Académique Documents

Professionnel Documents

Culture Documents

Liquid Ring Pump

Transféré par

kalyanm203515Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Liquid Ring Pump

Transféré par

kalyanm203515Droits d'auteur :

Formats disponibles

6

PAGE

277

The dimension drawings in this section display both metric and imperial measurements. Imperial measurements are shown in brackets.

shop online: www.bocedwards.com

Process systems

Liquid ring vacuum pumps

Single stage pumps 282

Alpha series single stage liquid ring vacuum pumps 292

AL series single stage liquid ring vacuum pumps 297

Two stage pumps 300

SHR series liquid ring vacuum pumps 315

Steam ejector vacuum systems 316

Deaeration equipment 318

Air blowers and compressors 321

BOC Edwards has purchased the vacuum and pressure interests of

The Smiths Group. The businesses acquired, were part of Smith's

Sealing Solutions Division, and are comprised of Stokes Vacuum,

Hick Hargreaves, Hibon and Wilhelm Klein (WKE). This section

reflects the Stokes Vacuum product lines now sold by

BOC Edwards.

6

PAGE

278

For North American orders shop online: www.bocedwards.com or call: 1-800-848-9800

LIQUID RING VACUUM PUMPS

Liquid ringvacuum pumps continue to provide the optimum solution for

many rough vacuum applications in the chemical and allied process indus-

tries. The general reliability, low maintenance requirements, low vibration

and noise levels coupled with the unique capabilities when handlingwet

gases all contribute to the popularity of the pump.

Operating range

Liquid ringpumps are suitable for continuous operation on vacuum appli-

cations at any suction pressure down to 30 mbar A. Standard performance

data is based upon 15 C water as the seal liquid, lower pressures may be

possible with alternative sealingliquid.

A wide range of capacities are offered from two basic pump configurations,

single and two stages.

The single stage range is capable of operation at 30 mbar A where required

but is most suited to applications with continuous operation at inlet pres-

sures from atmospheric down to 100 mbar A. The smallest pump in the

range is a 25 m

3

h

-1

close coupled model whilst the largest is 11000 m

3

h

-1

.

The two-stage range is most effective on applications with continuous

operation below 100 mbar A and has models from 200 up to 5000 m

3

h

-1

.

Detailed performance data is shown in the followingpages.

Comparison of Single and two stage performance

Materials of construction

The standard construction material is cast iron with a spheroidal graphite

impeller. However one of the main features of the liquid ringpump is the

availability of various alternative materials of construction the main options

are stainless steel, aluminum bronze, and duplex stainless steels. Some

pump sizes which are particularly suited to the pharmaceutical industry are

also available in hastelloy.

For details on material availability please contact your local sales office.

How it works

1 Suction 5 Sealingring

2 Discharge 6 Direction of rotation

3 Discharge port 7 Suction port

4 Casting 8 impeller

The impeller is mounted eccentrically to the axis of the pump casing, the

liquid ringcirculates concentrically within the axis of the casing. Process

gases are drawn through the inlet port into the impeller cells where the

gas is compressed and discharged through the discharge port. The seal liq-

uid which forms the liquid ringis supplied at a pressure equal to the dis-

charge pressure of the pump, which allows the pump to automatically

make up the amount of liquid which is discharged through the discharge

port, therefore removingthe heat of compression from the pump.

APPLICATIONS

Some of the more common processes which utilize liquid ringtechnology

are listed below.

Distillation

Filtration

Evaporation

Drying

Stripping

Solvent recovery

Deaeration

These processes are used in a wide range of industries and applications,

these include:

Chemical processing

Food processingand packaging

Pharmaceutical production

Oil exploration and refining

Glass Industry

Tobacco conditioning

Packaging

Electronics Industry

Automobile components

Power generation

Waste collection

Buildingmaterials

Soil remediation

500

400

300

200

100

0

30 40 60 80 100

Suction Pressure (mbar A)

S

u

c

t

i

o

n

C

a

p

a

c

i

t

y

(

m

3

/

h

r

)

D

r

y

A

i

r

Stage 2

Stage 1

1

8

2

3

5

4

6

7

NEW

P

R

O

C

E

S

S

S

Y

S

T

E

M

S

6

PAGE

279

For North American orders shop online: www.bocedwards.com or call: 1-800-848-9800

Systems

Liquid ringpumps are offered in a number of standard configurations, with

a selection of seal liquid systems to suit the particular application and envi-

ronment.

Once- through This is the most basic configuration available, it com-

prises of a pump complete with electric motor and drive and a discharge

separator. The seal liquid is supplied to the pump and as the name suggests

it goes once through and is then discharged to waste. These days this

arrangement is rarely used as environmental considerations ensure that

the discharge of waste liquid is kept to a minimum.

Partial recirculation

Again the name is self explanatory with part of the seal liquid beingre-cir-

culated, in order to remove sufficient heat from the liquid that is to be re-

circulated fresh cooler liquid must be added to it. This is achieved by

restrictingthe amount of fresh liquid supplied to the pump to approxi-

mately 50%of the total required and allowingthe pump to pull the balance

of liquid required from the discharge separator, the excess liquid that is

not re-circulated goes to waste via the discharge separator overflow.

Total recirculation

Total recirculation is used where it is desirable to minimize waste liquid

from the pump. All of the liquid is re-circulated back into the pump via a

heat exchanger, which removes the heat of compression and any latent

heat of condensation fromthe seal liquid. The seal liquid can then be re-

used by the pump minimizingthe effluent from the pump system.

The heat exchanger device may be shell and tube, plate type or even a cen-

tral coolingsystem. The system is of particular interest when the pump is

operatingon a solvent removal or dryingprocess where process vapors

are condensed within the pump, often the pump seal liquid can be the same

as the condensed process vapors.

Complex systems

More complex systems include special recirculation systems such as the

Recovac package (see later) or combinations of liquid ringpumps with

roots type mechanical boosters or air, gas or steamejectors. These hybrid

systems can extend the liquid ringpump based performance envelope sig-

nificantly.

Performance curve of booster group

1 MB54 / SHR 2750 3 G ejector

2 MB52 / SHR 2750 4 SHR 2750

Recovac system

The Recovac System adds a highly efficient closed circuit heat exchanger

system to the inherent chemical process pumpingbenefits of the liquid ring

vacuum pump. The result is a highly effective vacuum pump package with

in built emission cleaning/solvent recovery capability.

By combiningthe wide range of liquid ringpumps, ejectors and mechanical

boosters capacities up to 30, 000 m

3

h

-1

can be achieved with suction pres-

sure down to 0.01 mbar A.

To make the most of the Recovac system a seal liquid which is compatible

with the process should be selected, often this will be the same solvent

that is beingproduced from the wet vacuum process. This enables conden-

sation of process vapors in the liquid ringitself with further recovery being

achieved in the fallingfilm heat exchanger. Additional coolingcan be pro-

vided for further reduction in the discharge temperature.

0.1

250

0.2 0.5 1 2 5 10 20 50 100 200 500 1000

500

750

1000

1250

1500

1750

2000

2250

2500

2750

3000

Suction Pressure (mbar)

S

u

c

t

i

o

n

C

a

p

a

c

i

t

y

(

m

h

)

3

-

1

1

2

3

4

NEW

6

PAGE

280

For North American orders shop online: www.bocedwards.com or call: 1-800-848-9800

1.

1 Liquid ringpump D Suction connection

2 Non-return valve E Primary coolingin/outlet connections

3 Ejector (optional) F Secondarycoolingin/outlet connections

4 Drive motor G Overflow connection

5 Ringliquid heat exchanger H Drain connection

6 Ringliquid storage tank J Make up connection

7 Exhaust gas heat exchanger (optional) K Vent connection

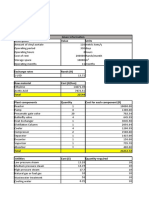

UNIT SIZE MOTOR SIZE SUCTION

VOLUME

A B C D E F G H J K TANK

CAPACITY

(kW)

(m

3

h

-1

) (mm) (mm) (mm) (DN) (DN) (DN) (DN) (DN) (DN) (DN) (liters)

JSF 1 3.0 55 1710 450 860 25 40 40 32 15 32 40 55

JSF 2 4.0 95 1780 490 880 25 40 40 32 15 32 40 55

JSF 3 5.5 120 1820 1100 1000 40 40 40 32 15 32 40 85

JSF 4 7.5 180 2000 1200 1010 50 40 40 32 15 32 40 85

JSF 5 11.0 255 2030 1500 1260 50 40 40 40 15 40 50 190

JSF 6 11.0 350 2250 1600 1270 65 40 40 40 15 40 50 190

JSF 7 18.5 460 2180 1700 1420 80 50 50 50 20 50 65 250

JSF 8 22.0 615 2380 1800 1420 80 50 50 50 20 50 65 250

JSF 9 37.0 1275 2880 2400 1820 125 80 80 80 32 80 100 565

JSF 10 45.0 1615 3130 2600 1820 150 80 80 80 32 80 100 565

5

E

D

J

E

G

6

'C' 'B'

1

'A'

3

2

H

4

F

7

F

K

NEW

P

R

O

C

E

S

S

S

Y

S

T

E

M

S

6

PAGE

281

For North American orders shop online: www.bocedwards.com or call: 1-800-848-9800

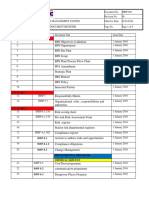

Standard recovac packages

1 Optional exhaust gas condenser/absorber filter 8 Gas inlet

2 Coolant in 9 Optional ejector complete with non-return valve

3 Coolant out 10 Liquid collection receiver

4 Gas outlet 11 Make-up connection

5 Ringliquid cooler 12 Recycle to process

6 Liquid ringvacuumpump 13 Drain

7 Motive air

3

2

2

4

1

10

11

12

13

6

7

8

3

5

9

NEW

6

PAGE

282

For North American orders shop online: www.bocedwards.com or call: 1-800-848-9800

LR1M25 SINGLE STAGE PUMP

Features & benefits

Pumps wet and dry gases

Suction pressure to 33 mbar A

Curved blade impeller and variable discharge port for optimum

performance

Variable pitch dynamically balanced impeller for low noise and vibration

level

DIN 24960 mechanical seal

TECHNICAL DATA

Performance details 50 Hz

Nominal capacity 25 m

3

h

-1

Suction pressure 33 mbar A

Nominal speed 2850 rpm

Motor power 0.75 kW

Service water flow 0.2 m

3

h

-1

Performance details 60 Hz

Nominal capacity 33 m

3

h

-1

Suction pressure 33 mbar A

Nominal speed 3450 rpm

Motor power 1.1 kW

Service water flow 0.2 m

3

h

-1

Materials of construction

1 60 Hz 2 50 Hz

1 60 Hz 2 50 Hz

Suction/Discharge size 1" BSP

STANDARD STAINLESS

STEEL

STAINLESS

STEEL FITTED

Casing Cast iron CF8M Cast iron

Impeller Bronze CF8M CF8M

Port plate Brass CF8M CF8M

Body Nitrided cast iron CF8M Nitrided cast iron

Shaft Motor Motor Motor

Seal Carbon / ceramic /

viton

Carbon / ceramic /

viton

Carbon / ceramic /

viton

ORDERING INFORMATION

LR1M25 model is available with the following motor options.

IEC Eurovoltage 220-240/380-415/3/50Hz, IP55, Class F, B3/B5

IEC 230-460/3/60Hz, IP55, Class F, B3/B5

NEMA UL CSA Epact 230-460/3/60Hz, IP55, Class F B3/B5

LR1L25 is a pedestal version of this pump suitable for direct mounting with C face

motors, it can be supplied bareshaft or with special motors. This pump can also be

supplied as a complete package system, suitable for once through, partial or total

recirculation of the seal liquid. Special and hazardous motors are available on request.

Custom engineered packages to meet more complex process system requirements are

also available.

For more information please contact your local sales office.

20000

200

16

4000

3300

33

4

0

8

12

120 60 40 80

8000

6000 12000

24

20

3

m

S

u

c

t

i

o

n

C

a

p

a

c

i

t

y

-

1

h

32

28

36

25

2

1

60 40 30 100

f

t

101300

1013 800 400

40000

80000

LR1M25

mbar

Pa

4

0

2

6

8

760 200 400 600

12

10

14

-

1

3

m

i

n

16

18

Torr

20

60

3300

LR1M25

400 200 120 80 33 40 60

12000 6000

4000 8000 20000

40000

30 40 25

mbar 1013 800

101300

80000

Pa

k

W

760 400 600 200 100 Torr

0.5

0.7

H

P

0.6

0.7

0.8

0.9

1.0

1.1

1

2

0.8

0.9

1.0

1.1

1.2

1.3

1.4

A

b

s

o

r

b

e

d

P

o

w

e

r

70 396 (15.59)

100 (3.94) 159 (6.26)

1

6

0

(

6

.

3

0

)

(

3

.

1

5

)

8

0

4 x 8 (0.32)

153 (6.02)

125 (4.92)

(2.76)

NEW

P

R

O

C

E

S

S

S

Y

S

T

E

M

S

6

PAGE

283

For North American orders shop online: www.bocedwards.com or call: 1-800-848-9800

LR1M50 SINGLE STAGE PUMP

Features & benefits

Pumps wet and dry gases

Suction pressure to 33 mbar A

Curved blade impeller and variable discharge port for optimum

performance

Variable pitch dynamically balanced impeller for low noise and vibration

level

DIN 24960 mechanical seal

TECHNICAL DATA

Performance details 50 Hz

Nominal capacity 45 m

3

h

-1

Suction pressure 33 mbar A

Nominal speed 2850 rpm

Motor power 1.5 kW

Service water flow 0.5 m

3

h

-1

Performance details 60 Hz

Nominal capacity 55 m

3

h

-1

Suction pressure 33 mbar A

Nominal speed 3450 rpm

Motor power 2.2 kW

Service water flow 0.5 m

3

h

-1

Materials of construction

1 60 Hz 2 50 Hz

1 60 Hz 2 50 Hz

Suction/Discharge size 1" BSP

STANDARD STAINLESS

STEEL

STAINLESS

STEEL FITTED

Casing Cast iron CF8M Cast iron

Impeller Bronze CF8M CF8M

Port plate Nitrided cast iron CF8M Nitrided cast iron

Body Nitrided cast iron CF8M Nitrided cast iron

Shaft Motor Motor Motor

Seal Carbon / ceramic /

viton

Carbon / ceramic /

viton

Carbon / ceramic /

viton

A

50 Hz 100

(3.94)

60 Hz 125

(4.92)

ORDERING INFORMATION

LR1M50 model is available with the following motor options.

IEC Eurovoltage 220-240/380-415/3/50Hz, IP55, Class F, B3/B5

IEC 230-460/3/60Hz, IP55, Class F, B3/B5

NEMA UL CSA Epact 230-460/3/60Hz, IP55, Class F B3/B5

LR1L50 is a pedestal version of this pump suitable for direct mounting with C face

motors, it can be supplied bareshaft or with special motors. This pump can also be

supplied as a complete package system, suitable for once through, partial or total

recirculation of the seal liquid. Special and hazardous motors are available on request.

Custom engineered packages to meet more complex process system requirements are

also available.

For more information please contact your local sales office.

m

80 60 33 40

4000

3300 6000

8000

5

0

10

20

15

25

mbar 800 1013 400 120 200

40000

20000

12000 101300

80000

Pa

LR1M50

0

5

10

15

f

t

h

3

-

1

35

30

40

50

45

55

30 25

60

60 40

1

2

25

20

m

i

n

3

-

1

30

100 200 760 600 400 Torr

35

S

u

c

t

i

o

n

C

a

p

a

c

i

t

y

60

3300

400 200 120 80 33 40 60

12000 6000

4000 8000 20000

40000

30 40 25

mbar 1013 800

101300

80000

Pa

760 400 600 200 100 Torr

1

2

0.5

1.0

1.5

2.0

2.5

k

W

3.0

H

P

LR1M50

2.5

1.5

2.0

1.0

A

b

s

o

r

b

e

d

P

o

w

e

r

75 435 (17.13)

A 178.5 (7.03)

1

7

3

(

6

.

8

1

)

(

3

.

5

4

)

9

0

4 x 8 (0.32)

170 (6.69)

140 (5.51)

(2.95)

NEW

6

PAGE

284

For North American orders shop online: www.bocedwards.com or call: 1-800-848-9800

LR1M90 SINGLE STAGE PUMP

Features & benefits

Pumps wet and dry gases

Suction pressure to 33 mbar A

Curved blade impeller and variable discharge port for optimum

performance

Variable pitch dynamically balanced impeller for low noise and vibration

level

DIN 24960 mechanical seal

TECHNICAL DATA

Performance details 50 Hz

Nominal capacity 70 m

3

h

-1

Suction pressure 33 mbar A

Nominal speed 1450 rpm

Motor power 2.2 kW

Service water flow 0.7 m

3

h

-1

Performance details 60 Hz

Nominal capacity 100 m

3

h

-1

Suction pressure 33 mbar A

Nominal speed 1750 rpm

Motor power 4 kW

Service water flow 0.8 m

3

h

-1

Materials of construction

1 60 Hz 2 50 Hz

1 60 Hz 2 50 Hz

Suction/Discharge size DN40 PN10

STANDARD STAINLESS

STEEL

STAINLESS

STEEL FITTED

Casing Cast iron CF8M Cast iron

Impeller Bronze CF8M CF8M

Port plate Cast iron CF8M Cast iron

Body Cast iron CF8M Cast iron

Shaft Motor Motor Motor

Mechanical seal Carbon / silicon

carbide / viton

Carbon / silicon

carbide / viton

Carbon / silicon

carbide / viton

A B C D E F

50 Hz 515

(20.28)

155.5

(6.12)

160

(6.30)

335

(13.19)

160

(6.30)

220

(8.66)

60 Hz 538

(21.18)

162.5

(6.40)

172

(6.77)

347

(13.66)

190

(7.48)

250

(9.84)

ORDERING INFORMATION

LR1M90 model is available with the following motor options.

IEC Eurovoltage 220-240/380-415/3/50Hz, IP55, Class F, B3/B5

IEC 230-460/3/60Hz, IP55, Class F, B3/B5

NEMA UL CSA Epact 230-460/3/60Hz, IP55, Class F B3/B5

LR1L90 is a pedestal version of this pump suitable for direct mounting with C face

motors, it can be supplied bareshaft or with special motors. This pump can also be

supplied as a complete package system, suitable for once through, partial or total

recirculation of the seal liquid. Special and hazardous motors are available on request.

Custom engineered packages to meet more complex process system requirements are

also available.

For more information please contact your local sales office.

20

10

33

40

30

80 40 60 120

90

60

50

m

3

h

-

1

80

70

100

110

2

1

LR1M90

400 200 800 1013 mbar

20000

3300

4000 8000

6000 12000 101300 40000

80000

Pa

25 60 40 30 100 760 200 600 400 Torr

10

20

30

40

50

60

f

t

-

1

3

m

i

n

S

u

c

t

i

o

n

C

a

p

a

c

i

t

y

60

3300

LR1M90

400 200 120 80 33 40 60

12000 6000

4000 8000 20000

40000

30 40 25

mbar 1013 800

101300

80000

Pa

k

W

760 400 600 200 100 Torr

1

H

P

1

2

2

3

4

5

2

3

4

5

6

A

b

s

o

r

b

e

d

P

o

w

e

r

A

D

C

B 225 (8.86) 4 x 12 E

F

180 (7.09)

NEW

P

R

O

C

E

S

S

S

Y

S

T

E

M

S

6

PAGE

285

For North American orders shop online: www.bocedwards.com or call: 1-800-848-9800

LR1M125 SINGLE STAGE PUMP

Features & benefits

Pumps wet and dry gases

Suction pressure to 33 mbar A

Curved blade impeller and variable discharge port for optimum

performance

Variable pitch dynamically balanced impeller for low noise and vibration

level

DIN 24960 mechanical seal

TECHNICAL DATA

Performance details 50 Hz

Nominal capacity 100 m

3

h

-1

Suction pressure 33 mbar A

Nominal speed 1450 rpm

Motor power 3 kW

Service water flow 0.78 m

3

h

-1

Performance details 60 Hz

Nominal capacity 120 m

3

h

-1

Suction pressure 33 mbar A

Nominal speed 1750 rpm

Motor power 4 kW

Service water flow 0.8 m

3

h

-1

Materials of construction

1 60 Hz 2 50 Hz

1 60 Hz 2 50 Hz

Suction/Discharge size DN40 PN10

STANDARD STAINLESS

STEEL

STAINLESS

STEEL FITTED

Casing Cast iron CF8M Cast iron

Impeller Bronze CF8M CF8M

Port plate Cast iron CF8M Cast iron

Body Cast iron CF8M Cast iron

Shaft Motor Motor Motor

Mechanical seal Carbon / silicon

carbide / viton

Carbon / silicon

carbide / viton

Carbon / silicon

carbide / viton

A B C D E F

50 Hz 534

(21.02)

174.5

(6.87)

160

(6.30)

335

(13.19)

160

(6.30)

220

(8.66)

60 Hz 557

(21.93)

181.5

(7.15)

172

(6.77)

347

(13.66)

190

(7.48)

250

(9.84)

ORDERING INFORMATION

LR1M125 model is available with the following motor options.

IEC Eurovoltage 220-240/380-415/3/50Hz, IP55, Class F, B3/B5

IEC 230-460/3/60Hz, IP55, Class F, B3/B5

NEMA UL CSA Epact 230-460/3/60Hz, IP55, Class F B3/B5

LR1L125 is a pedestal version of this pump suitable for direct mounting with C face

motors, it can be supplied bareshaft or with special motors. This pump can also be

supplied as a complete package system, suitable for once through, partial or total

recirculation of the seal liquid. Special and hazardous motors are available on request.

Custom engineered packages to meet more complex process system requirements are

also available.

For more information please contact your local sales office.

200

2

50

40

33

60

70

80 40 60 120

120

3

-

1

80

90

m

h

100

110

130

140

1

LR1M125

400 800 1013 mbar

25 60 40 30 100 760 200 600 400 Torr

20000

3300

4000 8000

6000 12000 101300 40000

80000

Pa

30

40

60

50

70

80

f

t

-

1

3

m

i

n

S

u

c

t

i

o

n

C

a

p

a

c

i

t

y

60

3300

LR1M125

400 200 120 80 33 40 60

12000 6000

4000 8000 20000

40000

30 40 25

mbar 1013 800

101300

80000

Pa

k

W

760 400 600 200 100 Torr

2

3

H

P

1

2 3

4

5

6

4

5

6

7

8

A

b

s

o

r

b

e

d

P

o

w

e

r

A

D

C

B 225 (8.86) 4 x 12 E

F

180 (7.09)

NEW

6

PAGE

286

For North American orders shop online: www.bocedwards.com or call: 1-800-848-9800

LR1M150 SINGLE STAGE PUMP

Features & benefits

Pumps wet and dry gases

Suction pressure to 33 mbar A

Curved blade impeller and variable discharge port for optimum

performance

Variable pitch dynamically balanced impeller for low noise and vibration

level

DIN 24960 mechanical seal

TECHNICAL DATA

Performance details 50 Hz

Nominal capacity 130 m

3

h

-1

Suction pressure 33 mbar A

Nominal speed 1450 rpm

Motor power 4 kW

Service water flow 0.8 m

3

h

-1

Performance details 60 Hz

Nominal capacity 160 m

3

h

-1

Suction pressure 33 mbar A

Nominal speed 1750 rpm

Motor power 5.5 kW

Service water flow 0.8 m

3

h

-1

Materials of construction

1 60 Hz 2 50 Hz

1 60 Hz 2 50 Hz

Suction/Discharge size DN40 PN10

STANDARD STAINLESS

STEEL

STAINLESS

STEEL FITTED

Casing Cast iron CF8M Cast iron

Impeller Bronze CF8M CF8M

Port plate Cast iron CF8M Cast iron

Body Cast iron CF8M Cast iron

Shaft Motor Motor Motor

Mechanical seal Carbon / silicon

carbide / viton

Carbon / silicon

carbide / viton

Carbon / silicon

carbide / viton

A B

50 Hz 607.5

(23.92)

209.5

(8.25)

60 Hz 605

(23.82)

207

(8.15)

ORDERING INFORMATION

LR1M150 model is available with the following motor options.

IEC Eurovoltage 220-240/380-415/3/50Hz, IP55, Class F, B3/B5

IEC 230-460/3/60Hz, IP55, Class F, B3/B5

NEMA UL CSA Epact 230-460/3/60Hz, IP55, Class F B3/B5

LR1L150 is a pedestal version of this pump suitable for direct mounting with C face

motors, it can be supplied bareshaft or with special motors. This pump can also be

supplied as a complete package system, suitable for once through, partial or total

recirculation of the seal liquid. Special and hazardous motors are available on request.

Custom engineered packages to meet more complex process system requirements are

also available.

For more information please contact your local sales office.

-

1

60

20

40

80

m

h

3100

LR1M150

400 200 120 80 33 40 60 mbar 1013 800

160

120

140

180

1

2

20

30

40

50

90

60

70

80

100

20000

3300

4000 8000

6000 12000 101300 40000

80000

Pa

25 60 40 30 100 760 200 600 400 Torr

f

t

-

1

3

m

i

n

S

u

c

t

i

o

n

C

a

p

a

c

i

t

y

60

3300

LR1M150

400 200 120 80 33 40 60

12000 6000

4000 8000 20000

40000

30 40 25

mbar 1013 800

101300

80000

Pa

k

W

760 400 600 200 100 Torr

2

H

P

1

2

3

4

5

6

3

4

5

6

7

8

A

b

s

o

r

b

e

d

P

o

w

e

r

A

3

6

7

(

1

4

.

4

5

)

1

9

2

B 225 (8.86) 4 x 12 216 (8.50)

276 (10.87)

180 (7.09)

(

7

.

5

6

)

NEW

P

R

O

C

E

S

S

S

Y

S

T

E

M

S

6

PAGE

287

For North American orders shop online: www.bocedwards.com or call: 1-800-848-9800

LR1L250 SINGLE STAGE PUMP

Features & benefits

Pumps wet and dry gases

Suction pressure to 33 mbar A

Curved blade impeller and variable discharge port for optimum

performance

Variable pitch dynamically balanced impeller for low noise and vibration

level

DIN 24960 mechanical seal

TECHNICAL DATA

Performance details 50 Hz

Nominal capacity 200 m

3

h

-1

Suction pressure 33 mbar A

Nominal speed 1450 rpm

Motor power 5.5 kW

Service water flow 1.2 m

3

h

-1

Performance details 60 Hz

Nominal capacity 220 m

3

h

-1

Suction pressure 33 mbar A

Nominal speed 1750 rpm

Motor power 7.5 kW

Service water flow 1.26 m

3

h

-1

Materials of construction

1 60 Hz 2 50 Hz

1 60 Hz 2 50 Hz

Suction/Discharge size DN65 PN10

STANDARD STAINLESS

STEEL

STAINLESS

STEEL FITTED

Casing Cast iron CF8M Cast iron

Impeller Bronze CF8M CF8M

Port plate Cast iron CF8M Cast iron

Body Cast iron CF8M Cast iron

Shaft 420S37 420S37 420S37

Mechanical seal Carbon / silicon

carbide / viton

Carbon / silicon

carbide / viton

Carbon / silicon

carbide / viton

ORDERING INFORMATION

LR1L250 model is a pedestal mounted pump and is available with the following motor

options as standard.

IEC Eurovoltage 220-240/380-415/3/50Hz, IP55, Class F, B3/B5

IEC 230-460/3/60Hz, IP55, Class F, B3/B5

NEMA UL CSA Epact 230-460/3/60Hz, IP55, Class F B3/B5

These pumps can be supplied as complete package systems, suitable for once through,

partial or total recirculation of the seal liquid. Special and hazardous motors are available

on request. Custom engineered packages to meet more complex process system

requirements are also available.

For more information please contact your local sales office.

80 33

60

80

120

100

40 60

h

160

140

m

3

200

180

-

1

240

220

260

1

400 200 120

2

1013

LR1L250

800 mbar

90

40

50

60

70

80

100

110

120

130

140

150

20000

3300

4000 8000

6000 12000 101300 40000

80000

Pa

f

t

-

1

3

m

i

n

25 60 40 30 100 760 200 600 400 Torr

S

u

c

t

i

o

n

C

a

p

a

c

i

t

y

60

3300

LR1L250

400 200 120 80 33 40 60

12000 6000

4000 8000 20000

40000

30 40 25

mbar 1013 800

101300

80000

Pa

k

W

760 400 600 200 100 Torr

4

H

P

1

2

5

6

7

8

6

7

8

9

10

A

b

s

o

r

b

e

d

P

o

w

e

r

4 x 18

(7.87)

200

385 (15.16)

4

1

0

(

1

6

.

1

4

)

1

9

5

(

7

.

6

8

)

226

(8.90) (12.40)

315

(7.28)

185

(7.28)

185

1048 (41.26) 50Hz

1086 (42.76) 60Hz

122

(4.80)

NEW

6

PAGE

288

For North American orders shop online: www.bocedwards.com or call: 1-800-848-9800

LR1L320 SINGLE STAGE PUMP

Features & benefits

Pumps wet and dry gases

Suction pressure to 33 mbar A

Curved blade impeller and variable discharge port for optimum

performance

DIN 24960 mechanical seal

Externally mounted bearings

Low noise level and vibration

TECHNICAL DATA

Performance details 50 Hz

Nominal capacity 300 m

3

h

-1

Suction pressure 33 mbar A

Nominal speed 1450 rpm

Motor power 7.5 kW

Service water flow 1.26 m

3

h

-1

Performance details 60 Hz

Nominal capacity 330 m

3

h

-1

Suction pressure 33 mbar A

Nominal speed 1750 rpm

Motor power 11 kW

Service water flow 1.45 m

3

h

-1

Materials of construction

1 60 Hz 2 50 Hz

1 60 Hz 2 50 Hz

Suction/Discharge size DN65 PN10

STANDARD STAINLESS

STEEL

STAINLESS

STEEL FITTED

Casing Cast iron CF8M Cast iron

Impeller Bronze CF8M CF8M

Port plate Cast iron CF8M Cast iron

Body Cast iron 420S37 Cast iron

Shaft 420S37 CF8M 420S37

Mechanical seal Carbon / silicon

carbide / viton

Carbon / silicon

carbide / viton

Carbon / silicon

carbide / viton

ORDERING INFORMATION

LR1L320 model is a pedestal mounted pump and is available with the following motor

options as standard.

IEC Eurovoltage 220-240/380-415/3/50Hz, IP55, Class F, B3/B5

IEC 230-460/3/60Hz, IP55, Class F, B3/B5

NEMA UL CSA Epact 230-460/3/60Hz, IP55, Class F B3/B5

These pumps can be supplied as complete package systems, suitable for once through,

partial or total recirculation of the seal liquid. Special and hazardous motors are available

on request. Custom engineered packages to meet more complex process system

requirements are also available.

For more information please contact your local sales office.

40

60

33 60 80

m

-

1

3

h

100

140

180

220

260

300

400 200 120

LR1L320

800 1013 mbar

2

1

340

380

40

60

80

100

120

200

160

140

180

220

f

t

-

1

3

m

i

n

20000

3300

4000 8000

6000 12000 101300 40000

80000

Pa

25 60 40 30 100 760 200 600 400 Torr

S

u

c

t

i

o

n

C

a

p

a

c

i

t

y

60

3300

LR1L320

400 200 120 80 33 40 60

12000 6000

4000 8000 20000

40000

30 40 25

mbar 1013 800

101300

80000

Pa

k

W

760 400 600 200 100 Torr

5

13

H

P

1

2

6

7

8

9

10

12

11

9

10

7

8

A

b

s

o

r

b

e

d

P

o

w

e

r

4 x 18

(7.87)

200

385 (15.16)

4

1

0

(

1

6

.

1

4

)

1

9

5

(

7

.

6

8

)

258

(10.16) (12.40)

315

1118 (44.02) 50Hz

1214 (47.80) 60Hz

NEW

P

R

O

C

E

S

S

S

Y

S

T

E

M

S

6

PAGE

289

For North American orders shop online: www.bocedwards.com or call: 1-800-848-9800

LR1L450 SINGLE STAGE PUMP

Features & benefits

Pumps wet and dry gases

Suction pressure to 33 mbar A

Curved blade impeller and variable discharge port for optimum

performance

Variable pitch dynamically balanced impeller for low noise and vibration

level

DIN 24960 mechanical seal

TECHNICAL DATA

Performance details 50 Hz

Nominal capacity 370 m

3

h

-1

Suction pressure 33 mbar A

Nominal speed 1450 rpm

Motor power 11 kW

Service water flow 1.45 m

3

h

-1

Performance details 60 Hz

Nominal capacity 440 m

3

h

-1

Suction pressure 33 mbar A

Nominal speed 1750 rpm

Motor power 15 kW

Service water flow 1.45 m

3

h

-1

Materials of construction

1 60 Hz 2 50 Hz

1 60 Hz 2 50 Hz

Suction/Discharge size DN65 PN10

STANDARD STAINLESS

STEEL

STAINLESS

STEEL FITTED

Casing Cast iron CF8M Cast iron

Impeller Bronze CF8M CF8M

Port plate Cast iron CF8M Cast iron

Body Cast iron CF8M Cast iron

Shaft 420S37 420S37 420S37

Mechanical seal Carbon / silicon

carbide / viton

Carbon / silicon

carbide / viton

Carbon / silicon

carbide / viton

ORDERING INFORMATION

LR1L450 model is a pedestal mounted pump and is available with the following motor

options as standard.

IEC Eurovoltage 220-240/380-415/3/50Hz, IP55, Class F, B3/B5

IEC 230-460/3/60Hz, IP55, Class F, B3/B5

NEMA UL CSA Epact 230-460/3/60Hz, IP55, Class F B3/B5

These pumps can be supplied as complete package systems, suitable for once through,

partial or total recirculation of the seal liquid. Special and hazardous motors are available

on request. Custom engineered packages to meet more complex process system

requirements are also available.

For more information please contact your local sales office.

420

40

100

33 60 80

h

m

3

-

1

140

180

220

260

300

340

380

LR1L450

400 200 120 1013 800 mbar

2

1

500

460

160

60

100

80

140

120

260

180

200

220

240

280

20000

3300

4000 8000

6000 12000 101300 40000

80000

Pa

f

t

-

1

3

m

i

n

25 60 40 30 100 760 200 600 400 Torr

S

u

c

t

i

o

n

C

a

p

a

c

i

t

y

60

3300

LR1L450

400 200 120 80 33 40 60

12000 6000

4000 8000 20000

40000

30 40 25

mbar 1013 800

101300

80000

Pa

k

W

760 400 600 200 100 Torr

6

H

P

1

2

8

10

12

14

16

12

14

16

18

20

10

A

b

s

o

r

b

e

d

P

o

w

e

r

4 x 18

(7.87)

200

385 (15.16)

4

1

0

(

1

6

.

1

4

)

1

9

5

(

7

.

6

8

)

303

(11.93) (12.40)

315

1259 (49.57) 50Hz

1303 (51.30) 60Hz

NEW

6

PAGE

290

For North American orders shop online: www.bocedwards.com or call: 1-800-848-9800

LR1S600 SINGLE STAGE PUMP

Features & benefits

Pumps wet and dry gases

Suction pressure to 33 mbar A

Curved blade impeller and variable discharge port for optimum

performance

DIN 24960 mechanical seal

Externally mounted bearings

Low noise level vibration

TECHNICAL DATA

Performance details 50 Hz

Nominal capacity 540 m

3

h

-1

Suction pressure 33 mbar A

Nominal speed 1450 rpm

Motor power 15 kW

Service water flow 2 m

3

h

-1

Performance details 60 Hz

Nominal capacity 625 m

3

h

-1

Suction pressure 33 mbar A

Nominal speed 1750 rpm

Motor power 22 kW

Service water flow 2.2 m

3

h

-1

Materials of construction

1 60 Hz 2 50 Hz

1 60 Hz 2 50 Hz

Suction/Discharge size DN100 PN10

STANDARD STAINLESS

STEEL

STAINLESS

STEEL FITTED

Casing Cast iron CF8M Cast iron

Impeller Bronze CF8M CF8M

Port plate Cast iron CF8M Cast iron

Body Cast iron CF8M Cast iron

Shaft 420S37 316 316

Mechanical seal Carbon / silicon

carbide / viton

Carbon / silicon

carbide / viton

Carbon / silicon

carbide / viton

ORDERING INFORMATION

LR1S600 model is a bareshaft machine and can be supplied as part of a standard

package, incorporating electric motor, baseplate and seal liquid recovery system, suitable

for once through, partial or total recirculation. Custom engineered packages to meet

more complex process system requirements are also available.

For more information please contact your local sales office.

-

1

150

m

h

3

LR1S600

400 200 120 80 33 40 60 mbar 1013 800

200

250

400

350

300

550

500

450

650

600

1

2

25 60 40 30 100 760 200 600 400 Torr

20000

3300

4000 8000

6000 12000 101300 40000

80000

Pa

120

160

240

200

280

320

360

f

t

-

1

3

m

i

n

S

u

c

t

i

o

n

C

a

p

a

c

i

t

y

1

2

40000

20000 8000 4000

12000 3300

33 40

6000

60 80 200 120 400

80000

1013

101300

800

Pa

mbar

LR1S600

8

k

W

H

P

12

25 30 40 60 100 200 760 400 600 Torr

10

12

14

16

18

20

22

14

16

18

20

22

24

26

28

A

b

s

o

r

b

e

d

P

o

w

e

r

(3.54)

458 (18.03)

410 (16.14)

(7.32)

186

4

2

(

1

.

6

5

)

306 (12.05)

697 (27.44)

90

6

4

0

(

2

5

.

2

0

)

(

8

.

8

6

)

2

2

5

340 (13.39)

4 x 20

2

2

5

(

8

.

8

6

)

(10.59)

269

470 (18.50)

(9.45)

240

NEW

P

R

O

C

E

S

S

S

Y

S

T

E

M

S

6

PAGE

291

For North American orders shop online: www.bocedwards.com or call: 1-800-848-9800

LR1S800 SINGLE STAGE PUMP

Features & benefits

Pumps wet and dry gases

Suction pressure to 33 mbar A

Curved blade impeller and variable discharge port for optimum

performance

DIN 24960 mechanical seal

Externally mounted bearings

Low noise level vibration

TECHNICAL DATA

Performance details 50 Hz

Nominal capacity 775 m

3

h

-1

Suction pressure 33 mbar A

Nominal speed 1450 rpm

Motor power 22 kW

Service water flow 2.5 m

3

h

-1

Performance details 60 Hz

Nominal capacity 900 m

3

h

-1

Suction pressure 33 mbar A

Nominal speed 1750 rpm

Motor power 30 kW

Service water flow 2.5 m

3

h

-1

Materials of construction

1 60 Hz 2 50 Hz

1 60 Hz 2 50 Hz

Suction/Discharge size DN100 PN10

STANDARD STAINLESS

STEEL

STAINLESS

STEEL FITTED

Casing Cast iron CF8M Cast iron

Impeller Bronze CF8M CF8M

Port plate Cast iron CF8M Cast iron

Body Cast iron CF8M Cast iron

Shaft 420S37 316 316

Mechanical seal Carbon / silicon

carbide / viton

Carbon / silicon

carbide / viton

Carbon / silicon

carbide / viton

ORDERING INFORMATION

LR1S800 model is a bareshaft machine and can be supplied as part of a standard

package, incorporating electric motor, baseplate and seal liquid recovery system, suitable

for once through, partial or total recirculation. Custom engineered packages to meet

more complex process system requirements are also available.

For more information please contact your local sales office.

1

2

20000 8000 4000

40

3300

33

6000

60 120

12000

80 200

80000

800 400

40000 101300

1013

Pa

mbar

100

LR1S800

3

m

h

-

1

200

300

400

500

600

700

800

900

1000

1100

30 25 40 100 60 600 200 400 Torr 760

m

i

n

f

t

3

-

1

100

200

300

400

500

600

S

u

c

t

i

o

n

C

a

p

a

c

i

t

y

1

2

80000

6000

4000

3300

8000

12000

60 40 33 120 80

40000

20000

200 800 400

101300 Pa

mbar 1013

LR1S800

8

k

W

H

P

600 30 25 40 60 100 200 400 Torr 760

12

16

20

24

28

32

36

18

22

26

30

34

38

42

46

14

A

b

s

o

r

b

e

d

P

o

w

e

r

(3.54)

562 (22.13)

514 (20.24)

(7.32)

186

4

2

(

1

.

6

5

)

358 (14.09)

801 (31.54)

90

6

4

0

(

2

5

.

2

0

)

(

8

.

8

6

)

2

2

5

340 (13.39)

4 x 20

DN100

2

2

5

(

8

.

8

6

)

(10.59)

269

470 (18.50)

(9.45)

240

(8.66)

220

(8.66)

220

NEW

6

PAGE

292

For North American orders shop online: www.bocedwards.com or call: 1-800-848-9800

ALPHA 14+ SINGLE STAGE

LIQUID RING VACUUM PUMP

Features & benefits

Curved blade impeller and variable discharge port for optimum

performance

Mechanical seals

Minimum number of body joints

Externally mounted bearings

Handles wet or dry gases

Unaffected by liquid carryover

Robust and simple construction

Materials of construction to suit application

Low noise level

TECHNICAL DATA

Performance details at maximumspeed

Nominal Capacity 1200 m

3

h

-1

Suction Pressure 33 mbar A

Nominal Speed 1150 rpm

Motor Power 55 kW

Service water flow 4 m

3

h

-1

Performance details at minimumspeed

Nominal Capacity 1000 m

3

h

-1

Suction Pressure 33 mbar A

Nominal Speed 980 rpm

Motor Power 30 kW

Service water flow 3.5 m

3

h

-1

Materials of construction

Suction/Discharge size DN150 PN10

STANDARD STAINLESS

STEEL

STAINLESS

STEEL FITTED

Casing Cast iron CF8M Cast iron

Impeller SG iron CF8M CF8M

Port plate Cast iron CF8M Cast iron

Body Cast iron CF8M Cast iron

Shaft SG iron CF8M CF8M

Mechanical seal Carbon / silicon

carbide / viton

Carbon / silicon

carbide / viton

Carbon / silicon

carbide / viton

ORDERING INFORMATION

Alpha 14+ model is a bareshaft machine and can be supplied as part of a standard

package, incorporating electric motor, baseplate and seal liquid recovery system, suitable

for once through, partial or total recirculation. Custom engineered packages to meet

more complex process system requirements are also available.

For more information please contact your local sales office.

3

m

S

u

c

t

i

o

n

C

a

p

a

c

i

t

y

-

1

h

f

t

-

1

3

m

i

n

1160

1070

970

880

820

735

750

700

650

600

550

500

450

400

350

300

250

200

150

100

50

0

pi (mbar abs.)

pi (Torr)

45

40

35

30

25

20

15

10

5

0

k

W

A

b

s

o

r

b

e

d

P

o

w

e

r

1160

1070

970

880

820

735

5

10

15

20

25

35

30

-25 -20 -15 -10 -5 0

pi (mm Hg)

pi ("Hg)

H

P

924

409 515

768

3

0

0

105

4 x 22

129 322 129

555

490 45 270

580

3

1

5

3

5

8

5

1

0

5

5

7

6

5

2

9

0

6

0

0

2

0

5

2

2

110 110 270

380 55

490

350 270

185 185 170

682.5

2

2

NEW

P

R

O

C

E

S

S

S

Y

S

T

E

M

S

6

PAGE

293

For North American orders shop online: www.bocedwards.com or call: 1-800-848-9800

ALPHA 20+ SINGLE STAGE

LIQUID RING VACUUM PUMP

Features & benefits

Curved blade impeller and variable discharge port for optimum

performance

Mechanical seals

Minimum number of body joints

Externally mounted bearings

Handles wet or dry gases

Unaffected by liquid carryover

Robust and simple construction

Materials of construction to suit application

Low noise level

TECHNICAL DATA

Performance details at maximumspeed

Nominal capacity 1600 m

3

h

-1

Suction pressure 33 mbar A

Nominal speed 1160 rpm

Motor power 55 kW

Service water flow 4 m

3

h

-1

Performance details at minimumspeed

Nominal capacity 1400 m

3

h

-1

Suction pressure 33 mbar A

Nominal speed 980 rpm

Motor power 45 kW

Service water flow 4 m

3

h

-1

Materials of construction

Suction/Discharge size DN150 PN10

STANDARD STAINLESS

STEEL

STAINLESS

STEEL FITTED

Casing Cast iron CF8M Cast iron

Impeller SG iron CF8M CF8M

Port plate Cast iron CF8M Cast iron

Body Cast iron CF8M Cast iron

Shaft SG iron CF8M CF8M

Mechanical seal Carbon / silicon

carbide / viton

Carbon / silicon

carbide / viton

Carbon / silicon

carbide / viton

ORDERING INFORMATION

Alpha 20+ model is a bareshaft machine and can be supplied as part of a standard

package, incorporating electric motor, baseplate and seal liquid recovery system, suitable

for once through, partial or total recirculation. Custom engineered packages to meet

more complex process system requirements are also available.

For more information please contact your local sales office.

3

m

S

u

c

t

i

o

n

C

a

p

a

c

i

t

y

-

1

h

f

t

-

1

3

m

i

n

k

W

H

P

A

b

s

o

r

b

e

d

P

o

w

e

r

670

580

3

0

0

560

858

1014

454

270

3

1

5

3

5

8

5

4 x 22

105

129 129

600

45

412

270 110 110

1

0

5

5

7

6

5

6

0

0

2

0

5

2

9

0

2

2

2

2

170 185 185

6825

NEW

6

PAGE

294

For North American orders shop online: www.bocedwards.com or call: 1-800-848-9800

ALPHA 30+ SINGLE STAGE

LIQUID RING VACUUM PUMP

Features & benefits

Curved blade impeller and variable discharge port for optimum

performance

Mechanical seals

Minimum number of body joints

Externally mounted bearings

Handles wet or dry gases

Unaffected by liquid carryover

Robust and simple construction

Materials of construction to suit application

Low noise level

Once through, partial or total recovery seal liquid

TECHNICAL DATA

Performance details at maximumspeed

Nominal capacity 2300 m

3

h

-1

Suction pressure 40 mbar A

Nominal speed 880 rpm

Motor power 75 kW

Service water flow 7 m

3

h

-1

Performance details at minimumspeed

Nominal capacity 1500 m

3

h

-1

Suction pressure 40 mbar A

Nominal speed 585 rpm

Motor power 37 kW

Service water flow 5 m

3

h

-1

Materials of construction

Suction/Discharge size DN150 PN10

STANDARD STAINLESS

STEEL

STAINLESS

STEEL FITTED

Casing Cast iron CF8M Cast iron

Impeller SG iron CF8M CF8M

Port plate Cast iron CF8M Cast iron

Body Cast iron CF8M Cast iron

Shaft 2C45 XC48 XC48

Mechanical seal Carbon / silicon

carbide / viton

Carbon / silicon

carbide / viton

Carbon / silicon

carbide / viton

ORDERING INFORMATION

Alpha 30+ model is a bareshaft machine and can be supplied as part of a standard

package, incorporating electric motor, baseplate and seal liquid recovery system, suitable

for once through, partial or total recirculation. Custom engineered packages to meet

more complex process system requirements are also available.

For more information please contact your local sales office.

3

m

S

u

c

t

i

o

n

C

a

p

a

c

i

t

y

-

1

h

f

t

-

1

3

m

i

n

k

W

H

P

A

b

s

o

r

b

e

d

P

o

w

e

r

400 150 150

1

4

0

0

1

0

3

0

8

1

5

2

5

0

3

7

0

2

2

2

4

8925

670

800

0

4

0

0

625

1110

1140

515

185 185

290

4

1

5

4

5

8

5

30

105

65

630

210 270 270 1425

NEW

P

R

O

C

E

S

S

S

Y

S

T

E

M

S

6

PAGE

295

For North American orders shop online: www.bocedwards.com or call: 1-800-848-9800

ALPHA 40+ SINGLE STAGE

LIQUID RING VACUUM PUMP

Features & benefits

Curved blade impeller and variable discharge port for optimum

performance

Mechanical seals

Minimum number of body joints

Externally mounted bearings

Handles wet or dry gases

Unaffected by liquid carryover

Robust and simple construction

Materials of construction to suit application

Low noise level

TECHNICAL DATA

Performance details at maximumspeed

Nominal capacity 2850 m

3

h

-1

Suction pressure 33 mbar A

Nominal speed 880 rpm

Motor power 90 kW

Service water flow 5 m

3

h

-1

Performance details at minimumspeed

Nominal capacity 1700 m

3

h

-1

Suction pressure 33 mbar A

Nominal speed 585 rpm

Motor power 45 kW

Service water flow 6 m

3

h

-1

Materials of construction

Suction/Discharge size DN150 PN10 STANDARD STAINLESS

STEEL

STAINLESS

STEEL FITTED

Casing Cast iron CF8M Cast iron

Impeller SG iron CF8M CF8M

Port plate Cast iron CF8M Cast iron

Body Cast iron CF8M Cast iron

Shaft 2C45 XC48 XC48

Mechanical seal Carbon / silicon

carbide / viton

Carbon / silicon

carbide / viton

Carbon / silicon

carbide / viton

ORDERING INFORMATION

Alpha 40+ model is a bareshaft machine and can be supplied as part of a standard

package, incorporating electric motor, baseplate and seal liquid recovery system, suitable

for once through, partial or total recirculation. Custom engineered packages to meet

more complex process system requirements are also available.

For more information please contact your local sales office.

3

m

S

u

c

t

i

o

n

C

a

p

a

c

i

t

y

-

1

h

f

t

-

1

3

m

i

n

k

W

H

P

A

b

s

o

r

b

e

d

P

o

w

e

r

670

800

4

0

0

625

1110

1140

515

185 185

290

4

1

5

4

5

8

5

30

105

65

630

150 150

1

4

0

0

1

0

3

0

8

1

5

2

5

0

3

7

0

2

2

2

4

8925

210 270 270 1425

400

NEW

6

PAGE

296

For North American orders shop online: www.bocedwards.com or call: 1-800-848-9800

ALPHA 50+ SINGLE STAGE

LIQUID RING VACUUM PUMP

Features & benefits

Curved blade impeller and variable discharge port for optimum

performance

Mechanical seals

Minimum number of body joints

Externally mounted bearings

Handles wet or dry gases

Unaffected by liquid carryover

Robust and simple construction

Materials of construction to suit application

Low noise level

TECHNICAL DATA

Performance details at maximumspeed

Nominal capacity 4200 m

3

h

-1

Suction pressure 33 mbar A

Nominal speed 735 rpm

Motor power 110 kW

Service water flow 9 m

3

h

-1

Performance details at minimumspeed

Nominal capacity 2800 m

3

h

-1

Suction pressure 33 mbar A

Nominal speed 490 rpm

Motor power 55 kW

Service water flow 6 m

3

h

-1

Materials of construction

Suction/Discharge size DN200 PN10

STANDARD STAINLESS

STEEL

STAINLESS

STEEL FITTED

Casing Cast iron CF8M Cast iron

Impeller SG iron CF8M CF8M

Port plate Cast iron CF8M Cast iron

Body Cast iron CF8M Cast iron

Shaft 2C45 316 316

Mechanical seal Carbon / silicon

carbide / viton

Carbon / silicon

carbide / viton

Carbon / silicon

carbide / viton

ORDERING INFORMATION

Alpha 50+ model is a bareshaft machine and can be supplied as part of a standard

package, incorporating electric motor, baseplate and seal liquid recovery system, suitable

for once through, partial or total recirculation. Custom engineered packages to meet

more complex process system requirements are also available.

For more information please contact your local sales office.

3

m

S

u

c

t

i

o

n

C

a

p

a

c

i

t

y

-

1

h

f

t

-

1

3

m

i

n

k

W

H

P

A

b

s

o

r

b

e

d

P

o

w

e

r

640

900

1040

4

5

0

740

1343

1330

603

200 200

290

4

7

0

5

0

1

2

0

4 x 36

130

70

785

150 150

1

5

7

0

1

1

2

0

9

4

0

3

0

0

4

5

0

2

4

3

0

1006

220 308 308 170

500

NEW

P

R

O

C

E

S

S

S

Y

S

T

E

M

S

6

PAGE

297

For North American orders shop online: www.bocedwards.com or call: 1-800-848-9800

AL 70+ SINGLE STAGE

LIQUID RING VACUUM PUMP

Features & benefits

Curved blade impeller and variable discharge port for optimum

performance

Mechanical seals

Minimum number of body joints

Externally mounted bearings

Handles wet or dry gases

Unaffected by liquid carryover

Robust and simple construction

Materials of construction to suit application

Low noise level

TECHNICAL DATA

Performance details at maximumspeed

Nominal capacity 6000 m

3

h

-1

Suction pressure 33 mbar A

Nominal speed 650 rpm

Motor power 180 kW

Service water flow 13 m

3

h

-1

Performance details at minimumspeed

Nominal capacity 3800 m

3

h

-1

Suction pressure 33 mbar A

Nominal speed 400 rpm

Motor power 75 kW

Service water flow 6 m

3

h

-1

Materials of construction

Suction/Discharge size DN200 PN10

CAST IRON STAINLESS

STEEL

STAINLESS

STEEL FITTED

Casing Cast iron CF8M Cast iron

Body Cast iron CF8M Cast iron

Impeller SG iron CF8M CF8M

Shaft 2C45 XC48 XC48

Seals Mechanical Mechanical Mechanical

ORDERING INFORMATION

AL 70+ model is a bareshaft machine and can be supplied as part of a standard

package, incorporating electric motor, baseplate and seal liquid recovery system, suitable

for once through, partial or total recirculation. Custom engineered packages to meet

more complex process system requirements are also available.

For more information please contact your local sales office.

3

m

S

u

c

t

i

o

n

C

a

p

a

c

i

t

y

-

1

h

f

t

-

1

3

m

i

n

k

W

H

P

A

b

s

o

r

b

e

d

P

o

w

e

r

2152

170

50 50

1

1

/

2

535 1060

75 75

740

1087 1055

1400

4 holes 36

403

1

3

1

5

2

1

/

2

1

0

1

8

1

1

7

8

1

8

6

5

2

4

5

563

530

403

215

5

0

0

490

640

820

NEW

6

PAGE

298

For North American orders shop online: www.bocedwards.com or call: 1-800-848-9800

AL 100+ SINGLE STAGE

LIQUID RING VACUUM PUMP

Features & benefits

Curved blade impeller and variable discharge port for optimum

performance

Packed Gland or Mechanical seals

Externally mounted bearings

Handles wet or dry gases

Unaffected by liquid carryover

Robust and simple construction

Materials of construction to suit application

Low noise level

Once through, partial or total recovery seal liquid available

TECHNICAL DATA

Performance details at maximumspeed

Nominal capacity 8000 m

3

h

-1

Suction pressure 33 mbar A

Nominal speed 545 rpm

Motor power 200 kW

Service water flow 18 m

3

h

-1

Performance details at minimumspeed

Nominal capacity 5000 m

3

h

-1

Suction pressure 33 mbar A

Nominal speed 335 rpm

Motor power 90 kW

Service water flow 9 m

3

h

-1

Materials of construction

Suction/Discharge size DN250 PN10

CAST IRON STAINLESS

STEEL

STAINLESS

STEEL FITTED

Casing Cast iron CF8M Cast iron

Body Cast iron CF8M Cast iron

Impeller SG iron CF8M CF8M

Shaft 2C45 XC48 XC48

Seals Mechanical Mechanical Mechanical

ORDERING INFORMATION

AL 100+ model is a bareshaft machine and can be supplied as part of a standard

package, incorporating electric motor, baseplate and seal liquid recovery system, suitable

for once through, partial or total recirculation. Custom engineered packages to meet

more complex process system requirements are also available.

For more information please contact your local sales office.

3

m

S

u

c

t

i

o

n

C

a

p

a

c

i

t

y

-

1

h

f

t

-

1

3

m

i

n

k

W

H

P

A

b

s

o

r

b

e

d

P

o

w

e

r

40

60

80

100

120

140

160

180

200

4 holes 40

450

1

5

0

0

0

2

1

/

2

1

1

8

0

1

3

5

5

2

1

6

5

3

2

0

625

615

955

450

260

2525

180

60 60

1

1

/

2

677 1140

75 75

850

1278 1247

1650

6

5

0

7

0

6

0

0

595

750

NEW

P

R

O

C

E

S

S

S

Y

S

T

E

M

S

6

PAGE

299

For North American orders shop online: www.bocedwards.com or call: 1-800-848-9800

AL 140+ SINGLE STAGE

LIQUID RING VACUUM PUMPS

Features & benefits

Curved blade impeller and variable discharge port for optimum

performance

Mechanical seals

Minimum number of body joints

Externally mounted bearings

Handles wet or dry gases

Unaffected by liquid carryover

Robust and simple construction

Materials of construction to suit application

Low noise level

TECHNICAL DATA

Performance details at maximumspeed

Nominal capacity 11000 m

3

h

-1

Suction pressure 33 mbar A

Nominal speed 470 rpm

Motor power 300 kW

Service water flow 25 m

3

h

-1

Performance details at minimumspeed

Nominal capacity 6500 m

3

h

-1

Suction pressure 33 mbar A

Nominal speed 290 rpm

Motor power 132 kW

Service water flow 12 m

3

h

-1

Materials of construction

Suction/Discharge size DN300 PN10

CAST IRON STAINLESS

STEEL

STAINLESS

STEEL FITTED

Casing Cast iron CF8M Cast iron

Body Cast iron CF8M Cast iron

Impeller SG iron CF8M CF8M

Shaft 2C45 XC48 XC48

Seals Mechanical Mechanical Mechanical

ORDERING INFORMATION

AL 140+ model is a bareshaft machine and can be supplied as part of a standard

package, incorporating electric motor, baseplate and seal liquid recovery system, suitable

for once through, partial or total recirculation. Custom engineered packages to meet

more complex process system requirements are also available.

For more information please contact your local sales office.

3

m

S

u

c

t

i

o

n

C

a

p

a

c

i

t

y

-

1

h

f

t

-

1

3

m

i

n

k

W

H

P

A

b

s

o

r

b

e

d

P

o

w

e

r

4 holes 40

588.5

1

6

6

7

.

5

3

1

2

9

5

1

6

1

5

2

4

4

0

3

1

0

808.5

770

790

980

1190

588.5

307.5

2790

210

75 75

2

725 1315

95 95

1015

1407.5 1382.5

1900

7

7

0

8

5

7

0

0

NEW

6

PAGE

300

For North American orders shop online: www.bocedwards.com or call: 1-800-848-9800

LR2S50 TWO STAGE PUMP

Features & benefits

Pumps wet and dry gases

Higher efficiency at low pressures

Selection of materials to suit application

DIN 24960 mechanical seal

Simple rugged design

Pedestal mountingoption

TECHNICAL DATA

Performance details 50 Hz

Nominal capacity 55 m

3

h

-1

Suction pressure 33 mbar A

Nominal speed 2850 rpm

Motor power 2.2 kW

Service water flow 0.8 m

3

h

-1

Performance details 60 Hz

Nominal capacity 65 m

3

h

-1

Suction pressure 33 mbar A

Nominal speed 3450 rpm

Motor power 3 kW

Service water flow 0.8 m

3

h

-1

Materials of construction

1 60 Hz 2 50 Hz

1 60 Hz 2 50 Hz

Suction/Discharge size 1 1/4" BSP

STANDARD STAINLESS

STEEL

STAINLESS

STEEL FITTED

Casing Cast iron CF8M Cast iron

Impeller Bronze CF8M CF8M

Port plate Cast iron CF8M Cast iron

Body Cast iron CF8M Cast iron

Shaft 420S37 316 420S37

Mechanical seal Carbon / silicon

carbide / viton

Carbon / silicon

carbide / viton

Carbon / silicon

carbide / viton

ORDERING INFORMATION

LR2S50 model is a bareshaft pump with a pedestal mounted option LR2L50 suitable for

C flange motors, following motor options are offered as standard.

IEC Eurovoltage 220-240/380-415/3/50Hz, IP55, Class F, B3/B5

IEC 230-460/3/60Hz, IP55, Class F, B3/B5

NEMA UL CSA Epact 230-460/3/60Hz, IP55, Class F B3/B5

These pumps can be supplied as complete package systems, suitable for once through,

partial or total recirculation of the seal liquid. Special and hazardous motors are available

on request. Custom engineered packages to meet more complex process system

requirements are also available.

For more information please contact your local sales office.

-

1

15

m

h

3

LR2S50

400 200 120 80 33 40 60 mbar 1013 800

20

25

40

30

35

55

45

50

70

60

65

75

2

1

10

15

25

20

30

40

35

f

t

-

1

3

m

i

n

25 60 40 30 100 760 200 600 400 Torr

20000

3300

4000 8000

6000 12000 101300 40000

80000

Pa

S

u

c

t

i

o

n

C

a

p

a

c

i

t

y

60

3300

LR2S50

400 200 120 80 33 40 60

12000 6000

4000 8000 20000

40000

30 40 25

mbar 1013 800

101300

80000

Pa

k

W

760 400 600 200 100 Torr

0.5

H

P

1

2

1.0

1.5

2.0

2.5

3.0

3.5

4.0

3.5

3.0

2.5

2.0

1.5

1.0

4.5

A

b

s

o

r

b

e

d

P

o

w

e

r

(2.28)

365 (14.37) 58

441 (17.36)

250 (9.84) 116 (4.57)

2

1

8

(

8

.

5

8

)

2

5

5

(

1

0

.

0

4

)

(

3

.

9

4

)

1

0

0

185 (7.28)

152 (5.98)

1

9

(

0

.

7

5

)

1

0

0

4 x 12

(0.47)

(

3

.

9

4

)

(1.58)

40

NEW

P

R

O

C

E

S

S

S

Y

S

T

E

M

S

6

PAGE

301

For North American orders shop online: www.bocedwards.com or call: 1-800-848-9800

LR2S100 TWO STAGE PUMP

Features & benefits

Pumps wet and dry gases

Higher efficiency at low pressures

Selection of materials to suit application

DIN 24960 mechanical seal

Simple rugged design

Pedestal mountingoption

TECHNICAL DATA

Performance details 50 Hz

Nominal capacity 90 m

3

h

-1

Suction pressure 33 mbar A

Nominal speed 1450 rpm

Motor power 3 kW

Service water flow 1 m

3

h

-1

Performance details 60 Hz

Nominal capacity 100 m

3

h

-1

Suction pressure 33 mbar A

Nominal speed 1750 rpm

Motor power 4 kW

Service water flow 1 m

3

h

-1

Materials of construction

1 60 Hz 2 50 Hz

1 60 Hz 2 50 Hz

Suction/Discharge size 1 1/2" BSP

STANDARD STAINLESS

STEEL

STAINLESS

STEEL FITTED

Casing Cast iron CF8M Cast iron

Impeller Bronze CF8M CF8M

Port plate Cast iron CF8M Cast iron

Body Cast iron CF8M Cast iron

Shaft 420S37 316 420S37

Mechanical seal Carbon / silicon

carbide / viton

Carbon / silicon

carbide / viton

Carbon / silicon

carbide / viton

ORDERING INFORMATION