Académique Documents

Professionnel Documents

Culture Documents

Non-Alloy Structural Steels: Mechanical Properties Available Dimensions

Transféré par

Palani Karthi0 évaluation0% ont trouvé ce document utile (0 vote)

46 vues1 pageThis document provides information on Salzgitter Flachstahl S275J2 steel, including its chemical composition, mechanical properties, available dimensions, minimum notch impact energy, usage, welding characteristics, and delivery and inspection standards. The steel has a carbon content between 0.18-0.2% and is a non-alloy structural steel classified as tensile strength class A according to DIN EN 10025-2. It can be ordered as hot-rolled coils or slit strip in various thickness and widths.

Description originale:

tty

Titre original

S275J2

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentThis document provides information on Salzgitter Flachstahl S275J2 steel, including its chemical composition, mechanical properties, available dimensions, minimum notch impact energy, usage, welding characteristics, and delivery and inspection standards. The steel has a carbon content between 0.18-0.2% and is a non-alloy structural steel classified as tensile strength class A according to DIN EN 10025-2. It can be ordered as hot-rolled coils or slit strip in various thickness and widths.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

46 vues1 pageNon-Alloy Structural Steels: Mechanical Properties Available Dimensions

Transféré par

Palani KarthiThis document provides information on Salzgitter Flachstahl S275J2 steel, including its chemical composition, mechanical properties, available dimensions, minimum notch impact energy, usage, welding characteristics, and delivery and inspection standards. The steel has a carbon content between 0.18-0.2% and is a non-alloy structural steel classified as tensile strength class A according to DIN EN 10025-2. It can be ordered as hot-rolled coils or slit strip in various thickness and widths.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 1

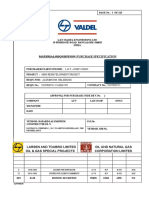

Salzgitter Flachstahl S275J2 Page 1 from 1 Edition: 06/06

Salzgitter Flachstahl GmbH Eisenhttenstrae 99 38239 Salzgitter

Phone +49 (0) 5341 21-2890 Fax +49 (0) 5341 21-8536

E-Mail achstahl@salzgitter-ag.de http://www.salzgitter-achstahl.de

Chemical composition

(in percent by weight)

min. max.

C 0.180%

Mn 1.500%

P 0.025%

S 0.025%

Cu 0.550%

1)

CE

2)

0.40%

S275J2

Non-alloy structural steels

Material no. 1.0145

according to DIN EN 10025-2

Tensile strength class A

Mechanical properties

1)

Nom. thick. e Yield strength ReH

16 mm 275 MPa

>16 mm 265 MPa

Nom. thick. e Tensile strength Rm

<3 mm 430 580 MPa

3 mm 410 560 MPa

Nom. thick. e Total elong. A

2)

(long./trans.)

<3 mm 19/ 17 %

3e40 mm 23/ 21 %

1) The tensile test values given in the table apply to

longitudinal samples (l); in case of strip and sheet

steel of widths of 600 mm they apply to transverse

samples (t).

2) It applies to nominal thickness e:

e < 3 mm: A80

e 3 mm: A5

1) Copper contents higher than 0.400% can cause

exfoliation corrosion.

2) Maximum carbon equivalent value

CE = C + Mn /6 + (Cr + Mo + V) /5 + (Cu + Ni) /15

Available dimensions

Hot-rolled coils unpickled, mill edge

Thickness in mm Width in mm

1.50 1.79 900 1250

1.80 1.99 900 1390

2.00 2.24 900 1540

2.25 2.49 900 1700

2.50 2.99 900 1880

3.00 3.99 900 1880

4.00 6.00 900 1880

6.01 12.70 900 1880

Hot-rolled slit strip

Thickness in mm Width in mm

1.50 1.79 100 515

1.80 1.99 100 635

2.00 2.24 100 760

2.25 7.00 100 800

7.01 8.00 140 800

8.01 9.00 175 800

9.01 10.00 233 800

<100 mm on request

Min. notch impact energy

1)

Temperature Min. notch impact energy

-20C 27 J

Usage

Suitability for coldforming such as bend-

ing, folding, bordering and anging etc.

can be ordered separately.

The user of these steel grades must

make sure that his calculation, design and

processing methods are appropriate for

the material. The welding technique used

must be suitable for the intended appli-

cation and comply with the state-of-the-

art.

With distinctly closer chemical com-

position values and mechanical proper-

ties, the steel grades of the S235S355

series are used as material for wheels of

passenger cars, lorries and other vehi-

cles.

Welding

The steel grades of the JR, JO, J2 and

K2 categories are in general suitable for

all welding techniques.

Condition of delivery, scope of

testing and certicate

The provisions of DIN 10025-2, chap-

ters 6.3 and 8 shall apply for delivery

and inspection. Other inspections may

be agreed.

1) Average values of 3 samples; one individual

value may fall short of the required minimum value

by not more than 30%. The sample width shall

equal the product thickness if the latter is between

5 and 10 mm. The tests are performed by using

samples similar to Charpy-V samples. The values

specied in the table above are to be reduced

proportionally to the sample width.

Vous aimerez peut-être aussi

- S235J0Document1 pageS235J0serzo75Pas encore d'évaluation

- S235J2 NDocument1 pageS235J2 Npraveenmenon86Pas encore d'évaluation

- S235JR SteelDocument1 pageS235JR SteelNguyễn Thanh CườngPas encore d'évaluation

- Non-Alloy Structural Steels: Mechanical Properties Available DimensionsDocument1 pageNon-Alloy Structural Steels: Mechanical Properties Available DimensionsOM PRAKASH PALPas encore d'évaluation

- S275JRDocument1 pageS275JRAkhilesh Kumar100% (1)

- Non Alloy Structural Steels S275J2 NDocument1 pageNon Alloy Structural Steels S275J2 Nserzo75Pas encore d'évaluation

- S 355 J2 + NDocument1 pageS 355 J2 + NValentin GalbenPas encore d'évaluation

- P265GHDocument2 pagesP265GHbakkali_bilalPas encore d'évaluation

- S355MCDocument2 pagesS355MCRodrigo Eduardo GomesPas encore d'évaluation

- Qste 340 TMDocument2 pagesQste 340 TMJuan José Viñas MéndezPas encore d'évaluation

- QStE 380 TM PDFDocument2 pagesQStE 380 TM PDFJetesh DevgunPas encore d'évaluation

- Fine-Grain Structural Steels, Normalised Rolled: Mechanical PropertiesDocument2 pagesFine-Grain Structural Steels, Normalised Rolled: Mechanical PropertieswentropremPas encore d'évaluation

- Usage: Non-Alloy Structural SteelsDocument2 pagesUsage: Non-Alloy Structural Steelssorin robertPas encore d'évaluation

- S235JRDocument1 pageS235JREmrahCayboyluPas encore d'évaluation

- S275JR PDFDocument1 pageS275JR PDFEmrahCayboylu100% (1)

- Price List For Hot Rolled Products January 1 2009Document3 pagesPrice List For Hot Rolled Products January 1 2009tdecebalusPas encore d'évaluation

- Non-Alloy Structural Steels: Mechanical Properties Available DimensionsDocument1 pageNon-Alloy Structural Steels: Mechanical Properties Available Dimensionssorin robertPas encore d'évaluation

- EN 10025 S355K2G3 / ABS EH 36 High Tensile Strength Plate: Sin Thai Special Steel Co., LTDDocument1 pageEN 10025 S355K2G3 / ABS EH 36 High Tensile Strength Plate: Sin Thai Special Steel Co., LTDJEORJEPas encore d'évaluation

- Bar STDDocument8 pagesBar STDtushk20100% (1)

- Inconel 82 (Austral-Wright)Document1 pageInconel 82 (Austral-Wright)Claudia MmsPas encore d'évaluation

- P460ML1Document2 pagesP460ML1Christiam Bernal MurilloPas encore d'évaluation

- Crom Plated BarsDocument24 pagesCrom Plated BarschonubobbyPas encore d'évaluation

- RST 37Document8 pagesRST 3725091972Pas encore d'évaluation

- Hot-Rolled Coils For The Manufacture of Large-Diameter PipesDocument2 pagesHot-Rolled Coils For The Manufacture of Large-Diameter PipesismailinesPas encore d'évaluation

- Dilli Max 690Document4 pagesDilli Max 690Fernando Alonso Troncos MendivesPas encore d'évaluation

- 20 MN CR 5Document1 page20 MN CR 5Sandeep KadamPas encore d'évaluation

- Structural Steel: Available Dimensions Mechanical PropertiesDocument1 pageStructural Steel: Available Dimensions Mechanical PropertiesBruce BarrPas encore d'évaluation

- Salem Product CatalogueDocument6 pagesSalem Product Cataloguedramilt0% (1)

- High-Strength Steels For Cold-Forming, Thermomechanically-RolledDocument2 pagesHigh-Strength Steels For Cold-Forming, Thermomechanically-RolledbenoiPas encore d'évaluation

- 3 SpringDocument66 pages3 Springall_meca_allPas encore d'évaluation

- Thyssenkrupp Materials International: Material Data SheetDocument4 pagesThyssenkrupp Materials International: Material Data SheetjaseerkannothPas encore d'évaluation

- DH 1400modDocument1 pageDH 1400modGopiNathPas encore d'évaluation

- Din en 1563Document2 pagesDin en 1563Tayfun Tezanlar78% (9)

- Technical Data 3CR12Document15 pagesTechnical Data 3CR12rudiskw456Pas encore d'évaluation

- DX51D Galvanized Coils For Cold Forming: Product DescriptionDocument2 pagesDX51D Galvanized Coils For Cold Forming: Product DescriptionsachedalPas encore d'évaluation

- BS3100 A2Document11 pagesBS3100 A2AlexPas encore d'évaluation

- Structural SteelsDocument1 pageStructural SteelsrjueiPas encore d'évaluation

- Welding Recommendation TS890Document2 pagesWelding Recommendation TS890max_powerPas encore d'évaluation

- DI-MC 355: Product DescriptionDocument4 pagesDI-MC 355: Product DescriptionvinodPas encore d'évaluation

- Sae 4140Document3 pagesSae 4140Anurag JainPas encore d'évaluation

- Equivalences Between Different Designations: Chemical CompositionDocument2 pagesEquivalences Between Different Designations: Chemical CompositionSuleman KhanPas encore d'évaluation

- DIMO 30M - Prehardened CrMnMo-alloyed Steel in Mold Quality For The Construction of Plastic MoldsDocument4 pagesDIMO 30M - Prehardened CrMnMo-alloyed Steel in Mold Quality For The Construction of Plastic MoldsFernando LaraPas encore d'évaluation

- Steel Grade: Material Data SheetDocument2 pagesSteel Grade: Material Data Sheetsorin robertPas encore d'évaluation

- EN 10025 S355J2G3 High Tensile Plate: Sin Thai Special Steel Co., LTDDocument1 pageEN 10025 S355J2G3 High Tensile Plate: Sin Thai Special Steel Co., LTDLeandro MarzonettoPas encore d'évaluation

- Hyundai Welding Handbook (12th) - GmawDocument30 pagesHyundai Welding Handbook (12th) - GmawErick Quan LunaPas encore d'évaluation

- Thermanit Chromo 9V SMAW enDocument1 pageThermanit Chromo 9V SMAW ensoft4gsmPas encore d'évaluation

- Technical Sheet Cusn12: The Above Data Are Subject To Change Without Notice by StellaDocument1 pageTechnical Sheet Cusn12: The Above Data Are Subject To Change Without Notice by StellaVarma DantuluriPas encore d'évaluation

- Hot Rolled China SteelDocument43 pagesHot Rolled China Steeledgarc999Pas encore d'évaluation

- Weld Like a Pro: Beginning to Advanced TechniquesD'EverandWeld Like a Pro: Beginning to Advanced TechniquesÉvaluation : 4.5 sur 5 étoiles4.5/5 (6)

- Welding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesD'EverandWelding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesPas encore d'évaluation

- The Essentials of Material Science and Technology for EngineersD'EverandThe Essentials of Material Science and Technology for EngineersÉvaluation : 5 sur 5 étoiles5/5 (1)

- Welding Tips & Tricks: All you need to know about welding machines, welding helmets, and welding gogglesD'EverandWelding Tips & Tricks: All you need to know about welding machines, welding helmets, and welding gogglesÉvaluation : 1 sur 5 étoiles1/5 (1)

- Advances in Solid Oxide Fuel Cells and Electronic CeramicsD'EverandAdvances in Solid Oxide Fuel Cells and Electronic CeramicsPas encore d'évaluation

- Materials Data for Cyclic Loading: Aluminium and Titanium AlloysD'EverandMaterials Data for Cyclic Loading: Aluminium and Titanium AlloysÉvaluation : 1 sur 5 étoiles1/5 (1)

- Weight & Balance-COG SHIFTDocument48 pagesWeight & Balance-COG SHIFTPalani KarthiPas encore d'évaluation

- Ps For HelideckDocument18 pagesPs For HelideckPalani KarthiPas encore d'évaluation

- Design Aspects in Welding: Dr. V.P. RaghupathyDocument26 pagesDesign Aspects in Welding: Dr. V.P. RaghupathyPalani KarthiPas encore d'évaluation

- Hand Calcs Rs15 - DeckliftDocument5 pagesHand Calcs Rs15 - DeckliftPalani KarthiPas encore d'évaluation

- Load-Calculator 4 Points Rev 8 ProtectedDocument4 pagesLoad-Calculator 4 Points Rev 8 ProtectedPalani KarthiPas encore d'évaluation

- Material Requisition / Purchase SpecificationDocument16 pagesMaterial Requisition / Purchase SpecificationPalani KarthiPas encore d'évaluation

- Safe LiftingDocument22 pagesSafe LiftingMahmoud Abdallah67% (3)

- Multi Lift Point CalcsDocument4 pagesMulti Lift Point CalcsPalani KarthiPas encore d'évaluation

- Sling Force Calculation About COGDocument4 pagesSling Force Calculation About COGPalani KarthiPas encore d'évaluation

- Steel Technical CablesDocument37 pagesSteel Technical Cablesgreat2007Pas encore d'évaluation

- Design of Saddle Supports & Stresses in Vessel On Two Saddles Using ZICK's Method - by Abdel Halim GalalaDocument16 pagesDesign of Saddle Supports & Stresses in Vessel On Two Saddles Using ZICK's Method - by Abdel Halim GalalaRaymond Metselaar83% (6)

- Design of Lifting and Tailing LugsNetsc001Document30 pagesDesign of Lifting and Tailing LugsNetsc001Tshilidzi Irene Netselo100% (1)

- Chapter3 Cog ShiftDocument56 pagesChapter3 Cog ShiftPalani KarthiPas encore d'évaluation

- Strain Aging TestDocument6 pagesStrain Aging TestPalani KarthiPas encore d'évaluation

- 2.6 - Lifting and Transportation Procedure - Rev.0Document3 pages2.6 - Lifting and Transportation Procedure - Rev.0Palani KarthiPas encore d'évaluation

- 02 Wire Rope StrandDocument39 pages02 Wire Rope Strandmanuelperezz2567% (3)

- ASME SpreaderBar CalcsDocument5 pagesASME SpreaderBar Calcsganesh100% (1)

- S355 European Standard SteelDocument7 pagesS355 European Standard SteelmaiquelernPas encore d'évaluation

- American App Examples 2007 CompleteDocument388 pagesAmerican App Examples 2007 CompleteJay NatoPas encore d'évaluation

- 2.6 - Lifting and Transportation Procedure - Rev.0Document3 pages2.6 - Lifting and Transportation Procedure - Rev.0Palani KarthiPas encore d'évaluation

- Heavy Lift Installation Study of Offshore Structure 2004Document203 pagesHeavy Lift Installation Study of Offshore Structure 2004Quang-derer75% (4)

- ABS Data SheetDocument2 pagesABS Data Sheetom12315Pas encore d'évaluation

- LC - DamagedDocument4 pagesLC - DamagedPalani KarthiPas encore d'évaluation

- Welded ConnectionsDocument1 pageWelded ConnectionsPalani KarthiPas encore d'évaluation

- To Be Submitted To The Registrar, Bharathiar University, Without EnclosuresDocument3 pagesTo Be Submitted To The Registrar, Bharathiar University, Without EnclosureskrishnithyanPas encore d'évaluation

- Offshore Structural DesignDocument36 pagesOffshore Structural Designmesserklinge100% (1)

- Excel Windload CalculatorDocument1 pageExcel Windload CalculatorPalani KarthiPas encore d'évaluation

- SuiteB Implementer G-11Suite B Implementer's Guide To NIST SP 800-56A3808Document33 pagesSuiteB Implementer G-11Suite B Implementer's Guide To NIST SP 800-56A3808jeffgr1776Pas encore d'évaluation

- E ApplicationDocument2 pagesE ApplicationsanjeevchhanchhiaPas encore d'évaluation

- OSA5533C Rev-L4 PDFDocument67 pagesOSA5533C Rev-L4 PDFjohn100% (1)

- Candapter ManualDocument11 pagesCandapter ManualAnie DelgadoPas encore d'évaluation

- Baixar Livos... It Gets Worse de Shane Dawson ..Unlimited Ebooks PDFDocument5 pagesBaixar Livos... It Gets Worse de Shane Dawson ..Unlimited Ebooks PDFbenjaminPas encore d'évaluation

- En 50216-10Document16 pagesEn 50216-10Mahmoud ShaheenPas encore d'évaluation

- BS en 857-2015Document19 pagesBS en 857-2015Srinivasan100% (2)

- BWare English Brochure en-LRDocument4 pagesBWare English Brochure en-LRJorge Palma LaraPas encore d'évaluation

- IP AddressDocument8 pagesIP AddressnebjakPas encore d'évaluation

- ComcaleDocument8 pagesComcalemrparadichlorobenzenePas encore d'évaluation

- Overhead Line DesignDocument37 pagesOverhead Line DesignPramod B.Wankhade100% (4)

- Canon Ir3225n Ir3235n Ir3245n PrintersDocument4 pagesCanon Ir3225n Ir3235n Ir3245n PrintersirteenPas encore d'évaluation

- 966h 972h Sn-bj6 WXZ Bs6 NpeDocument75 pages966h 972h Sn-bj6 WXZ Bs6 NpeevanPas encore d'évaluation

- Free Video To Flash Converter LogDocument12 pagesFree Video To Flash Converter LogThomas HillPas encore d'évaluation

- ASTM B121 Leaded Brass Sheet PlateDocument4 pagesASTM B121 Leaded Brass Sheet Platestrip1100% (2)

- Uv-5r V1.0-Annotated by KC9HI PDFDocument74 pagesUv-5r V1.0-Annotated by KC9HI PDFAugusto DriesPas encore d'évaluation

- 4 2 2Document403 pages4 2 2joPas encore d'évaluation

- RRB Alp CBT 1 Paper 31 Aug 2018 Shift 02Document22 pagesRRB Alp CBT 1 Paper 31 Aug 2018 Shift 02maheshPas encore d'évaluation

- User Manual SP-3360ADocument12 pagesUser Manual SP-3360AMarielaUgoliniPas encore d'évaluation

- Hytera X1pi Owners ManualDocument49 pagesHytera X1pi Owners ManualNani2220Pas encore d'évaluation

- Scania Engine Data 1588878Document20 pagesScania Engine Data 1588878Anderson Aguiar69% (16)

- APPENDIX SLB PUMP-dirotasiDocument60 pagesAPPENDIX SLB PUMP-dirotasiadhitya suzari putraPas encore d'évaluation

- HP LaserJet Pro 4202Document4 pagesHP LaserJet Pro 4202MihaiPas encore d'évaluation

- Telematrix PhoneDocument55 pagesTelematrix PhoneKris IribePas encore d'évaluation

- Data Structures & Algorithm in Java - Robert Lafore - PPTDocument682 pagesData Structures & Algorithm in Java - Robert Lafore - PPTmonsterspyPas encore d'évaluation

- Technical Specification For FlangesDocument13 pagesTechnical Specification For FlangesRahul GangulyPas encore d'évaluation

- GD11 GD15Document4 pagesGD11 GD15Gerardo Balbino TorresPas encore d'évaluation

- CSCI262 Dos DdosDocument86 pagesCSCI262 Dos Ddosami_haroonPas encore d'évaluation

- Performance Measurement Using TWAMP LightDocument30 pagesPerformance Measurement Using TWAMP LightrahmanPas encore d'évaluation