Académique Documents

Professionnel Documents

Culture Documents

TDS - Barrier 90 - English (Uk) - Issued.05.10.2011

Transféré par

ansarALLAAHCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

TDS - Barrier 90 - English (Uk) - Issued.05.10.2011

Transféré par

ansarALLAAHDroits d'auteur :

Formats disponibles

Barrier 90 Page 1 of 4

Technical Data

Barrier 90

Product description

Barrier 90 is a two-pack zinc rich epoxy primer with a high content of zinc. Complies with the compositional requirements

for SSPC Paint 20 level 1, BS 4652 and BS 5493, and AS/NZS 3750.9.1994. This product is supplied with ASTM D520

Type II zinc dust.

Recommended use

As a primer on blast cleaned steel. Barrier 90 is used in combination with most advanced coating systems to further

improve protection against corrosion.

Film thickness and spreading rate

Minimum Maximum

Typical

Film thickness, dry (m) 25 90 40

Film thickness, wet (m) 45 170 75

Theoretical spreading rate (m/l) 21,2 5,9 13,3

Comments

When the maximum Dry Film Thickness is applied the Drying time will increase.

Physical properties

Colour Grey

Solids (vol %)* 53 2

Flash point 27C 2 (Setaflash)

VOC 370 gms/ltr UK-PG6/23(97). Appendix 3

Gloss

Flat

Water resistance

Excellent

Abrasion resistance Very good

Solvent resistance Very good

Flexibility Good

*Measured according to ISO 3233:1998 (E)

Barrier 90 Page 2 of 4

Surface preparation

All surfaces should be clean, dry and free from contamination. The surface should be assessed and treated in

accordance with ISO 8504.

Bare steel

Cleanliness: Blast cleaning to min. Sa 2 (ISO 8501-1:2007) or for maintenance UHPWJ to WJ2 (NACE No.5/SSPC-

SP 12). Roughness: using abrasives suitable to achieve minimum grade Fine (ISO 8503-2).

Other surfaces

The coating may be used on other substrates. Please contact your local Jotun office for more information.

Condition during application

The temperature of the substrate should be minimum 5C and at least 3C above the dew point of the air, temperature

and relative humidity measured in the vicinity of the substrate. Good ventilation is required in confined areas to ensure

correct drying.

Application methods

Spray Use airless spray

Brush Recommended for stripe coating and small areas, care must be taken to achieve the specified dry

film thickness.

Application data

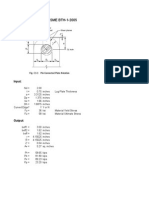

Mixing ratio (volume) 6:1

Mixing

6 part Comp. A (base) to be mixed thoroughly with 1 part Barrier 90, Comp. B

(curing agent).

Induction time

30 minutes.

Pot life (23C)

24 hours. (Reduced at higher temp.).

Thinner/Cleaner

Jotun Thinner No. 17

Guiding data airless spray

Pressure at nozzle

15 MPa min (150 kp/cm, 2100 psi.).

Nozzle tip

0.38 - 0.53 mm (0.015 - 0.021").

Spray angle

40 - 80

Filter

Check to ensure that filters are clean.

Drying time

Drying times are generally related to air circulation, temperature, film thickness and number of coats, and will be

affected correspondingly. The figures given in the table are typical with:

* Good ventilation (Outdoor exposure or free circulation of air)

* Typical film thickness

* One coat on top of inert substrate

Barrier 90 Page 3 of 4

Substrate temperature 5C 10C 23C 40C

Surface dry 50 min 20 min 10 min 4 min

Through dry 3 h 2 h 1.5 h 40 min

Cured 10 d 7 d 5 d 2 d

Dry to recoat, minimum

1

3 h 2 h 1.5 h 40 min

Dry to recoat, maximum

1,2

1. Recommended data given for recoating with coatings normally specified on top of zinc epoxy coatings.

2. The surface should be dry and free from any contamination prior to application of the subsequent coat.

The given data must be considered as guidelines only. The actual drying time/times before recoating may be shorter or

longer, depending on film thickness, ventilation, humidity, underlying paint system, requirement for early handling and

mechanical strength etc. A complete system can be described on a system sheet, where all parameters and special

conditions could be included.

Typical paint system

Barrier 90 1 x 25 - 75 m (Dry Film Thickness)

Subsequent coating(s) by choice e.g.: epoxy, acrylic or vinyl.

Other systems may be specified, depending on area of use

Storage

The product must be stored in accordance with national regulations. Storage conditions are to keep the containers in a

dry, cool, well ventilated space and away from source of heat and ignition. Containers must be kept tightly closed.

Handling

Handle with care. Stir well before use. Continuous stirring during application will prevent the heavy zinc pigment from

settling.

Packing size

8.75 litre unit: 7.5 litres comp. A (base) in a 10 litre container and 1.25 litres Barrier 90, Comp. B (curing agent) in a 3

litre container.

Health and safety

Please observe the precautionary notices displayed on the container. Use under well ventilated conditions. Do not

breathe or inhale mist. Avoid skin contact. Spillage on the skin should immediately be removed with suitable cleanser,

soap and water. Eyes should be well flushed with water and medical attention sought immediately.

For detailed information on the health and safety hazards and precautions for use of this product, we refer to

the Material Safety Data Sheet.

DISCLAIMER

The information in this data sheet is given to the best of our knowledge based on laboratory testing and practical

experience. However, as the product can be used under conditions beyond our control, we can only guarantee the

quality of the product itself. We also reserve the right to change the given data without notice. Minor product variations

may be implemented in order to comply with local requirements.

If there is any inconsistency in the text the English (UK) version will prevail.

Jotun is a World Wide company with factories, sales offices and stocks in more than 50 countries. For your nearest local Jotun address

please contact the nearest regional office or visit our website at www.jotun.com

Barrier 90 Page 4 of 4

ISSUED 5 OCTOBER 2011 BY JOTUN

THIS DATA SHEET SUPERSEDES THOSE PREVIOUSLY ISSUED

Vous aimerez peut-être aussi

- Barrier 90 - English (Uk) - Issued.06.12.2007Document3 pagesBarrier 90 - English (Uk) - Issued.06.12.2007Mohamed FaragPas encore d'évaluation

- Barrier 80 Zinc Rich Epoxy Primer Technical Data SheetDocument3 pagesBarrier 80 Zinc Rich Epoxy Primer Technical Data SheetMohamed FaragPas encore d'évaluation

- Futura As - English (Uk) - Issued.06.12.2007Document3 pagesFutura As - English (Uk) - Issued.06.12.2007Mohamed FaragPas encore d'évaluation

- Marathon XHB Epoxy Coating Technical DataDocument3 pagesMarathon XHB Epoxy Coating Technical DataMohamed FaragPas encore d'évaluation

- Penguard Stayer - English (Uk) - Issued.06.12.2007Document3 pagesPenguard Stayer - English (Uk) - Issued.06.12.2007Mohamed FaragPas encore d'évaluation

- Naviguard ME - English (Uk) - Issued.06.12.2007Document3 pagesNaviguard ME - English (Uk) - Issued.06.12.2007Mohamed FaragPas encore d'évaluation

- Penguard Midcoat - English (Uk) - Issued.26.11.2010Document4 pagesPenguard Midcoat - English (Uk) - Issued.26.11.2010Faisal NismarPas encore d'évaluation

- Marathon IQ GF - English (Uk) - Issued.06.12.2007Document3 pagesMarathon IQ GF - English (Uk) - Issued.06.12.2007Mohamed FaragPas encore d'évaluation

- Jotun-Penguard Primer - Tech DataDocument4 pagesJotun-Penguard Primer - Tech Dataanwarali1975Pas encore d'évaluation

- Penguard FC - English (Uk) - Issued.06.12.2007Document4 pagesPenguard FC - English (Uk) - Issued.06.12.2007Mohamed FaragPas encore d'évaluation

- Alkydprimer - English (Uk) - Issued.06.12.2007Document3 pagesAlkydprimer - English (Uk) - Issued.06.12.2007Mohamed FaragPas encore d'évaluation

- TDS - Jotacote 410 - Issued.06.12.2007 - 2Document3 pagesTDS - Jotacote 410 - Issued.06.12.2007 - 2musaismail8863Pas encore d'évaluation

- TDS - Penguard Express ZP - English (Uk) - Issued.26.11.2010Document4 pagesTDS - Penguard Express ZP - English (Uk) - Issued.26.11.2010Anindya Aulia PratiwiPas encore d'évaluation

- Vinyguard Silvergrey 88 - English (Uk) - Issued.06.12.Document3 pagesVinyguard Silvergrey 88 - English (Uk) - Issued.06.12.Mohamed FaragPas encore d'évaluation

- Barrier ZepDocument3 pagesBarrier ZepJairo Gómez SánchezPas encore d'évaluation

- TDS - Solvalitt Midtherm - English (Uk) - Issued.26.11.2010Document4 pagesTDS - Solvalitt Midtherm - English (Uk) - Issued.26.11.2010Fauzan BenraxidPas encore d'évaluation

- Penguard HB: Technical DataDocument4 pagesPenguard HB: Technical DataStephen MalobaPas encore d'évaluation

- Futura Matt - English (Uk) - Issued.06.12.2007Document3 pagesFutura Matt - English (Uk) - Issued.06.12.2007Mohamed FaragPas encore d'évaluation

- Penguard HB - English (Uk) - Issued.06.12.2007Document4 pagesPenguard HB - English (Uk) - Issued.06.12.2007Mohamed FaragPas encore d'évaluation

- Mid-Temperature Paint Technical Data SheetDocument3 pagesMid-Temperature Paint Technical Data SheetMohamed FaragPas encore d'évaluation

- Tankguard AR Technical Data SheetDocument4 pagesTankguard AR Technical Data SheetSherif Abdelhameed100% (1)

- TDS - Alkyd Topcoat - English (Uk) - Issued.28.02.2011 JotunDocument3 pagesTDS - Alkyd Topcoat - English (Uk) - Issued.28.02.2011 JotunmanbkkPas encore d'évaluation

- Hardtop HB Technical Data SheetDocument3 pagesHardtop HB Technical Data SheetMohamed FaragPas encore d'évaluation

- TDS Tankguard 412 English (Uk) Issued.22.05.2009Document4 pagesTDS Tankguard 412 English (Uk) Issued.22.05.2009Ahmed NabilPas encore d'évaluation

- Ballastic Black CoatingDocument3 pagesBallastic Black CoatingMekhmanPas encore d'évaluation

- Zinc Epoxy Primer Technical Data SheetDocument3 pagesZinc Epoxy Primer Technical Data SheetMohamed FaragPas encore d'évaluation

- Jotaguard 630Document4 pagesJotaguard 630Christine HermawanPas encore d'évaluation

- Penguard Primer Datasheet " Azadjotun"Document3 pagesPenguard Primer Datasheet " Azadjotun"AzadAhmadPas encore d'évaluation

- Hardtop Flexi Technical Data SheetDocument3 pagesHardtop Flexi Technical Data SheetMohamed FaragPas encore d'évaluation

- Jotun Resist 5WFDocument4 pagesJotun Resist 5WFSergio SmithPas encore d'évaluation

- Epoxy Floor Coating Technical Data SheetDocument4 pagesEpoxy Floor Coating Technical Data SheetMohamed FaragPas encore d'évaluation

- Safeguard Universal ES - English (Uk) - Issued.06.12.2Document3 pagesSafeguard Universal ES - English (Uk) - Issued.06.12.2Mohamed FaragPas encore d'évaluation

- Coal Tar Epoxy 83 - English (Uk) - Issued.06.12.2007Document3 pagesCoal Tar Epoxy 83 - English (Uk) - Issued.06.12.2007Mohamed FaragPas encore d'évaluation

- Penguard ZP AO - English (Uk) - Issued.06.12.2007Document3 pagesPenguard ZP AO - English (Uk) - Issued.06.12.2007Mohamed FaragPas encore d'évaluation

- Durosan 02 Matt Datasheet " AzadJotun"Document3 pagesDurosan 02 Matt Datasheet " AzadJotun"AzadAhmadPas encore d'évaluation

- Penguard Special - English (Uk) - Issued.06.12.2007Document3 pagesPenguard Special - English (Uk) - Issued.06.12.2007Mohamed FaragPas encore d'évaluation

- Penguard HBDocument4 pagesPenguard HBhedisanjayaPas encore d'évaluation

- Durosan 03 Matt Exterior (Azad Jotun)Document3 pagesDurosan 03 Matt Exterior (Azad Jotun)AzadAhmadPas encore d'évaluation

- TDS - Chemflake Special - English (Uk) - Azad (Jotun Paints Ras Tanutra)Document4 pagesTDS - Chemflake Special - English (Uk) - Azad (Jotun Paints Ras Tanutra)Robert ClarkPas encore d'évaluation

- TDS - Muki Z 2008 - English (Uk) - Issued.26.11.2010Document4 pagesTDS - Muki Z 2008 - English (Uk) - Issued.26.11.2010Keith ChooPas encore d'évaluation

- High Build Epoxy Midcoat Technical DataDocument4 pagesHigh Build Epoxy Midcoat Technical DatavitharvanPas encore d'évaluation

- SeaForce 90 - English (Uk) - Issued.06.12.2007Document3 pagesSeaForce 90 - English (Uk) - Issued.06.12.2007Mohamed FaragPas encore d'évaluation

- JOTUN DECO Jotashield Extreme SilkDocument3 pagesJOTUN DECO Jotashield Extreme SilkhemajsuryaPas encore d'évaluation

- Chemtech GM Clear - English (Uk) - Issued.06.12.2007Document3 pagesChemtech GM Clear - English (Uk) - Issued.06.12.2007Mohamed Farag50% (2)

- Hardtop AsDocument4 pagesHardtop AsulusoynPas encore d'évaluation

- Jotafloor Coating Technical Data SheetDocument4 pagesJotafloor Coating Technical Data SheetMohamed FaragPas encore d'évaluation

- Resist GTI - English (Uk) - Issued.06.12.2007Document4 pagesResist GTI - English (Uk) - Issued.06.12.2007Mohamed FaragPas encore d'évaluation

- Baltoflake - English (Uk) - Issued.25.03.2010Document4 pagesBaltoflake - English (Uk) - Issued.25.03.2010Mohamed FaragPas encore d'évaluation

- J Primer TdsDocument3 pagesJ Primer Tdswey5316Pas encore d'évaluation

- TDS - Penguard Primer - Issued.26.11.2010Document4 pagesTDS - Penguard Primer - Issued.26.11.2010vitharvanPas encore d'évaluation

- Interline 1012+ds+engDocument4 pagesInterline 1012+ds+engSUBHOMOYPas encore d'évaluation

- High Build Epoxy CoatingDocument4 pagesHigh Build Epoxy Coatingwey5316Pas encore d'évaluation

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesD'EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesÉvaluation : 3.5 sur 5 étoiles3.5/5 (3)

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryD'EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryPas encore d'évaluation

- Water-Based Paint Formulations, Vol. 3D'EverandWater-Based Paint Formulations, Vol. 3Évaluation : 4.5 sur 5 étoiles4.5/5 (6)

- ISO Hole Limits TolerancesDocument3 pagesISO Hole Limits TolerancesansarALLAAHPas encore d'évaluation

- Lifting Lug Design Per ASME BTH-1-2005: InputDocument4 pagesLifting Lug Design Per ASME BTH-1-2005: InputcoolkaisyPas encore d'évaluation

- LOLER NSL Inspection MetricDocument1 pageLOLER NSL Inspection MetricbudygmoodPas encore d'évaluation

- DOS CommandDocument6 pagesDOS CommandManoj PandeyPas encore d'évaluation

- Synchro FlexDocument19 pagesSynchro FlexsilvaronePas encore d'évaluation

- Precision Engineering Directory Singapore 2009Document60 pagesPrecision Engineering Directory Singapore 2009ansarALLAAH100% (1)

- Beeline Timing BeltsDocument1 pageBeeline Timing BeltsansarALLAAHPas encore d'évaluation

- List of CNC Machine CodesDocument5 pagesList of CNC Machine CodesansarALLAAHPas encore d'évaluation

- How R Boxes MadeDocument6 pagesHow R Boxes MadeKeka SomaiahPas encore d'évaluation

- Paadeye S TypeDocument148 pagesPaadeye S TypeansarALLAAHPas encore d'évaluation

- Fluid Power Seal GuideDocument424 pagesFluid Power Seal GuideDillibabu RPas encore d'évaluation

- NOK Packing Seal - GeneralDocument9 pagesNOK Packing Seal - GeneralansarALLAAHPas encore d'évaluation

- Weld Assure GasPurifiersDocument2 pagesWeld Assure GasPurifiersansarALLAAHPas encore d'évaluation

- Tempil Preheating ChartDocument1 pageTempil Preheating ChartansarALLAAHPas encore d'évaluation

- Strandjack H 300Document1 pageStrandjack H 300ansarALLAAHPas encore d'évaluation

- Strandjack H-400 PDFDocument1 pageStrandjack H-400 PDFansarALLAAHPas encore d'évaluation

- Strandjack H 140Document1 pageStrandjack H 140ansarALLAAHPas encore d'évaluation

- Strandjack H-140 - Connecting Piece CP-140Document1 pageStrandjack H-140 - Connecting Piece CP-140ansarALLAAHPas encore d'évaluation

- LR Soot Blow PDFDocument35 pagesLR Soot Blow PDFvtbk100% (1)

- Rotary SootDocument8 pagesRotary SootAnoop Kumar AllankiPas encore d'évaluation

- Viking Energy PresentationDocument8 pagesViking Energy PresentationansarALLAAHPas encore d'évaluation

- Stainless SteelDocument8 pagesStainless SteelAlvaro Alexis Mendoza PradaPas encore d'évaluation

- Zaclon Galvanizing HandbookDocument127 pagesZaclon Galvanizing HandbookMohammed Abdallah100% (2)

- American Structural ShapesDocument16 pagesAmerican Structural ShapesAlfonsoPas encore d'évaluation

- Zeron100 Welding GuidelinesDocument8 pagesZeron100 Welding GuidelinesansarALLAAHPas encore d'évaluation

- Mig Spool Gun Accessories GuideDocument2 pagesMig Spool Gun Accessories GuideansarALLAAHPas encore d'évaluation

- Vector Techlok BrochureDocument34 pagesVector Techlok BrochureRobert Murray100% (2)

- ZS Customer and Project-NewDocument3 pagesZS Customer and Project-NewansarALLAAHPas encore d'évaluation

- ZinkPower Batam - Company BrochureDocument6 pagesZinkPower Batam - Company BrochureansarALLAAHPas encore d'évaluation

- Heat ExchangersDocument30 pagesHeat Exchangerstakis.papadopoulos6672Pas encore d'évaluation

- Moving AveragesDocument8 pagesMoving AveragesRenuka SushilPas encore d'évaluation

- An Evaluation of The Bioclimatic ChartDocument497 pagesAn Evaluation of The Bioclimatic ChartIon C. AndronachePas encore d'évaluation

- Cutting The Fat Tail of Climate Risk: Carbon Backstop Technologies As A Climate Insurance PolicyDocument56 pagesCutting The Fat Tail of Climate Risk: Carbon Backstop Technologies As A Climate Insurance PolicyHoover InstitutionPas encore d'évaluation

- SWOT AnalysisDocument3 pagesSWOT Analysisakhil-4108100% (5)

- 850Document4 pages850Ssubrat RrudraPas encore d'évaluation

- Airbus Helicopters Brochure AS365N3Document20 pagesAirbus Helicopters Brochure AS365N3ZZTOP100% (1)

- Ozone DepletionDocument44 pagesOzone DepletionAzam AziPas encore d'évaluation

- PUGNOLLI Tabela de Comandos 3.0 INCOMPLETADocument438 pagesPUGNOLLI Tabela de Comandos 3.0 INCOMPLETACarlos Eduardo da silvaPas encore d'évaluation

- Oregairu Volume 11Document37 pagesOregairu Volume 11Michele RogersPas encore d'évaluation

- Development of Standard Calibration Equipment For The Rain GaugesDocument6 pagesDevelopment of Standard Calibration Equipment For The Rain GaugesCespi-peru SacPas encore d'évaluation

- Worksheet Unit 9aDocument2 pagesWorksheet Unit 9aMayra Sofia Rojas Huamani100% (1)

- Thanksgiving Worksheets: Date NameDocument11 pagesThanksgiving Worksheets: Date NameSarahDinElena100% (2)

- NoteDocument71 pagesNoteAmmutha Sokayah100% (2)

- Climograph LessonDocument13 pagesClimograph LessonCheryl LimPas encore d'évaluation

- Battery Sizing Calculation KPD 981 Com E4 005 p0Document16 pagesBattery Sizing Calculation KPD 981 Com E4 005 p0drawler0% (1)

- ClimateDocument26 pagesClimateJenny ManagoPas encore d'évaluation

- Heat Transfer and Expansion NotesDocument8 pagesHeat Transfer and Expansion NotesmelissaPas encore d'évaluation

- E 1925 - 01 - Rte5mjuDocument12 pagesE 1925 - 01 - Rte5mjuMauricio Antonio SalgadoPas encore d'évaluation

- DMV Practice Test: 25 QuestionsDocument6 pagesDMV Practice Test: 25 QuestionsMadhesi Sah100% (1)

- Sound Generated AerodynamicallyDocument33 pagesSound Generated AerodynamicallyAbraham Benjamin Britto100% (1)

- Accident Prevention in A Ski Resort, The Example of Grandvalira AndorraDocument17 pagesAccident Prevention in A Ski Resort, The Example of Grandvalira AndorraMedisport AndorraPas encore d'évaluation

- The Anglo Saxon Rune PoemDocument6 pagesThe Anglo Saxon Rune PoemLetícia Félix OliveiraPas encore d'évaluation

- Brochure189 GB BSDocument8 pagesBrochure189 GB BSAir Repair, LLCPas encore d'évaluation

- Jubail United Petrochemical Company (United) Job Safety Analysis - Worksheet (Attachment V)Document4 pagesJubail United Petrochemical Company (United) Job Safety Analysis - Worksheet (Attachment V)Muhammad Umar GondalPas encore d'évaluation

- Sist en 50617Document92 pagesSist en 50617radou99Pas encore d'évaluation

- The Uses of TensesDocument3 pagesThe Uses of TensesAjal P100% (1)

- Quantitative Risk Analysis (QRA) : Germanischer Lloyd - Service/Product DescriptionDocument12 pagesQuantitative Risk Analysis (QRA) : Germanischer Lloyd - Service/Product DescriptionMani KalyanaramanPas encore d'évaluation

- Time SeriesDocument91 pagesTime SeriesRajachandra VoodigaPas encore d'évaluation

- Weathering Erosion and TransportationDocument22 pagesWeathering Erosion and TransportationchetanPas encore d'évaluation