Académique Documents

Professionnel Documents

Culture Documents

80 Afue Deluxe Two Stage Multi-Position Gas-Fired Furnaces

Transféré par

ardavan77Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

80 Afue Deluxe Two Stage Multi-Position Gas-Fired Furnaces

Transféré par

ardavan77Droits d'auteur :

Formats disponibles

036-21086-002 Rev.

A (5/00)

TECHNICAL GUIDE

80 AFUE DELUXE TWO STAGE MULTI-POSITION GAS-FIRED FURNACES

57-120 MBH INPUT MID-EFFICIENCY INDUCED COMBUSTION

DESCRIPTION

These high efficiency, compact units employ induced combustion, reliable hot surface ignition and high heat transfer tubular heat exchangers. The units are factory shipped for installation in upflow or horizontal applications. These furnaces are designed for residential installation in a basement, closet, alcove, attic, recreation room or garage and are also ideal for commercial applications. All units are factory assembled, wired and tested to assure safe dependable and economical installation and operation. These units are available in standard natural gas or dedicated LoNox models. These units are Category I listed and may be common vented with another gas appliance as allowed by the National Fuel Gas Code ANSI Z223.1 (latest edition).

WARRANTY

20-year limited warranty on the heat exchanger. 10-year heat exchanger warranty on commercial applications. 5-year limited parts warranty.

FEATURES

Two stage heating operation includes: - Two stage gas valve - Two stage inducer operation - Two speed blower operation This provides both increased comfort level and very quiet unit operation Delay timer allows two stage operation with single stage thermostat Acoustically insulated blower compartment for reduced blower sound level Humidifier and Electronic Air Cleaner control wires are provided to the power wiring box for easy field connection. 100% shut off main gas valve for added safety Easily applied in upflow, horizontal left or horizontal right installation with no conversion necessary Dedicated LoNox models Rollout safety control Low unit amp requirement for easy replacement application High quality two speed inducer motor for quiet operation Built-in self diagnostics with fault code display High velocity filter provided for field installation 40 VA control transformer fuse protected Cooling relay supplied for easy installation of add-on cooling Multi-speed PSC, direct-drive blower motor to match cooling reuirements Adjustable fan-off settings to eliminate cold-blow Compact 40-in. height allows installation in small space confines All models are propane convertible, except LoNox models

MODELS: G8D-UH / L8D-UH

FOR DISTRIBUTION USE ONLY - NOT TO BE USED AT POINT OF RETAIL SALE

036-21086-002 Rev. A (5/00)

TWO-STAGE UPFLOW/HORIZONTAL FURNACE DIMENSIONS

D B 3/4 20

(Vent Connection) POWER WIRING 7/8" HOLE

13-3/4

5-3/8 2-1/2

14-3/4

40

GAS INLET 1-1/4" X 2-1/2"

ACCESS WIRING 7/8" K.O.

2 32-1/2 14 23-1/2

OPTIONAL SIDE RETURN CUT-OUT (EITHER SIDE)

8-3/4

16

2-1/4

1-1/8 A 28-1/2

T'STAT WIRING 7/8" K.O.

FRONT

LEFT SIDE

RIGHT SIDE

B

A 1-1/ 8

Upflow/Horizontal Models G8D-UH / L8D-UH G8D06012UHA11* G8D08012UHA11*

C

A 14-1/2 14-1/2 17-1/2 17-1/2 21 21 21

B 13-1/4 13-1/4 16-1/4 16-1/4 19-3/4 19-3/4 19-3/4

C 10-1/8 10-1/8 13-1/8 13-1/8 16-5/8 16-5/8 16-5/8

D 4 4 4 4 4 4 4

E 10-1/8 10-1/8 11-5/8 11-5/8 13-3/8 13-3/8 13-3/8

F 3-3/4 3-3/4 3-3/4 3-3/4 3-3/4 3-3/4 3-3/4

20

Power Wiring 7/8" K.O.

Vent Connection (vent size)

20

G8D08016UHB11

7-3/ 8

1-7/ 8 E

D 5

G8D10012UHB11 G8D10020UHC11* G8D12016UHC11 G8D12020UHC11 *

*

1-1/ 8

FRONT

TOP IMAGE

FRONT

BOTTOM IMAGE

L in the first character indicates LoNox.

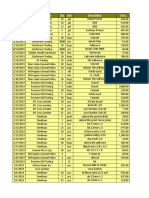

TWO-STAGE UPFLOW/HORIZONTAL RATINGS & PHYSICAL/ELECTRICAL DATA

MODELS

G8D--UH / L8D-UH

OUTPUT MBH H/L NOM. CFM

CABINET WIDTH (IN.)

LOW FIRE * AFUE TEMP RISE

HIGH FIRE TEMP RISE F

MAX. OUTLET AIR TEMP

BLOWER TOTAL UNIT HP AMPS SIZE (IN) AMPS

MAX. OVERCURRENT PROTECT

MIN WIRE SIZE OPER WGT. (LBS)

INPUT MBH H/L

F 80.0 80.0 80.0 80.0 80.0 80.0 80.0 25 - 55 30 - 60 25 - 55 25 - 55 25 - 55 25 - 55 25 - 55

F 165 175 160 170 160 180 170

(AWG) @ 75 FT.

ONE WAY

57/42 80/59 80/59 100/65 100/65 120/78 120/78

46/34 64/48 64/48 80/53 80/53 96/64 96/64

1200 1200 1600 1200 2000 1600 2000

A 14-1/2 A 14-1/2 B 17-1/2 B 17-1/2 C 21 C 21 C 21

35 - 65 40 - 70 25 - 55 40 - 70 30 - 60 45 - 75 35 - 65

1/3 1/3 3/4 1/2 1 1/2 1

6.2 6.2 11.5 7.0 12.2 10.4 12.2

10 x 7 10 x 7 11 x 8 10 x 8 11 x 10 10 x 10 11 x 10

9.0 9.0 12.0 12.0 14.0 12.0 14.0

20 20 20 20 20 20 20

14 14 14 14 12 14 12

105 117 126 128 145 145 147

* AFUE numbers are determined in accordance with DOE test procedures. Wire size and overcurrent protection must comply with the National Electrical Code (NFPA-70-latest edition).

For altitudes above 2,000 ft., reduce capacity 4% for each 1,000 ft. above sea level. Refer to Form 650.74-N1.1V. Wire size based on copper conductors, 60 C, 3% voltage drop. Continuous return air temperature must not be below 55 F.

Unitary Products Group

036-21086-002 Rev. A (5/00)

BLOWER PERFORMANCE - CFM - UPFLOW/HORIZONTAL (WITHOUT FILTER)

NOTE: Data below reflects air flows with single return opening, either left or right side or bottom.

MODELS: G8D--UH / L8D-UH*

SPEED TAP HIGH

EXTERNAL STATIC PRESSURE, INCHES W.C. 0.10 1580 1110 845 675 1675 1270 955 1970 1445 1245 2040 1725 1365 2400 2050 1690 0.20 1530 1100 840 665 1645 1260 950 1935 1435 1235 1975 1685 1355 2320 2025 1675 0.30 1470 1075 830 660 1595 1250 945 1900 1425 1225 1925 1650 1325 2275 1980 1660 0.40 1405 1060 815 645 1530 1240 935 1850 1415 1215 1855 1610 1290 2200 1930 1630 0.50 1330 1030 790 620 1465 1215 920 1795 1405 1205 1780 1555 1265 2115 1855 1610 0.60 1245 980 750 585 1385 1185 905 1735 1375 1190 1695 1500 1250 2025 1805 1560 0.70 1150 920 670 530 1280 1125 865 1660 1350 1170 1610 1425 1210 1930 1720 1500 0.80 1045 835 595 455 1155 1035 810 1590 1300 1135 1505 1340 1140 1825 1635 1430 1840 1635 1420 0.90 890 680 480 360 1025 910 685 1495 1240 1090 1380 1220 1045 1700 1530 1330 1725 1535 1340 1.00 650 520 320 255 810 695 510 1395 1160 995 1225 1075 940 1570 1400 1225 1600 1410 1235

60 / 48 / 1200 / "A" 80 / 64 / 1200 / "A"

MED-HIGH

MED-LOW LOW HIGH 100 / 80 / 1200 / "B" MED LOW 80 / 64 / 1600 / "B" HIGH MED LOW HIGH MED LOW 100 / 80 / 2000 / "C" 120 / 96 / 2000 / "C" HIGH MED LOW

120 / 96 / 1600 / "C"

NOTE: Data below reflects airflows with two return openings - two sides or one side and bottom. HIGH 2405 2340 2275 2210 2130 2050 1955 100 / 80 / 2000 / "C" MED 2005 1990 1965 1935 1880 1815 1725 120 / 96 / 2000 / "C" LOW 1655 1640 1625 1610 1585 1540 1485 * Input / Output / CFM / Cabinet Type (A = 14-1/2, B = 17-1/2, C = 21, D = 24-1/2) Airflow is expressed in standard cubic feet per minute Motor voltage at 115V Indicates LoNox models available

UPFLOW MODELS - ELECTRICAL WIRING

L 1 ( H OT ) N

W IR IN G IN SI D E J UN CT IO N B OX

: B LK /B LK W H I/W H I G RN /G RN

G R D

R N B LK G

W H I

J U NC T IO N B OX

B

U

R

N

E

R

C

O

M

P

A

R

T

M

E

N

T

D

OO

R

S

W

IT

C

H

T

RA

N

S

F

OR

M

E

R

H

UM

E

AC

X

FM

R

L

IN

E

C

IR

B L O W E R C O M P A R T M E N T

Unitary Products Group

C O O L

X FM R

H U M

P AR K

H E AT

P AR K

E AC

L IN E

IG NI T IO N M O DU L E

C Y

C L A S S 2 S Y S T E M C ON TR OL W IR IN G T O T H E R M OS T A T

036-21086-002 Rev. A (5/00)

FILTER PERFORMANCE

The airflow capacity data published in Blower Performance Table above, represents blower performance WITHOUT filters. To determine the approximate blower performance of the system, apply the filter drop value for the filter being used or select an appropriate value from the Table below.

NOTE: The filter pressure drop values in Blower PerformanceTables are typical values for the type of filter listed and should only be used as a guideline. Actual pressure drop ratings for each filter type vary between filter manufacturer.

FILTER PERFORMANCE - PRESSURE DROP INCHES W.C.

Minimum Opening Size Airflow Range (in.2) 1 Opening 0 - 750 751 - 1000 1001 - 1250 1251 - 1500 1501 - 1750 1751 - 2000 2001 & Above * 230 330 330 330 380 380 463 658 658 658 2 Openings Disposable 1 Opening 0.01 0.05 0.10 0.10 0.15 0.19 0.19 0.09 0.11 0.11 2 Openings Filter Type Hogs Hair* 1 Opening 0.01 0.05 0.10 0.10 0.14 0.18 0.18 0.08 0.10 0.10 2 Openings Pleated 1 Opening 0.15 0.20 0.20 0.25 0.30 0.30 0.30 0.17 0.17 0.17 2 Openings

Hogs Hair Filters are the type supplied with furnace (if supplied).

APPLYING FILTER PRESSURE DROP TO DETERMINE SYSTEM AIRFLOW

To determine the approximate airflow of the unit with a filter in place, follow the steps below: 1. 2. Select the filter type. Select the number of return air openings or calculate the return opening size in square inches to determine the proper filter pressure drop. Determine the External System Static Pressure (ESP) without the filter. Select a filter pressure drop from the table based upon the number of return air openings or return air opening size and add to the ESP from Step 3 to determine the total system static. If total system static matches a ESP value in the airflow table (i.e. 0.20, 0.60, etc,) the system airflow corresponds to the intersection of the ESP column and Model/ Blower Speed row. If the total system static falls between ESP values in the table (i.e. 0.58, 0.75, etc.), the static pressure may be rounded to the nearest value in the table determining the airflow using Step 5 or calculate the airflow by using the following example.

Example: For a 120,000 Btuh furnace with 2 return openings and operating on high speed blower, it is found that total system static is 0.58" w.c. To determine the system airflow, complete the following steps: 1. Obtain the airflow values at 0.50" & 0.60" ESP. Airflow @ 0.50": 2130 CFM Airflow @ 0.60": 2050 CFM 2. Subtract the airflow @ 0.50" from the airflow @ 0.60" to obtain airflow difference. 2050 - 2130 = -80 CFM 3. Subtract the total system static from 0.50" and divide this difference by the difference in ESP values in the table, 0.60" - 0.50", to obtain a percentage. (0.58 - 0.50) / (0.60 - 0.50) = 0.8 4. Multiply percentage by airflow difference to obtain airflow reduction. (0.8) x (-80) = -64 5. Subract airflow reduction value from airflow @ 0.50" to obtain actual airflow @ 0.58" ESP. 2130 - 64 = 2066

3. 4.

5.

6.

Unitary Products Group

036-21086-002 Rev. A (5/00)

UNIT CLEARANCES TO COMBUSTIBLES (ALL DIMENSIONS IN INCHES)

(All surfaces identified with the unit in an upflow configuration)

APPLICATION TOP FRONT REAR LEFT SIDE RIGHT SIDE FLUE FLOOR/ BOTTOM CLOSET ALCOVE ATTIC LINE CONTACT

UPFLOW / HORIZONTAL MODELS P*DU/ G8D-UH / L8D-UH

UPFLOW UPFLOW B-VENT HORIZONTAL HORIZONTAL B-VENT * 1 1 1 1 6 3 6 3 0 0 0 0 0 0 0 0 3 0 3 0 6 1 6 1 COMBUSTIBLE COMBUSTIBLE COMBUSTIBLE COMBUSTIBLE YES YES NO NO YES YES YES YES YES YES YES YES NO NO YES* YES*

Line contact only permitted between lines formed by the intersection of the rear panel and side panel (top in horizontal postion) of the furance jacket and building joists, studs or framing.

FILTER SIZE / ADD-ON COOLING

FILTER SIZE MODEL SIDE G8D06012UHA11 G8D08012UHA11 G8D08016UHB11 G8D10012UHB11 G8D10020UHC11 G8D12016UHC11 G8D12020UHC11 16 X 26 16 X 26 16 X 26 16 X 26 (2) 16 X 26 16 X 26 (2) 16 X 26 BOTTOM 14 X 26 14 X 26 16 X 26 16 X 26 20 X 26 20 X 26 20 X 26 TONS 1- 1/2, 2, 2-1/2, 3 1- 1/2, 2, 2-1/2, 3 3, 3- 1/2, 4 2, 2- 1/2, 3 3- 1/2, 4 ,5 3, 3- 1/2, 4 3- 1/2, 4 ,5 ADD-ON COOLING CFM @ .5 ESP* 1330 1330 1795 1465 2115 1780 2115

* ESP (External Static Pressure) .5 W.C. is at furnace outlet ahead of cooling coil, and includes filter. Includes LoNox models NOTE: High velocity filters provided.

Unitary Products Group

036-21086-002 Rev. A (5/00)

ACCESSORIES

Propane Conversion Kits 1NP0480 These accessory conversion kits may be used to convert natural gas units for propane (LP) operation. Conversions must be made by qualified distributor or dealer personnel. LoN ox m odels cannot be converted to propane (LP ) operation. High Altitude Pressure Switch Kits These accessory kits may be used to convert units for high altitude operation. Conversion must be made by qualified distributor or dealer personnel.

KIT APPLICATION MODELS G8D06012UHA11* G8D08012UHA11* 1PS0313 2000 - 10,000 FT G8D08016UHB11* G8D10012UHB11 G8D10020UHC11 1PS0314 * 2000 - 10,000 FT.

*

FIELD WIRING DIAGRAMS

SINGLE STAGE THERMOSTAT

S IN G L E S T A G E T H E R M O S T A T C O N N E C T I O N D I A G R A M T O A I R C O N D I T I O N E R R OO M F UR N A C E C ON D E N S I N G U N I T T HE R M O S T A T C ON T R O L 2 4 V C O M . ( I F R E Q ) B C F AN G G 4 V P O W E R R R H 2 R C C O O L IN G 1 Y Y L U E H E AT W 1 W 1 B W H IT E W 2

D E LA Y T IM ER

TWO STAGE THERMOSTAT

T WO S T A G E T H E R M O S TA T C O N NE C T I O N D I A G R A M T O A I R C O N D I T I O N E R R OO M F UR N A C E C ON D E N S I N G U N I T T HE R M O S T A T C ON T R O L 2 4 V C O M M O N B C F AN G G 4 V P O W E R R R H 2 R C C O O L IN G 1 Y Y B L U E H E A T ( L O W ) W W 1 1 W H IT E H E AT ( H IG H ) W 2* W 2 D E LA Y

R e mo v e w i re s ( bl ue & w hi t e ) fr o m ti me r *

T IM ER

G8D12016UHC11 G8D12020UHC11*

Includes LoNox models.

NOTES: For high altitude conversion, an orifice change may also be required. See Form 650.77-N1.1V for application information.

External Side Return Filter Rack - 1SR0302 (Upflow) Provides a 16 x 26 cleanable, high velocity type filter and attaches to the furnace side panel and the return air duct. The filter is easily replaced. Package contains six filter racks with filters. External Bottom Return Upflow Or Horizontal End Return Filter Rack Provides a cleanable, high velocity type filter and rack. Attaches to the end of the furnace and provides duct flanges. 1BR0314 - 14-1/2" "A"cabinet 1BR0317 - 17-1/2" "B" cabinet 1BR0321 - 21" "C" cabinet

Unitary Products Group

036-21086-002 Rev. A (5/00)

NOTES

Unitary Products Group

NOTES

Subject to change without notice. Printed in U.S.A. CD: 6-21014 Copyright by Unitary Products Group 2000. All rights reserved. Unitary Products Group 5005 York Drive

036-21086-002 Rev. A (5/00) Supersedes: 650.77-TG1U (1199) Norman OK 73069

Vous aimerez peut-être aussi

- 2-Stage Upflow/horizontal Mid-Efficiency Natural Gas Furnaces - (80%)Document8 pages2-Stage Upflow/horizontal Mid-Efficiency Natural Gas Furnaces - (80%)ardavan77Pas encore d'évaluation

- HIGH EFFICIENCY TUBULAR HEAT EXCHANGER SERIES MODELS: P DU / G8D-UH / L8D-UH (Two Stage Upflow / LoNOx)Document24 pagesHIGH EFFICIENCY TUBULAR HEAT EXCHANGER SERIES MODELS: P DU / G8D-UH / L8D-UH (Two Stage Upflow / LoNOx)ardavan77Pas encore d'évaluation

- 0G8D UHColorBrochure 0901Document4 pages0G8D UHColorBrochure 0901ardavan77Pas encore d'évaluation

- Deluxe Gas-Fired Furnaces Two Stage Mid-Efficiency Multi-Position (Upflow/horz.) Models: G8DDocument2 pagesDeluxe Gas-Fired Furnaces Two Stage Mid-Efficiency Multi-Position (Upflow/horz.) Models: G8Dardavan77Pas encore d'évaluation

- USER'S INFORMATION, MAINTENANCE AND SERVICE MANUAL MODELS: P DU / G8D-UH / L8D-UH (Two Stage Upflow / LoNOx)Document16 pagesUSER'S INFORMATION, MAINTENANCE AND SERVICE MANUAL MODELS: P DU / G8D-UH / L8D-UH (Two Stage Upflow / LoNOx)ardavan77Pas encore d'évaluation

- ProvfcstDocument16 pagesProvfcstardavan77Pas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (72)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Conector Tipo C PanduitDocument1 pageConector Tipo C PanduitBrandon SarriaPas encore d'évaluation

- Utkarsh India Limited - Best Swaged Pole Manufacturer in IndiaDocument8 pagesUtkarsh India Limited - Best Swaged Pole Manufacturer in IndiaUtkarsh India LTD.Pas encore d'évaluation

- Design Calculations For Bottom RaftDocument3 pagesDesign Calculations For Bottom RaftRahulPas encore d'évaluation

- PANORAMA Specifications Feb FINALDocument13 pagesPANORAMA Specifications Feb FINALagmibrahim5055Pas encore d'évaluation

- Bhatti ADocument19 pagesBhatti AanthraxpPas encore d'évaluation

- Series CNMJDocument6 pagesSeries CNMJThu Hiền NguyễnPas encore d'évaluation

- Tappi Tip 0402-18Document19 pagesTappi Tip 0402-18pedroPas encore d'évaluation

- Piping QuizDocument3 pagesPiping QuizAnji Reddy DPas encore d'évaluation

- Material Compliance-New DesignDocument6 pagesMaterial Compliance-New DesignvtalexPas encore d'évaluation

- Institutional Assessment Tools FBS NciiDocument16 pagesInstitutional Assessment Tools FBS NciiJohn Lester M. Dela Cruz100% (3)

- Mesh Tech Sheet PDFDocument1 pageMesh Tech Sheet PDFluisaPas encore d'évaluation

- Minimum Top Reinforcement RaftDocument10 pagesMinimum Top Reinforcement RaftHIREN DESAIPas encore d'évaluation

- Materials, Properties, and Processes in MetallurgyDocument3 pagesMaterials, Properties, and Processes in MetallurgyMicko AllaniguePas encore d'évaluation

- KP200Document4 pagesKP200DrGanesh Kame100% (1)

- PricesDocument16 pagesPricesMingVitugPas encore d'évaluation

- Eia On Multi - Storey Building Water SupplyDocument20 pagesEia On Multi - Storey Building Water SupplySANGEETHA A 18MEEE009Pas encore d'évaluation

- RC Desktop Toolkit v2Document27 pagesRC Desktop Toolkit v2pbharadwaj545Pas encore d'évaluation

- Types of DrawingsDocument25 pagesTypes of DrawingsRajesh Prabtani100% (1)

- Morin Catalog 2015 WebDocument24 pagesMorin Catalog 2015 WebBergadamusPas encore d'évaluation

- Courtyard Housing Issuu PDFDocument248 pagesCourtyard Housing Issuu PDFAnda Zota100% (10)

- Fatal Accidents in The Construction IndustryDocument21 pagesFatal Accidents in The Construction IndustryNikola LopacaninPas encore d'évaluation

- ch2 p2 PDFDocument31 pagesch2 p2 PDFYahya Abdulsalam0% (1)

- Barozzi Veiga Profile WebDocument42 pagesBarozzi Veiga Profile WebEduardo MartinPas encore d'évaluation

- Loader - Front and Back Assembly PDFDocument170 pagesLoader - Front and Back Assembly PDFChristian NkomayombiPas encore d'évaluation

- Rta Typical Service Utility Road Cross-Section (38.10m) : Arabian Ranches Iii Phase 2ADocument1 pageRta Typical Service Utility Road Cross-Section (38.10m) : Arabian Ranches Iii Phase 2Aanooppattazhy100% (2)

- Waste Foundry Sand in Concrete: International Research Journal of Engineering and Technology (IRJET)Document5 pagesWaste Foundry Sand in Concrete: International Research Journal of Engineering and Technology (IRJET)Janak RaazzPas encore d'évaluation

- Fire Standpipe System Basic Course BNBC & NFPADocument28 pagesFire Standpipe System Basic Course BNBC & NFPAMRZ100% (2)

- Design Proforma AmdDocument5 pagesDesign Proforma AmdsantkabirPas encore d'évaluation

- COMPANY Container Site OfficeDocument1 pageCOMPANY Container Site OfficeGrenda SatriaPas encore d'évaluation

- What We Learn With Pleasure We Never ForgetDocument5 pagesWhat We Learn With Pleasure We Never Forgetnik_nik_mailmePas encore d'évaluation