Académique Documents

Professionnel Documents

Culture Documents

Fixed Bolted Joint

Transféré par

ngocDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Fixed Bolted Joint

Transféré par

ngocDroits d'auteur :

Formats disponibles

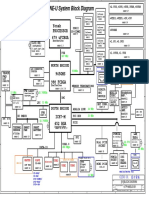

PROJECT : PAGE :

CLIENT : DESIGN BY :

JOB NO. : DATE : REVIEW BY :

DESIGN CRITERIA

THE FIXED MOMENT CONNECTION HAS BEEN CHECKED BY PREQUALIFIED

CONNECTION 8ES FOR CAPACITY AND DEFORMATION. BECAUSE THIS IS

NON-SEISMIC CONNECTION , THE BEAM & COLUMN SECTION LIMITS AND

BEAM-COLUMN RATIO REQUIREMENT HAVE BEEN RELEASED. THE BENDING

MOMENT AT THE BEAM BOTTOM FACE IS FROM ACTUAL COLUMN END

FORCE, NOT FROM THE COLUMN SECTION CAPACITY.

INPUT DATA & DESIGN SUMMARY

BENDING MOMENT AT THE JOINT FACE M

f

= 1086.8 ft-kips, SD level

STRUCTURAL STEEL YIELD STRESS F

y

= 50 ksi

THE FACTOR AXIAL LOAD ON THE COLUMN P

u

= 800 kips

THE FACTOR SHEAR LOAD AT THE JOINT FACE V

u

= 76.5 kips

BEAM LENGTH BETWEEN COL. CENTERS L = 38.73 ft

AVERAGE STORY HEIGHT OF ABOVE & BELOW h = 15 ft

BOLTS f = 1 7/8 in

GRADES (A325 or A490) A490

PLATE & SHIM t

p

= 1 1/2 in

NUMBER COLUMN N

c

= 1 (Bottom Only)

NUMBER BEAM N

b

= 1 (One Side Only)

COLUMN SECTION = > W18X158

A d t

w

b

f

t

f

S

x

I

x

r

x

r

y

Z

x

k

46.3 19.7 0.81 11.30 1.44 310 3060 8.13 2.74 356 1.84

BEAM SECTION = > W24X162

A d t

w

b

f

t

f

S

x

I

x

r

x

r

y

Z

x

k

47.7 25.0 0.71 13.00 1.22 414 5170 10.41 3.05 468 1.72

THE DESIGN IS ADEQUATE.

ANALYSIS

g =Max( b

bf

- f , t

w

+ 3 f ) = 6.00 in c = 2 P

f

+ t

bf

= 5.44 in P

b

= 3 f = 5.63 in,

P

f

= 1.5 f = 2.00 in (AISC 358 Tab 6.1) b

p

= g + 3 f = 11.63 in P

c

= 3.36 in,

S

h

= d

c

/ 2 + t

p

+ 1" + (2P

f

+ P

b

- 1") tan

-1

30

o

= 29.94 in < b

cf

[Satisfactory] d

e

= 4.18 in

CHECK BEAM LOCAL BUCKLING LIMITATIONS (AISC 341-10 Tab. D1.1)

b

f

/ (2t

f

) = 5.33 < 0.3 (E

s

/ F

y

)

0.5

= 7.22 [Satisfactory]

Where E

s

= 29000 ksi

h / t

w

= 30.58 < 2.45 (E

s

/ F

y

)

0.5

= 59.00 [Satisfactory]

CHECK COLUMN LOCAL BUCKING LIMITATIONS (AISC 341-10 Tab. D1.1)

b

f

/ (2t

f

) = 3.92 < 0.3 (E

s

/ F

y

)

0.5

= 7.22 [Satisfactory]

3.76(E

s

/F

y

)

0.5

(1-2.75P

u

/f

b

P

y

) = N/A , for P

u

/f

b

P

y

0.125

1.12(E

s

/F

y

)

0.5

(2.33-P

u

/f

b

P

y

) = 52.49 , for P

u

/f

b

P

y

> 0.125

[Satisfactory] Where f

b

= 0.9 , P

y

= F

y

A = 2315 kips

CHECK BEAM - COLUMN RATIO REQUIREMENT (AISC 341-10 Sec. E3.4a)

SM

pc

* / (SM

pb

* ) = 0.50 < 1.00 [Non-seismic, Not Apply]

Where SM

pc

* = N

c

Z

c

(F

yc

- P

u

/ A

g

) = 971 ft-kips

SM

pb

* = N

b

Z

b

F

yb

= 1950 ft-kips

CHECK BENDING MOMENT AT THE JOINT FACE (FEMA Sec. 3.6.1.1.2 & AISC 360-10 J3)

M

f

, input value for non-seismic = 1087 ft-kips

< 3.4 T

ub

(d

0

+ d

i

) = 1457 ft-kips [Satisfactory]

< f 8 T

b

d

c

= 1458 ft-kips [Satisfactory]

Where d

0

= d

c

+ P

f

- 0.5 t

cf

= 20.98 in T

b

= 148 kips, (AISC 360-10, Tab. J3.1)

d

i

= d

0

- c - P

b

= 9.92 in A

bt

= 1.47

in

2

/ bolt

F

fu

= M

f

/ ( d

c

- t

cf

) = 714.18 kips

f =

0.75 , (AISC 360-10, J3.6)

T

ub

= 166.4 kips, (FEMA Sec. 3.6.1.1 & 3.6.2.1.2)

> (0.00002305 P

f

0.591

F

fu

2.583

/ (t

p

0.895

d

bt

1.909

t

cw

0.327

b

p

0.965

) + T

b

= 165.2 kips

[Satisfactory]

CHECK SHEAR CAPACITY AT THE JOINT FACE (FEMA Sec. 3.6.1.1.3& AISC 360-10 J3)

A

b

= 1.47

in

2

> [2 M

f

/ (H - d

b

) + V

u

] / 6F

v

= 0.91 [Satisfactory]

Where F

v

= f F

nv

= 45 ksi, (AISC 360-10, Tab. J3.2)

Fixed 8-Bolted Joint, with Beam Sitting on Top of Column, Based on AISC 358-10 8ES & FEMA-350

(Continuity column stiffeners 1-1/2 x 12 with 7/16" fillet weld to web & CP to flanges. A doubler plate is not required. 4 rows @ equal o.c. between flanges. )

h / t

w

= 19.78 <

(Cont'd)

CHECK END PLATE THICKNESS (AISC 358-10 Eq 6.10-13)

t

p

= 1.50

in

> [1.11 M

f

/ f

d

F

yp

Y

p

)]

0.5

= 1.17

in

[Satisfactory]

Where Y

p

= 293 in, (AISC 358-10 Tab. 6.4 Case 1)

F

yp

= 36 ksi f

d

= 1.0

CHECK CONTINUITY PLATE REQUIREMENT (AISC 358-10 Eq 6.10-13, FEMA Sec 3.3.3.1)

t

bf, reqD

= [1.11 M

f

/ f

d

F

yb

Y

b

)]

0.5

= 0.38 in < t

bf, actual

Where Y

b

= 1990 in, (AISC 358-10 Tab. 6.5 Stiffened)

t

bw, reqD

= M

f

/ [( d

c

- t

cf

)( 6 k

b

+ 2 t

p

+ t

cf

) F

yb

] = 0.97 in > t

bw, actual

(The continuity plates required.)

t

st

= t

cf

for interior connection, or (t

cf

/2) for exterior connection = 1.44 in, USE 1.50 in, ( 1-1/2 in )

b

st

= 12 in < 0.56 (E / F

yst

)

0.5

t

st

= 23.84 in, (AISC 358-10 Eq 6.10-10)

[Satisfactory]

f

c

P

n,st

= f

c

F

cr

A

= 1568.7 kips

Where f

c

= 0.9 ,(AISC 360 E1) h

st

= d

c

- 2k

c

= 16.02 in

K = 0.75 K h

st

/ r

st

< 200 (AISC 360 E2) [Satisfactory]

I = t

st

(2b

st

+ t

wb

)

3

/ 12 = 1885

in

4

F

e

= 77168 ksi (AISC 360 E3)

A = 2b

st

t

st

+ 25(t

wb

)

2

= 48

in

2

F

cr

= 35.99 ksi (AISC 360 E3)

r

st

= ( I / A )

0.5

= 6.24 in F

yst

= 36 kips, plate yield stress

P

u,st

= R

yc

F

yc

b

fc

t

fc

= 895.0 kips < f

c

P

n,st

[Satisfactory]

Where R

y

= 1.1 (AISC 341-10 Tab. A3.1)

The best fillet weld size (AISC 360 Sec.J2.2b)

> w

MIN

= 0.25 in

< w

MAX

= 0.5625 in

[Satisfactory]

The required weld length between A36 continuity plates and column web (FEMA Fig 3-6)

L

w

= 0.6t

st

L

nst

F

y

/ [(2) f F

w

(0.707 w)] = (1.5 x 18.6) x 36 / [(2) 0.75 (0.6x70)(0.707x7/16)] = 23.50 in

Where L

net

= d

b

- 2(k

b

+ 1.5) = 18.6 < 2(L

net

-0.5) [Satisfactory]

(Use complete joint penetration groove welds between continuity plates & column flanges.)

CHECK PANEL ZONE THICKNESS REQUIREMENT (AISC 341 Sec. E3.6e & FEMA Sec. 3.3.3.2)

t

ReqD

= MAX (t

1

, t

2

) = 0.61 in

0.61 in

Where C

y

= S

b

/ (C

pr

Z

hing

) = 0.79

S

c

= 2I

c

/ d

c

= 311

in

2

I

c

= I

x

= 3060

in

4

M

b

= SM

pc

* = 971 ft-kips

C

pr

= 1.1 (FEMA Sec. 3.5.5.1)

t

2

= (d

z

+ w

z

) / 90 = (d

c

-2t

st

+ d

b

- 2k

b

) / 90 = 0.43 in

Since t

wb

= 0.71 in

> t

ReqD

, a doubler plate is

not required.

Technical References:

1. AISC 341-10: "Seismic Provisions for Structural Steel Buildings", American Institute of Steel Construction, 2010.

2. AISC 358-10: "Prequalified Connections for Special and Intermediate Steel Moment Frames for Seismic Applications",

American Institute of Steel Construction, 2010.

3. AISC 360-10: "Specification for Structural Steel Buildings", American Institute of Steel Construction, 2010.

4. FEMA 350: "Recommended Seismic Design Criteria for New Steel Moment-frame Buildings.", SAC Joint Venture, 2000.

w = 7/16 in

t

1

= C

y

M

b

(h - d

c

) / [0.9 (0.6) F

yb

R

yb

d

b

(d

c

- t

fc

) h] =

PROJECT : PAGE :

CLIENT : DESIGN BY :

JOB NO. : DATE : REVIEW BY :

DESIGN CRITERIA

THE FIXED MOMENT CONNECTION HAS BEEN CHECKED BY PREQUALIFIED

CONNECTION 4ES FOR CAPACITY AND DEFORMATION. BECAUSE THIS IS

NON-SEISMIC CONNECTION , THE BEAM & COLUMN SECTION LIMITS AND

BEAM-COLUMN RATIO REQUIREMENT HAVE BEEN RELEASED. THE BENDING

MOMENT AT THE BEAM BOTTOM FACE IS FROM ACTUAL COLUMN END

FORCE, NOT FROM THE COLUMN SECTION CAPACITY.

INPUT DATA & DESIGN SUMMARY

BENDING MOMENT AT THE JOINT FACE M

f

= 285 ft-kips, SD level

STRUCTURAL STEEL YIELD STRESS F

y

= 50 ksi

THE FACTOR AXIAL LOAD ON THE COLUMN P

u

= 800 kips

THE FACTOR SHEAR LOAD AT THE JOINT FACE V

u

= 76.5 kips

BEAM LENGTH BETWEEN COL. CENTERS L = 38.73 ft

AVERAGE STORY HEIGHT OF ABOVE & BELOW h = 15 ft

BOLTS f = 1 3/4 in

GRADES (A325 or A490) A490

PLATE & SHIM t

p

= 2 1/4 in

NUMBER COLUMN N

c

= 1 (Bottom Only)

NUMBER BEAM N

b

= 1 (One Side Only)

COLUMN SECTION = > W18X158

A d t

w

b

f

t

f

S

x

I

x

r

x

r

y

Z

x

k

46.3 19.7 0.81 11.30 1.44 310 3060 8.13 2.74 356 1.84

BEAM SECTION = > W24X162

A d t

w

b

f

t

f

S

x

I

x

r

x

r

y

Z

x

k

47.7 25.0 0.71 13.00 1.22 414 5170 10.41 3.05 468 1.72

THE DESIGN IS ADEQUATE.

ANALYSIS

g =Max( b

bf

- f , t

w

+ 3 f ) = 6.00 in c = 2 P

f

+ t

bf

= 5.44 in d

e

= 4.11 in

P

f

= 1.5 f = 2.00 in (AISC 358 Tab 6.1) b

p

= g + 3 f = 11.25 in

S

h

= d

c

/ 2 + t

p

+ 1" + (2P

f

- 1") tan

-1

30

o

= 20.95 in < b

cf

[Satisfactory]

CHECK BEAM LOCAL BUCKLING LIMITATIONS (AISC 341-10 Tab. D1.1)

b

f

/ (2t

f

) = 5.33 < 0.3 (E

s

/ F

y

)

0.5

= 7.22 [Satisfactory]

Where E

s

= 29000 ksi

h / t

w

= 30.58 < 2.45 (E

s

/ F

y

)

0.5

= 59.00 [Satisfactory]

CHECK COLUMN LOCAL BUCKING LIMITATIONS (AISC 341-10 Tab. D1.1)

b

f

/ (2t

f

) = 3.92 < 0.3 (E

s

/ F

y

)

0.5

= 7.22 [Satisfactory]

3.76(E

s

/F

y

)

0.5

(1-2.75P

u

/f

b

P

y

) = N/A , for P

u

/f

b

P

y

0.125

1.12(E

s

/F

y

)

0.5

(2.33-P

u

/f

b

P

y

) = 52.49 , for P

u

/f

b

P

y

> 0.125

[Satisfactory] Where f

b

= 0.9 , P

y

= F

y

A = 2315 kips

CHECK BEAM - COLUMN RATIO REQUIREMENT (AISC 341-10 Sec. E3.4a)

SM

pc

* / (SM

pb

* ) = 0.50 < 1.00 [Non-seismic, Not Apply]

Where SM

pc

* = N

c

Z

c

(F

yc

- P

u

/ A

g

) = 971 ft-kips

SM

pb

* = N

b

Z

b

F

yb

= 1950 ft-kips

CHECK BENDING MOMENT AT THE JOINT FACE (FEMA Sec. 3.6.1.1.2 & AISC 360-10 J3)

M

f

, input value for non-seismic = 285 ft-kips

< 2 T

ub

(d

0

+ d

i

) = 945 ft-kips [Satisfactory]

< f 4 T

b

d

c

= 729 ft-kips [Satisfactory]

Where d

0

= d

c

+ P

f

- 0.5 t

cf

= 20.98 in T

b

= 148 kips, (AISC 360-10, Tab. J3.1)

d

i

= d

0

- c = 15.54 in A

bt

= 1.37

in

2

/ bolt

F

fu

= M

f

/ ( d

c

- t

cf

) = 187.29 kips

f =

0.75 , (AISC 360-10, J3.6)

T

ub

= 155.3 kips, (FEMA Sec. 3.6.1.1 & 3.6.2.1.2)

> (0.00002305 P

f

0.591

F

fu

2.583

/ (t

p

0.895

d

bt

1.909

t

cw

0.327

b

p

0.965

) + T

b

= 148.4 kips

[Satisfactory]

CHECK SHEAR CAPACITY AT THE JOINT FACE (FEMA Sec. 3.6.1.1.3& AISC 360-10 J3)

A

b

= 1.37

in

2

> [2 M

f

/ (H - d

b

) + V

u

] / 3F

v

= 0.89 [Satisfactory]

Where F

v

= f F

nv

= 45 ksi, (AISC 360-10, Tab. J3.2)

Fixed 4-Bolted Joint, with Beam Sitting on Top of Column, Based on AISC 358-10 4ES & FEMA-350

(Continuity column stiffeners 1-1/2 x 12 with 7/16" fillet weld to web & CP to flanges. A doubler plate is not required. )

19.78 < h / t

w

=

(Cont'd)

CHECK END PLATE THICKNESS (AISC 358-10 Eq 6.10-13)

t

p

= 2.25

in

> [1.11 M

f

/ f

d

F

yp

Y

p

)]

0.5

= 0.26

in

[Satisfactory]

Where Y

p

= 1506 in, (AISC 358-10 Tab. 6.3 Case 1)

F

yp

= 36 ksi f

d

= 1.0

CHECK CONTINUITY PLATE REQUIREMENT (AISC 358-10 Eq 6.10-13, FEMA Sec 3.3.3.1)

t

bf, reqD

= [1.11 M

f

/ f

d

F

yb

Y

b

)]

0.5

= 0.20 in < t

bf, actual

Where Y

b

= 1990 in, (AISC 358-10 Tab. 6.5 Stiffened)

t

bw, reqD

= M

f

/ [( d

c

- t

cf

)( 6 k

b

+ 2 t

p

+ t

cf

) F

yb

] = 0.23 in < t

bw, actual

(The continuity plates may not be required.)

t

st

= t

cf

for interior connection, or (t

cf

/2) for exterior connection = 1.44 in, USE 1.50 in, ( 1-1/2 in )

b

st

= 12 in < 0.56 (E / F

yst

)

0.5

t

st

= 23.84 in, (AISC 358-10 Eq 6.10-10)

[Satisfactory]

f

c

P

n,st

= f

c

F

cr

A

= 1568.7 kips

Where f

c

= 0.9 ,(AISC 360 E1) h

st

= d

c

- 2k

c

= 16.02 in

K = 0.75 K h

st

/ r

st

< 200 (AISC 360 E2) [Satisfactory]

I = t

st

(2b

st

+ t

wb

)

3

/ 12 = 1885

in

4

F

e

= 77168 ksi (AISC 360 E3)

A = 2b

st

t

st

+ 25(t

wb

)

2

= 48

in

2

F

cr

= 35.99 ksi (AISC 360 E3)

r

st

= ( I / A )

0.5

= 6.24 in F

yst

= 36 kips, plate yield stress

P

u,st

= R

yc

F

yc

b

fc

t

fc

= 895.0 kips < f

c

P

n,st

[Satisfactory]

Where R

y

= 1.1 (AISC 341-10 Tab. A3.1)

The best fillet weld size (AISC 360 Sec.J2.2b)

> w

MIN

= 0.25 in

< w

MAX

= 0.5625 in

[Satisfactory]

The required weld length between A36 continuity plates and column web (FEMA Fig 3-6)

L

w

= 0.6t

st

L

nst

F

y

/ [(2) f F

w

(0.707 w)] = (1.5 x 18.6) x 36 / [(2) 0.75 (0.6x70)(0.707x7/16)] = 23.50 in

Where L

net

= d

b

- 2(k

b

+ 1.5) = 18.6 < 2(L

net

-0.5) [Satisfactory]

(Use complete joint penetration groove welds between continuity plates & column flanges.)

CHECK PANEL ZONE THICKNESS REQUIREMENT (AISC 341 Sec. E3.6e & FEMA Sec. 3.3.3.2)

t

ReqD

= MAX (t

1

, t

2

) = 0.61 in

0.61 in

Where C

y

= S

b

/ (C

pr

Z

hing

) = 0.79

S

c

= 2I

c

/ d

c

= 311

in

2

I

c

= I

x

= 3060

in

4

M

b

= SM

pc

* = 971 ft-kips

C

pr

= 1.1 (FEMA Sec. 3.5.5.1)

t

2

= (d

z

+ w

z

) / 90 = (d

c

-2t

st

+ d

b

- 2k

b

) / 90 = 0.43 in

Since t

wb

= 0.71 in

> t

ReqD

, a doubler plate is

not required.

Technical References:

1. AISC 341-10: "Seismic Provisions for Structural Steel Buildings", American Institute of Steel Construction, 2010.

2. AISC 358-10: "Prequalified Connections for Special and Intermediate Steel Moment Frames for Seismic Applications",

American Institute of Steel Construction, 2010.

3. AISC 360-10: "Specification for Structural Steel Buildings", American Institute of Steel Construction, 2010.

4. FEMA 350: "Recommended Seismic Design Criteria for New Steel Moment-frame Buildings.", SAC Joint Venture, 2000.

t

1

= C

y

M

b

(h - d

c

) / [0.9 (0.6) F

yb

R

yb

d

b

(d

c

- t

fc

) h] =

w = 7/16 in

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Design of Bolted Beam Splice Connections According To EC3Document11 pagesDesign of Bolted Beam Splice Connections According To EC3Franklyn Genove100% (2)

- En 12604 (2000) (E)Document7 pagesEn 12604 (2000) (E)Carlos LanzillottoPas encore d'évaluation

- Write A Report For A University Lecturer Describing The Information in The Table BelowDocument2 pagesWrite A Report For A University Lecturer Describing The Information in The Table BelowngocPas encore d'évaluation

- Write A Report For A University Lecturer Describing The Information Belo4Document1 pageWrite A Report For A University Lecturer Describing The Information Belo4ngocPas encore d'évaluation

- Write A Report For A University Lecturer Describing The Information in The Graph BelowDocument1 pageWrite A Report For A University Lecturer Describing The Information in The Graph Belowngoc100% (1)

- Write A Report For A University Lecturer Describing The Information in The Two Graphs BelowDocument2 pagesWrite A Report For A University Lecturer Describing The Information in The Two Graphs BelowngocPas encore d'évaluation

- Write A Report For A University Lecturer Describing The Information BelowDocument2 pagesWrite A Report For A University Lecturer Describing The Information BelowngocPas encore d'évaluation

- The Table Below Shows The Consumer DurablesDocument1 pageThe Table Below Shows The Consumer DurablesngocPas encore d'évaluation

- Write A Report For A University Lecturer Describing The Information in The Graphs BelowDocument2 pagesWrite A Report For A University Lecturer Describing The Information in The Graphs BelowngocPas encore d'évaluation

- The Graph Shows Underground Station Passenger Numbers in LondonDocument1 pageThe Graph Shows Underground Station Passenger Numbers in LondonngocPas encore d'évaluation

- Write A Report Describing The Information in The Graph Belo1Document2 pagesWrite A Report Describing The Information in The Graph Belo1ngocPas encore d'évaluation

- The Graph Shows Internet Usage in Taiwan by Age GroupDocument2 pagesThe Graph Shows Internet Usage in Taiwan by Age GroupngocPas encore d'évaluation

- The Graphs Below Show The Types of Music Albums Purchased by People in Britain According To s3x and AgeDocument2 pagesThe Graphs Below Show The Types of Music Albums Purchased by People in Britain According To s3x and AgengocPas encore d'évaluation

- The Graph Below Shows The Different Modes of Transport Used To Travel To and From Work in One European City in 1960Document2 pagesThe Graph Below Shows The Different Modes of Transport Used To Travel To and From Work in One European City in 1960ngocPas encore d'évaluation

- Write A Report For A University Lecturer Describing The Information Belo2Document2 pagesWrite A Report For A University Lecturer Describing The Information Belo2ngocPas encore d'évaluation

- The Line Graph Below Gives Information On Cinema Attendance in The UKDocument1 pageThe Line Graph Below Gives Information On Cinema Attendance in The UKngocPas encore d'évaluation

- The Line Graph Below Shows The Number of Annual Visits To Australia by Overseas ResidentsDocument2 pagesThe Line Graph Below Shows The Number of Annual Visits To Australia by Overseas ResidentsngocPas encore d'évaluation

- Write A Report Describing The Information in The Graph BelowDocument2 pagesWrite A Report Describing The Information in The Graph BelowngocPas encore d'évaluation

- The Table Below Shows The Figures For Imprisonment in Five Countries Between 1930 and 1980Document1 pageThe Table Below Shows The Figures For Imprisonment in Five Countries Between 1930 and 1980ngocPas encore d'évaluation

- Write A Report For A University Lecturer Describing The Information Belo1Document1 pageWrite A Report For A University Lecturer Describing The Information Belo1ngocPas encore d'évaluation

- The Diagram Below Shows The Average Hours of Unpaid Work Per Week Done by People in Different CategoriesDocument2 pagesThe Diagram Below Shows The Average Hours of Unpaid Work Per Week Done by People in Different CategoriesngocPas encore d'évaluation

- The Graph Shows Estimated Oil Production Capacity For Several Gulf Countries Between 1990 and 2010Document1 pageThe Graph Shows Estimated Oil Production Capacity For Several Gulf Countries Between 1990 and 2010ngocPas encore d'évaluation

- He Chart Below Gives Information About Global Sales of Games SoftwareDocument1 pageHe Chart Below Gives Information About Global Sales of Games SoftwarengocPas encore d'évaluation

- Bai 5 - Dam Truc GiaoDocument4 pagesBai 5 - Dam Truc GiaongocPas encore d'évaluation

- The Graph Above Show Information of Employment Rates Across 6 Countries in 1995 and 2005Document2 pagesThe Graph Above Show Information of Employment Rates Across 6 Countries in 1995 and 2005ngocPas encore d'évaluation

- The Graphs Show Enrolment in Different Colleges in The Higher Colleges of Technology in 1999Document2 pagesThe Graphs Show Enrolment in Different Colleges in The Higher Colleges of Technology in 1999ngocPas encore d'évaluation

- The Table Below Shows Social and Economic Indicators For Four Countries in 1994Document1 pageThe Table Below Shows Social and Economic Indicators For Four Countries in 1994ngocPas encore d'évaluation

- The Chart Below Shows Estimated World Literacy Rates by Region and by Gender For The Year 2000Document2 pagesThe Chart Below Shows Estimated World Literacy Rates by Region and by Gender For The Year 2000ngocPas encore d'évaluation

- The Chart Below Shows The Sleep Patterns of People in Five Different Occupations According To A Canadian StudyDocument2 pagesThe Chart Below Shows The Sleep Patterns of People in Five Different Occupations According To A Canadian StudyngocPas encore d'évaluation

- Bai 4 - KH - PH BETONG+THEPDocument6 pagesBai 4 - KH - PH BETONG+THEPngocPas encore d'évaluation

- In June 1996Document2 pagesIn June 1996ngocPas encore d'évaluation

- Problem 1-4Document6 pagesProblem 1-4Anonymous xIzzEifjPPas encore d'évaluation

- Adequate Bearing Material and Heat TreatmentDocument20 pagesAdequate Bearing Material and Heat TreatmentdavidePas encore d'évaluation

- V1 V2 Cal PRCDocument5 pagesV1 V2 Cal PRCCyril J PadiyathPas encore d'évaluation

- Renovation Modernization and Uprating of Hydro Power StationsDocument5 pagesRenovation Modernization and Uprating of Hydro Power StationsAbhijeet SinghPas encore d'évaluation

- Draft ITP Pipeline Recertification Pearl OILDocument3 pagesDraft ITP Pipeline Recertification Pearl OILIrsyad RosyidiPas encore d'évaluation

- Clevo M620ne-UDocument34 pagesClevo M620ne-UHh woo't hoofPas encore d'évaluation

- Programmable Safety Systems PSS-Range: Service Tool PSS SW QLD, From Version 4.2 Operating Manual Item No. 19 461Document18 pagesProgrammable Safety Systems PSS-Range: Service Tool PSS SW QLD, From Version 4.2 Operating Manual Item No. 19 461MAICK_ITSPas encore d'évaluation

- Electrical Panel Data MSC PG: NO Panel Desc Panel CodeDocument6 pagesElectrical Panel Data MSC PG: NO Panel Desc Panel CodeAjeng AyuPas encore d'évaluation

- SAP Hybris Thinking Outside The Box. PART 1Document18 pagesSAP Hybris Thinking Outside The Box. PART 1Rauf AlievPas encore d'évaluation

- Activa NewDocument160 pagesActiva NewSiddharth Jain100% (1)

- SAP IdMDocument34 pagesSAP IdMshabab_14Pas encore d'évaluation

- Fundamentals of Fluid Mechanics (5th Edition) - Munson, OkiishiDocument818 pagesFundamentals of Fluid Mechanics (5th Edition) - Munson, OkiishiMohit Verma85% (20)

- Department of Education: Republic of The PhilippinesDocument14 pagesDepartment of Education: Republic of The PhilippinesRich TactaconPas encore d'évaluation

- Cinegy User ManualDocument253 pagesCinegy User ManualNizamuddin KaziPas encore d'évaluation

- En Privacy The Best Reseller SMM Panel, Cheap SEO and PR - MRPOPULARDocument4 pagesEn Privacy The Best Reseller SMM Panel, Cheap SEO and PR - MRPOPULARZhenyuan LiPas encore d'évaluation

- NAWTEC18-3507: Comparison of Acid Gas Control Technologies in Efw FacilitiesDocument10 pagesNAWTEC18-3507: Comparison of Acid Gas Control Technologies in Efw FacilitiesPunki KokoPas encore d'évaluation

- METCALDocument28 pagesMETCALa1006aPas encore d'évaluation

- Analysis of Metal Matrix Composite (MMC) Applied Armor System Analysis of Metal Matrix Composite (MMC) Applied Armor SystemDocument8 pagesAnalysis of Metal Matrix Composite (MMC) Applied Armor System Analysis of Metal Matrix Composite (MMC) Applied Armor SystemDerianSyahPas encore d'évaluation

- Lab Manual 11 Infrared SpectrosDocument5 pagesLab Manual 11 Infrared SpectrosLuca Selva CampobassoPas encore d'évaluation

- Phys114 Ps 1Document11 pagesPhys114 Ps 1Reine Amabel JarudaPas encore d'évaluation

- .Preliminary PagesDocument12 pages.Preliminary PagesKimBabPas encore d'évaluation

- Tda - 2002 PDFDocument19 pagesTda - 2002 PDFJose M PeresPas encore d'évaluation

- Paper AeroplaneDocument19 pagesPaper Aeroplanejkb SudhakarPas encore d'évaluation

- CP 001 - 18 - PP - Eng - 00 - CP Umk450t (2018) 18VR5K01 (Eng)Document52 pagesCP 001 - 18 - PP - Eng - 00 - CP Umk450t (2018) 18VR5K01 (Eng)Honda almagrorepuestosPas encore d'évaluation

- Unit 16 AssignmentDocument15 pagesUnit 16 AssignmentRavi Gajenthran100% (1)

- (Ebook - Electronics) - Principles of PLL - Tutorial (Kroupa 2000)Document66 pages(Ebook - Electronics) - Principles of PLL - Tutorial (Kroupa 2000)양종렬Pas encore d'évaluation

- Api 682Document132 pagesApi 682Raul Gonzalez FernandezPas encore d'évaluation

- Technical Data For Elevator Buckets - Bucket ElevatorDocument1 pageTechnical Data For Elevator Buckets - Bucket ElevatorFitra VertikalPas encore d'évaluation