Académique Documents

Professionnel Documents

Culture Documents

Wittich2011 SonkusaleVandervelde

Transféré par

vishiwizard0 évaluation0% ont trouvé ce document utile (0 vote)

21 vues1 pagedededde

Titre original

Wittich2011_SonkusaleVandervelde

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentdededde

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

21 vues1 pageWittich2011 SonkusaleVandervelde

Transféré par

vishiwizarddededde

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 1

Solar cells are a promising, green energy source; however,

cost and efficiency limitations prevent widespread

adoption. We propose a solar cell design that is cost-

effective both in production and materials. Here, the

junction is made of copper (I) oxide and zinc oxide, which

are oxides of earth-abundant metals. Furthermore, we

utilize a wet chemistry fabrication process, making the

production of such cells inexpensive and easily scalable.

The process involves growing copper nanowires,

depositing zinc, oxidizing, and depositing a top contact,

detailed in the fabrication section. This is a greener

manufacturing method of solar cells where no harmful

compounds or excessive energy is used in fabrication.

Currently results are pending.

Abstract Results

Conclusion

Wet Chemistry Based Low Cost Nanowire Photovoltaic Cells

S. MacNaughton

1

, D. F. DeMeo

2

, Sameer Sonkusale

1

, Thomas E. Vandervelde

2

1

Nanoscale Integrated Circuits and Sensors Laboratory,

2

Renewable Energy and Applied Photonics Laboratory

ECE department, Tufts University, Medford, MA, USA

Fabrication

We thank the support from the Wittich family as part of the Tufts School of Engineering Wittich Energy Sustainability Initiative for this research

Motivation and Significance

Results Comparison to traditional Si solar cell

Nanowire, earth abundant oxide solar cells offer

several advantages over traditional bulk silicon:

Inexpensive materials - copper, zinc and their oxides

are earth-abundant and easily refined elements and

molecules.

Inexpensive fabrication - the electrochemical

fabrication techniques presented here are used

extensively in industry due to their ease of operation

and cost-effectiveness at all scales of production.

Hot carrier conversion - the nanowire arrangement of

this cell allows for more energy to be harvested from

each photon absorbed.

Increased absorption - the nanowires create a dark

surface which improves absorption in the cell.

Although the nanowire geometry will suffer from a decreased quantum efficiency due

to the spacing between the individual wires, it will be able to convert more energy

from each incident photon that strikes the active area. This is called harvesting hot

carriers. A hot carrier is a photon with an energy above the band gap of the material.

Normally these will be absorbed and the excess energy above the band gap will be

lost thermally, but with the decreased distance to the contacts in the nanowire

geometry more of this excess energy will be converted into electricity.

Entire cell is less than 15m thick.

Flexible

Cell weighs 15mg/cm2

Material costs are <$1USD per m

2

Much progress has been made on

developing the process to fabricate these

solar cells. The largest difficulty is to

overcome short circuiting the layers when

depositing the top contact. As can be seen

we see a diode response before the top

contact layer is applied, however once the

top contact is in place the cell only exhibits a

resistive response.

Future work includes further testing and

fabrication to obtain a working sample.

There is also much work to be done in

optimizing each layer. The ITO transparent

conducting oxide can be optimized for

increased transmittance and conductance.

We eventually hope to replace this with a

cheaper, more abundant TCO such as TiO

2

or ZnO.

Thermal

oxidation causes

interdiffusion

across the Cu/Zn

boundary.

Therefore ZnO is

directly

electroplated

onto the copper

oxide nanowires.

Right: Copper nanowire

growth is successful

and consistent

Left: Zinc on copper

nanowires

Right: EDS showing the presence

of both zinc and copper

Zn evaporated

onto CuO

nanowires

Top View

Thermalization of hot carrier IV curve of Flat cell on glass

An early sample of the nanowire cell.

ZnO Deposition

Left: Deposition rate of ZnO and ZnO:Al 2% lms as function of substrate temperature

Right: Inuence of deposition temperature on the resistivity of both undoped and doped

2%Al ZnO layers (Yousfi et. al. Thin Solid Films Volume 387, Issues 1-2, 29 May 2001, Pages 29-32)

Reduced Reflection

Vous aimerez peut-être aussi

- Defects Impact on Photoelectric ContactsDocument5 pagesDefects Impact on Photoelectric ContactsСергей ХрипкоPas encore d'évaluation

- Solar Panel Out of CD Disk and DiodeDocument11 pagesSolar Panel Out of CD Disk and DiodeJoseph Pendon67% (3)

- Narendra Seminar NewDocument21 pagesNarendra Seminar NewnagarjunareddyPas encore d'évaluation

- Electrodeposition of Cu2O/ZnO Nanopillar Solar CellsDocument5 pagesElectrodeposition of Cu2O/ZnO Nanopillar Solar CellsCamelia AlexandraPas encore d'évaluation

- Voltage Electric Current Light Photoelectric EffectDocument15 pagesVoltage Electric Current Light Photoelectric EffectKool KingPas encore d'évaluation

- Wiki Dye Sensitized Solar Cell-2Document12 pagesWiki Dye Sensitized Solar Cell-2singhadityaramPas encore d'évaluation

- 754 FullDocument1 page754 FullGetachew YirgaPas encore d'évaluation

- Development of Solar CellsDocument15 pagesDevelopment of Solar CellsPrithvi HarvePas encore d'évaluation

- Quantum Dot Solar CellDocument7 pagesQuantum Dot Solar CellmokhaladPas encore d'évaluation

- Functionalization of carbon nanotubes with quantum dots for photovoltaic applicationsDocument138 pagesFunctionalization of carbon nanotubes with quantum dots for photovoltaic applicationsJosé Augusto LucenaPas encore d'évaluation

- Rohil Kumar 17M713Document13 pagesRohil Kumar 17M713mokhaladPas encore d'évaluation

- Solar CellDocument14 pagesSolar CellKalirajan KPas encore d'évaluation

- Vincent 09ch043Document15 pagesVincent 09ch043kumaran.DPas encore d'évaluation

- What is NanotechnologyDocument52 pagesWhat is NanotechnologyOmkar ShetePas encore d'évaluation

- Solar Cells and Nanotechnology: Bharathidasan.D, Muhibullah.JDocument4 pagesSolar Cells and Nanotechnology: Bharathidasan.D, Muhibullah.JTanaji PatilPas encore d'évaluation

- Solar Cell IntroductionDocument12 pagesSolar Cell Introductionmuhammad shahbazPas encore d'évaluation

- Quantum Dot Solar Cell: PH.D Course 2 Semester / 2019-2020Document7 pagesQuantum Dot Solar Cell: PH.D Course 2 Semester / 2019-2020mokhaladPas encore d'évaluation

- Deli Gianni 2011Document7 pagesDeli Gianni 2011Youssef ChePas encore d'évaluation

- Bernd Schmid-Solar CellsDocument19 pagesBernd Schmid-Solar CellsMariya AQ NasutionPas encore d'évaluation

- DR N K Singh Amit VermaDocument4 pagesDR N K Singh Amit Vermaamit vermaPas encore d'évaluation

- Electrodeposition: A Technology For The Future: by Walther SchwarzacherDocument4 pagesElectrodeposition: A Technology For The Future: by Walther Schwarzachervivalavida31Pas encore d'évaluation

- Solar Cell Basics and Future TechnologyDocument37 pagesSolar Cell Basics and Future TechnologyMuhammad FauzanPas encore d'évaluation

- PPTDocument15 pagesPPTRavi JoshiPas encore d'évaluation

- Fabrication of Flexible Dye Sensitized Solar Cells On Plastic SubstratesDocument16 pagesFabrication of Flexible Dye Sensitized Solar Cells On Plastic SubstratesMuhammad Bilal QadirPas encore d'évaluation

- EME4353: Advanced Engineering Materials Assignment 1Document7 pagesEME4353: Advanced Engineering Materials Assignment 1Shakil MalikPas encore d'évaluation

- Copperoxide in Solar CellsDocument3 pagesCopperoxide in Solar CellsMichelle EscollarPas encore d'évaluation

- Nanotech Solar Cells: Dye, Quantum Dot and PerovskiteDocument4 pagesNanotech Solar Cells: Dye, Quantum Dot and PerovskiteVishwasPas encore d'évaluation

- Solar - New - Knit Final Submitted PresentedDocument3 pagesSolar - New - Knit Final Submitted Presentedamit vermaPas encore d'évaluation

- Solar Cell Basics ExplainedDocument36 pagesSolar Cell Basics ExplainedsahitPas encore d'évaluation

- A Comprehensive Review On Current Performance, Challenges and Progress in Thin Film Solar CellsDocument21 pagesA Comprehensive Review On Current Performance, Challenges and Progress in Thin Film Solar CellsREMO MosesPas encore d'évaluation

- Physics Investigatory Project++Document14 pagesPhysics Investigatory Project++saifahPas encore d'évaluation

- Introduction To PhotovoltaicDocument11 pagesIntroduction To PhotovoltaicGautam Kumar DeepakPas encore d'évaluation

- Electrodeposition for Low-Cost Solar Cell FabricationDocument7 pagesElectrodeposition for Low-Cost Solar Cell FabricationGiuseppe LulloPas encore d'évaluation

- NANOTECHNOLOGY SOLAR CELLSDocument2 pagesNANOTECHNOLOGY SOLAR CELLSNancy MohamedPas encore d'évaluation

- Solar Cell CourseworkDocument5 pagesSolar Cell Courseworkbcqy65mx100% (2)

- Nano-Enabled Tandem Solar Cell for Hydrogen ProductionDocument16 pagesNano-Enabled Tandem Solar Cell for Hydrogen ProductionnoorjahaPas encore d'évaluation

- Nanoparticle Enhanced Thin Film Solar Cells Boost AbsorptionDocument16 pagesNanoparticle Enhanced Thin Film Solar Cells Boost AbsorptionJorge RamirezPas encore d'évaluation

- Catchpole-Red Shifting The Surface Plasmon Resonance of Silver Nanoparticles For Light Trapping in Solar CellsDocument9 pagesCatchpole-Red Shifting The Surface Plasmon Resonance of Silver Nanoparticles For Light Trapping in Solar CellsVenus DilluPas encore d'évaluation

- Nano Technology of Solar EnergyDocument5 pagesNano Technology of Solar EnergySMITARANISAHOOPas encore d'évaluation

- Solar TechDocument24 pagesSolar TechmilanpkPas encore d'évaluation

- Perovskite Solar Cell With CeO2 Based ETLDocument23 pagesPerovskite Solar Cell With CeO2 Based ETLrahulpelectronics100% (2)

- Solar CoatingDocument5 pagesSolar CoatingBineesh BrunoPas encore d'évaluation

- Report Infrared Solar CellDocument22 pagesReport Infrared Solar Cellabhishek5singh5surajPas encore d'évaluation

- Effect of Al3 Doping Concentration and Film Thickness of ZnO Nan - 2020 - SolarDocument9 pagesEffect of Al3 Doping Concentration and Film Thickness of ZnO Nan - 2020 - SolarLENNART CHRIS BRUNA MUÑOZPas encore d'évaluation

- Carbon Nanotubes Research PaperDocument5 pagesCarbon Nanotubes Research PaperKeyur100% (1)

- Nanomaterials 11 02944 v3Document27 pagesNanomaterials 11 02944 v3Aizaz MuhammadPas encore d'évaluation

- University of BahrainDocument35 pagesUniversity of Bahrainapi-291560513Pas encore d'évaluation

- Increasing Solar PV Penetration Through System Flexibility and Energy StorageDocument45 pagesIncreasing Solar PV Penetration Through System Flexibility and Energy StorageDarshan KhuntPas encore d'évaluation

- Flexible Solid-State Cu X O-Based - Pseudo-Supercapacitor by Thermal Oxidation - of Copper FoilsDocument9 pagesFlexible Solid-State Cu X O-Based - Pseudo-Supercapacitor by Thermal Oxidation - of Copper FoilsEdgar Fabian Pinzon NietoPas encore d'évaluation

- Organic Solar Cells: Historical Developments and ChallengesDocument4 pagesOrganic Solar Cells: Historical Developments and ChallengesUttam SharmaPas encore d'évaluation

- Photovoltaic EnergyDocument6 pagesPhotovoltaic EnergyKento FujimoriPas encore d'évaluation

- P3HT e ZnO - OlsonDocument9 pagesP3HT e ZnO - OlsonrcnonatoPas encore d'évaluation

- D7 Solar Panel DevicesDocument12 pagesD7 Solar Panel Devicesarunguptha_gs100% (1)

- Multi-Junction Solar Cell: From Wikipedia, The Free EncyclopediaDocument13 pagesMulti-Junction Solar Cell: From Wikipedia, The Free EncyclopediaAryan KhannaPas encore d'évaluation

- Week 4_EMIDocument10 pagesWeek 4_EMIMuhammad ShahzaibPas encore d'évaluation

- Submitted By: Pritam Rath Regd No: 0911013206 Electrical Engineering Guided By: Mr. Manas Ranjan Nayak Assistant Professor Department of Electrical Engineering Iter, BhubaneswarDocument22 pagesSubmitted By: Pritam Rath Regd No: 0911013206 Electrical Engineering Guided By: Mr. Manas Ranjan Nayak Assistant Professor Department of Electrical Engineering Iter, BhubaneswarPutri PratiwiPas encore d'évaluation

- Single-Graded CIGS With Narrow Bandgap For Tandem Solar CellsDocument9 pagesSingle-Graded CIGS With Narrow Bandgap For Tandem Solar CellsKevin LópezPas encore d'évaluation

- Aditi Jain 192105119Document17 pagesAditi Jain 192105119aditi jainPas encore d'évaluation

- Background Theory Solar Tracker by S. M. Khaled FerdousDocument17 pagesBackground Theory Solar Tracker by S. M. Khaled Ferdousrinti_shams71% (7)

- ACM2 TAU Datasheet enDocument5 pagesACM2 TAU Datasheet envishiwizardPas encore d'évaluation

- Part Winding Startting The Three-Phase Squirrel Cage Induction Motor Air Gap Magnetic Field AnalysisDocument6 pagesPart Winding Startting The Three-Phase Squirrel Cage Induction Motor Air Gap Magnetic Field AnalysisIjabiPas encore d'évaluation

- 50 SCS Automotive Coatings - Rev0913Document4 pages50 SCS Automotive Coatings - Rev0913vishiwizardPas encore d'évaluation

- LJLVJK LVJJV LKJVDocument5 pagesLJLVJK LVJJV LKJVvishiwizardPas encore d'évaluation

- Jeas 1012 787Document5 pagesJeas 1012 787vishiwizardPas encore d'évaluation

- 5 SmanualDocument16 pages5 SmanualMark ThomasPas encore d'évaluation

- Engineered PlasticsDocument61 pagesEngineered Plastics고병석Pas encore d'évaluation

- Hardware Inloop Simulation IEEE LabVIEWDocument1 pageHardware Inloop Simulation IEEE LabVIEWvishiwizardPas encore d'évaluation

- Electric Vehicle Motor Design NotesDocument131 pagesElectric Vehicle Motor Design NotesvishiwizardPas encore d'évaluation

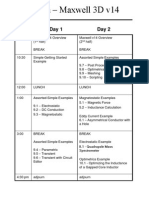

- Maxwell 3D v14 Training AgendaDocument1 pageMaxwell 3D v14 Training AgendavishiwizardPas encore d'évaluation

- Nit 3600 1Document5 pagesNit 3600 1vishiwizardPas encore d'évaluation

- Op - XT546 246 346 - Op288 V03Document2 pagesOp - XT546 246 346 - Op288 V03vishiwizardPas encore d'évaluation

- ReadmeDocument4 pagesReadmevishiwizardPas encore d'évaluation

- Recent Advances in Materials For Use in Permanent Magnet Machines - A ReviewDocument7 pagesRecent Advances in Materials For Use in Permanent Magnet Machines - A ReviewvishiwizardPas encore d'évaluation

- TRL Definitions PDFDocument1 pageTRL Definitions PDFBHARadwajPas encore d'évaluation

- FAB Resistivity White PaperDocument8 pagesFAB Resistivity White PapervishiwizardPas encore d'évaluation

- Presentation 1Document1 pagePresentation 1vishiwizardPas encore d'évaluation

- Maxwell 2dDocument7 pagesMaxwell 2dvishiwizardPas encore d'évaluation

- Big Energy Series 11.5.2012 Qing-Chang ZhongDocument1 pageBig Energy Series 11.5.2012 Qing-Chang ZhongvishiwizardPas encore d'évaluation

- Lit Survey RamamurthyDocument9 pagesLit Survey RamamurthyvishiwizardPas encore d'évaluation

- Electrical Resin BenefitsDocument2 pagesElectrical Resin BenefitsvishiwizardPas encore d'évaluation

- Brushless Motor FundamentalsDocument13 pagesBrushless Motor FundamentalsvishiwizardPas encore d'évaluation

- FTF Aut f0234Document38 pagesFTF Aut f0234vishiwizardPas encore d'évaluation

- Sensors Used in HEVDocument4 pagesSensors Used in HEVvishiwizard100% (1)

- A Brief Overview of Electric & Hybrid Electric Vehicle TechnologiesDocument1 pageA Brief Overview of Electric & Hybrid Electric Vehicle TechnologiesvishiwizardPas encore d'évaluation

- Motor Primer1Document2 pagesMotor Primer1vishiwizardPas encore d'évaluation

- How to Check a MOSFETDocument2 pagesHow to Check a MOSFETvishiwizardPas encore d'évaluation

- Cam DesignDocument13 pagesCam DesignvishiwizardPas encore d'évaluation

- Sona SPEED CatalogueDocument13 pagesSona SPEED CataloguevishiwizardPas encore d'évaluation

- Arduino Project: Smart Irrigation SystemDocument13 pagesArduino Project: Smart Irrigation SystemAleeza AnjumPas encore d'évaluation

- Interventional Radiology & AngiographyDocument45 pagesInterventional Radiology & AngiographyRyBone95Pas encore d'évaluation

- Fire Resistance Ratings - ANSI/UL 263: Design No. U309Document4 pagesFire Resistance Ratings - ANSI/UL 263: Design No. U309DavidPas encore d'évaluation

- Archana PriyadarshiniDocument7 pagesArchana PriyadarshiniJagriti KumariPas encore d'évaluation

- BlockStack Top 21 Trends in Web3 1676290935Document9 pagesBlockStack Top 21 Trends in Web3 1676290935Ahmed BachaPas encore d'évaluation

- India MedTech 23 CompendiumDocument326 pagesIndia MedTech 23 Compendiumudiptya_papai2007Pas encore d'évaluation

- Compiled Lecture in Engineering Economy PDFDocument78 pagesCompiled Lecture in Engineering Economy PDFLJ dela PazPas encore d'évaluation

- Mechanical Properties of Rna NanowiresDocument4 pagesMechanical Properties of Rna NanowiresIJAR JOURNALPas encore d'évaluation

- Program Python by ShaileshDocument48 pagesProgram Python by ShaileshofficialblackfitbabaPas encore d'évaluation

- Baseline Switch 2226 Plus: User GuideDocument92 pagesBaseline Switch 2226 Plus: User GuideOswaldoPas encore d'évaluation

- Housekeeping ProcedureDocument3 pagesHousekeeping ProcedureJeda Lyn100% (1)

- Lecture Nsche Engr Mafe SIWESDocument38 pagesLecture Nsche Engr Mafe SIWESoluomo1Pas encore d'évaluation

- Peterbilt Essentials Module3 Sleepers PDFDocument6 pagesPeterbilt Essentials Module3 Sleepers PDFLuis Reinaldo Ramirez ContrerasPas encore d'évaluation

- Underground Cable FaultDocument8 pagesUnderground Cable FaultMohammad IrfanPas encore d'évaluation

- Research Instruments SamplesDocument29 pagesResearch Instruments SamplesJUNRIL BUTALPas encore d'évaluation

- Agriculture DisciplineDocument3 pagesAgriculture DisciplineUmair FaheemPas encore d'évaluation

- Monroes Motivated Sequence LessonDocument3 pagesMonroes Motivated Sequence Lessonapi-257123630Pas encore d'évaluation

- 7310 Installation InstructionsDocument2 pages7310 Installation InstructionsmohamedPas encore d'évaluation

- A LITTLE CHEMISTRY Chapter 2-1 and 2-2Document5 pagesA LITTLE CHEMISTRY Chapter 2-1 and 2-2Lexi MasseyPas encore d'évaluation

- Reactive DyeingDocument23 pagesReactive Dyeingshivkalia8757100% (2)

- Indonesian Hotel Annual ReviewDocument34 pagesIndonesian Hotel Annual ReviewSPHM HospitalityPas encore d'évaluation

- Magnesium Alloy Anodes For Cathodic ProtectionDocument2 pagesMagnesium Alloy Anodes For Cathodic Protectiongautam100% (1)

- Curriculum Design and Development Part IDocument18 pagesCurriculum Design and Development Part IAngel LimboPas encore d'évaluation

- ACE Personal Trainer Manual Chapter 13Document59 pagesACE Personal Trainer Manual Chapter 13Đạt NguyễnPas encore d'évaluation

- Principles of Clinical Chemistry Automation and Point-of-Care TestingDocument27 pagesPrinciples of Clinical Chemistry Automation and Point-of-Care TestingMalliga SundareshanPas encore d'évaluation

- First Gospel of The Infancy of Jesus ChristDocument16 pagesFirst Gospel of The Infancy of Jesus ChristOdracir OiravlacPas encore d'évaluation

- Silver Bells Convent School Annual Examination 2021-22: Duration:2hours Subject: Science M. M.: 40 Class: IXDocument2 pagesSilver Bells Convent School Annual Examination 2021-22: Duration:2hours Subject: Science M. M.: 40 Class: IXAnkit SharmaPas encore d'évaluation

- Learning Team Aet562 - Self-Guided Social Media Training ManualDocument18 pagesLearning Team Aet562 - Self-Guided Social Media Training Manualapi-646128900Pas encore d'évaluation

- Pe Unit2Document2 pagesPe Unit2srikaanth06Pas encore d'évaluation

- Your IndiGo Itinerary July - SN9NVMDocument5 pagesYour IndiGo Itinerary July - SN9NVMaagama gurukulPas encore d'évaluation