Académique Documents

Professionnel Documents

Culture Documents

Gym Area Boq For Nri Club House

Transféré par

Santosh Thakur0 évaluation0% ont trouvé ce document utile (0 vote)

477 vues5 pagesDf

Titre original

Gym Area Boq for Nri Club House

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDf

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

477 vues5 pagesGym Area Boq For Nri Club House

Transféré par

Santosh ThakurDf

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 5

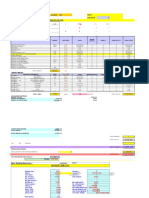

Item Pay Description Total Total

No. Unit Qty. mat lab Rate Amount

CLUB HOUSE - MAIN POWER PANEL

1.0 MV SWITCHGEAR & POWER PANELS

1.1 Supply, installation, testing and

commissioning of cubicle type panels

as specified and shown on drawing.

i) Main busbars with bar type feeder

connections & all internal wiring and

connections.

ii) Earthing all components, frame etc. to

a common internal earth bar.

iii) Painting all sheet metal works.

iv) All accessories & supporting structure.

v) Brass glands for sending and receiving

ends.

(Crimping lugs forming part of

the termination)

vi) All ammeters with C.T's and voltmeter

and energy meters with necessary

fuses.

vii) Panel components as specified.

viii) MS base frame.

ix) All switch gear to have short circuit

levels as specified.

1.1.1 Each Main LT Panel with Capacitor - as specified 1 425,000 18,000 443,000 443,000

and shown on the drawings complete

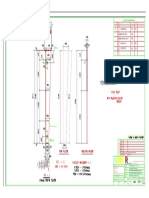

as per drawing L261 - E - 502

Total for 1.0 443,000

2.0 DISTRIBUTION BOARDS

2.1 Supply, installation, testing & commissioning

of 500V Distribution Boards as specified &

shown on drawing with

i) Copper busbars together with tapped neutral

bar for individual phases.

ii) Copper earth strip with tapping for EEC

iii) Interconnections and earthing.

iv) Sheet steel enclosure suitable for recessed

or surface mounting with hinged lockable

doors interlocked with the incomer switch.

v) Phase to phase barriers in case of 3Ph boards.

vi) Necessary support frame & painting, labeling,

phase indicating lamps with fuses etc.

complete.

2.1.1 Each Power Distribution Board for GYM area 1 11,500 1,400 12,900 12,900

Incomer

I) 1# 63A TPN ELMCB(30 mA)

Outgoing :

i) 8 x 3 = 16/20A SP MCB

2.1.2 Each Lighting Distribution Board 1 10,550 1400 11,950 11,950

Rate

BOQ FOR ELECTRICAL WORK WITH CLUB HOUSE MAIN POWER PANEL & GYM AREA - NRI CLUB HOUSE PROJECT

Incomer

I) 1# 40A TPN ELMCB (30 mA)

Outgoing :

iii) 6 x 3# 10A SP MCB

2.1.3 Each 63 A TPN MCB WITH Enclouser 6 4,300 500 4,800 28,800

2.1.4 Each 40 A TPN MCB WITH Enclouser 3 4800 500 5,300 15,900

2.1.5 Each 6 Way VTPN Steam DB 1 18500 1600 20,100 20,100

as per drawing L261 - E - 502

Total for 2.0 89650

3 CABLING

3.1 Power Cabling (PVC)

Supply and laying heavy duty

1100V grade PVC insulated sheathed

& armoured Fire Retarded

AL / Cu conductors as specified and

shown on drgs. complete with:

a) Cable clamps on walls,trays columns,

beams, built-up trenches, cable

markers etc. for indoor cables.

b) Covering bricks or tiles, cable markers

etc. for outdoor cables.

c) Earthing the glands armouring etc.

3.1.1 m 3.5 C 185 sqmm XL - AL R.O.

3.1.2 m 3.5 C 300 sqmm XLPE-AL 24 1250 160 1,410 33,840

3.1.3 m 3.5 C 150 sqmm XLPE-AL R.O.

3.1.4 m 3.5 C 120 sqmm XLPE-AL R.O.

3.1.5 m 3.5 C 95 sqmm XLPE-AL R.O.

3.1.6 m 3.5 C 70 sqmm XLPE-AL 40 210 60 270 10,800

3.1.7 m 3.5 C 25 sqmm XLPE-AL R.O.

3.1.8 m 3.0 C 35 sqmm XLPE-AL R.O.

3.1.9 m 3.5 C 25 sqmm XLPE-AL R.O.

3.1.10 m 4 C 10 sqmm YRY 35 410 30 440 15,400

3.1.11 m 4 C 6 sqmm YRY R.O.

3.1.12 m 4 C 4 sqmm YRY R.O.

3.1.13 m 4 C 2.5 sqmm YRY R.O.

3.1.14 m 4 C 16 sqmm YRY 120 570 45 615 73,800

3.1.15 m 3 C 10 sqmm YRY R.O.

3.1.16 m 3 C 6 sqmm YRY R.O.

Total for 3.0 133840

4 Cable Termination

4.1 Making cable end terminations

including brass double compression

crimping type copper lugs for

cable sizes mentioned below of

(Glands form part of Panels / DB's)

4.1.1 Each 3C, 3.5C, 4C 300 4 2550 750 3,300 13,200

4.1.2 Each 3C, 3.5C, 4C 185 R.O.

4.1.3 Each 3C, 3.5C, 4C 150 R.O.

4.1.4 Each 3C, 3.5C, 4C 120 R.O.

4.1.5 Each 3C, 3.5C, 4C 95 R.O.

4.1.6 Each 3C, 3.5C, 4C 70 2 1200 125 1,325 2,650

4.1.7 Each 3C, 3.5C, 4C 35 R.O.

4.1.8 Each 3C, 3.5C, 4C 25 R.O.

4.1.9 Each 3C, 3.5C, 4C 16 10 390 90 480 4,800

4.1.10 Each 3C, 3.5C, 4C 10 2 280 65 345 690

4.1.11 Each 3C, 3.5C, 4C 6 R.O.

4.1.12 Each 3C, 3.5C, 4C 4 R.O.

Total for 4.0 21340

5.0 CONDUIT WIRING

5.1 Supply & ITC of Conduit wiring for lights, fans, socket outlets

consisting of:

a) FR Wiring with PVC MMS conduit with all it's necessary

junction box, couplers, bend etc.

b) 1100V grade PVC copper wires as specified. The PVC

wires should comply IS :694-1990. The PVC conduits should

comply with IS 3418-1989 for rigid conduits. The interiors of

the PVC coduits should be free from obstruction and should

be ISI marked. No PVC conduit less than 20mm in diameter

shall be used.

c) Conduiting and wiring excluding switches, sockets &

including supply & fixing of pipe conduits with junction box,

couplers, bends, elbows, PVC plates, wires etc. complete with

box earthing, interconnections etc.

d) Connecter of angle holder / ceiling rose as required shall be

provided.

e) The point rate shall include submains wiring from DB to

switchboard with Copper PVC insulated stranded wire. This

also includes wires used for switchboard interconnections.

f) NOTE:-

Secondary Light Point : Looping from Primary Light Point will

be considered as Secondary Light Point and will be controlled

from the same switch provided for Primary Light Point.

5.1 GYM AREA POINT WIRING

5.1.1 Pt. Primary Points (From DB):- 10 1100 220 1,320 13,200

The final subcircuit wiring commencing from the distribution

board feeder to the first light point (With 2R X 2.5Sq.mm and

1R X 1.5Sq.mm and 25mm FR PVC conduits).

5.1.2 Pt. Secondary Points (From DB):- 25 760 115 875 21,875

1-way secondary light point from above primary point,

subsequent points controlled by same DB feeder switch (With

2R X 1.5Sq.mm and 1R X 1.5Sq.mm and 20mm FR PVC

conduits).

5.1.3 Pt. Primary Points (From Switch Box):- 30 1120 220 1,340 40,200

The final subcircuit wiring commencing from the distribution

board feeder to the first light point (With 2R X 2.5Sq.mm and

1R X 1.5Sq.mm and 20/25mm FR PVC rigid conduits) and

from there to the light point complete with switch drop (With

2R X 1.5Sq.mm and 1R X 1.5Sq.mm and 20mm FR PVC

conduits).

5.1.4 Pt. Secondary Points (From Switch Box):- 31 760 115 875 27,125

1-way secondary light point from above primary point,

subsequent points controlled by same switch (With 2R X

1.5Sq.mm and 1R X 1.5Sq.mm and 20/25mm FR PVC

conduits).

5.1.5 Pt. Ceiling fan point complete R.O.

(With 2Rx1.5Sq.mm and 1Rx1.5Sq.mm and PVC mm conduits)

5.1.6 Pt. Exhaust fan point with 5A socket near fan controlled by 6A

SP switch 1.5 sq mm

4

1450 260 1,710 6,840

located on lighting switch board(With 2Rx1.5Sq.mm and

20mm conduits)

5.1.7 Pt. 20A Socket with 20A SP neon indicator Switch for AC spilt

unit IDU

8

3050 330 3,380 27,040

(with 2Rx4Sq.mm+1Rx1.5Sq.mm and 25mm conduit)

5.1.8 Pt. 6A Plug Point 4 1450 260 1,710 6,840

(2Rx1.5Sq.mm+1Rx1.5Sq.mm and 20mm conduit)

5.1.9 Pt. 16A Power Plug Point 16 1500 260 1,760 28,160

(2Rx2.5Sq.mm+1Rx1.5Sq.mm and 20mm conduit)

Total for 5.0 171280

6.1 Supply & Installation of switches, sockets,

mild steel electro galvanised back box etc.

complete with box earthing, interconnections

etc.

6.1.1 Each 1# - 5A Switch 25 185 60 245 6,125

6.1.2 Each 1# - 5A Switch & 1# 3P 5A 6 365 70 435 2,610

socket

6.1.3 Each 1# 15A switch & 5/15A 20 335 70 405 8,100

socket with indicator.

Total for 6.0 16835

7 LIGHT FIXTURES

7.1 Supply, installation, testing &

commissioning of light fixtures

complete with:

a) All fixing accessories

mounting bracket

b) Earthing of fittings

7.1.1 Each 1 x 28w Fluroscent light fitting similar 10 2,580 80 2,660 26,600

to WIPRO make WIF 21128 APF or

equivalent (Surface mounted / suspended)

7.1.2 Each 1 x 18w Recess mounted CFL down 45 1,500 80 1,580 71,100

lighter similar to WIPRO make

WCP 32118SGW

7.1.3 Each 2 x 18w Recess mounted CFL down 20 1,700 100 1,800 36,000

lighter similar to WIPRO make

WCP 32218SGW

7.1.4 Each 1 x 18w wall mounted light similar to 4 2,580 80 2,660 10,640

7.1.5 Each 2 x 11w surface mounted light similar R.O.

to WIPRO make WVP 41211

Total for 7.0 144340

8 EARTHING

8.1 Earthing Stations

-

8.1.1 Providing plate earthing stations for 2 14500 4900 19,400 38,800

Transformer body and neutral and also

for equipment earthing with 600 x 600

x 3mm copper plate as specified and

as per IS 3043 - 1987 complete with

a) Excavation in hard murram

b) Electrode with disconnecting

link arrangement.

c) Watering pipe.

d) Brick masonary chamber with C.I

frame and hinged covers.

e) Bentonite fill.

8.2 Earth wire/strips

Supply & laying Cu earthing strips for

interconnecting the earthing stations,

panels, DB's etc. in built-up trenches,

on walls/ceiling, buried in ground,

generally as specified & shown

on drawings complete with;

a) Fixing accessories.

b) Corrosion protection of

buried conductors with

bituminous coating and

covered with PVC tapes.

8.2.1 m 25 x 6 mm Cu 150 555 65 620 93,000

8.2.2 m 25 x 4 mm Cu R.O

8.2.3 m 25 x 3 mm Cu R.O

8.2.4 m 20 x 6 mm Cu R.O

8.2.5 m No. 8 SWG Cu bare wire 150 110 20 130 19,500

8.2.6 m No. 6 SWG Cu bare wire R.O.

Total for 8.0 151300

9.1 FIRE SAFETY AUXILIARIES

9.1,1 m

2

b) Supply and installation of 1000 V 6 1,550 150 1,700 10,200

grade rubber matting in front of

panels

9.1.2 Each Supply and installation of First aid 4 1,050 175 1,225 4,900

box & framed first aid chart in

LT panel room

9.1.3 Each Supply and instalaltion of shock 4 875 175 1,050 4,200

treatment chart in LT room

9.1.4 Each Supply & Installation of 440V 10 520 135 655 6,550

Danger boards

Total for 9.0 3,995 635 25,850

Vous aimerez peut-être aussi

- Electrical Load Schedule AppendixDocument4 pagesElectrical Load Schedule AppendixOmid TajikPas encore d'évaluation

- Competitive Quotation for PEB Civil Foundation WorkDocument2 pagesCompetitive Quotation for PEB Civil Foundation WorkSreenivas BandiPas encore d'évaluation

- Megas Architectural Services PVT - LTD.: A Civil /interior WorksDocument3 pagesMegas Architectural Services PVT - LTD.: A Civil /interior WorksSantosh ThakurPas encore d'évaluation

- InverterDocument52 pagesInverterD'ivy M Chico100% (3)

- Bom - HeadraceDocument14 pagesBom - HeadraceBethoven KhoPas encore d'évaluation

- BOQ Jabalpur - 6 LotDocument15 pagesBOQ Jabalpur - 6 Lotvipinkr_2000Pas encore d'évaluation

- Saudi Aramco Residential Building Fire Water System DesignDocument9 pagesSaudi Aramco Residential Building Fire Water System DesignDilshad AhemadPas encore d'évaluation

- Trus-Joist Specifier's GuideDocument24 pagesTrus-Joist Specifier's Guiderhunter2010Pas encore d'évaluation

- Rapid Dry Envelope Construction Using Ayrshire Steel FramingDocument34 pagesRapid Dry Envelope Construction Using Ayrshire Steel FramingjohnautodidactePas encore d'évaluation

- Schedule-I (Price & Quantity)Document10 pagesSchedule-I (Price & Quantity)Pratik987Pas encore d'évaluation

- STAIRS Design & ConstructionDocument47 pagesSTAIRS Design & Constructionsowmeyam100% (1)

- KamranDocument7 pagesKamranHunterPas encore d'évaluation

- Control Room Building EstimatingDocument11 pagesControl Room Building EstimatingVikas NagalPas encore d'évaluation

- Admore Gas (PVT) LTD: Bulk Oil Installation Depot at DaulatpurDocument12 pagesAdmore Gas (PVT) LTD: Bulk Oil Installation Depot at DaulatpurBilal Mustafa SiddiquiPas encore d'évaluation

- Kirby ConfrenceDocument97 pagesKirby ConfrenceAbstruse ConsultnatsPas encore d'évaluation

- Pressure Plate PDFDocument1 pagePressure Plate PDFparag narkhedePas encore d'évaluation

- Design CaculationsDocument29 pagesDesign Caculationsg4goharPas encore d'évaluation

- Daily Site Book My HouseDocument11 pagesDaily Site Book My Housemustafurade1Pas encore d'évaluation

- Miscella Neous Civil Works: SR - Description Unit Rate Quantity AmountDocument7 pagesMiscella Neous Civil Works: SR - Description Unit Rate Quantity AmountSenthilnathan NagarajanPas encore d'évaluation

- Comparison For 1200mm Dia & 600 MM Dia and DismantlingDocument5 pagesComparison For 1200mm Dia & 600 MM Dia and DismantlingUmamaheshwarrao VarmaPas encore d'évaluation

- BOQ-Hvac Hall - 24.06.23 FinalDocument19 pagesBOQ-Hvac Hall - 24.06.23 FinalAnkit AgarwalPas encore d'évaluation

- Tubes and PipesDocument1 pageTubes and PipesLLPas encore d'évaluation

- Sample PEB BOQDocument19 pagesSample PEB BOQPraveen JosePas encore d'évaluation

- Sectional Properties of Standard Steel Beams and ColumnsDocument4 pagesSectional Properties of Standard Steel Beams and Columnsinsane88Pas encore d'évaluation

- Estimate No. CHBDocument33 pagesEstimate No. CHBJefelyn AyapPas encore d'évaluation

- CCT CT ConcreteDocument2 pagesCCT CT Concreteepe civil1Pas encore d'évaluation

- Steel Structures 2 Project AnalysisDocument36 pagesSteel Structures 2 Project AnalysisAnamaria-Ileana LăzăroiuPas encore d'évaluation

- Comtech Metals Pvt Ltd Manufacturing Facility ProfileDocument17 pagesComtech Metals Pvt Ltd Manufacturing Facility ProfilepalsPas encore d'évaluation

- Documento 5 - RR01c - Narrative With Appendices Revised 05.16.12Document113 pagesDocumento 5 - RR01c - Narrative With Appendices Revised 05.16.12Galo SerranoPas encore d'évaluation

- Civil & Structures: Scope SummaryDocument4 pagesCivil & Structures: Scope Summaryriaz16shaikPas encore d'évaluation

- Loop Check: Operator's GuideDocument21 pagesLoop Check: Operator's Guidemc_prayerPas encore d'évaluation

- Protection, Monitoring and Control of Shunt ReactorsDocument198 pagesProtection, Monitoring and Control of Shunt Reactorsrodrigocmam100% (3)

- 37 PDFDocument14 pages37 PDFID SkechtPas encore d'évaluation

- E Commerce 311 v1Document408 pagesE Commerce 311 v1Santosh ThakurPas encore d'évaluation

- Group Profile and Manufacturing UnitsDocument20 pagesGroup Profile and Manufacturing UnitsSumit R SharmaPas encore d'évaluation

- Toaz - Info Septic Tank Boq PRDocument8 pagesToaz - Info Septic Tank Boq PRKunal SeeboruthPas encore d'évaluation

- BEAM 5m ACI-318-11Document1 pageBEAM 5m ACI-318-11AWOUNANGPas encore d'évaluation

- Microcontrollers Embedded Programming - Let's Start CodingDocument80 pagesMicrocontrollers Embedded Programming - Let's Start CodingjayanthPas encore d'évaluation

- PUBALI BANK LIMITED RENOVATION ELECTRICAL SCHEDULEDocument6 pagesPUBALI BANK LIMITED RENOVATION ELECTRICAL SCHEDULESaiful Hoque SohelPas encore d'évaluation

- PROFORMA OF SCHEDULES ELECTRICAL INSTALLATIONDocument13 pagesPROFORMA OF SCHEDULES ELECTRICAL INSTALLATIONAmit SharmaPas encore d'évaluation

- Electrical BOQDocument3 pagesElectrical BOQRakesh Mitra100% (1)

- GC 1Document1 pageGC 1Karthik NPas encore d'évaluation

- WC 1Document1 pageWC 1Karthik NPas encore d'évaluation

- MR 8 PDFDocument1 pageMR 8 PDFKarthik NPas encore d'évaluation

- Bill of Material: Raft Detail 5 3025 MR-4 Top Flange Plate 125 X 5 3235 5 Bottom Flange Plate 125 X 5 5 2598Document1 pageBill of Material: Raft Detail 5 3025 MR-4 Top Flange Plate 125 X 5 3235 5 Bottom Flange Plate 125 X 5 5 2598Karthik NPas encore d'évaluation

- Leader in ERW Pipes & TubesDocument2 pagesLeader in ERW Pipes & Tubesguiness_joe9154Pas encore d'évaluation

- Building infrastructure and industry with quality steel tubesDocument6 pagesBuilding infrastructure and industry with quality steel tubesDamodharan ChandranPas encore d'évaluation

- Nagendra Ji QuotationDocument2 pagesNagendra Ji QuotationWhole Solar100% (1)

- Compact title for abutment structural drawingDocument1 pageCompact title for abutment structural drawingHari Tri YuliansyahPas encore d'évaluation

- Venus Pipes Tubes Corporate BrochureDocument20 pagesVenus Pipes Tubes Corporate BrochurerajPas encore d'évaluation

- Electrical works bill of quantitiesDocument20 pagesElectrical works bill of quantitiesjobswithkumarPas encore d'évaluation

- Builder's Mart Access Road Construction Cost EstimateDocument3 pagesBuilder's Mart Access Road Construction Cost EstimateDamola PopoolaPas encore d'évaluation

- Renz Electrical ExcellDocument4 pagesRenz Electrical ExcellEdwin LoquinaPas encore d'évaluation

- Costing Calculations:: Enquiry 588 (CS)Document10 pagesCosting Calculations:: Enquiry 588 (CS)Rakesh SharmaPas encore d'évaluation

- Electrical InstallationDocument3 pagesElectrical InstallationAmpumuza AdrianPas encore d'évaluation

- Industrial StructuresDocument33 pagesIndustrial StructuresSharon ShinePas encore d'évaluation

- Quotation For Solar Street LightDocument3 pagesQuotation For Solar Street LightDebabrata GhoshPas encore d'évaluation

- Material Inspection SummaryDocument34 pagesMaterial Inspection SummarySUDDHA CHAKRABARTYPas encore d'évaluation

- Construction of Boundary Wall For Mr. Kugan at Kokuvil: Removing of Fence and Site ClearingDocument48 pagesConstruction of Boundary Wall For Mr. Kugan at Kokuvil: Removing of Fence and Site ClearingNavam NanthanPas encore d'évaluation

- Tender Schedule For Electrical Work PDFDocument6 pagesTender Schedule For Electrical Work PDFnakul4491_88890127Pas encore d'évaluation

- Essential tools and equipment listDocument4 pagesEssential tools and equipment listSURJAKANTA JANAPas encore d'évaluation

- Itemwise Detailed Technical SpecificationDocument3 pagesItemwise Detailed Technical Specificationanku4frenzPas encore d'évaluation

- Erection BOQ - ChamparanDocument170 pagesErection BOQ - ChamparanPrasanna kumar subudhiPas encore d'évaluation

- WiringDocument8 pagesWiringANKIT KUMAR RAJPas encore d'évaluation

- Boq Elect - Bpo at CoimbatureDocument9 pagesBoq Elect - Bpo at CoimbatureBenadict JoshuaPas encore d'évaluation

- Gym Area Boq For Nri Club HouseDocument5 pagesGym Area Boq For Nri Club HouseRamesh Arjun TPas encore d'évaluation

- Electrical BOQ for BMM Staff ApartmentDocument10 pagesElectrical BOQ for BMM Staff ApartmentKrm ChariPas encore d'évaluation

- Connect Mail - Re - Space Matrix - Savills Office Refurbish at Capital - MOM - 03 - DrainDocument6 pagesConnect Mail - Re - Space Matrix - Savills Office Refurbish at Capital - MOM - 03 - DrainSantosh ThakurPas encore d'évaluation

- Planters DetailsDocument1 pagePlanters DetailsSantosh ThakurPas encore d'évaluation

- Research On DesignDocument1 pageResearch On DesignSantosh ThakurPas encore d'évaluation

- Due Diligence Report - AW RefurbDocument32 pagesDue Diligence Report - AW RefurbSantosh ThakurPas encore d'évaluation

- 24th Sep 2017 Loose Furniture With Fabricating CostingDocument20 pages24th Sep 2017 Loose Furniture With Fabricating CostingSantosh ThakurPas encore d'évaluation

- Architect with 15+ years experienceDocument3 pagesArchitect with 15+ years experienceSantosh ThakurPas encore d'évaluation

- SITE:-Sodexo 6 FL - Andheri: Additional WorkDocument3 pagesSITE:-Sodexo 6 FL - Andheri: Additional WorkSantosh ThakurPas encore d'évaluation

- Srinagar ItenearyDocument1 pageSrinagar ItenearySantosh ThakurPas encore d'évaluation

- Tender Document EditedDocument57 pagesTender Document EditedSantosh ThakurPas encore d'évaluation

- SITE:-Sodexo 6 FL - Andheri: Additional WorkDocument3 pagesSITE:-Sodexo 6 FL - Andheri: Additional WorkSantosh ThakurPas encore d'évaluation

- InvoiceDocument1 pageInvoiceSantosh ThakurPas encore d'évaluation

- Exam B.SCDocument3 pagesExam B.SCSantosh ThakurPas encore d'évaluation

- Deduction Sheet InteriroDocument3 pagesDeduction Sheet InteriroSantosh ThakurPas encore d'évaluation

- Mumbai Lucknow 18Document1 pageMumbai Lucknow 18Santosh ThakurPas encore d'évaluation

- 5.6.1 Lessons Learnt TemplateDocument1 page5.6.1 Lessons Learnt TemplateSantosh ThakurPas encore d'évaluation

- SITC Signal Cabling Wiring Floor RacewaysDocument1 pageSITC Signal Cabling Wiring Floor RacewaysSantosh Thakur100% (1)

- Fire Alarm SystemDocument3 pagesFire Alarm SystemSantosh ThakurPas encore d'évaluation

- Corner GuardDocument1 pageCorner GuardSantosh ThakurPas encore d'évaluation

- Plumbing Work: Shop No: - 01 Khokar House Naya Nagar, Mira Road (East) Thane 401107Document4 pagesPlumbing Work: Shop No: - 01 Khokar House Naya Nagar, Mira Road (East) Thane 401107Santosh ThakurPas encore d'évaluation

- Request For Design Proposal 16-6-2014Document10 pagesRequest For Design Proposal 16-6-2014Santosh ThakurPas encore d'évaluation

- (r1) Kotak Brancj-Jaipur Elec & LV Boq (6 Nov 14)Document21 pages(r1) Kotak Brancj-Jaipur Elec & LV Boq (6 Nov 14)Santosh ThakurPas encore d'évaluation

- Ele A CtricalDocument7 pagesEle A CtricalSantosh ThakurPas encore d'évaluation

- Kitchen Cabinet Plans with Walnut and White LaminateDocument1 pageKitchen Cabinet Plans with Walnut and White LaminateSantosh ThakurPas encore d'évaluation

- View bank statement onlineDocument2 pagesView bank statement onlineSantosh ThakurPas encore d'évaluation

- Ar. Santosh Thakur's Resume - LEED AP Architect focused on Green Design, Project ManagementDocument2 pagesAr. Santosh Thakur's Resume - LEED AP Architect focused on Green Design, Project ManagementSantosh ThakurPas encore d'évaluation

- Diploma in Corporate Law Course ModulesDocument1 pageDiploma in Corporate Law Course ModulesSantosh ThakurPas encore d'évaluation

- Elevator Control Module User's ManualDocument44 pagesElevator Control Module User's ManualWissam RgailyPas encore d'évaluation

- 8-Port Antenna with Integrated RET and 4.3-10 ConnectorsDocument2 pages8-Port Antenna with Integrated RET and 4.3-10 ConnectorsYarinaPas encore d'évaluation

- Data Parallel ArchitectureDocument17 pagesData Parallel ArchitectureSachin Kumar BassiPas encore d'évaluation

- Machine Experiment 1Document7 pagesMachine Experiment 1Ujin MalabananPas encore d'évaluation

- A New High-Speed Foreign Fiber Detection System With Machine VisionDocument23 pagesA New High-Speed Foreign Fiber Detection System With Machine VisionijtrobinPas encore d'évaluation

- 16 FDocument10 pages16 Fbebeto90Pas encore d'évaluation

- XL4015 5A 180KHz 36V Buck DC to DC Converter DatasheetDocument9 pagesXL4015 5A 180KHz 36V Buck DC to DC Converter DatasheetJose M PeresPas encore d'évaluation

- Sr90 StandardDocument26 pagesSr90 Standardflorin74Pas encore d'évaluation

- The Art and Science of Protective RelayingDocument9 pagesThe Art and Science of Protective RelayingsouvikPas encore d'évaluation

- M57TE Block DiagramDocument9 pagesM57TE Block DiagramjmkcbePas encore d'évaluation

- Sea 1630Document2 pagesSea 1630Cool AshuuPas encore d'évaluation

- Tensan 4109A one-component epoxy adhesive technical data sheetDocument1 pageTensan 4109A one-component epoxy adhesive technical data sheetthe hoangPas encore d'évaluation

- SDVC31 Series Intelligent Digital VVVF Vibratory Feeder Controller Instruction BookDocument45 pagesSDVC31 Series Intelligent Digital VVVF Vibratory Feeder Controller Instruction Booknasser4858100% (1)

- Self Balancing Robot Using PidDocument21 pagesSelf Balancing Robot Using Pidline follower robotPas encore d'évaluation

- 7 1 2 Valerio - LippariniDocument35 pages7 1 2 Valerio - LippariniDILLIBABU EPas encore d'évaluation

- Datasheet Cyrix I 400A ENDocument2 pagesDatasheet Cyrix I 400A ENTom TomPas encore d'évaluation

- Minor Project SynopsisDocument3 pagesMinor Project SynopsisHappy RajputPas encore d'évaluation

- CD4011BCDocument10 pagesCD4011BCKike DavilaPas encore d'évaluation

- Third Angle Projection: YPF - Plaza Huincul Generator Protection G60 SettingsDocument92 pagesThird Angle Projection: YPF - Plaza Huincul Generator Protection G60 SettingsclauPas encore d'évaluation

- Pulsar2 User Manual - ENDocument83 pagesPulsar2 User Manual - ENJanette SouzaPas encore d'évaluation

- Low Threshold DMOS FETs for Logic Level InterfacesDocument4 pagesLow Threshold DMOS FETs for Logic Level InterfacesSaikumarPas encore d'évaluation

- PR ChargedEV Wire Bonding 2016 SDocument5 pagesPR ChargedEV Wire Bonding 2016 STHEJA G CPas encore d'évaluation

- Standards Specifications For Instrument CablesDocument10 pagesStandards Specifications For Instrument CablesAmmar AltamimyPas encore d'évaluation

- Esser Katalog 2013 Voice EvacuationDocument100 pagesEsser Katalog 2013 Voice EvacuationsllazicPas encore d'évaluation

- 1 Product Category SpecialDocument16 pages1 Product Category SpecialOmar SaeedPas encore d'évaluation

- FMS DS en V06Document13 pagesFMS DS en V06sr12562842Pas encore d'évaluation