Académique Documents

Professionnel Documents

Culture Documents

Assembly & Lubrication Poster

Transféré par

anhntran4850Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Assembly & Lubrication Poster

Transféré par

anhntran4850Droits d'auteur :

Formats disponibles

2 1

5 4

7

B

C

6

3

D

5

5

Allen Keys -

For bearing and housing assembly.

Feeler Gauges -

To ensure correctly spaced joint gaps.

Flat Bladed Screwdriver -

For cage clip removal and cage separation.

Micrometer - To measure the shaft.

Soft Faced Hammer -

To ensure correct seating of components.

Torque Wrench -

To ensure correct torque on screws.

For mor e i nf or mat i on, vi si t www. Cooper Bear i ngs. com or cont act your near est Aut hor i sed Co oper Di st r i but or

Easy Assembly in 7 Easy Steps

A S S E M B L I N G A C O O P E R S P L I T R O L L E R B E A R I N G

Cooper Roller Bearings Company Limited, Wisbech Road, Kings Lynn, Norfolk PE30 5JX, England. Telephone: +44 (0) 1553 763 447. Fax: +44 (0) 1553 761 113

Offices and Representation Worldwide A Kaydon

Company

Expansion (EX) Bearing

Bearings with grooved inner race assemblies and plain

outer races for radial loads. To be fitted in EX

cartridges without side screws.

Special Expansion (EXILOG) Bearing

Bearing with plain inner race assemblies and grooved

outer races, must be fitted into GR cartridges with

side screws.

Fixed (GR) Bearing

Bearings with grooved inner race assemblies and

grooved outer races for radial and axial loads.

To be fitted in GR cartridges with side screws.

B e a r i n g Ty p e s

Comprehensive assembly procedures are shown in our Product

Catalogue and on the instructions included with all new bearings.

Full assembly information is also available from our website at

www.CooperBearings.com

1 Clean the shaft and check the diameter, roundness and parallelism.

2 Position the matched halves of the inner race on the shaft and

ensure there is a gap at the inner race joints.

3 Fit the clamping rings, making sure the joints are at 90 to the inner

race joints and tighten screws.

4 To ensure correct seating, tap down the clamping rings with a soft

faced hammer and re-tighten screws. Repeat until the bearing

parts are fully seated. Ensure there is a gap of equal amount at each

race joint.

5 Coat the roller cage and the inner race with grease and assemble

the cage around the inner race. Insert U clip where supplied, or

snap the two halves together if plate or pressed steel type cages.

6 Fit the outer race into the appropriate cartridge halves, noting the

lubrication hole is in the upper half outer race. Fit radial screws

(D) where appropriate and side screws (C) on GR (fixed) type

cartridges.

7 Install the seals having followed the appropriate recommendations

for the seal type as described in our full installation guide. Coat the

outer race and seals with grease. Close the cartridge and tighten

joint screws. Lubricate spherical seating as recommended.

B a s i c To o l s Re q u i r e d O v e r v i e w o f A s s e m b l y P r o c e d u r e

Vous aimerez peut-être aussi

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Why File A Ucc1Document10 pagesWhy File A Ucc1kbarn389100% (4)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- LM2TB8 2018 (Online)Document252 pagesLM2TB8 2018 (Online)SandhirPas encore d'évaluation

- Internet Bill FormatDocument1 pageInternet Bill FormatGopal Singh100% (1)

- Timken Ball Bearings CatalogDocument126 pagesTimken Ball Bearings Catalogmohananc67Pas encore d'évaluation

- Villamaria JR Vs CADocument2 pagesVillamaria JR Vs CAClarissa SawaliPas encore d'évaluation

- Q4 Music 6 Module 2Document15 pagesQ4 Music 6 Module 2Dan Paolo AlbintoPas encore d'évaluation

- Ni Hms 584775Document13 pagesNi Hms 584775anhntran4850Pas encore d'évaluation

- PageManager9 1Document1 pagePageManager9 1anhntran4850Pas encore d'évaluation

- JWST DTA Stepper Motor Anomaly and Lessons Learned-7!23!15Document8 pagesJWST DTA Stepper Motor Anomaly and Lessons Learned-7!23!15anhntran4850Pas encore d'évaluation

- JWST Brushless DC Motor Characteristics Analysis 2-5-2016Document13 pagesJWST Brushless DC Motor Characteristics Analysis 2-5-2016anhntran4850Pas encore d'évaluation

- Effects of Bearing Cleaning Peter WardDocument16 pagesEffects of Bearing Cleaning Peter Wardanhntran4850Pas encore d'évaluation

- 3-1-2 Guo Bearing Stiffness PDFDocument26 pages3-1-2 Guo Bearing Stiffness PDFanhntran4850Pas encore d'évaluation

- Space Station Control Moment Gyroscope Lessons LearnedDocument15 pagesSpace Station Control Moment Gyroscope Lessons Learnedanhntran4850Pas encore d'évaluation

- Stepper Motor KramerDocument46 pagesStepper Motor Krameranhntran4850Pas encore d'évaluation

- General Static Load Capacity in Slewing Bearings. Unified Theoretical Approach For Crossed Roller Bearings and Four Contact Point Angular Ball BearingsDocument7 pagesGeneral Static Load Capacity in Slewing Bearings. Unified Theoretical Approach For Crossed Roller Bearings and Four Contact Point Angular Ball Bearingsanhntran4850Pas encore d'évaluation

- Shock and Vibration Testing of An Amb Supported Energy Storage FlywheelDocument6 pagesShock and Vibration Testing of An Amb Supported Energy Storage Flywheelanhntran4850Pas encore d'évaluation

- BizCard XpressDocument1 pageBizCard Xpressanhntran4850Pas encore d'évaluation

- Friction and Wear of Titanium Alloys Sliding Against Metal, Polymer, and Ceramic CounterfacesDocument9 pagesFriction and Wear of Titanium Alloys Sliding Against Metal, Polymer, and Ceramic Counterfacesanhntran4850Pas encore d'évaluation

- Dry Friction Coefficient Versus Surface RoughnessDocument12 pagesDry Friction Coefficient Versus Surface Roughnessanhntran4850Pas encore d'évaluation

- Ancra 1500 Lbs 425 Ksi 430ksi 52100 AllowableDocument10 pagesAncra 1500 Lbs 425 Ksi 430ksi 52100 Allowableanhntran4850Pas encore d'évaluation

- 1) Import The Stress Model Into TAS. Save The Model As A TAS ModelDocument4 pages1) Import The Stress Model Into TAS. Save The Model As A TAS Modelanhntran4850Pas encore d'évaluation

- PageManager9 1Document1 pagePageManager9 1anhntran4850Pas encore d'évaluation

- Document Management and Filing SolutionDocument1 pageDocument Management and Filing Solutionanhntran4850Pas encore d'évaluation

- DxDiag Copy MSIDocument45 pagesDxDiag Copy MSITạ Anh TuấnPas encore d'évaluation

- Lesson: The Averys Have Been Living in New York Since The Late NinetiesDocument1 pageLesson: The Averys Have Been Living in New York Since The Late NinetiesLinea SKDPas encore d'évaluation

- Optimal Dispatch of Generation: Prepared To Dr. Emaad SedeekDocument7 pagesOptimal Dispatch of Generation: Prepared To Dr. Emaad SedeekAhmedRaafatPas encore d'évaluation

- Powerwin EngDocument24 pagesPowerwin Engbillwillis66Pas encore d'évaluation

- Timetable - Alton - London Timetable May 2019 PDFDocument35 pagesTimetable - Alton - London Timetable May 2019 PDFNicholas TuanPas encore d'évaluation

- Asus Test ReportDocument4 pagesAsus Test ReportFerry RiantoPas encore d'évaluation

- Docsity Detailed Lesson Plan 5Document4 pagesDocsity Detailed Lesson Plan 5Sydie MoredoPas encore d'évaluation

- UntitledDocument13 pagesUntitledTestPas encore d'évaluation

- 0 BA Design ENDocument12 pages0 BA Design ENFilho AiltonPas encore d'évaluation

- Lista de Precios Agosto 2022Document9 pagesLista de Precios Agosto 2022RuvigleidysDeLosSantosPas encore d'évaluation

- QuinnmcfeetersresumeDocument1 pageQuinnmcfeetersresumeapi-510833585Pas encore d'évaluation

- The Grass Rink Summer Final 2019Document9 pagesThe Grass Rink Summer Final 2019api-241553699Pas encore d'évaluation

- Engine Controls (Powertrain Management) - ALLDATA RepairDocument3 pagesEngine Controls (Powertrain Management) - ALLDATA RepairRonald FerminPas encore d'évaluation

- Britannia Volume 12 Issue 1981 (Doi 10.2307/526240) Michael P. Speidel - Princeps As A Title For 'Ad Hoc' CommandersDocument8 pagesBritannia Volume 12 Issue 1981 (Doi 10.2307/526240) Michael P. Speidel - Princeps As A Title For 'Ad Hoc' CommandersSteftyraPas encore d'évaluation

- Holiday AssignmentDocument18 pagesHoliday AssignmentAadhitya PranavPas encore d'évaluation

- Getting Returning Vets Back On Their Feet: Ggoopp EennddggaammeeDocument28 pagesGetting Returning Vets Back On Their Feet: Ggoopp EennddggaammeeSan Mateo Daily JournalPas encore d'évaluation

- Geometry and IntuitionDocument9 pagesGeometry and IntuitionHollyPas encore d'évaluation

- Japanese GardensDocument22 pagesJapanese GardensAnmol ChughPas encore d'évaluation

- Liquid Chlorine SdsDocument7 pagesLiquid Chlorine SdsIPKL RS BHAYANGKARA KEDIRIPas encore d'évaluation

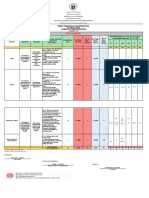

- Revised Final Quarter 1 Tos-Rbt-Sy-2022-2023 Tle-Cookery 10Document6 pagesRevised Final Quarter 1 Tos-Rbt-Sy-2022-2023 Tle-Cookery 10May Ann GuintoPas encore d'évaluation

- Discrete Mathematics and Its Applications: Basic Structures: Sets, Functions, Sequences, and SumsDocument61 pagesDiscrete Mathematics and Its Applications: Basic Structures: Sets, Functions, Sequences, and SumsBijori khanPas encore d'évaluation

- Public Access - The GauntletDocument1 pagePublic Access - The GauntletTesting0% (2)

- How To Present A Paper at An Academic Conference: Steve WallaceDocument122 pagesHow To Present A Paper at An Academic Conference: Steve WallaceJessicaAF2009gmtPas encore d'évaluation

- 1996 OKI LCD Driver Controller DatabookDocument232 pages1996 OKI LCD Driver Controller Databookpiptendo100% (1)

- Financial Accounting 1: Chapter 5 Cash and Short Term InvestmentDocument31 pagesFinancial Accounting 1: Chapter 5 Cash and Short Term InvestmentCabdiraxmaan GeeldoonPas encore d'évaluation