Académique Documents

Professionnel Documents

Culture Documents

Filter Separator English Letter

Transféré par

marcoo8Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Filter Separator English Letter

Transféré par

marcoo8Droits d'auteur :

Formats disponibles

www.exterran.

com

HORIZONTAL FILTER SEPARATOR

Remove Damaging Contaminants from

High Gas/Low Liquid Flow Applications

Key Benefits

Maximize Production

Startup faster with quick delivery from our large

inventory of new vessels.

Increase production and minimize downtime

with the proven design and construction of an

industry leader.

Simplify operation with extended flter supports

that eliminate the need for an inlet diverter.

Lower Costs

Protect your equipment from damaging

contaminants with thorough and reliable fltration.

Extend flter element life with our unique supporting

brackets that prevent elements from sagging.

Obtain fast, professional service, support and

spare parts from our local technicians in every

major oil & gas producing area.

Manage Risk

Optimize safety with the latest ASME standards

code stamped on each unit and ensuring

consistent design and construction.

Safeguard your investment with our warranty 12

months from startup or an 18 months from delivery.

Standard Features

Sight glass assembly

Liquid level controllers

Liquid dump valve(s)

Thermometer and thermowell

Instrument gas supply drip pot with regulators

High/low pressure regulator

Differential pressure indicator (DPI) with three

valve manifold

Pressure gauge

Pressure relief valve

Jonell-brand flter elements

Wire mesh mist extractor

Single liquid boot on 6-30 inch units

Dual liquid boots on 30 inch and larger units

Lifting lugs for safe handling

OVERVIEW

The Exterran Production Solutions Horizontal Filter Separator is a

sturdy, combination package designed to remove contaminants from

liquid-free natural gas streams.

Available in single and dual boot, flter-separators containing one

micron flter elements are used for the removal of dust, rust and

small particles and handle gas capacities up to 321 MMscfd at

1400 psig.

Vessels containing 0.3 micron elements are used for the removal

of lube oil and other contaminants and handle gas capacities up to

221 MMscfd at 1400 psig. Exterran also offers expertise to design

and build customized units outside of our standard range.

Our flter separators are designed for high gas/low liquid fow

operations and are typically employed upstream and downstream of

compressors, glycol dehydration units and fuel gas applications.

HOW IT WORKS

As natural gas enters the unit, flter tubes and elements in the frst

section capture solid particles and cause any liquids present in the

stream to coalesce into larger droplets. In the second section, the wire

mesh or vane mist extractor captures the liquid droplets. The resulting

stream is then virtually free of all particles two microns and larger.

The standard unit is equipped with one or two liquid boots to collect

fuids removed from the gas stream. The fuids are discharged

from the vessel by means of an automatic level controller and level

control valve.

Length

Length

OD

Length

Length

OD

www.exterran.com

This tech sheet is intended for general information purposes only and is not intended as a

representation or warranty of any kind, or as a statement of any terms or conditions of sale.

The information herein is believed to be correct, but is not warranted for correctness or

completeness or for applicability to any particular customer or situation.

Copyright 2012 Exterran Holdings, Inc. All rights reserved. FILTER-PDS-08-04-EN-DE12-US

Corporate Offce

16666 Northchase Drive

Houston, TX 77060

Options Checklist

o API 14C rated

o Flanged connections

o Sentry closure (other brands available)

o Three-valve bypass

o Vane mist extractor

o Customized capacity ratings

o Manway

o Skid-mounted with drain pan

o Concrete blocks

o Full installation

o NACE service

HORIZONTAL FILTER SEPARATOR

Remove Damaging Contaminants from High Gas/Low Liquid Flow Applications

Notes

ooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooo

ooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooo

Sizing Requirements

Gas Flow

Rate (MMscfd)

Pressure (psig)

Temp (F)

Specifc Gravity

Sour Service

Yes/No

CO

2

(mol%)

H

2

S (ppm)

Skid Mounted Yes / No

Standard Paint Yes / No

Application

Lube Oil

Solid Particles

* Dual boot 42 inch unit is available with either 0.3 or 1 micron flter element.

Standard specifcations based on design: T=60 F, SG=0.65, C=80 fps.

Standard MWAP is 1440 psig unless otherwise specifed.

Contact an Exterran representative to submit sizing information.

Precise measurements for freight permits should be confrmed prior to shipping.

Side View

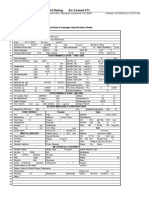

DIMENSIONS

Top View

Standard Specifcations

Part No. Boot

Filter

Element

(Micron)

OD X

Length S/S

(in x ft)

Gas Capacity (MMscfd) at Flow Rate (psig)

400 600 800 1000 1200 1400

486506007 1 1 6.625 x 5.5 2.5 3 3.4 3.8 4.2 4.5

486508007 1 1 8.625 x 7.5 7.5 9.1 10 11 12 13

486510008 1 1 10.75 x 8.0 7.5 9.1 10 11 12 13

486512008 1 1 12.75 x 8.0 9.4 11 13 15 16 18

486516008 1 1 16 x 8.5 19 23 26 29 32 34

486520008 1 1 20 x 8.5 23 28 32 35 38 41

486520012 1 1 20 x 12.0 23 28 32 35 38 41

486524013/4 1 1 24 x 12.5 45 56 64 71 77 83

486530012 1 1 30 x 12.5 80 98 112 125 136 145

486530013 1 1 30 x 12.5 80 98 *Rated at 720 psig

486536015 1 1 36 x 12.5 111 135 155 173 188 201

486542013* 2 1 42 x 12.5 172 209 241 268 292 321

486530016 2 0.3 30 x 12.5 52 65 75 85 94 103

486536016 2 0.3 36 x 12.5 72 89 104 118 130 142

486542013* 2 0.3 42 x 12.5 113 139 162 183 203 221

Vous aimerez peut-être aussi

- Performance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallD'EverandPerformance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallÉvaluation : 4 sur 5 étoiles4/5 (8)

- Music GcseDocument45 pagesMusic GcseAimee DohertyPas encore d'évaluation

- Quantifying Oil - Water Separation Performance in Three-Phase Separators-Part 1.PDF - ImportantDocument12 pagesQuantifying Oil - Water Separation Performance in Three-Phase Separators-Part 1.PDF - ImportantmofiyinfoluPas encore d'évaluation

- Acceptance Test Template ExampleDocument20 pagesAcceptance Test Template Examplemarcoo8Pas encore d'évaluation

- BAsket Strainer Sizing HaywardDocument1 pageBAsket Strainer Sizing Haywardmarcoo8Pas encore d'évaluation

- Natural Gas Quality Enhancement: Training Report ONDocument20 pagesNatural Gas Quality Enhancement: Training Report ONRajkishan GuptaPas encore d'évaluation

- Mitsubishi diesel forklifts 1.5-3.5 tonnesDocument2 pagesMitsubishi diesel forklifts 1.5-3.5 tonnesJoniPas encore d'évaluation

- Gas Filter Separators 4Document8 pagesGas Filter Separators 4Anonymous bHh1L1Pas encore d'évaluation

- 3 Phase SeperatorDocument9 pages3 Phase SeperatorHammad Zaidi100% (3)

- Air Drying ProcessDocument2 pagesAir Drying Processmarcoo8Pas encore d'évaluation

- Metering Systems for Oil and Gas ApplicationsDocument45 pagesMetering Systems for Oil and Gas Applicationssina giahkarPas encore d'évaluation

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentD'EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentPas encore d'évaluation

- Filtro Peco HorizontalDocument4 pagesFiltro Peco HorizontalEdgar CanelasPas encore d'évaluation

- PVC PLasticisersDocument2 pagesPVC PLasticisersKrishna PrasadPas encore d'évaluation

- Sizing of Glycol ContactorDocument10 pagesSizing of Glycol ContactorGODWIN ANYIMAH100% (1)

- Horizontal Three Phase Separator DesignDocument5 pagesHorizontal Three Phase Separator DesignAymen KhlifiPas encore d'évaluation

- Putting It All Together: OperationsDocument34 pagesPutting It All Together: OperationsIbrahim FaqaihPas encore d'évaluation

- Three Phase Separators - Times DefinitionDocument5 pagesThree Phase Separators - Times DefinitionMohsin MohammedPas encore d'évaluation

- Gas-Liquid Vertical Separator PDFDocument2 pagesGas-Liquid Vertical Separator PDFRathish RagooPas encore d'évaluation

- JCI Process Filter Separator Technical BrochureDocument8 pagesJCI Process Filter Separator Technical BrochureVAN_JCIPas encore d'évaluation

- PECO Filters PDFDocument12 pagesPECO Filters PDFG.SWAMI100% (1)

- Slug Catcher - Finger Type DesignDocument3 pagesSlug Catcher - Finger Type Designhasifpp2013Pas encore d'évaluation

- Petrogas Filtration CatalogueDocument12 pagesPetrogas Filtration Catalogueleandroperao5374Pas encore d'évaluation

- CoalescerDocument16 pagesCoalescerHeny Martha100% (2)

- Filtration / Separation Products & Services: Making The World Safer, Healthier and More ProductiveDocument16 pagesFiltration / Separation Products & Services: Making The World Safer, Healthier and More Productivesuraj pandeyPas encore d'évaluation

- Flaresim - Flare SystemDocument2 pagesFlaresim - Flare SystemJeEJyZaPas encore d'évaluation

- EX Firetube Boiler Changed by Advances in Design TechnologyDocument7 pagesEX Firetube Boiler Changed by Advances in Design TechnologyXamir Suarez AlejandroPas encore d'évaluation

- Gas Dehydration and TEG Regeneration Process OverviewDocument60 pagesGas Dehydration and TEG Regeneration Process OverviewSuryaprakashPas encore d'évaluation

- CMPAPPP Separator Vessel and Filter Design GuideDocument18 pagesCMPAPPP Separator Vessel and Filter Design GuideJWilson73Pas encore d'évaluation

- Filtration in HydrotreatingDocument2 pagesFiltration in Hydrotreatingck196548400% (1)

- Data Sheet - Gas-Gas Heat ExchangerDocument1 pageData Sheet - Gas-Gas Heat ExchangerPrabhakarPas encore d'évaluation

- M07 PDFDocument48 pagesM07 PDFAdrian GuzmanPas encore d'évaluation

- MAHLE IF PremiumSelectElements ENDocument6 pagesMAHLE IF PremiumSelectElements ENJamin SmtpngPas encore d'évaluation

- Separator PDSDocument7 pagesSeparator PDSprabhuarunkumarPas encore d'évaluation

- WPS Office 2016Document22 pagesWPS Office 2016Muhammad Aliff SyukriPas encore d'évaluation

- Glycol Dehydration Instrumentation and ControlsDocument3 pagesGlycol Dehydration Instrumentation and ControlsdndudcPas encore d'évaluation

- A New Approach For Sizing Finger Slug CatcherDocument15 pagesA New Approach For Sizing Finger Slug CatcherHaryadiPas encore d'évaluation

- WelChem BubbleCapTray 2020-2Document6 pagesWelChem BubbleCapTray 2020-2Joel OkohPas encore d'évaluation

- Gas (Amine) Sweetening Process - Jonell Filtration Applications GasSweet 1015Document2 pagesGas (Amine) Sweetening Process - Jonell Filtration Applications GasSweet 1015Bob PeppingPas encore d'évaluation

- Gas Coalescer SizingDocument6 pagesGas Coalescer SizingAde IskandarPas encore d'évaluation

- Conder Separator Brochure NewDocument8 pagesConder Separator Brochure Newednavilod100% (1)

- 3.0 Systems Division-FiltersDocument8 pages3.0 Systems Division-Filtersmatteo2009Pas encore d'évaluation

- Process Design: Vessel Sizing (Liquid & Vapour Separators)Document36 pagesProcess Design: Vessel Sizing (Liquid & Vapour Separators)Krishanu SahaPas encore d'évaluation

- 06 - Savvy Separator - UNDERPERFORMING GAS SCRUBBERS PDFDocument8 pages06 - Savvy Separator - UNDERPERFORMING GAS SCRUBBERS PDFabhijit kharotePas encore d'évaluation

- Thermosyphon Reboiler (Horizontal) GPSADocument6 pagesThermosyphon Reboiler (Horizontal) GPSAsyamsudin2006Pas encore d'évaluation

- JEWEL T Hydrocarbon Dew Point ControlDocument2 pagesJEWEL T Hydrocarbon Dew Point ControljojeecaresPas encore d'évaluation

- KIRK Sep-Calc SoftwareDocument4 pagesKIRK Sep-Calc Softwaredhl_tuPas encore d'évaluation

- Pressure Vessel Cone Design ToolDocument1 pagePressure Vessel Cone Design ToolPramod KumarPas encore d'évaluation

- Seprasol Plus: Liquid/Gas CoalescersDocument4 pagesSeprasol Plus: Liquid/Gas CoalescersSiavash YarahmadiPas encore d'évaluation

- SeparatorDocument9 pagesSeparatorGelorawan AditPas encore d'évaluation

- FL1627Document2 pagesFL1627Isaac Montero BarreraPas encore d'évaluation

- Flare Gas Recovery PDFDocument13 pagesFlare Gas Recovery PDFSadad MohamadPas encore d'évaluation

- The Physical Properties of The Hot Fluid Have Been Extrapolated Beyond The Valid Temperature RangeDocument3 pagesThe Physical Properties of The Hot Fluid Have Been Extrapolated Beyond The Valid Temperature RangeSrihari KodimelaPas encore d'évaluation

- Vibration Analysis of Aes Type Shell and Tube Heat Exchanger by Htri SoftwareDocument5 pagesVibration Analysis of Aes Type Shell and Tube Heat Exchanger by Htri SoftwarevikramPas encore d'évaluation

- Delivering Excellence in Combustion and Process Heating SystemsDocument11 pagesDelivering Excellence in Combustion and Process Heating SystemssajjadyasinPas encore d'évaluation

- Filters FbaDocument1 pageFilters FbaSpoonful BurnsidePas encore d'évaluation

- Datasheet For PACE Mist Eliminator/s (Demister) : Existing DetailsDocument1 pageDatasheet For PACE Mist Eliminator/s (Demister) : Existing DetailsAnonymous LLLK3pq50% (2)

- Aspen Exchanger Design and Rating Sheet for Forced Draft Air Cooled Heat ExchangerDocument1 pageAspen Exchanger Design and Rating Sheet for Forced Draft Air Cooled Heat ExchangerHafidzAliyufaPas encore d'évaluation

- H07127 ThreePhaseHorzSepDocument2 pagesH07127 ThreePhaseHorzSepGuillermo Manuel SchödlPas encore d'évaluation

- Fuel Gas Conditioning-EmailDocument2 pagesFuel Gas Conditioning-Emailkelburn50% (2)

- FILTROSDocument24 pagesFILTROSJessica MontenegroPas encore d'évaluation

- AX5 Vaporizer Electric Water Bath Type LPG VaporizerDocument2 pagesAX5 Vaporizer Electric Water Bath Type LPG VaporizerRicky DermawanPas encore d'évaluation

- Bulk Water SeparationDocument1 pageBulk Water SeparationSean MiddletonPas encore d'évaluation

- 50P Series: High Pressure FiltersDocument10 pages50P Series: High Pressure FiltersPartsGopher.comPas encore d'évaluation

- Tiresaver CatalogDocument10 pagesTiresaver CatalogJose Luis Barrios MoorePas encore d'évaluation

- Tur-Flwmtr Nf00152 0912fDocument2 pagesTur-Flwmtr Nf00152 0912fAntonio ImperiPas encore d'évaluation

- RACOR 500FG Turbine SeriesDocument8 pagesRACOR 500FG Turbine Serieswarrimaint2Pas encore d'évaluation

- Ashcroft PRessure GaugeDocument1 pageAshcroft PRessure Gaugemarcoo8Pas encore d'évaluation

- Chem Eng Book ReferenceDocument1 pageChem Eng Book Referencemarcoo8Pas encore d'évaluation

- Cooling TowersDocument4 pagesCooling TowersAjay SastryPas encore d'évaluation

- Book1 (TEG Guide)Document2 pagesBook1 (TEG Guide)marcoo8Pas encore d'évaluation

- Mist ElimDocument1 pageMist Elimmarcoo8Pas encore d'évaluation

- Math FundamentalDocument1 pageMath Fundamentalmarcoo8Pas encore d'évaluation

- Double Block Valves (Orion)Document8 pagesDouble Block Valves (Orion)marcoo8Pas encore d'évaluation

- Appendix (VCM Plant)Document2 pagesAppendix (VCM Plant)marcoo8Pas encore d'évaluation

- Note (Handwritten)Document1 pageNote (Handwritten)marcoo8Pas encore d'évaluation

- Note (Handwritten)Document1 pageNote (Handwritten)marcoo8Pas encore d'évaluation

- Double Block Valves (Orion)Document8 pagesDouble Block Valves (Orion)marcoo8Pas encore d'évaluation

- Flow Charet 12Document1 pageFlow Charet 12marcoo8Pas encore d'évaluation

- Flow CharetDocument1 pageFlow Charetmarcoo8Pas encore d'évaluation

- Trim Details For API 602Document2 pagesTrim Details For API 602marcoo8Pas encore d'évaluation

- TechBulletin Care Handling Bacteria CarbonDocument3 pagesTechBulletin Care Handling Bacteria Carbonmarcoo8Pas encore d'évaluation

- T 1046Document1 pageT 1046marcoo8Pas encore d'évaluation

- Alberta CompaniesDocument1 pageAlberta Companiesmarcoo8Pas encore d'évaluation

- Job DescriptionDocument1 pageJob Descriptionmarcoo8Pas encore d'évaluation

- Refining ProcessDocument1 pageRefining Processmarcoo8Pas encore d'évaluation

- Designing Efficient Air Flow SystemsDocument3 pagesDesigning Efficient Air Flow Systemsmarcoo8Pas encore d'évaluation

- Active Packaging For Food Applications (Reference)Document1 pageActive Packaging For Food Applications (Reference)marcoo8Pas encore d'évaluation

- Wika Connection HeadDocument1 pageWika Connection Headmarcoo8Pas encore d'évaluation

- MAgnetrol 75 Seires LEvelDocument8 pagesMAgnetrol 75 Seires LEvelmarcoo8Pas encore d'évaluation

- Marc Slagt Design2 IExDocument20 pagesMarc Slagt Design2 IExmarcoo8Pas encore d'évaluation

- Designing Air Flow Systems GuideDocument3 pagesDesigning Air Flow Systems Guidemarcoo8Pas encore d'évaluation

- Design Air SystemsDocument41 pagesDesign Air Systemssmacna100% (12)

- Instrumentation Design UTHMDocument5 pagesInstrumentation Design UTHMAnis AzwaPas encore d'évaluation

- Ms-Dos Device Drivers: Device Drivers Are The That in File atDocument13 pagesMs-Dos Device Drivers: Device Drivers Are The That in File atJass GillPas encore d'évaluation

- Nord Factory Restore Instructions Edition CDocument1 pageNord Factory Restore Instructions Edition CTonino CannavacciuoloPas encore d'évaluation

- Database Classification TypesDocument10 pagesDatabase Classification TypesBhiea Mische MatilacPas encore d'évaluation

- CS 102 Programming Fundamentals Lecture NotesDocument14 pagesCS 102 Programming Fundamentals Lecture NotesOkay OkayPas encore d'évaluation

- Matlab programs to fit common curves using least squares methodDocument5 pagesMatlab programs to fit common curves using least squares methodRavi ParkhePas encore d'évaluation

- Exam 1 Study Guide Bio 6C Ecology and EvolutionDocument2 pagesExam 1 Study Guide Bio 6C Ecology and EvolutionVyNguyễn0% (1)

- USB GPW CB03 MT02 - EngDocument21 pagesUSB GPW CB03 MT02 - EngRafael BispoPas encore d'évaluation

- Network Layer: Computer Networking: A Top Down ApproachDocument83 pagesNetwork Layer: Computer Networking: A Top Down ApproachMuhammad Bin ShehzadPas encore d'évaluation

- Great Lakes PGDM Interview Access DetailsDocument1 pageGreat Lakes PGDM Interview Access DetailsJaswanth konkepudiPas encore d'évaluation

- Climate Change: The Fork at The End of NowDocument28 pagesClimate Change: The Fork at The End of NowMomentum Press100% (1)

- Submittal Chiller COP 6.02Document3 pagesSubmittal Chiller COP 6.02juan yenquePas encore d'évaluation

- Velocity profiles and incompressible flow field equationsDocument2 pagesVelocity profiles and incompressible flow field equationsAbdul ArifPas encore d'évaluation

- Excel Dynamic Arrays: Department Item Quantity Price Total $Document5 pagesExcel Dynamic Arrays: Department Item Quantity Price Total $Bilal Hussein SousPas encore d'évaluation

- Probability Statistics and Random Processes Third Edition T Veerarajan PDFDocument3 pagesProbability Statistics and Random Processes Third Edition T Veerarajan PDFbhavyamPas encore d'évaluation

- Pumps - IntroductionDocument31 pagesPumps - IntroductionSuresh Thangarajan100% (1)

- RelativedensityipgDocument2 pagesRelativedensityipgapi-310625232Pas encore d'évaluation

- ID Pengaruh Persistensi Laba Alokasi Pajak Antar Periode Ukuran Perusahaan PertumbuDocument21 pagesID Pengaruh Persistensi Laba Alokasi Pajak Antar Periode Ukuran Perusahaan PertumbuGheaMarisyaPuteriPas encore d'évaluation

- Pipeline Corrosion Assessment MethodsDocument21 pagesPipeline Corrosion Assessment MethodsGilletPas encore d'évaluation

- Apriori AlgorithmDocument13 pagesApriori AlgorithmKiran JoshiPas encore d'évaluation

- Geotehnical Engg. - AEE - CRPQsDocument48 pagesGeotehnical Engg. - AEE - CRPQsSureshKonamPas encore d'évaluation

- MongoDB Replication Guide PDFDocument106 pagesMongoDB Replication Guide PDFDante LlimpePas encore d'évaluation

- Ex - No: 4 Integrator and Differentiator Using Fpaa DateDocument4 pagesEx - No: 4 Integrator and Differentiator Using Fpaa DatechandraprabhaPas encore d'évaluation

- The Professional DesktopDocument318 pagesThe Professional Desktopalintuta2Pas encore d'évaluation

- EET422 EMC Intro-Banana Skins 2011-2012 MSWDocument6 pagesEET422 EMC Intro-Banana Skins 2011-2012 MSWVeeradasan PerumalPas encore d'évaluation

- HowTo Work With CR 90Document87 pagesHowTo Work With CR 90WagBezerraPas encore d'évaluation