Académique Documents

Professionnel Documents

Culture Documents

Work Undertaken: 3.1 Fabrication/Development

Transféré par

lokeshjakharDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Work Undertaken: 3.1 Fabrication/Development

Transféré par

lokeshjakharDroits d'auteur :

Formats disponibles

33

CHAPTER 3

WORK UNDERTAKEN

3.1 Fabrication/Development

The project is fabricated in four main steps

Step 1: Adding 2

nd

Spark Plug in Head of Two Stroke Gasoline Engine:

First of all cylinder head is opened and with help of lathe machine a hole is drilled in the

cylinder head where 2

nd

spark plug is fitted. After that cylinder head is checked for

leaking and leakage is prevent by applying some industrial glue which can withstand at

high temperature and pressure. Figure 3.1 shows the cylinder head having two spark plug.

Figure 3.1: Cylinder Head having two spark plug

Step 2: Pulley is attached to the flywheel

Figure 3.2: Attachment of Pulley with Flywheel

1

st

Spark Plug

2

nd

Spark Plug

Flywheel

Pulley

34

Pulley is attached to flywheel by extending crankshaft. It is useful in measuring brake

power with help of rope brake dynamometer.

Step 3: Mounting Engine on Iron Strip Frame

After attaching the pulley, whole engine is mounted on the frame so that testing can be

done easily.

Figure 3.3: Mounting Engine on Frame

Step 4: Attaching Fuel Bottle for measuring fuel consumption

After mounting the engine on frame, fuel bottle is attached with the input of carburetor.

Main function of this fuel bottle is to supply the fuel to engine.

Figure 3.4: Fuel Bottle arrangement

Iron Frame

Fuel Bottle

35

3.2 Performance Parameters

1. Brake Power

The break power is the power available at the crank shaft. The break power of an I.C.

engine is, usually, measured by means of break mechanism.

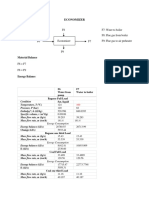

Break power (B.P) =

2

60

watts

T = Torque in N-m

= W * L N-m

W = Break load in Newton.

L = Length of arm in meters,

N = Speed of the engine in R.P.M

2. Fuel Consumption

The fuel consumption characteristics of an engine and it is defined as the mass of

fuel consumed per second. Its unit is Kg/sec.

Mass of fuel in kg per second, m

f

=

v

t

v = Volume of fuel consumed per second in m

3

/Sec.

= Density of fuel in Kg/m

3

t = Time in Seconds

3. Brake Thermal Efficiency

It is the ratio of the heat equivalent to one KW hour to the heat in the fuel per B.P

hour. It is also known as overall thermal efficiency of the engine.

Brake thermal efficiency,

=

Brake power

Energy supplied

*100%

Energy Supplied = m

f

*C

m

f

= Mass of fuel consumed in Kg/Sec.

C = Calorific value of fuel in KJ/Kg

3.3 Experimental Procedure

The performance test on the engine was carried out as follows:-

At first, it was checked that the fuel tank was filled by fuel and the fuel line were free

from air.

Then the engine was started.

36

By keeping the load constant speed was varied and data were taken when only 1

st

Spark Plug is turned ON and when both Spark Plugs are turned ON.

For every 10 cc of fuel consumption the time was taken and noted that for a particular

rpm.

The rpm was taken from the crank shaft by the tachometer.

Similarly five data was taken by the previous procedure.

Figure 3.5: Two Stroke Gasoline Engine Test Rig

3.4 Experimental Data

For 1 Kg Load and only one spark plug is turned on

Table 3.1: Experimental data table for 1 Kg Load and 1

st

Spark Plug is ON

S.No.

Speed in rpm Time/10cc fuel consumption

(Sec.)

01

2030 110

02

2223 101

03

2310 98

04

2435 91

05 2555 85

37

Table 3.2: Calculation table for load 1 Kg and 1

st

Spark Plug is ON

For 1 Kg Load and Both Spark Plugs are Turned ON

Table 3.3: Experimental data table for 1 Kg Load and both Spark Plugs are ON

Load

(kg)

S.No. Speed

(rpm)

Time for

10cc fuel

Con.(sec)

Mass of

fuel

consumed

in

Kg per sec

mf*10

-5

Brake

power

(KW)

Brake

thermal

efficiency

(%)

1

01 2030 110 6.73 0.271 8.364

02 2223 101 7.327 0.2969 8.43

03 2310 98 7.55 0.3085 8.49

04 2435 91 8.132 0.3252 8.31

05 2555 85 8.605 0.3412 8.24

S.No.

Speed in rpm Time/10cc fuel

consumption

(Sec.)

01

2038 112

02

2235 104

03

2315 101

04

2431 93

05 2550 88

38

Table 3.4: Calculation table for load 1 Kg and both Spark Plugs are ON

For 1.5 Kg Load and only one Spark Plug is Turned ON

Table 3.5: Experimental data table for 1.5 Kg Load and 1

st

Spark Plug is ON

Load

(kg)

S.No. Speed

(rpm)

Time for

10cc fuel

Con.(sec)

Mass of fuel

consumed

in

Kg per sec

mf*10

-5

Brake

power

(KW)

Brake

thermal

efficiency

(%)

1

01 2038 112 6.60 0.272 8.56

02 2235 104 7.11 0.298 8.71

03 2315 101 7.32 0.309 8.77

04 2431 93 7.95 0.324 8.47

05 2550 88 8.40 0.340 8.41

S.No.

Speed in rpm Time/10cc fuel consumption

(Sec.)

01

1954 97

02

2103 92

03

2265 90

04

2351 84

05 2447 79

39

Table 3.6: Calculation table for load 1.5 Kg and 1

st

Spark Plug is ON

For 1.5 Kg Load and Both Spark Plugs are Turned ON

Table 3.7: Experimental data table for 1.5 Kg Load and both Spark Plugs are ON

Load

(kg)

S.No. Speed

(rpm)

Time for

10cc fuel

Con.(sec)

Mass of fuel

consumed in

Kg per sec

mf*10

-5

Brake

power

(KW)

Brake

thermal

efficiency

(%)

1.5

01 1954 97 7.62 0.3914 10.67

02 2103 92 8.04 0.421 10.90

03 2265 90 8.22 0.453 11.46

04 2351 84 8.80 0.470 11.11

05 2447 79 9.36 0.490 10.88

S.No.

Speed in rpm Time/10cc fuel consumption

(Sec.)

01

1960 100

02

2125 94

03

2293 92

04

2365 88

05 2468 83

40

Table 3.8: Calculation table for load 1.5 Kg and both Spark Plugs are ON

For 2 Kg Load and only one Spark Plug is Turned ON

Table 3.9: Experimental data table for 2 Kg Load and 1

st

Spark Plug is ON

Load

(kg)

S.No. Speed

(rpm)

Time for

10cc fuel

Con.(sec)

Mass of fuel

consumed in

Kg per sec

mf*10

-5

Brake

power

(KW)

Brake

thermal

efficiency

(%)

1.5

01 1960 100 7.40 0.392 11.01

02 2125 94 7.87 0.425 11.22

03 2293 92 8.04 0.459 11.86

04 2365 88 8.40 0.473 11.70

05 2468 83 8.91 0.494 11.52

S.No.

Speed in rpm Time/10cc fuel consumption

(Sec.)

01

1835 77

02

1960 73

03

2042 69

04

2156 67

05 2239 61

41

Table 3.10: Calculation table for load 2 Kg and 1

st

Spark Plug is ON

For 2 Kg Load and Both Spark Plugs are Turned ON

Table 3.11: Experimental data table for 2 Kg Load and both Spark Plugs are ON

Load

(kg)

S.No. Speed

(rpm)

Time for

10cc fuel

Con.(sec)

Mass of fuel

consumed in

Kg per sec

mf*10

-5

Brake

power

(KW)

Brake

thermal

efficiency

(%)

2

01 1835 77 9.61 0.490 10.60

02 1960 73 10.14 0.523 10.72

03 2042 69 10.72 0.545 10.57

04 2156 67 11.04 0.575 10.83

05 2239 61 12.13 0.598 10.24

S.No.

Speed in rpm Time/10cc fuel consumption

(Sec.)

01

1840 79

02

1963 76

03

2049 72

04

2158 70

05 2242 62

42

Table 3.12: Calculation table for load 2 Kg and both Spark Plugs are ON

3.5 Sample Calculation

Density of Gasoline, =740 kg/m

3

Calorific value of Gasoline, C=48100 kj/kg

For 1 Kg Load and Only One Spark Plug is Turned ON

Speed 2310 rpm

Time / 10cc of fuel consumption, t = 98 s

Mass of fuel in kg per second, m

f

=

v

t

=

7401010

6

98

= 7.55 10

5

kg/s

Energy supplied by fuel =

= 7.55 10

5

48100

= 3.63 kw

Brake power, B.P. =

T2N

60

=

19.81.1323.14162310

60

= 0.3085 kw

Brake thermal efficiency,

=

Brake power

Energy supplied

*100%

Load

(kg)

S.No. Speed

(rpm)

Time for

10cc fuel

Con.(sec)

Mass of fuel

consumed

in

Kg per sec

mf*10

-5

Brake

power

(KW)

Brake

thermal

efficiency

(%)

2

01 1840 79 9.36 0.491 10.91

02 1963 76 9.73 0.524 11.19

03 2049 72 10.27 0.547 11.07

04 2158 70 10.57 0.576 11.32

05 2242 62 11.93 0.599 10.43

43

=

0.3085

3.63

*100% = 8.49%

For 1 Kg Load and both Spark Plugs are Turned ON

Speed 2315 rpm

Time / 10cc of fuel consumption, t = 101 s

Mass of fuel in kg per second, m

f

=

v

t

=

7401010

6

101

= 7.32 10

5

kg/s

Energy supplied by fuel =

= 7.32 10

5

48100

= 3.52 kw

Brake power, B.P. =

T2N

60

=

19.81.1323.14162315

60

= 0.309 kw

Brake thermal efficiency,

=

Brake power

Energy supplied

*100%

=

0.309

3.52

*100%

= 8.77%

For 1.5 Kg Load and Only One Spark Plug is Turned ON

Speed 2265 rpm

Time / 10cc of fuel consumption, t = 90 s

Mass of fuel in kg per second, m

f

=

v

t

=

7401010

6

90

= 8.22 10

5

kg/s

Energy supplied by fuel =

= 8.22 10

5

48100

= 3.95 kw

Brake power, B.P. =

T2N

60

=

1.59.81.1323.14162265

60

= 0.453 kw

44

Brake thermal efficiency,

=

Brake power

Energy supplied

*100%

=

0.453

3.95

*100% = 11.46%

For 1.5 Kg Load and both Spark Plugs are Turned ON

Speed 2293 rpm

Time / 10cc of fuel consumption, t = 92 s

Mass of fuel in kg per second, m

f

=

v

t

=

7401010

6

92

= 8.04 10

5

kg/s

Energy supplied by fuel =

= 8.04 10

5

48100

= 3.867 kw

Brake power, B.P. =

T2N

60

=

1.59.81.1323.14162293

60

= 0.459 kw

Brake thermal efficiency,

=

Brake power

Energy supplied

*100%

=

0.459

3.867

*100%

= 11.86%

For 2 Kg Load and Only One Spark Plug is Turned ON

Speed 2156 rpm

Time / 10cc of fuel consumption, t=67 s

Mass of fuel in kg per second, m

f

=

v

t

=

7401010

6

67

= 11.045 10

5

kg/s

Energy supplied by fuel =m

f

c

=11.045 10

5

48100

=5.312 kw

Brake power, B.P. =

T2N

60

=

29.81.1323.14162156

60

45

= 0.5758 kw

Brake thermal efficiency,

=

Brake power

Energy supplied

*100%

=

0.5758

5.312

*100%

= 10.83%

For 2 Kg Load and both Spark Plugs are Turned ON

Speed 2158 rpm

Time / 10cc of fuel consumption, t = 70 s

Mass of fuel in kg per second, m

f

=

v

t

=

7401010

6

70

= 10.57 10

5

kg

s

Energy supplied by fuel =

= 10.57 10

5

48100

= 5.084 kw

Brake power, B.P. =

T2N

60

=

29.81.1323.14162158

60

= 0.576 kw

Brake thermal efficiency,

=

Brake power

Energy supplied

*100% =

0.576

5.084

100%

= 11.32%

3.6 Costing Details

Costing details of the fabrication of project is as follows:

Table 3.13: Costing Details

Sr.

No.

Items Cost ( )

1. Two Stroke Gasoline Engine 5500

2. Spark Plug 300

3. Iron Frames Strips 1200

4. Switching Arrangement 700

5. Lathe Work 1000

6. Pulley with Lathe Machine Work 500

7. Extension of Crank Shaft 450

46

8. Carburetor Arrangement with Speed Wire 800

9. Miscellaneous Arrangements 200

Total 10,650

Vous aimerez peut-être aussi

- Diesel Engine: Dublin Institute of TechnologyDocument6 pagesDiesel Engine: Dublin Institute of TechnologyShiyas BasheerPas encore d'évaluation

- 4 Stroke Single Cylinder Diesel EngineDocument4 pages4 Stroke Single Cylinder Diesel EngineDebadatta RathaPas encore d'évaluation

- Morse TestDocument5 pagesMorse TestAbhishek KhatavkarPas encore d'évaluation

- Experiment No. 7 - PascualDocument14 pagesExperiment No. 7 - PascualJefferson PascualPas encore d'évaluation

- Internal Combustion Engine: Name: Hossam Gamal Mahmoud Khalil ID:18010553Document15 pagesInternal Combustion Engine: Name: Hossam Gamal Mahmoud Khalil ID:18010553hossam gamalPas encore d'évaluation

- Anurag Porte - IC Engines Lab Report: Lab-1: Performance Measurement of The EngineDocument11 pagesAnurag Porte - IC Engines Lab Report: Lab-1: Performance Measurement of The EngineAnurag portePas encore d'évaluation

- Cycle Engine PDFDocument6 pagesCycle Engine PDFk marcusPas encore d'évaluation

- Applied Mechanical Engineering Engine Power Cycle: SolutionDocument6 pagesApplied Mechanical Engineering Engine Power Cycle: SolutionAlteaAlPas encore d'évaluation

- Abstract.: Pakkip KraisodaDocument6 pagesAbstract.: Pakkip KraisodaNixon WibisonoPas encore d'évaluation

- VCR EngineDocument6 pagesVCR EngineAbPas encore d'évaluation

- Thermodynamics ReportDocument6 pagesThermodynamics ReportHarsh Vora100% (1)

- 1 - Lab - ICE - Engine Energy BalanceDocument7 pages1 - Lab - ICE - Engine Energy BalanceAcfMacPas encore d'évaluation

- 7 National Certification Examination FOR Energy Auditors - Nov., 2008Document8 pages7 National Certification Examination FOR Energy Auditors - Nov., 2008venkatraman1985Pas encore d'évaluation

- Diesel Engine Lab ReportDocument11 pagesDiesel Engine Lab ReportJoshua ReynoldsPas encore d'évaluation

- Load Test On A Perkins Diesel EngineDocument8 pagesLoad Test On A Perkins Diesel EnginePeshala Gamage100% (1)

- Ic Enginelab (Me3475) Experiment 2 Kangad Devang (Me16Btech11015)Document4 pagesIc Enginelab (Me3475) Experiment 2 Kangad Devang (Me16Btech11015)Devang KangadPas encore d'évaluation

- Boiler Dengan Safety FactorDocument8 pagesBoiler Dengan Safety FactorFarah HafizhahPas encore d'évaluation

- Boiler Specific Energy Consumption and Heat Rate CalculationDocument11 pagesBoiler Specific Energy Consumption and Heat Rate CalculationNimi SharmaPas encore d'évaluation

- Experiment 17: ObjectiveDocument5 pagesExperiment 17: ObjectiveAbdullah KhanPas encore d'évaluation

- A. B. C. D. E.: Where R (D + D) /2 or (D + T) /2 M, and W (Load) (S - S) KGDocument5 pagesA. B. C. D. E.: Where R (D + D) /2 or (D + T) /2 M, and W (Load) (S - S) KGal hasan kanonPas encore d'évaluation

- Example 6 GasturbineDocument2 pagesExample 6 GasturbineAb BasitPas encore d'évaluation

- Economize R 3 TrialDocument19 pagesEconomize R 3 TrialNitish AmnerkarPas encore d'évaluation

- Afriyie UE20045213 ICE AssignmentDocument11 pagesAfriyie UE20045213 ICE AssignmentFrancis OfosuPas encore d'évaluation

- Experiment No.-04: Heat Balance On 4 Stroke Single Cylinder Diesel Engine AIMDocument8 pagesExperiment No.-04: Heat Balance On 4 Stroke Single Cylinder Diesel Engine AIMRohu PaliwalPas encore d'évaluation

- Internal Combustion Engines Lab: ObjectivesDocument9 pagesInternal Combustion Engines Lab: ObjectivesM Junaid tabassumPas encore d'évaluation

- Model Calculation NKarthickDocument24 pagesModel Calculation NKarthickSeenu Hassan100% (2)

- Gujarat BOE 2015 Paper 1 SolutionDocument7 pagesGujarat BOE 2015 Paper 1 SolutionSaravana Prasad100% (1)

- MEC 4402 LAB 3 Effect of Varrying The Compression Ratio Ricardo E.6 EngineDocument12 pagesMEC 4402 LAB 3 Effect of Varrying The Compression Ratio Ricardo E.6 EngineJoseph MwansaPas encore d'évaluation

- Linked Que 4-7Document5 pagesLinked Que 4-7Pranav MishraPas encore d'évaluation

- Thermal CyclesDocument6 pagesThermal CyclesSathish Kasilingam0% (1)

- Practical Exercise 1-2-3Document14 pagesPractical Exercise 1-2-3Pink FloydaPas encore d'évaluation

- Performace Test On Otto Engine With Premium and Pertamax FuelDocument12 pagesPerformace Test On Otto Engine With Premium and Pertamax FuelRifanni JuliantiPas encore d'évaluation

- Foundations of Energy Past Paper 1 SolutionsDocument6 pagesFoundations of Energy Past Paper 1 Solutionsapi-3765936Pas encore d'évaluation

- 2 Stroke Petrol EngineDocument9 pages2 Stroke Petrol EnginePurushotham PulivarthiPas encore d'évaluation

- Fallsem2013-14 Cp0084 Asgn03 Assignment3Document2 pagesFallsem2013-14 Cp0084 Asgn03 Assignment3Agnibh PrakashPas encore d'évaluation

- 2 15 139047550627 32Document6 pages2 15 139047550627 32Sunil SingireddyPas encore d'évaluation

- Energy Assesment of BoilerDocument22 pagesEnergy Assesment of BoilerBrijesh SrivastavPas encore d'évaluation

- General Sciences ProblemsDocument9 pagesGeneral Sciences ProblemsArvn Christian Santicruz Flores0% (1)

- Soal Dan Jawaban InternalcombustionenginesDocument8 pagesSoal Dan Jawaban Internalcombustionenginesrobyharyudha100% (1)

- Conversion Used: Name: Manish Paradkar Assignment No 1Document9 pagesConversion Used: Name: Manish Paradkar Assignment No 1Ankush JakhmolaPas encore d'évaluation

- Apg1000 Specs 74hc595 NXPDocument7 pagesApg1000 Specs 74hc595 NXPNatgas WebmasterPas encore d'évaluation

- Applied Thermodynamics Otto Dual Ic EnginesDocument2 pagesApplied Thermodynamics Otto Dual Ic EnginesAkshay A KumarPas encore d'évaluation

- MEET 324L MEE31 32 ME Lab2 Midterm Summative Ass Set B (15 21mar2024)Document5 pagesMEET 324L MEE31 32 ME Lab2 Midterm Summative Ass Set B (15 21mar2024)kimbenedictaguilar19Pas encore d'évaluation

- SantroDocument16 pagesSantroThapa Pramod100% (1)

- Solved ProblemsDocument15 pagesSolved ProblemsMichaelle Angela Arnedo70% (10)

- Final PPT (1) .Document34 pagesFinal PPT (1) .Sharath 303Pas encore d'évaluation

- FD Fan Efficiency CalculationDocument6 pagesFD Fan Efficiency CalculationPraveen VaratharajanPas encore d'évaluation

- Fuel Cost ComaparaisionDocument8 pagesFuel Cost ComaparaisionIrfan AhmedPas encore d'évaluation

- ProjectDocument18 pagesProjectSharath 303Pas encore d'évaluation

- Benha University Final Examination2009 SolutionDocument13 pagesBenha University Final Examination2009 SolutionAyman Esa100% (1)

- Heat Balance SheetDocument5 pagesHeat Balance SheetAnmol MalgotraPas encore d'évaluation

- Performance Test of Pelton TurbineDocument6 pagesPerformance Test of Pelton TurbineMd. Tariqul Islam MunnaPas encore d'évaluation

- ECE Conentration and Unit Problems - T1Document9 pagesECE Conentration and Unit Problems - T1DanialPas encore d'évaluation

- Gujarat Boiler Examination Board Boiler Operation Engineer Exam-2017Document6 pagesGujarat Boiler Examination Board Boiler Operation Engineer Exam-2017Alok DoshiPas encore d'évaluation

- Heat BalanceDocument18 pagesHeat BalanceVinish Shankar100% (1)

- MCG 2131 Exam 08Document6 pagesMCG 2131 Exam 08子豪王Pas encore d'évaluation

- Heat Exchanger DesignDocument15 pagesHeat Exchanger DesignCharito Sollera AlbaricoPas encore d'évaluation

- 11.solid Waste Management PDFDocument4 pages11.solid Waste Management PDFVivek KodoorPas encore d'évaluation

- ASI Rhinophalt Technical and SafteyDocument2 pagesASI Rhinophalt Technical and SafteyIndrajeet UpadhyayPas encore d'évaluation

- History Additive ManufacturingDocument7 pagesHistory Additive ManufacturingbrunosipodPas encore d'évaluation

- Combined Instrument Transformers Ivokt TMCDocument8 pagesCombined Instrument Transformers Ivokt TMCRamzan100% (1)

- Phase Changes Independent Practice Spring 2016Document3 pagesPhase Changes Independent Practice Spring 2016Jarrod CollinsPas encore d'évaluation

- Borneras ChintDocument2 pagesBorneras ChintGina Moron MoronPas encore d'évaluation

- Extraction and Uses of Metals 3 MS PDFDocument7 pagesExtraction and Uses of Metals 3 MS PDFAngus AnizPas encore d'évaluation

- Omm 1106c GensetDocument92 pagesOmm 1106c GensetJessica Tatiana Muñoz Ortiz100% (1)

- Approved: Materials Engineering SpecificationDocument2 pagesApproved: Materials Engineering SpecificationRonald AraujoPas encore d'évaluation

- (Environmental Engineering Vol. 2) Santosh Kumar Garg - SEWAGE DISPOSAL and AIR POLLUTION ENGINEERING. 2-Khanna Publishers (2012)Document1 016 pages(Environmental Engineering Vol. 2) Santosh Kumar Garg - SEWAGE DISPOSAL and AIR POLLUTION ENGINEERING. 2-Khanna Publishers (2012)syed tabPas encore d'évaluation

- Pneumatic CylindersDocument5 pagesPneumatic CylindersgokulahbPas encore d'évaluation

- 8 p1517 1550 FH - en PDFDocument34 pages8 p1517 1550 FH - en PDFfarid kerrouchePas encore d'évaluation

- Design A Hybrid Solar BicycleDocument32 pagesDesign A Hybrid Solar Bicycleakash100% (1)

- Cafflano Ç Klassic User TipsDocument14 pagesCafflano Ç Klassic User TipsismuPas encore d'évaluation

- Techinical Guide ZF 078 Thru 150 R410A Predator Single Packaged Unitr (Generation 6) - 528194-Ytg-M-0813Document68 pagesTechinical Guide ZF 078 Thru 150 R410A Predator Single Packaged Unitr (Generation 6) - 528194-Ytg-M-0813Rolando VenegasPas encore d'évaluation

- Surface PreparationDocument31 pagesSurface PreparationT aljuPas encore d'évaluation

- Monitor m8-m9 User ManualDocument242 pagesMonitor m8-m9 User Manualcarlos6696Pas encore d'évaluation

- Honeywell Searchpoint OptimaPlus MAN0551Document140 pagesHoneywell Searchpoint OptimaPlus MAN0551Sameer KaparePas encore d'évaluation

- Carrier 30s InstallationDocument30 pagesCarrier 30s InstallationpuzsooPas encore d'évaluation

- Septic Tank Design ComputationDocument1 pageSeptic Tank Design ComputationEngilbert AragonPas encore d'évaluation

- Safety Data Sheet: Masterseal 345Document7 pagesSafety Data Sheet: Masterseal 345mkashkooli_scribdPas encore d'évaluation

- ATLAS OF ISOTHERMAL TRANSFORMATION AND COOLING TRANSFORMATION DIAGRAMS - CompressedDocument430 pagesATLAS OF ISOTHERMAL TRANSFORMATION AND COOLING TRANSFORMATION DIAGRAMS - CompressedYENIFER PLATA LOPEZPas encore d'évaluation

- Safety EngineeringDocument32 pagesSafety EngineeringPrecious Anne Palma100% (3)

- Hermes-Pjt Training Manual: RSJ1/RSH1Document152 pagesHermes-Pjt Training Manual: RSJ1/RSH1Cesar Calderon Gr100% (2)

- Inspection ChecklistDocument1 pageInspection ChecklistAli Asim Iftikhar75% (4)

- Delco Remy Diagnostic Procedures Manual PDFDocument32 pagesDelco Remy Diagnostic Procedures Manual PDFjohansen05100% (2)

- CEBECO I LINE COST (As of July 2006)Document24 pagesCEBECO I LINE COST (As of July 2006)Sugar RayPas encore d'évaluation

- Feasibility Study of Jamalpur EZDocument204 pagesFeasibility Study of Jamalpur EZTawseef HossainPas encore d'évaluation

- DWM Solids Control HandbookDocument321 pagesDWM Solids Control HandbookMahmoud Ahmed Ali Abdelrazik100% (1)

- Thermo Electron 15Document2 pagesThermo Electron 15AlexPas encore d'évaluation