

Backhoe bucket

with teeth

Backhoe bucket

with cutting edge

HD-backhoe bucket

Backhoe bucket with

limited digging depth

Backhoe bucket

with clip-on cutting edge

Backhoe bucket with univer-

sal mounting bracket

Suitable for very abrasive materials due to wear

protection and side reinforcement

Suitable for digging up hard ground

A backhoe bucket with teeth that can be

equipped with a cutter if required

Suitable for any rapid-change systems

Optimum penetration due to low digging resistance

If the rapid-change slot of a backhoe bucket is

wider than the backhoe bucket itself, this limits the

digging depth.

For cases such as this Liebherr offers backhoe

buckets with an extended basic shape. This

increases the maximum digging depth.

5

Tilt bucket

Tiltable ditch

cleaning bucket

Rigid ditch

cleaning bucket

Suitable for shaping, levelling and grading earth walls

Ideal when using a tilt rotator

Suitable for levelling and excavation

6

Backhoe buckets

Backhoe buckets are essential tools for Liebherr excavators. Due to their well

thought-out geometry, the weight optimized genuine buckets are well matched to

the Liebherr excavators. Good penetration characteristics and high productivity

are the results.

Backhoe bucket with teeth (technical data on page 35)

Applications

Typical utility jobs with medium to high break-out forces

Digging and loading of loosened material, e.g. dirt or clay

Features

Weld-on tooth adapters

Generous cutting lip thickness

Bucket back reinforcement with wear resistant material

Benets

Buckets are optimally matched to excavator model

Versatility

Good penetration characteristic

easy lling and dumping due to improved

bucket geometry

effortless eroding possible due to long

bucket base

Backhoe bucket with cutting edge

(technical data on page 35)

Applications

General civil engineering

Utility

Garden- and landscaping work

Loading

Features

Weld-on cutting lip

Bucket-back reinforcements with wear

resistant material

Benets

Efcient operation

easy grading of surfaces

easy lling and dumping due to improved bucket geometry

effortless eroding possible due to long bucket base

low digging resistance as a backhoe bucket with clip-on

cutting edge with identical bucket radius

high fuel efciency

Backhoe bucket with teeth

7

Backhoe bucket with cutting edge Backhoe bucket with clip-on cutting edge

8

L-shape*

With a longer bottom and strongly curved side cutters.

Suitable for rocky ground conditions as well as loading

of hard and coarse material (large boulders) and to place

rip-rap for embankment construction.

Various bucket shapes

Cutting edge shapes

Straight edge*

With straight cutting lips for general loading jobs. Good

oor maintenance capability.

Delta edge**

With the pointed V-shaped cutting lip and pull-up

single tooth at the center for difcult to break, layered

material. Optimal penetration characteristics for severe

ripping jobs.

V-delta edge**

With the trapezoidal cutting lip and pulled-up teeth in

the center for difcult to break, layered material. Optimal

penetration characteristics, low torsion due to center

target, limited oor maintenance capability.

V-delta Delta Straight

L-shape

starting R 936 (R 934) and for large machines

9

Bucket versions

Standard*

Wear resistance cutting edge and bottom with weld-on

tooth adapter. Suitable for general utility, for digging and

loading of matured and loosened but not abrasive materi-

al such as top soil, clay etc..

HD*

Additional back- (wear- and denting protection) and

side reinforcements, weld-on tooth adapters for excava-

tor jobs with a higher use. Suitable for digging and loa-

ding of harder and abrasive materials such as topsoil,

rock, sand/clay, sand/gravel and limestone with low to

medium quality.

HDV**

Additional back- and side reinforcement, weld-on tooth

adapter, reinforced cutting lip and additional wear parts.

Suitable for extreme excavator jobs such as quarry or

demolition, for digging and loading of mixed soil with

high share of rock and other abrasive material such as

rock, slag, quartz etc..

*starting R 936 (R 934) **only for large excavators

Standard

HD

HDV

10

The right tooth

for every appl ication

The economic use of a hydraulic excavator is only possible if the tooth shape

matches the relating application. Liebherr offers a broad tooth program with tooth

shapes for every task.

Due to its low overall heigth and the slim, self-sharpening tooth shape the

Liebherr U-system stands for best diggning behavior at lowest penetration

resistance. Highly wear-resistant steel provides familiar reliability under hard

conditions, which has already stood the test on wheel loaders. The lateral rolled pin

fastening allows a simple and safe change of teeth.

Pointed tooth HD-tooth Standard tooth

Features:

Pointed tooth for good penetration, reversible.

Application:

for very hard and frozen soil, non-friable rock

(limestone, shale, brown coal, mining of wall

gravel etc.).

Features:

Cap with high share of material for long service

life in wear-intensive applications.

Application:

for extremely abrasive soils (granite, basalt,

sandstone, rocks with high share of silica etc.).

Features:

symetric caps with cut-out at the front, self

sharpening, reversible.

Application:

for friable and medium-weight friable soils

(loamy sand, gravel, soft brown coal, soft/

medium clay etc.).

Liebherr Uni tooth system:

A 910 Compact (A 309) - A 918 (A 900) / R 918 - R 920

(technical data on page 42)

11

The right tooth

for every appl ication

Liebherr Z tooth system: A 918 (A 900) / R 920 - R 980 SME

(technical data on page 43)

The optimized tooth design leads to efciency increase of the Liebherr Z-system on the jobsite. The low digging resistance,

the self-sharpening tooth shape or the simple hammer-free change of teeth speak for the Liebherr Z-system. The teeth are

made out of high-strength steel which distinguishes itself through highest wear resistance and long service life.

C-tooth

R-tooth

CL-tooth CR-tooth

P-tooth PF-tooth

Features:

The conical shape allows for very good penetra-

tion capacity in non-cohesive soils.

Application:

Friable soils and weak non-cohesive soils, such

as loose, loamy sand, ne to medium gravels,

and wet or soft clay.

Features:

Narrow cutting width and high wear volume for

high penetrating forces and extended life.

Application:

Hard-to-penetrate ground, particularly abrasive

materials, rock, i. e. limestone, shale, very hard

clay, lignite.

Features:

Long-drawn pointed shape with sharp cutting

edge for very good penetration properties.

Application:

Medium-weight friable and non-cohesive soil

types up to soils with medium plasticity, such as

hard, loamy sand, medium-hard clay, and ne to

medium gravel.

Features:

The long drawn tip allows for good penetration

in broken ground and debris. The wide, thick

sole of the tooth provides for a long service life

even under intensive wear conditions.

Application:

Abrasive soils and rocks, such as granite, basalt,

and sandstone. Predominantly in combination

with bottom dump bucket operations.

Features:

Pointed tooth with good penetration properties

even in hard stone and rocky applications.

Application:

Very hard, frozen ground, non-friable rock such

as compacted, unweathered clay schist

Features:

Fork tip with excellent penetration properties in

extremely compact soils. Can be tted as a sup-

plement to the P-tips on the bucket corners in

order to retain the inclination angle.

Application:

Very hard, frozen ground, non-friable rock such

as compacted, non-weathered clay schist,

heavy ores with medium and weak cleavage,

slag heaps at steel plants.

Shrouds

Wearing cap

Wearing caps are designed to increase lifetimes

of adapters in extreme abrasive applications

For precise jobs where the terrain surface

must be left smooth

For tougher applications

Reduces exposure of the bucket to impacts

and abrasion, extending ist wear life. Allows

you to carry more material and to increase pe-

netration, thereby improving productivity of the

machine.

Tooth holder

single bracket

Tooth holder

double bracket

12

Buckets for special application

Liebherr provides its customers with buckets in the very best

material quality and outstanding workmanship.

Far more than in pure earthmoving applications, they prove their

worth day after day in mining operations, demolition jobs, ma-

rine engineering and a string of other special applications.

With performance, dependability and protability, they set the

standard as effective excavator tools in these extraordinary jobs.

starting R 936 (R 934)

Backhoe bucket in marine engineering Backhoe bucket in demolition

13

Buckets for special application

14

Tilt buckets and

ditch cleaning buckets

The proven tilt buckets of the Liebherr excavators are the all-rounders for professional humus

soil work and excavation. The rugged ditch cleaning buckets with patented tilt mechanism and

protected, inside mounted, cylinders in various cutting widths are utilized as effective tools for

grading and scarping.

Tilt bucket (technical data on page 37)

Capacities of 0.5 - 2.0 m, cutting widths of 1,200-1,800 mm also available in HD version

Applications

Slope nishing

Grading

Excavation

Loading trucks

Features

Thick wear plate on bucket bottom

2 x 50 tiltable both sides

Tilt cylinder installed protected

Cutting edge available as an option

(serrated upon request)

Benets

Particularly suitable for various slope angles and excavation

Ditch cleaning bucket (technical data on page 37)

Capacities from 0.3 2.4 m

3

, cutting widths from

1,200 mm 2,400 mm

Applications

Prole required digging of trenches

Grading

Scraping and modeling of banks

Garden- and landscaping work

Features

Tilt cylinder installed protected

Rigid or as an alternative 2 x 50 tiltable

Standard back-cutting edge

Continuos bottom plate

Bolt-on cutting edge available as an option

Benets

Particularly accurate grading work

Optimal emptying in digging work

Longevity due to protected cylinders

Tilt bucket optional with bolt-on cutting edge

Ditch cleaning bucket optional with bolt-on cutting edge

15

16

Examples for individual solutions

Upon request Liebherr offers the suitable working tool for almost every application. The tools

are optimally matched to the excavator and consequently provide the highest digging perfor-

mances. Adapting to the many types of problems, our designers have developed individual

solutions in order to achieve optimal job results.

Backhoe Bucket with Ejector

Applications

For claylike and binding soil

Utility

Pipeline

Features

Mechanical or hydraulic ejector

Trench width of 300 mm 650 mm depen-

ding on bucket version

Mountable directly to stick or to quick

coupler

Benets

With binding material, the ejector facilitates

the emptying of the bucket

Ripper Tooth (no picture)

Applications

To loosen hard to break ground or rock

Features

Rugged design

Fitted design for good penetration cha-

racteristics

Build for most severe jobs

Use of highly wear resistant materials

Mountable directly to stick or to quick

coupler

Benets

Dedicated tool utilization

Loose material can be quicker and

more effectively further processed

V-Buckets (no picture)

Applications

Digging of V-prole trenches

Ditch cleaning work

Features

Steady trench prole in one operation

Dened oor width

Various slope angles available

Benets

Predetermined slope angle and oor

width provides steady trench prole

17

Examples for individual solutions

4-in1 Bucket

Applications

Utility and pipeline

Back-ll work

Inner city use

Features

Shovel bucket function

Pick-up of small material volume

possible (bottom-dump-bucket)

Mountable directly to stick or to quick

coupler

Benets

Effective utilization of back-ll work due

to exible operation

Marine Bucket

Applications

Dredging of channels

Embankments

Pipeline construction

Features

Water drainage holes for optimal

ll factor

Sealed bearings

Dedicated teeth possible

Benets

Effective work under water, even

with difcult material

18

Hydraulic tilt-rotator

Liebherr-Proportional-Control for intuitive control of working tools Protected cylinders, no extruding parts

Applications

Challenging proling

Pipeline

Garden- and landscaping work

Complex digging work

Features

360 innite rotation

best possible protection for tilt

and swing drive

Tiltable both sides by 50

Rugged design

Benets

Increase of the productive worktime (accurate

excavation, precise backlling and quick proling)

Expanded utilization of the excavator

Highly accurate due to easy handling

Signicant time savings since excavator needs

repositioning less often

Everything from one source

Liebherr excavator controls include tilt-rotator function

Backhoe bucket can also be used as a face shovel

Tilt rotators have today become an essential part of civil engineering. Thanks to the exible use

of the backhoe bucket, the unproductive repositioning of the hydraulic excavator during work

can be substantially reduced, and the productivity of the machine is increased.

Lieberr tilt rotators have a slewing angle of 2 x 50 and can rotate innitely through 360. The

integrated rotating cylinder itself, which is protected and located horizontally, has no projecting

parts even at maximum rotating angle, which could otherwise be damaged when working in

conned spaces. This ensures that servicing costs are kept low, and makes Liebherr tilt rotators

the ideal tool for working in lining operations or when close to building structures. In conjunction

with the ergonomic Liebherr proportional control system, the tilt rotator can be put to use rapidly,

with ne sensitivity, and with maximum precision, which helps achieve high productivity for the

hydraulic excavator.

The preparation of complex excavation contours and the exposing of existing structural

elements such as drain shafts, pipes, etc. can be carried out extremely rapidly with Liebherr

tilt rotators. Tedious and sometime dangerous shaft excavation by hand can be reduced to a

minimum, and personnel can move on to the next tasks to be dealt with.

It is recommended that Liebherr tilt rotators be tted on the upper side with the Likux quick

coupling system from Liebherr. In this way, the tilt rotator is only attached when it is actually

needed, which reduces fuel consumption, increases the service life of the tilt rotator, and allows

for the maximum load capacity of the hydraulic excavator to be fully exploited during hoisting

operations. In traditional earthmoving situations, taking off the tilt rotator allows for the largest

possible backhoe bucket to be tted, in order to achieve high handling performance with low

fuel consumption.

Together with Liebherr wheel and crawler excavators, Liebherr tilt rotators attain maximum

productivity, reliability, and safety on the construction site.

19

Installation possibilities of the tilt rotator

Tilt

50

360 innite rotation

Equipment of excavator Movement possibilities

Middle pressure lines and Liebherr

quick coupler (mech. or hydr.)

Turning or swiveling (changeover

via rocker switch in joystick)

Middle pressure lines, high pressure lines and

Liebherr quick coupler (mech. or hydr.)

Turning or swiveling

simultaneously

Middle pressure lines, high pressure

lines and LIKUFIX

Turning or swiveling

simultaneously

Middle pressure lines and third party

quick coupler

Turning or swiveling (changeover

via rocker switch in joystick)

Middle pressure lines, high pressure lines

and third party quick coupler

Turning or swiveling

simultaneously

20

Clamshells

Next to the backhoe bucket, the clamshell is one of the most important digging tools in the

utility business. The clamshell selection is based on the ground condition, the specic mate-

rial weight and the required production performance. The selection of the entire clamshell

attachment is signicant in order to determine the required digging depth.

Clamshell (technical data on page 40)

Capacities from 0.1 2.0 m

3

, shell width from 3002,000 mm

Applications

Narrow and deep trench digging, also over the side

Loading and unloading and handling of various bulk goods,

respectively

Excavation

Special excavating (e.g. round shells)

Features

Innite rotation

Optimally matched to machine size

Rugged design

Protected cylinder

Depending on application with or without teeth

Optional ejectors for digging shells available

HD-version for severe jobs

Quick-change system applicable

Grab extension available as an option

Benets

Accurate and secure placement of material of all

type due to maneuverability and high closing force

Optional different shell width adaptable

to one mechanism

Well-thought-out design with

Liebherr components

Round-hole grab Quick change clamshells (quickly changeable)

21

Clamshell

22

Liebherr demolition

and sorting grapples

The demolition and sorting grapples are designed for both

demolition and for material handling applications. They also

optimize the use of the hydraulic excavator at the construction

site. Sorting, loading or even demolition, they can handle so

easily.

The stone grapple is a special type of the demolition and

sorting grapple. Their shape makes it ideal for setting and

loading stones.

Sorting grapple (technical data on page 41)

Capacity up to 0.5-1.3 m

3

Job reports

Sorting operations on construction sites

Demolition work

Quarry and waterway construction work

Features

Solid Liebherr components

Optimum own weight

Easy maintenance and service-friendly

Sealed bearing points

Optimum lubrication system

Endless hydraulic slewing device

Complete hydraulic inside

Benefits

High closing force

Lightweight construction

Sensitive working on sorting activities

Different tine shapes for individual applications

Sorting grapple (perforated)

23

24

Functionality

Pipe-laying tool

The pipe-layer developed by Liebherr enables signicant productivity increase when laying

sewage pipes. The pipe is picked up, positioned at the end of a pipe already in place, aligned

and inserted into the previously installed pipe in accordance with existing standards using

a horizontal ram. The pipe-layer enables quick and efcient installation of pipes of various

lengths, diameters, weights, materials and nominal sizes. Thanks to this system, operational

safety on pipe-laying sites is raised considerably, since no one is forced to remain in the dan-

ger area.

Applications

Sewage construction

Pipe-laying jobs

Highway construction

Development

Features

For pipes up to a length of 3.50 m

Pipes with outer diameter of 450 up to 800 mm installable

Pipes up to 230 mm outer diameter can be installed as an option

Curb weight appr. 1,400 kg

Lift capacity: approx. 1,500 kg

Solid construction

360 endlessly turnable

Adapter for plastic pipes deliverable

With LIKUFIX or universal adapter

Pipe feed: manual changeover on unit, alternatively from the operators cab

Suitable for excavators starting A 918 (A900) / R 918 (R 900)

Benefits

Excellent pipe-laying performance

Operation in accordance with existing standards

Adjustable insertion pressure, thus less pipe damages

Simple and quick unloading of delivered pipes

Excellent operational safety, no person permanently in the direct danger zone

Minimum 10% productivity increase

Pipes can be layed from any direction and independent from any incline

Space saving in conned spaces: the Liebherr pipe laying unit hardly needs

more space than the pipe itself

Position

25

Align Insert

26

Material classification

1) The actual values depend upon moisture content, grain size and compaction.

Tests are required to determine exact material characteristics.

S

p

e

c

i

f

i

c

w

e

i

g

h

t

1

)

k

g

/

m

3

/

b

a

n

k

S

w

e

l

l

f

a

c

t

o

r

%

S

w

e

l

l

f

a

c

t

o

r

S

p

e

c

i

f

i

c

w

e

i

g

h

t

k

g

/

m

3

/

l

o

o

s

e

Material

Weathered material -

75% rock, 25% dirt 2,790 42 0.70 1,960

50% rock, 50% dirt 2,280 33 0.75 1,720

25% rock, 75% dirt 1,960 24 0.80 1,570

Basalt 2,970 52 0.66 1,960

Bauxite, Kaolin 1,900 33 0.75 1,420

Topsoil dry compact 1,900 26 0.79 1,510

wet loosened 2,020 26 0.79 1,600

Clay 1,540 23 0.81 1,250

Gypsum broken 3,170 75 0.57 1,660

crushed 2,790 68 0.60 1,670

Granite broken 2,730 64 0.61 1,660

Limestone broken 2,610 69 0.59 1,540

crushed - - - 1,540

Gravel moist 2,170 12 0.89 1,930

dry 1,690 12 0.89 1,510

(accord. to DIN 18300)

S

p

e

c

i

f

i

c

w

e

i

g

h

t

1

)

k

g

/

m

3

/

b

a

n

k

S

w

e

l

l

f

a

c

t

o

r

%

S

w

e

l

l

f

a

c

t

o

r

S

p

e

c

i

f

i

c

w

e

i

g

h

t

k

g

/

m

3

/

l

o

o

s

e

Material

Clay natural bed 2,020 22 0.82 1,660

dry 1,840 24 0.80 1,480

wet 2,080 24 0.80 1,660

Clay with gravel dry 1,660 17 0.86 1,420

wet 1,840 19 0.84 1,540

Topsoil 1,370 44 0.69 950

Natural stone crushed 2,670 67 0.60 1,600

Sand dry loose 1,600 12 0.89 1,420

moist 1,900 12 0.89 1,690

wet 2,080 13 0.88 1,840

Sand with clay loose 2,020 26 0.79 1,600

compacted - - - 2,400

Sand with gravel dry 1,930 12 0.89 1,720

wet 2,230 10 0.91 2,020

Limestone 2,520 67 0.60 1,510

Slag broken 2,940 68 0.60 1,750

27

Class 1: Top soil

Top soil is the most upper layer of the ground, which contains besides in-

organic matters, e.g. gravel-, sand-, silt- and clay mixes as well as humus

and organic organisms.

Class 2: Fluid material

Material of uid or mushy composition from which water is not easily drained.

Class 3: Easy diggable material

Non-cohesive to semi-cohesive sand, gravel and sand-gravel mixture with

up to 15 weight-% addition of silt and clay (grain size less than 0.06 mm)

and with maximum of 30 weight-% of rocks of larger than 63 mm grain

size up to 0.01 m

3

volume. Organic material with low water content (e.g.

compacted peat).

Class 4: Medium diggable material

Mixture of sand, gravel, silt and clay with a share of more than 15 weight-%,

grain sizes smaller than 0.06 mm. Cohesive material of light to medium

malleability, which are soft to semi-rm depending on the water content

and with no more than 30 weight-% of rocks larger than 63 mm grain size

up to 0.01 m

3

volume.

Class 5: Tough to penetrate material

Material accord. to class 3 an 4, but with more than 30 weight-% of rocks

larger than 63 mm grain size up to 0.01 m

3

volume. Non-cohesive and

cohesive material with no more than 30 weight-% rocks larger than 0.01 m

3

volume. Particularly plastic clay, soft to medium hard depending on the

water content.

Class 6: Easy to penetrate rock

and comparable material

Rock, which has an internal, mineral bund cohesion, but severely frac-

tured, brittle, crumbly, slated, soft or weathered as well as comparably

compact or solidied non-cohesive and cohesive material with more than

30 weight-% rocks of more than 0.01 m

3

to 0.10 m

3

volume.

Class 7: Tough to penetrate rock

Rock, which has an internal, mineral bund cohesion and high structural

density and is only slightly fractured or weathered. Highly compact, un-

weathered clay slate, sedimentary rock layers, slag heaps at iron and steel

works and similar. Rocks of larger than 0.10 m

3

volume.

(accord. to DIN 18300)

Basis of calculation

Each material, extracted from its natural position

whether by blasting or other means, grows in volume.

This increase in volume is measured in % or is given

as a ratio.

Swelling (%) = ( -1) X 100%

Swell factor =

volume after breaking

grown volume

100%

100% + swelling

28

LIKUFIX

What is LIKUFIX?

LIKUFIX is a hydraulic quick-change system combined with an automatic hydraulic coupling

device which was designed by Liebherr. LIKUFIX allows quick and safety changing of

mechanical and hydraulic attachments for hydraulic excavators, directly from the cab.

The technical advantages:

Fully automatic play compensation

Tight connection between the hydraulic circuits thanks to

the hydro-mechanical compensation system

More than 25 years experience in fully-automatic coupling systems

Reliable system with long service life

No problem at all in converting an existing hydraulic quick change system to LIKUFIX

The convenience advantage:

Reliable hydraulic connection free of oil leaks

Low operating and maintenance costs

Add-on parts can be changed from the cab

The economic advantage:

Easy equipping of existing hydraulic excavators

Hydraulic add-on parts changed in a matter of seconds

meaning better machine utilisation with different applications on the same unit

Major time savings in comparison with hydraulic-hose changes

Low operating and maintenance costs with maximum productivity

Carefully selected use of the add-on parts for long tool service life

Coupling into the unit Connected to the unit, mechanically

and hydraulically

Moving to the unit

29

Hydraulic excavator -

short summary of mounting

possibilities

The extension is also possible for Liebherr material handling machines and similar machines of competitiors.

Liebherr quick coupler sizes

* on request

Operating weight

kg

SW 22 SW 33 SW 48 SW 66 SW 77 SW 92

Q

u

i

c

k

c

o

u

p

l

i

n

g

s

y

s

t

e

m

s

QC Mechanical

QC Hydraulic

LIKUFIX

L

i

e

b

h

e

r

r

h

y

d

r

a

u

l

i

c

e

x

c

a

v

a

t

o

r

m

o

d

e

l

s

Competition machines 8,000 - 10,000 M M/H/L

A 910 Compact (A 309) 11,600 - 12,800 M M/H/L

A 912 Compact (A 311) 12,700 - 14,100 M M/H/L

A 914 Compact (A 312) 14,700 - 16,600 M/H/L M/H/L

A 914 (A 314) 15,200 - 17,500 M/H/L M/H/L

R 914 Compact (R 313) 15,100 - 17,500 M/H/L M/H/L

A 916 (A 316) 16,800 - 19,000 M/H/L M/H/L

A 918 Compact 17,500 - 19,500 M/H/L M/H/L

A 918 (A 900) 17,700 - 19,900 M/H/L M/H/L

R 918 (R 317) 18,150 - 21,750 M/H/L M/H/L

A 920 (A 904) 18,900 - 21,700 M/H/L

R 920 (R 900) 20,200 - 23,500 M/H/L

R 922 (R 906 Advanced - Classic) 21,350 - 23,600 M/H/L

A 924 21,400 - 26,500 M/H/L

R 924 (R 916 Advanced - Classic) 23,500 - 27,600 M/H/L

R 924 Compact 25,150 - 29,050 M/H/L

R 926 (R 926 Advanced - Classic) 25,700 - 28,950 M/H/L

A 928 (A 924 Plus) 26,500 - 27,600 M/H/L

R 936 (R 934) 30,550 - 33,850 M/H/L

R 946 (R 944) 38,050 - 41,600 M/H/L

R 950 SME 42,950 - 44,800 M*/H/L*

R 956 (R 954) 49,600 - 57,100 M/H/L

R 960 SME 58,980 - 60,600 M*/H/L*

R 966 (R 964) 66,000 - 76,300 H

R 970 SME 76,800 - 78,600 H

R 976 (R 974) 85,300 - 95,500 H

R 980 SME 93,900 - 97,800 H

30

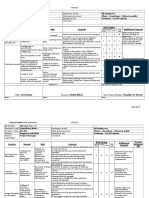

Backhoe

bucket with

teeth

Backhoe bucket

with cutting

edge

Ditch-cleaning-

bucket

Tilting

bucket

STD HD HDV STD HD tiltable rigid

A 910 Compact (A 309)

A 912 Compact (A 311)

A 914 Compact (A 312)

A 914 (A 314)

R 914 Compact (R 313)

A 916 (A 316)

A 918 Compact

A 918 (A 900)

R 918 (R 317)

A 920 (A 904)

R 920 (R 900)

R 922 (R 906 Advanced - Classic)

A 924

R 924 (R 916 Advanced - Classic)

R 924 Compact

R 926 (R 926 Advanced - Classic)

A 928 (A 924 Plus)

R 936 (R 934)

R 946 (R 944)

R 950 SME

R 956 (R 954)

R 960 SME

R 966 (R 964)

R 970 SME

R 976 (R 974)

R 980 SME

Backhoe bucket line

31

A 910 Compact (A 309) /

A 912 Compact (A 311) with SW 33

A 914 Compact (A 312) /

R 914 Compact (R 313) /

A 914 (A 314) with SW 48

1)

Width Teeth Cutting

edge

HD

(with teeth)

2)

Width Teeth Cutting

edge

HD

(with teeth)

2)

mm m

3

kg m

3

kg m

3

kg mm m

3

kg m

3

kg m

3

kg

300

3)

0.15 160 0.15 150 - - 300

3)

0.17 270 0.18 260 0.17 300

400

3)

0.20 190 0.21 180 - - 400

3)

0.24 290 0.26 280 0.24 320

450 0.20 170 0.21 160 - - 500

3)

0.32 280 0.34 270 0.32 320

550 0.22 190 0.24 190 - - 650 0.36 300 0.39 290 0.36 340

650 0.27 210 0.30 210 - - 850 0.50 350 0.53 340 0.50 400

750 0.33 230 0.35 220 - - 1,050 0.65 400 0.71 390 0.65 450

850 0.38 240 0.42 240 - - 1,250 0.80 450 0.87 430 0.80 510

950 0.44 270 0.48 270 - - - - - - - - -

A 914 Compact (A 312) /

R 914 Compact (R 313) /

A 914 (A 314) with SW 33

1)

A 916 (A 316) / A 918 Compact /

A 918 (A 900) / A 900 ZW /

R 918 (R 317) / R 920 (R 900) with SW 48

300

3)

0.17 220 0.18 210 0.17 250 300

3)

0.17 270 0.18 260 0.17 300

400

3)

0.24 250 0.26 240 0.24 280 400

3)

0.24 290 0.26 280 0.24 320

500 0.32 250 0.30 240 0.28 280 500

3)

0.32 290 0.34 280 0.32 330

550 0.29 260 0.31 250 0.29 290 650 0.45 400 0.45 380 0.45 440

650 0.36 290 0.39 270 0.36 320 850 0.60 430 0.65 410 0.60 480

850 0.50 340 0.53 320 0.50 380 1,050 0.80 510 0.85 490 0.80 570

1,050 0.65 380 0.71 370 0.65 430 1,250 0.95 560 1.05 530 0.95 630

1,250 0.80 430 0.87 420 0.80 490 - - - - - - -

A 916 (A 316) / A 918 Compact /

A 918 (A 900) / A 900 ZW /

R 918 (R 317) / R 900 with SW 33

A 920 (A 904) / R 922 (R 906) /

R 924 Compact with SW 48

- - - - - - - 300

3/4)

0.17 270 0.18 260 0.17 300

- - - - - - - 400

3/4)

0.24 290 0.26 280 0.24 320

- - - - - - - 500

3/4)

0.32 290 0.34 280 0.32 330

300

3)

0.17 220 0.18 210 0.17 250 650 0.55 510 0.60 530 0.55 570

400

3)

0.24 250 0.26 240 0.24 280 850 0.60 550 0.65 590 0.60 620

500 0.32 290 0.32 270 0.30 320 1,050 0.80 630 0.85 670 0.80 710

650 0.45 350 0.45 330 0.45 390 1,250 1.00 730 1.05 770 1.00 820

850 0.60 400 0.65 380 0.60 450 1,400 1.15 790 1.20 840 1.15 880

1,050 0.80 480 0.85 460 0.80 540 - - - - - - -

1,250 0.95 520 1.05 500 0.95 590 - - - - - - -

Bucket A 910 Compact (A 309) - R 906

The attaching tool permitted for the corresponding machine conguration you can see from the relating excavator brochure.

1)

HD-bucket for A 914 Compact (A 312) not available

2)

HD-version also available with cutting edge

3)

Backhoe bucket with limited digging depth

4)

only after consultation

32

1)

HD-version also available with cutting edge

2)

also available with increased content by arrangement

3)

Backhoe bucket with limited digging depth

4)

only after consultation

R 936 (R 934) / R 946 (R 944) / R 950 SME

Width STD

Teeth (Z50)

HD

Teeth (Z50)

mm m

3

kg m

3

kg

1,050 0.95 860 0.95 1,050

1,250 1.15 960 1.15 1,160

1,400 1.35 1,020 1.35 1,270

1,500 1.75 1,470 1.75 1,520

1,650 2.00 1.600 2.00 1,700

1,650 - - 2.25 1,850

1,800 - - 2.50 2,000

R 956 (R 954) / R 960 SME Teeth (Z70) Teeth (Z70)

1,300 1.65 2,100 - -

1,500 2.00 2,250 - -

1,550 - - 2.00 2,800

1,700 2.35 2,500 - -

1,750 - - 2.35 3,050

1,900 2.70 2,650 - -

1,950 - - 2.70 3,300

2,100 - - 3.25 3,400

2,250 - - 3.50 3,700

R 966 (R 964) / R 970 SME Teeth (Z70) Teeth (Z90)

1,550 2.50 2,950 2.00 3,300

1,750 3.00 3,150 2.50 3,500

1,950 3.50 3,450 3.00 3,800

2,100 - - 3.50 4,150

2,150 4.00 3,650 -

2,400 4.50 3,850 4.00 4,350

2,600 5.00 4,100 -

R 976 (R 974) / R 980 SME Teeth (Z90) Teeth (Z90)

1,550 3.20 3,500 -

1,750 3.80 3,750 3.60 4,150

1,900 4.30 3,950 4.10 4,500

2,100 4.80 4,200 4.60 4,800

2,250 5.80 4,550 -

2,400 - - 6.20 6,350

A 924 / A 928 (A 924 Plus) / R 924 (R 916) / R 926 (R 926 Advanced - Classic)

Width Teeth Cutting

edge

HD

(with teeth)

1)

mm m

3

kg m

kg

m

kg

300

3/4)

0.17 270 0.18 260 0.17 300

400

3/4)

0.24 290 0.26 280 0.24 320

500

3/4)

0.32 290 0.34 280 0.32 330

650 0.55 540 0.60 530 0.55 600

850 0.75 650 0.80 630 0.75 690

1,050 0.95 720 1.05 720 0.95 800

1,250 1.15 810 1.30 800 1.15 910

1,400 1.35 880 1.50 870 1.35 960

1,400 1.50

2)

880 1.70

2)

870 1.50 960

1,500 1.45

2)

890 1.65

2)

890 1.45 1,000

1,600 1.55

2)

950 1.75

2)

980 1.55 1,060

Backhoe bucket with SW 48, A 924 - R 926 (R 926 Advanced - Classic)

Backhoe bucket R 936 (R 934) - R 974

33

Tilt buckets / Ditch cleaning buckets

with SW 33, A 910 Compact (A 309) - R 920 (R 900)

A 910 Compact (A 309)

Width Tiltable ditch

cleaning bucket

2)

Rigid ditch

cleaning bucket

Tilt bucket

2)

mm m

3

kg m kg m kg

1,200 0.29 385 - - - -

1,300

0.28 300 - - - -

1,500

1)

0.33 330 0.33 210 - -

1,500 0.36 420 - - - -

A 912 Compact (A 311)

1,200 0.29 385 - - - -

1,500

1)

0.33 330 0.33 210 - -

1,500 0.36 420 - - - -

1,700

1)

0.37 390 - - - -

1,700 0.41 455 - - - -

2,000 - - 0.45 270 - -

A 914 Compact (A 312)

1,500 - - 0.50 360 0.60 660

1,600 0.55 640 - - - -

2,000 0.50 660 0.48 350 - -

2,000 - - 0.65 390 - -

A 914 (A 314) / R 914 Compact (R 313)

1,500 - - 0.50 360 0.60 660

1,600 0.55 640 - - - -

2,000 0.50 660 0.48 350 - -

2,000 - - 0.65 390 - -

A 916 (A 316)

1,500 - - 0.50 360 0.60 660

1,600 0.55 640 - - 0.80 740

1,600 0.80 770 - - - -

2,000 0.50 660 0.48 350 - -

2,000 - - 0.65 390 - -

A 918 (A 900) / R 918 (R 317) / R 920 (R 900)

1,500 - - 0.50 360 0.60 660

1,600 0.55 640 - - 0.80 740

1,600 0.80 770 - - - -

2,000 0.50 660 0.48 350 - -

2,000 0.70 790 0.65 390 - -

The attaching tool permitted for the corresponding machine conguration you can see from the relating excavator brochure.

1)

2 x 45 tiltable

2)

2 x 50 tiltable

34

Tilt buckets / Ditch cleaning buckets with SW 48,

A 914 Compact (A 312) - R 926 (R 926 Adv.-Cl.)

A 914 Compact (A 312) / A 914 (A 314) / R 914 Compact (R 313)

Width

Tiltable ditch

cleaning bucket

1)

Rigid ditch

cleaning bucket

Tilt bucket

1)

mm m

3

kg m

3

kg m

3

kg

1,500 - - - - 0.60 680

1,600 0.55 690 - - - -

2,000 0.50 690 0.48 400 - -

A 916 (A 316)

1,500 - - 0.50 430 0.60 680

1,600 0.55 690 - - - -

1,600 0.80 850 - - - -

2,000 0.50 690 0.48 400 - -

A 918 (A 900) / R 918 (R 317) / R 920 (R 900)

1,500 - - 0.50 430 0.60 680

1,600 0.55 690 - - 0.80 820

1,600 0.80 850 - - - -

2,000 0.50 690 0.48 400 - -

2,000 0.70 880 - - - -

A 920 (A 904) / R 922 (R 906 Adv.-Cl.)

1,500 - - 0.50 430 1.20 970

1,600 0.55 690 - - 0.80 820

1,600 0.80 850 - - 1.00 890

2,000 0.50 690 0.70 520 - -

2,000 0.70 880 - - - -

2,000 1.00 940 - - - -

2,200 0.80 880 - - - -

2,200 1.15 980 - - - -

2,400 0.85 890 - - - -

A 924 / A 928 (A 924 Plus) / R 924 Compact / R 924 (R 916 Adv.-Cl.) / R 926 (R 926 Adv.-Cl.)

1,500 - - 0.50 430 1.20 970

1,600 0.80 850 - - 0.80 820

1,600 - - - - 1.00 890

1,600 - - - - 1.35 970

1,600 - - - - 1.55 1,120

2,000 0.50 690 0.70 520 - -

2,000 0.70 880 1.20 640 - -

2,000 1.00 940 - - - -

2,200 0.80 880 - - - -

2,200 1.15 980 - - - -

2,200 1.40 1,000 - - - -

2,400 0.85 890 0.85 610 - -

2,400 1.25 1,000 - - - -

1)

2 x 50 tiltable

C

50

A

B

35

Tilt buckets / Ditch cleaning buckets R 936 (R 934) - R 946 (R 944)

R 936 (R 934) / R 946 (R 944)

Width Tiltable ditch

cleaning bucket

1)

Rigid ditch

cleaning bucket

Tilt bucket

1)

mm

m

3

kg m

3

kg m

3

kg

1,600

- - - - 1.45 1,530

- - - - 1.75 1,630

1,700 - - - - 1.85 1,700

1,800

- - - - 1.60 1,620

- - - - 2.00 1,750

2,000

0.70 1,350 0.70 550 - -

1.45 1,600 - - - -

2,200

1.65 1,590 - - - -

1.65 1,660 - - - -

2,400

0.85 1,480 0.85 635 - -

1.45 1,610 1.15 685 - -

The attaching tool permitted for the corresponding machine conguration you can see from the relating excavator brochure.

1)

2 x 50 tiltable

1)

LH-TR 20 with SW 33, LH-TR 25 with SW 48

Hydraulic tilt-rotator

LH-TR 20 LH-TR 25

Model classification

A 914 (A 314) -

A 918 (A 900) / R 920 (R 900)

A 918 (A 900) / R 920 (R 900) -

R 936 (R 934)

weight

1)

470 kg 720 kg

A

1)

600 mm 680 mm

B 870 mm 880 mm

C

1)

220 mm 315 mm

D

C

E

B

A

36

Clamshell

Clamshell

Capacity

A

Shell

width

B

Opening

C

Heigth

open

D

Heigth

closed

E

Span

width

Weight

GM 5B m

3

mm mm mm mm mm kg

0.10 300 1,195 1,070 1,400 1,343 410

0.13 400 1,195 1,070 1,400 1,343 440

0.20 600 1,195 1,070 1,400 1,343 470

0.27 800 1,195 1,070 1,400 1,343 510

GM 8B

0.17 320 1,520 1,990 2,420 1,645 710

0.22 400 1,520 1,990 2,420 1,645 750

0.30 600 1,450 1,920 2,385 1,575 750

0.40 800 1,450 1,920 2,385 1,575 800

GM 10B

0.17 320 1,530 2,685 2,440 1,697 770

0.22 400 1,530 2,685 2,440 1,697 820

0.35 600 1,530 2,685 2,440 1,697 860

0.45 800 1,530 2,685 2,440 1,697 910

0.60 1,000 1,530 2,685 2,440 1,697 970

GM 20B

0.45 600 1,955 1,920 2,420 1,650 1,160

0.60 800 1,955 1,920 2,420 1,650 1,210

0.75 1,000 1,955 1,920 2,420 1,650 1,285

0.90 1,200 1,955 1,920 2,420 1,650 1,350

Wheeled

Excavator

A 910

Compact

(A 309)

A 912

Compact

(A 311)

A 914

Compact

(A 312)

A 914

(A 314)

A 916

(A 316)

A 918

(A 900)

A 920

(A 904)

A 924

A 928

(A 924

Plus)

Crawler

Excavator

R 914

Compact

(R 313)

R 918

(R 317)

R 920

(R 900)

R 922

(R 906)

R 916

R 924

R 926

Grab mechanism GM 5B GM 5B GM 5B GM 5B

Grab mechanism GM 8B GM 8B GM 8B GM 8B

Grab mechanism GM 10B GM 10B GM 10B GM 10B

Grab mechanism GM 20B GM 20B*

* for A 928 (A 924 Plus)

B

A

C

D

37

Sorting grapples

Capacity Shell

width

Closing

force

A

Heigth

closed

B

Heigth

open

C

Width

open

D

Width

closed

Weight

SG 25

m

3

mm t mm mm mm mm kg

Corrugated

0.50 800 6 1,510 1,380 1,970 1,380 1,100

0.65 1,000 6 1,510 1,380 1,970 1,380 1,180

Perforated

0.55 800 6 1,510 1,380 1,970 1,380 1,050

0.75 1,000 6 1,510 1,380 1,970 1,380 1,100

Rock grapple 0.55 800 6 1,620 1,635 2,200 1,460 1,240

SG 30

Corrugated

0.75 1,000 8 1,625 1,485 2,140 1,515 1,510

0.90 1,150 8 1,625 1,485 2,140 1,515 1,590

Perforated

0.85 1,000 8 1,625 1,485 2,140 1,515 1,490

1.00 1,150 8 1,625 1,485 2,140 1,515 1,570

Rock grapple 0.80 1,050 8 1,730 1,780 2,315 1,530 1,765

SG 40

Corrugated 1.10 1,100 10 1,920 1,740 2,560 1,790 2,360

Perforated 1.30 1,100 10 1,920 1,740 2,560 1,790 2,230

Shells perforated (standard) Shells ribbed (option) Rock grapple

= best for standard applications

= Consultation with manufacturer required since only permitted for certain applications

= for extremely heavy applications on this excavator

Wheeled

Excavator

Standard Longfront

A 914

(A 314)

A 916

(A 316)

A 918

(A 900)

A 920

(A 904)

A 924

A 928

(A 924

Plus)

Crawler

Excavator

R 914

Compact

(R 313)

R 918

(R 317)

R 920

(R 900)

R 922

(R 906)

R 924

(R 916)

R 926

(R 926)

R 936

(R 934)

R 946

(R 944)

R 956

(R 954)

R 936

(R 934)

R 946

(R 944)

R 956

(R 954)

R 976

(R 974)

SG 25

SG 30

SG 40

38

Liebherr Uni tooth system

Elements Tooth size

Uni 25-2 Uni 35-3

Tooth holder

Tooth shape

Pointed

Standard

HD

Roll pin

Cotter pin driver

Liebherr Z tooth system

available

Order numbers are available from your service partner.

Element

Tooth size

35 40 50 70 90

Tooth holder

single bracket*

Tooth holder

double bracket

Tooth form

C

CL

P

PF

CR

R

Lip shrouds

Length: 240

Middle

Left

Right

Length: 280

Middle

Left

Right

Length: 320

Middle

Left

Right

Side shrouds

protection

Thickness of

sheet plate

30 to 50 LS***

50 to WS 50**

* for precise grading work, ** High impact resistance, *** Higher bucket capacity

available

Order numbers are available from your service partner.

39

available

Hydraulic excavator model

Tooth system Uni Tooth system Z

U25-2 U35-3 Z35 Z40 Z50 Z70 Z90

A 910 Compact (A 309)

A 912 Compact (A 311)

A 914 Compact (A 312)

A 914 (A 314)

R 914 Compact (R 313)

A 916 (A 316)

A 918 Compact

A 918 (A 900)

R 918 (R 317)

A 920 (A 904)

R 920 (R 900)

R 922 (R 906 Advanced - Classic)

A 924

R 924 (R 916 Advanced - Classic)

R 924 Compact

R 926 (R 926 Advanced - Classic)

A 928 (A 924 Plus)

R 936 (R 934)

R 946 (R 944)

R 950 SME

R 956 (R 954)

R 960 SME

R 966 (R 964)

R 970 SME

R 976 (R 974)

R 980 SME

Assignment to machine types

Liebherr-Hydraulikbagger GmbH

Liebherrstrae 12, D-88457 Kirchdorf / Iller

+49 7354 80-0, Fax +49 7354 80-72 94

www.liebherr.com, E-Mail: info.lhb@liebherr.com

www.facebook.com/LiebherrConstruction

Liebherr-France SAS

2 avenue Joseph Rey, B.P. 90287, FR-68005 Colmar Cedex

+33 3 89 21 30 30, Fax +33 3 89 21 37 93

www.liebherr.com, E-Mail: info.lfr@liebherr.com

www.facebook.com/LiebherrConstruction

The Liebherr Group of Companies

Wide Product Range

The Liebherr Group is one of the largest construction

equipment manufacturers in the world. Liebherrs

high-value products and services enjoy a high reputation

in many other fields, too. The wide range includes

domes tic appliances, aerospace and transportation

systems, machine tools and maritime cranes.

Exceptional Customer Benefit

Every product line provides a complete range of models

in many different versions. With both their technical

excel lence and acknowledged quality, Liebherr products

offer a maximum of customer benefits in practical

application.

State-of-the-art Technology

To provide consistent, top quality products, Liebherr

attaches great importance to each product area, its

components and core technologies. Important modules

and components are developed and manufactured

in-house, for instance the entire drive and control

techno logyfor construction equipment.

Worldwide and Independent

Hans Liebherr founded the Liebherr family company in

1949. Since that time, the enterprise has steadily grown

to a group of more than 120 companies with over

35,000employees located on all continents. The corporate

headquarters of the Group is Liebherr-International AG

inBulle, Switzerland. The Liebherr family is the sole owner

of the company.

www.liebherr.com

Liebherr-Hydraulikbagger GmbH

Liebherrstrae 12, D-88457 Kirchdorf / Iller

+49 7354 80-0, Fax +49 7354 80-72 94

www.liebherr.com, E-Mail: info.lhb@liebherr.com

www.facebook.com/LiebherrConstruction

P

r

i

n

t

e

d

i

n

G

e

r

m

a

n

y

b

y

T

y

p

o

d

r

u

c

k

B

K

-

R

P

L

H

B

1

0

3

3

0

3

4

1

-

2

-

0

4

.

1

3

_

e

n

G

B

S

u

b

j

e

c

t

t

o

t

e

c

h

n

i

c

a

l

m

o

d

i

c

a

t

i

o

n

s

.

Vous aimerez peut-être aussi

- BP Anbauwerkzeuge enGB PDFDocument40 pagesBP Anbauwerkzeuge enGB PDFRomanPas encore d'évaluation

- Backhoe Work ToolsDocument24 pagesBackhoe Work ToolsJesus Carreon100% (1)

- PECP9067-03 - Liebherr GET PDFDocument12 pagesPECP9067-03 - Liebherr GET PDFRyan Abubakar Obili PakayaPas encore d'évaluation

- Drilling Solutions CatalogDocument15 pagesDrilling Solutions Catalogعلی محمودیPas encore d'évaluation

- Catalogo 2200SM ENGDocument12 pagesCatalogo 2200SM ENGAntonio Quispe Patiño100% (1)

- Erkat Products (En)Document21 pagesErkat Products (En)Pasc ClaudiuPas encore d'évaluation

- Wheel Loader Common ModuleDocument68 pagesWheel Loader Common ModulecarlitobernabejrPas encore d'évaluation

- PPV PresentationDocument66 pagesPPV PresentationIvan BogdanPas encore d'évaluation

- HD (Heavy Duty) Buckets: Features and SpecsDocument1 pageHD (Heavy Duty) Buckets: Features and SpecsScott GuimondPas encore d'évaluation

- Vsi 1Document2 pagesVsi 1Vivek AgrawalPas encore d'évaluation

- KPI Full BrochureDocument10 pagesKPI Full BrochureOrlando Melipillan100% (1)

- 2 Borehole EnlargementDocument8 pages2 Borehole EnlargementYeisber Mauricio Mendez DussanPas encore d'évaluation

- p28 - 29 Ds II Permanent Gravel Pack PackerDocument2 pagesp28 - 29 Ds II Permanent Gravel Pack PackerPak RioPas encore d'évaluation

- JC Series Jaw Crusher PDFDocument8 pagesJC Series Jaw Crusher PDFgarrybieber100% (1)

- Caterpillar®Adapters and Bucket TipsDocument8 pagesCaterpillar®Adapters and Bucket TipsVICTOR GARCIAPas encore d'évaluation

- Catalogo 2500SM ENGDocument12 pagesCatalogo 2500SM ENGAntonio Quispe Patiño100% (1)

- Brochure Nordberg C Series 4226 06 23 en AggDocument20 pagesBrochure Nordberg C Series 4226 06 23 en AggKaiser CarloPas encore d'évaluation

- AEHQ5853 Cat BucketsDocument4 pagesAEHQ5853 Cat BucketsJavier MorontaPas encore d'évaluation

- Heavy DuutyDocument11 pagesHeavy Duutytesfayebulti33Pas encore d'évaluation

- wmd1253 Isogate Brochure 2020Document16 pageswmd1253 Isogate Brochure 2020Matias OnatePas encore d'évaluation

- Aggregate Processing EquipmentDocument30 pagesAggregate Processing EquipmentFredrick Omondi OlewePas encore d'évaluation

- Joy Sizers BrochureDocument12 pagesJoy Sizers Brochurehilmy yusuf maulanaPas encore d'évaluation

- Tenmat Ferobide BrochureDocument12 pagesTenmat Ferobide BrochureJosé Alessandro Chiroque YoveraPas encore d'évaluation

- ITM Mining_ENG_140415Document20 pagesITM Mining_ENG_140415Alex LeePas encore d'évaluation

- Lubrite Catalog To PDFDocument28 pagesLubrite Catalog To PDFnildon_fPas encore d'évaluation

- Why Use Stone Column: High Speed Installation Saves 20-70% vs PilingDocument6 pagesWhy Use Stone Column: High Speed Installation Saves 20-70% vs PilingZeal Lea50% (2)

- B Gen 200 0903Document16 pagesB Gen 200 0903Joan CzPas encore d'évaluation

- Product Directory: Material Handling SolutionsDocument8 pagesProduct Directory: Material Handling Solutionsemuno008Pas encore d'évaluation

- Surface mining equipment: Buldozers and their applicationsDocument52 pagesSurface mining equipment: Buldozers and their applicationsabhimanyu choudharyPas encore d'évaluation

- WR424GB00DDocument16 pagesWR424GB00DIgor San Martín PeñalozaPas encore d'évaluation

- Hand Auger (2m Depth)Document8 pagesHand Auger (2m Depth)ConciselyPas encore d'évaluation

- TVIS850 Vertical Shaft Impact CrusherDocument1 pageTVIS850 Vertical Shaft Impact Crushermartinez gerardoPas encore d'évaluation

- Spare parts for earthmoving and mining equipmentDocument12 pagesSpare parts for earthmoving and mining equipmentBYG Spare PartsPas encore d'évaluation

- REDBACK® Roller Reamers: Technical OverviewDocument3 pagesREDBACK® Roller Reamers: Technical OverviewNoe LopezPas encore d'évaluation

- 17mc67 (Drsri Precast)Document20 pages17mc67 (Drsri Precast)jagadeshPas encore d'évaluation

- SuperCor 2008Document16 pagesSuperCor 2008PD AWSSIESPPas encore d'évaluation

- b5860 For Slurry ApplicationDocument6 pagesb5860 For Slurry Applicationpeach5Pas encore d'évaluation

- Drill Bits - Taurex PDFDocument14 pagesDrill Bits - Taurex PDFCarlos Antonio Padra PerezPas encore d'évaluation

- Rotary Bit Information Tcm45-3560367Document56 pagesRotary Bit Information Tcm45-3560367DTPas encore d'évaluation

- Varel Mining CatalogDocument24 pagesVarel Mining CatalogEmerson Phocco Yauli100% (1)

- The Reliable Solution For Automated Conveying Systems: Inverted-Tooth Chains From RexrothDocument24 pagesThe Reliable Solution For Automated Conveying Systems: Inverted-Tooth Chains From RexrothLuis Eduardo Albarracin RugelesPas encore d'évaluation

- Screen SandDocument2 pagesScreen SandIng Jose BelisarioPas encore d'évaluation

- DSA Excavation Services Sydney 0418228965Document12 pagesDSA Excavation Services Sydney 0418228965José Roberto SimõesPas encore d'évaluation

- Wr430gb00b BMP Cat Discl EngDocument12 pagesWr430gb00b BMP Cat Discl EngJoseph BernardPas encore d'évaluation

- Secondary Impact CrushersDocument8 pagesSecondary Impact CrushersKevin David Guao BolanoPas encore d'évaluation

- Comprehensive Range of Gear ToolsDocument16 pagesComprehensive Range of Gear Toolsleosac6Pas encore d'évaluation

- 0086-21-58300272Website: www.sbmchina.comDocument6 pages0086-21-58300272Website: www.sbmchina.comrabiemPas encore d'évaluation

- 6 Different Excavator TypesDocument8 pages6 Different Excavator TypesDaniel ReyesPas encore d'évaluation

- Single Roll CrushersDocument8 pagesSingle Roll CrushersRinaldi SaputraPas encore d'évaluation

- Size Reduction Techniques and Industrial ApplicationsDocument86 pagesSize Reduction Techniques and Industrial ApplicationsalaialiPas encore d'évaluation

- TrenchDocument3 pagesTrenchbridge14Pas encore d'évaluation

- D352004107-MKT-001 Rev 02 Drilling Solutions MissionDocument13 pagesD352004107-MKT-001 Rev 02 Drilling Solutions MissionAshok SureshPas encore d'évaluation

- Roll Crusher BrochureDocument4 pagesRoll Crusher BrochureWaris La Joi Wakatobi100% (1)

- Sonotube CatalogoDocument2 pagesSonotube Catalogorodrigo2aguilarPas encore d'évaluation

- PTH Crusher GBDocument16 pagesPTH Crusher GBElvis Eberth Huanca MachacaPas encore d'évaluation

- Rock Excavation Methods FinalDocument50 pagesRock Excavation Methods FinalJoanna GamboaPas encore d'évaluation

- Descriptive Pamphlet of the Richmond Mill Furnishing WorksD'EverandDescriptive Pamphlet of the Richmond Mill Furnishing WorksPas encore d'évaluation

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!D'EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Évaluation : 5 sur 5 étoiles5/5 (2)

- Workshops and Urban Settlement in Buto - Egyptian Archaeology 40 2012 P. 14-17Document4 pagesWorkshops and Urban Settlement in Buto - Egyptian Archaeology 40 2012 P. 14-17Loïc MazouPas encore d'évaluation

- Method Statement Retaining WallDocument3 pagesMethod Statement Retaining WallPravin Pelanisamy100% (1)

- Bearing Pad InstallationDocument49 pagesBearing Pad InstallationfarooqPas encore d'évaluation

- Work InstructionsDocument32 pagesWork InstructionshainguyenbkvhvPas encore d'évaluation

- Mock Grant ProposalDocument38 pagesMock Grant ProposalargautreauPas encore d'évaluation

- Art and CrimeDocument283 pagesArt and CrimeanauenePas encore d'évaluation

- Earthwork in Construction SiteDocument13 pagesEarthwork in Construction SiteMuhammad Nuriqram40% (10)

- Ras Laffan Onshore Expansion Project Firewater Line Excavation Method StatementDocument4 pagesRas Laffan Onshore Expansion Project Firewater Line Excavation Method Statementrvsreddy1972Pas encore d'évaluation

- Site Supervision and Organization Chapter 3Document11 pagesSite Supervision and Organization Chapter 3Attempt FailPas encore d'évaluation

- 03 ContentsDocument32 pages03 ContentsSam SonPas encore d'évaluation

- 3916 West Kennet Eval 12227 Complete PDFDocument24 pages3916 West Kennet Eval 12227 Complete PDFJoseph Speed-MettPas encore d'évaluation

- The Stability Graph Method For Qpen-Stope DesignDocument8 pagesThe Stability Graph Method For Qpen-Stope Designlou721Pas encore d'évaluation

- Chap01 PDFDocument24 pagesChap01 PDFmmmmm100% (2)

- Excavation MethodDocument11 pagesExcavation MethodKrm ChariPas encore d'évaluation

- Rate Analysis of Excavation in EarthworkDocument5 pagesRate Analysis of Excavation in EarthworkAnonymous KUNMyMBEE100% (2)

- CC Oct 2003Document69 pagesCC Oct 2003Mohammed AliPas encore d'évaluation

- The Origin and Exchange of Obsidian From PDFDocument16 pagesThe Origin and Exchange of Obsidian From PDFMilica DespenićPas encore d'évaluation

- Visoka and Staro Bonche: Center of The Kingdom of Pelagonia and The Royal Tomb of Pavla Chuka - Viktor Lilchikj Adams, Antonio JakimovskiDocument44 pagesVisoka and Staro Bonche: Center of The Kingdom of Pelagonia and The Royal Tomb of Pavla Chuka - Viktor Lilchikj Adams, Antonio JakimovskiSonjce Marceva100% (1)

- Final Exam Idioma ModernoDocument5 pagesFinal Exam Idioma ModernoIsa RealPas encore d'évaluation

- 8.EXACAVATION and Confined SpaceDocument16 pages8.EXACAVATION and Confined SpaceIhuhwa Marta TauPas encore d'évaluation

- Matsuda 1998Document11 pagesMatsuda 1998gasenciosPas encore d'évaluation

- Pre-Construction WorkDocument2 pagesPre-Construction WorkakanagesPas encore d'évaluation

- Civil Work Specification Part 04Document10 pagesCivil Work Specification Part 04mr.xinbombayPas encore d'évaluation

- The La Tène Culture in Central Croatia The Problem of The Eastern Border of The Taurisci in The Podravina RegionDocument20 pagesThe La Tène Culture in Central Croatia The Problem of The Eastern Border of The Taurisci in The Podravina RegionFevziŞahinPas encore d'évaluation

- Assumed Missing Reported Buried As Published 23 March 2015Document210 pagesAssumed Missing Reported Buried As Published 23 March 2015Markus Milligan100% (2)

- The Castles, West Shipley Farm, Hamsterley, Co. DurhamDocument39 pagesThe Castles, West Shipley Farm, Hamsterley, Co. DurhamWessex Archaeology100% (4)

- Ifc2 ConstDocument27 pagesIfc2 ConstPhat Tran QuangPas encore d'évaluation

- Manual Handling, COSHH and Excavation SafetyDocument8 pagesManual Handling, COSHH and Excavation SafetybonyhermawanPas encore d'évaluation

- Basement ConstructionDocument49 pagesBasement ConstructionRaymond Nguyen100% (6)

- The Early Dynastic Cemeteries of Naga-ed-Dêr (1908)Document310 pagesThe Early Dynastic Cemeteries of Naga-ed-Dêr (1908)Timothy SmithPas encore d'évaluation