Académique Documents

Professionnel Documents

Culture Documents

All Ceramics - Dr. Yashendra

Transféré par

njucyCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

All Ceramics - Dr. Yashendra

Transféré par

njucyDroits d'auteur :

Formats disponibles

Seminar

On

Dental Ceramics-

All Ceramics

INTRODUCTION

Over the last 3 decades, a trend to shift toward metal-free restorations has

been observed in the dental field. To meet the increased demands of patients and

dentists for highly aesthetic, biocompatible, and long-lasting restorations, several

types of all ceramic systems have been developed.

Silicate and glass ceramics are used as a veneer for metal or all-ceramic

cores to optimize form and aesthetics.

In a monolithic application, small-sized restorations such as inlays, onlays,

laminate veneers, and crowns can also be fabricated. igh-strength ceramics such

as aluminum and zirconium o!ide ceramics were developed as a core material for

crowns and fi!ed dental prostheses "#$%s& to e!tend the indication ranges to the

high-load bearing areas.

'ost recently, monolithic zirconia restorations are increasingly promoted for

single crown and full-mouth rehabilitation, in particular for patients with

parafunctional habits.

HISTORY

The interest in nonmetallic and biocompatible restorative materials increased after

the introduction of the feldspathic porcelain crown in ()*3 by +and.

In (),-, 'c+ean pioneered the concept of adding aluminum o!ide to feldspathic

porcelain in an attempt to enhance mechanical properties. owever, the clinical

shortcomings ofthese materials, such as brittleness, crac. propagation, low tensile

strength, wear resistance, and marginal accuracy, discontinued its use.

In the early ())*s, the lost wa! press techni/ue was introduced to dentistry as an

innovative processing method for all-ceramic restorations.

The lithium disilicate ceramic was introduced as I%S 0mpress 1 "Ivoclar 2ivadent&

In ())3

4n array of 54$654' systems has evolved since #. $uret introduced the concept

in()7(

8ecently 54$654' capabilities creating separate core and veneer layers that

could then be 9oined with non-thermal methods are evolving and are of

particular interest for e!tended restorations.

TERMINOLOGIES

Alumina core: 4 ceramic containing sufficient crystalline alumina "4l

1

O

3

& to achieve

ade/uate strength and opacity when used for the production of a core for ceramic

9ac.et crowns.

Aluminous orcelain: 4 ceramic composed of a glass matri! phase and 3- vol: of

more of 4l

1

O

3

.

CAD-CAM ceramic: 4 machinable ceramic material formulated for the production of

inlays and crowns through the use of a computer aided design, computer aided

machining process.

Casta!le "ental ceramic: 4 dental ceramic specially formulated to be cast using a

lost wa! process.

Ceramic: 4 compound of metallic and nonmetallic elements.

Ceramic# "ental: 4 compound of metals "such as aluminium, calcium, lithium,

magnesium, potassium, sodium, tin, titanium, and zirconium& and non metals "such

as silicon, boron, fluorine, and o!ygen& that may be used as a single structural

component, such as when used in a 54$-54' inlay, or as one of several layers that

are used in the fabrication of a ceramic based prosthesis. $ental ceramics are

formulated to provide one or more of the following properties, castability, moldability,

in9ectability, color, opacity, translucency, machinability, abrasion resistance, strength

and toughness.

Ceramic $ac%et cro&n 'C(C): 4n all ceramic crown without a supporting metal

substrate that is made from a ceramic with a substantial crystal content "; -* vol:&

from which its higher strength and6or toughness is derived. These crowns are

distinguished from porcelain 9ac.et crowns that are made with porcelain to produce

an aesthetic porcelain margin as an alternative to a metal margin on a metal ceramic

crown.

Sinterin*: The process of heating closely pac.ed particles to achieve interparticle

bonding and sufficient diffusion to decrease the surface area or increase the density

of the structure. #or products such as In-5eram and In-5eram Spinel, surface

contact sintering and minimal density change are re/uired.

Sinel or Sinelle: 4 hard crystalline mineral "'g4l

1

O

<

& consisting of magnesium

and aluminium. 4lso, any of a group of mineral o!ides of ferrous iron, magnesium,

manganese or zinc.

Stain: 4 mi!ture of one or more pigmented metal o!ides and usually a low fusing

glass that when dispersed in an a/ueous slurry or monomer medium, applied to the

surface of porcelain or other specialized ceramic dried or light cured and fired, will

modify the shade of the ceramic based restoration. One product is supplied in a light

curable binder. These stain product are also called surface colorants or

characterization porcelains.

T+ermal comati!ilit,: The desirable condition of low transient and residual tensile

stress in porcelain ad9acent to a metal coping that is associated with a small

difference in the thermal contraction coefficients between the metal and the

veneering porcelains. The contraction coefficient of the metal should be slightly

greater than that of the porcelains so that residual a!ial and .noop compressive

stresses are produced. This condition will ensure the cooling of metal ceramic

prostheses without immediate crac. formation or delayed fracture caused by residual

tensile stresses in porcelain.

In"ications

for feldspathic porcelains-

= ighly esthetic veneers or anterior crowns in cases where color

mas.ing is not an issue

for leucite-reinforced ceramics-

= 0sthetic veneers and anterior crowns

= 4s a layering porcelain on leucite-reinforced, lithium disilicate,

alumina, or zirconia cores

for lithium disilicate ceramics-

= 2eneers

= %remolars and molars - inlays, onlays and crowns

= Three-unit bridges > anterior and premolar region

for zirconia-based ceramics -

= 4nterior and posterior crowns

= ?ru!ers > full-contour crowns

= 4nterior and posterior bridges "ma!imum (<-unit bridges, span depends on product and

number of abutments&

= 0ndodontically treated teeth

= Implant abutments

= Inlay bridges

= 'aryland bridges

= ?loc.-out of dar.ened tooth structure or cores

CERAMIC -ROCESSING METHODS

The processing stages of the ceramic core for production of ceramic prostheses are

summarized as follows@

The /uality of the final ceramic prosthesis is dependent on each stage of the fabrication

process.

CONDENSATION 'COM-ACTION)

The process of pac.ing the powder particles together and removing e!cess water is

.nown as condensation. %roper condensation gives dense pac.ing and reduce the

shrin.age of porcelain and minimize porosity in the fired porcelain.

5ondensation procedure is followed in application of core, dentin and enamel

porcelain either in porcelain 9ac.et crown or porcelain fused to metal.

The porcelain powder is mi!ed with distilled water or special li/uid supplied by the

manufacturer to form a thic. paste. Small portions of the paste are then applied to the

platinum matri! in 9ac.et crown preparation over the die until the desired shape of the crown

has been attained. 0!cess water is removed by blotting with a linen cloth or similar

absorbent material.

The remaining water serves as a binder for the powder so that the crown may be

properly shaped before firing. %owder consisting of a mi!ture of particle sizes compact more

easily than those with particles of one size only. This reduces the size of the spaces

between the particles and thus reduces firing shrin.age.

4 well compacted crown not only reduces firing shrin.age but also shows a regular

contraction over its entire surface.

Met+o"s o. con"ensation:

1) Vibration: 'ild vibration are used to densely pac. the wet powder upon the underlying

matri!. The e!cess water comes to the surface and its is blotted with a tissue paper.

2) Spatulation: 4 small spatula is used to apply and smoothen the wet porcelain. This

action brings e!cess water to the surface.

3) Wet brush technique: The mi! should be creamy and capable of being transferred in

small increments to the platinum matri! with hair brush.

5ondensed mass is gradually heated by first placing it in front of the muffle of a

preheated furnace and later inserting into the furnace.

/) Lo& !is0ue sta*e: The flu! begins to melt and flow in between the porcelain particles.

The mass attains some rigidity but very little cohesion. 4t this stage the material is

porous and undergoes minimum of shrin.age. The porcelain do not have translucency

and glaze.

1) Me"ium !is0ue sta*e: ere the flu! flows freely in between the particles the material is

still porous, but there is complete cohesion between the particles and most of the

shrin.age is complete. In this stage also there is lac. of translucencey and glaze.

2) Hi*+ !is0ue sta*e: ere with shrin.age is completed. There is very little porosity, the

mass has attained complete rigidity and smoothness, the body does not appear to be

glazed. 'ost of the addition and alterations are carried out after the porcelain has

attained medium bis/ue stage.

+ess the number of firing, higher is the strength and better the esthetics. Too many

firings give a life less, over translucent porcelain.

-ORCELAIN 3URNACE

The ordinary air fire porcelain furnace consists of a muffle, a pyrometer, a

thermocouple and in its most simple form a rheostat or variable transformer for control of

firing temperature and sophisticated automatic and programmable time and temperature

controller for the most modern furnaces.

The muffle is the heating unit providing necessary high temperature for ba.ing of

porcelain. The heating element is a coiled wire of platinum and is embedded into the

refractory material of the muffle. The muffle is provided with a door for easy access and to

prevent fluctuation of temperature due to heat loss.

The pyrometer is a millivoltmeter calibrated to read in degree of temperature. The

thermocouple consists of platinum wire 9oined at one end with another wire made of )*:

platinum and (*: rhodium. The 9oint is placed inside the muffle, this is .nown as hot

9unction of the thermocouple. The free ends of the thermocouple are attached to the

pyrometer outside the muffle. Ahen heat is generated inside the muffle, the dissimilar

metals of the thermocouple at the hot 9unction generates and electromotive force which

deflects the needle of the pyrometer indicating the calibrated temperature.

4s the electromotive force varies with variation in temperature inside the muffle, such

variations can be measured as temperature on the pyrometer. The temperature controller

regulates the current fed to the heating element inside the muffle thereby inducing increase

or decrease in muffle temperature.

The main problem in air fired furnace is the opacity of the porcelain due to porosity.

$ifferent methods and porcelain firings are@

(& 4ir firing

1& 2acuum firing

/) Air .irin*:

4ir inside a furnace is modulated to the same atmospheric pressure during this

procedure. There is more chances of air entrapment in porcelain. Ae will get more

porous, less translucent porcelain.

1) 4acuum .irin*:

%artial vacuum firing reduces air voids, so porosity is reduced, so better translucent

effect.

The air from the furnace is evacuated and this eliminating air from porous spaces

which collapses on itself. This is the best and widely used method.

CERAMIC -ROSTHESES:

Aluminous -orcelain Cro&ns:

4nother method of bonding porcelain to metal ma.es use of tin o!ide coatings on

platinum foil. The ob9ective of this techni/ue is to improve the aesthetics by a replacement

of the thic.er metal coping with a thin platinum foil, thus allowing more room for porcelain.

The method consists of bonding aluminous porcelain to platinum foil copings. 4ttachment of

the porcelain is secured by electroplating the platinum foil with a thin layer of tin and then

o!idizing it in a furnance to provide a continuous film of tin o!ide for porcelain bonding. The

rationale is that the bonded foil will act as an inner s.in on the fit surface to reduce

subsurface porosity and formation of microcrac.s in the porcelain, thereby increasing the

fracture resistance of crowns and bridges. The clinical performance of these crowns has

been e!cellent for anterior teeth, but appro!imately (-: of these crowns fractured within 7

years after they were cemented to molar teeth with a glass ionomer cement.

?ased on a ())< survey, metal-ceramic crowns and bridges were used for

appro!imately )*: of all fi!ed restorations. owever, recent developments in ceramic

products with improved fracture resistance and e!cellent aesthetic capability have led to a

significant increase in the use of all-ceramic products. 5eramic crowns and bridges have

been in widespread use since the beginning of the twentieth century. The ceramics

employed in the conventional ceramic crown were high fusing feldspathic porcelains. The

relatively low strength of this type of porcelain prompted 'c+ean and ughes "(),-& to

develop an alumina-reinforced porcelain core material for the fabrication of ceramic crowns.

The alumina-reinforced crowns are generally regarded as providing slightly better

aesthetics for anterior teeth than are the metal-ceramic crowns that employ a metal coping.

owever, the strength of the core porcelain used for alumina-reinforced crowns is

inade/uate to warrant the use of these prostheses for posterior teeth. In fact 'c+ean

reported a fracture rate of molar aluminous porcelain crowns of appro!imately (-: after -

years.

Casta!le an" mac+ina!le Glass-Ceramics 'Dicor an" Dicor MGC)

Ahen used for posterior crowns, ceramic crowns are most susceptible to fracture.

Shown in #igure 1(-, "see also the color plate& is the stress distribution computed by finite

element analysis in a *.-mm-thic. molar $icor crown loaded on the occlusal surface, 9ust

within the marginal ridge area. The ma!imum tensile stress is located within the internal

surface directly below the point of applied force and 9ust above the -* m-thic. layer of resin

cement "see the arrow in fig. 1(.,&. this site represents the critical flaw responsible for crac.

initiation under an applied intraoral force. The location of initial crac. formation was

consistent with the location of ma!imum tensile stress predicted by the finite element

calculations as shown in figure 1(.,. an S0' image of a fractured clinical crown of $icor

glass-ceramic is shown in fig 1(.3. because of the smaller forces e!erted on anterior

crowns, the ris. for fracture of anterior crowns is significantly less than that for posterior

crowns.

The first commercially available castable ceramic material for dental use, $icor, was

developed by 5orning Blass wor.s and mar.eted by $entsply international. $icro is a

castable glass that is formed into an inlay, facial veneer, or full-crown restoration by a lost-

was casting process similar to that employed for metals. 4fter the glass casting core or

coping is recovered, the glass is sandblasted to remove resideual casting investment and

the sprues are gently cut away. The glass is then covered by a protective CembedmentC

material and sub9ected to a heat treatment that causes microscopic plateli.e crystals of

crystalline material "mica& to grow within the glass matri!. This crystal nucleation and crystal

growth process is called ceramming. Once the glass has been cerammed, it is fit on the

prepared dies, ground as necessary, and then coated with veneering porcelain "as shown in

fig. 1(.3& to match the shape and appearance of ad9acent teeth. $icor glass-ceramic is

capable of producing surprisingly good aesthetics, perhaps because of the CchameleonC

effect, where part of the color of the restoration is pic.ed up from the ad9acent teeth as well

as from the tinted cements used for luting the restorations.

$icor glass-ceramic contains about -- vol: of tetrasilicic fluormica crystals. The

ceramming process results in increased strength and toughness, increased resistance to

abrasion, thermal shoc. resistance, chemical durability, and decreased transluency. $icor

'B5 is a higher /uality product that is crystallized by the manufacturer and provided as

54$-54' blan.s or ingots. The 54$-54' ceramic $icor 'B5 contains 7* vol: of

tetrasilicic fluormica platelets, which are appro!imately 1m in diameter. The mechanical

properties of $icor 'B5 are similar to those of $icor glass-ceramaic, although it has less

translucency "contrast ratio of *.<( -*.<< versus *.-,, respectively&.

$icor has recently been discontinued presumably because of low tensile strength

and the need to color the prosthesis on the e!terior region rather that within the core region,

which would more closely resemble a natural tooth. 4lthough $icor is no longer sold, the

principles for selection are useful when products of similar mechanical and physical

properties are being considered. The advantages of $icor glass-ceramic were ease of

fabrication, improved aesthetics, minimal processing shrin.age, good marginal fit,

moderately high fle!ural strength, low thermal e!pansion e/ual to that of tooth structure, and

minimal abrasiveness to tooth enamel.

The disadvantages of $icor glass-ceramic were its limited use in low-stress areas

and its inability to be colored internally. 4s designed, it was colored with a thin outer layer of

shading porcelain and surface stain to ieve acceptable aesthetics. owever, $icor 'B5

ingots have been supplied in light and dar. shades, ma.ing it possible for technicians to

build depth of color into the fabrication process.

4lthough both of the $icor products were based on a glass-ceramic core that was

minimally abrasive to opposing tooth enamel, the re/uired shaduing or veneering porcelains

were more abrasive. 4esthetically, $icor crowns were more lifeli.e than metal-ceramic

crowns, which often e!hibit a metal collar, a gray shadow subginigivally, or poor

translucency. The life e!pectancy of $icor crowns in high-stress areas is not as good as that

of %0' crowns. Two veneering materials were used to improve the color of $icor crowns@

$icor %lus, which consisted a pigmented feldspathic porcelain veneer, and AilliDs Blass, a

veneer of 2itadur E aluminous porcelain.

Tooth preparation for glass-ceramic of this type is the same as that re/uired for

metal-ceramic prostheses e!cept that, for first and second molars a reduction of 1mm is

recommended. Occlusal surfaces and incisal edges must be reduced a minimum of (.-mm.

4!ial surfaces should be reduced a minimum of (.*mm. The preparation should be either a

shoulder with a rounded gingivoa!ial line angle or a heavy chamfer.

-ressa!le Glass-Ceramics:

4 glass-ceramic is a material that is formed into the desired shape as a glass, then

sub9ected to a heat treatment to induce partial devitrification "i.e., loss of glassy structure by

crystallization of the glass&. The crystalline particles, needles, or plates formed during this

ceramming process serve to interrupt the propagation of crac.s in the material when an

intraoral force is applied, thereby causing increased strength and toughness. The use of

glass-ceramics in dentistry was first proposed by 'ac5ulloch in (),3. e used a

continuous glass-molding process to produce denture teeth. e also suggested that it

should be possible to fabricate crowns and inlays by centrifugal casting of molten glass.

%ressure molding is used to ma.e small, intricate ob9ects. This method uses a

piston to force a heated ceramic ingot through a heated tube into a mol., where the ceramic

form cools and hardens to the shape of the mold. Ahen the ob9ect has solidified, the

refractory mold "investment& is bro.en apart and the ceramic piece is removed. It is then

debrided and either stained and glazed "certain inlays& or veneered with one or more layers

of a thermally compatible ceramic.

I%S 0mpress is a glass-ceramic provided as core ingots that are heated and pressed

until the ingot flows into a mold. It contains a higher concentration of leucite crystals that

increase the resistance to crac. propagation "fracture&. The hot-pressing process occurs

over a <- min period at a high temperature to produce the ceramic substructure. This crown

form can be either stained and glazed or build up using a conventional layering techni/ue.

The advantages of this ceramic are its lac. of metal, a translucent ceramic core, a

moderately high fle!ural strength "similar to that of Optimal %ressable ceramic&, e!cellent fit,

and e!cellent aesthetics. The disadvantages are its potential to fracture in posterior areas

and the need to use a resin cement to bond the crown micromechanically to tooth structure.

I%S 0mpress and I%S 0mpress1 are typical products representative of several other

leucite-reinforced and lithia disilicate-reinforced glass-ceramics, respectively. Some

properties of I%S 0mpress and I%S 0mpress1 glass-ceramic core materials are listed in

table. 1(.,. I%S 0mpress is a leucite-containing glass-ceramic that contains about 3- vol:

of leucite "F4ISI1O,& crystals, which increases the resistance to crac. propagation "fracture&.

The veneering ceramic also contains leucite crystals in a glass matri!. 4fter hot pressing,

divesting, and separation of the ceramic units the sprue segments, they are veneered with

porcelain containing leucite crystals in a glass matri!.

4 cross-sectional illustration of an I%S 0mpress crown is illustrated in fig. 1(.). The

I%S 0mpress1 is similar e!cept that the core consists of lithia disilicate crystals in a glass

matri! and the veneering ceramic contains apatite crystals. The very small apatite crystals

cause light scattering in a way that resemble by the structure and components of tooth

enamel. The coefficient of e!pansion of the apatite glass-ceramic veneering ceramic is ).7

ppm6

*

5, which is similar to that of I%S 0mpress1 core ceramic "(*., ppm6

*

5&. Obviously,

this veneering ceramic should not be used with the I%S 0mpress core ceramic that has a

much higher e!pansion coefficient "(-* ppm6

*

5&.

The core microstructure of I%S 0mpress1 glass ceramic is /uite different from that of

I%S 0mpress, as evidenced by the 7* vol: of elongated lithia disilicate crystals in I%S

0mpress1. The primary crystal particles in I%S 0mpress1 are *.- to <m in length. 4 smaller

concentration of lithium orthophosphate crystals "+i1 Si1 O-& appro!imately *.( to *.3m in

diameter has also been reported "oland et al., 1***&. The microstructural difference

between I%S 0mpress and I%S empress1 results in a slight decrease in translucency for I%S

5mpress1 "*.--& "olland et al., 1***&. 4s is the case for most pressable glass-ceramics,

the advantages of I%S empress and I%S 0mpress1 glass-ceramic core materials are their

potential for accurate fit, e!cellent transluency and overall aesthetics, and a metal-free

structure. $isadvantages are their low to moderately high fle!ural strength and fracture

toughness. These properties limit their use to conservative designs in low to moderate

stress environments. Shown in fig. 1(-(*, 1(-(( and 1(-(1 are three-unit glass-ceramic

#%$s made from a lithia-disilicate-based core material. The #%$ shown in fig. 1(-(1 was

made without a veneering ceramic to enhance the fracture resistnce. 4 summary of

important properties is presented in Table 1(-7 for a variety of dental ceramics. 4 list of

pressable ceramics and their veneering ceramics is summarized.

O%5 and O%5 3B are two pressable ceramics that are similar in nature to I%S

0mpress and I%S 0mpress1, respectively. O%5 is a leucite-containing ceramic and O%5

3B contains lithia disilicate crystals. The ultralow-fusing temperature of the veneering

porcelain suggests a low level of wear of opposing enamel. owever, insufficient clinical

data are available to support this hypothesis.

In-5eram 4lumina, In-5eram Spinell, and In-5eram Girconia

In-5eram is supplied as one of three core ceramics@ "(& In-5eram spinell "1& in-

5eram 4lumina, and "3& in-5eram Girconia. 4 slurry of one of these materials is slip-cast on

a porous refractory die and heated in a furnace to produce a partially sintered coping or

framewor.. The partially sintered core is infiltrated with glass at ((**

*

5 for < hr to eliminate

porosity and to strengthen the slip-cast core. The initial sintering process for the alumina

core produces a minimal shrin.age because the temperature and time are sufficient only to

cause bonding between particles and to produce a desired level of sintering. Thus the

marginal adaptation and fit of this core material should be ade/uate because little shrin.age

occurs. The fle!ural strength "modulus or rupture& values of the glass-infiltrated core

materials are appro!imately 3-* 'pa for in-5eram spinell "I5S&, -** 'pa for In-5eram

4lumina "I54&and 7** 'pa for In-5eram Girconia "I5G& compared with strengths of (** to

<** 'pa for $icor, Optec %ressable 5eramic, I%S 0mpress and I%S 0mpress1. $espite the

relatively high strength of these materials, failures can still occur in single crowns as well as

#%$s.

?ecause of the variation in strength, the primary indications for these core ceramics

vary as shown in Table 1(-). #or e!ample, I5S is indicated for use as anterior single-unit

inlays, onlays, crowns, and veneers, I54 is indicated for anterior and posterior crowns and

anterior three-unit #%$s. ?ecause of its high level of opacity, I5G is not recommended for

anterior prostheses. owever, because of its e!tremely high strength and fracture

toughness, it can be used for posterior crowns and posterior #%$s. 4s suggested in

chapter <, it is essential that the gingival embrasure areas of ceramic #%$ connectors be

designed with a large radius of curvature to minimize the stress-raiser effect in areas of

moderate to high tensile stress. The connectors also should be sufficiently thic. to minimize

stresses during loading. #or 0mpress and 0mpress1 ceramics used in molar areas, the

connector height should be at least <mm.

3 tables@ %age Eo. ,37 to ,3)

Hntil in-5eram was introduced, aluminous porcelain had not been used successfully

to produce #%$s because of low fle!ural strength and high sintering shrin.age. Thus the

principal indications for aluminous porcelain crowns were the restoration of ma!illary anterior

crowns when aesthetics was important and their use in patients with allergies to metals. Its

advantages and disadvantages are summerized in the following.

4 schematic drawing of an In-5eram crown is shown in #ig 1(.(3 The same diagram

can be used to illustrate crowns made with In-5eram Spinell "I5S& and In-5eram Girconia

"I5G&, which will be discussed below. The three In-5eram ceramics are glass-infiltrated core

materials used for single anterior crowns "all three products&, posterior crowns "In-5eram

4lumina and in-5eram Girconia&, anterior three-unit #%$s "In-5eram 4lumina&, and three-

unit posteriro bridges "In-5eram Girconia&.

The most translucent of the three ceramics- In-5eramics, In-5eram Spinell, was

introduced as an alternative to in-5eram 4lumina. This ceramic has a lower fle!ural

strength, but its increased translucency provides improved aesthetics in clinical situations in

which the ad9acent teeth or restorations are /uite translucent. The core of I5S is 'g4l (O<

and that for I5G is a mi!ture of 4l1O3 and GrO1. These core ceramics are also infiltrated with

glass, and they are fabricated in a manner similar to that for I54, although the firing

temperatures and times may be different.

The final I54 core consists pf 7* wt: alumina infiltrated with 3* wt: sodium

lanthanum glass. The final I5S core consists of glass-infiltrated magnesium spindl

"'g4l1O<&. I5G contains appro!imately 3*wt: zirconia and 7* wt: alumina. The power-

li/uid slurry is slip cast onto a porous die that absorbs water from the slurry, thereby

densifying the agglomeration of particles onto the die. Steps for fabricating in-5eram

prostheses are as follows@ "(& prepare teeth with an occlusal reduction of (.- to 1.*mm and a

heavy circumferential chamfer "(.1mm&, "1& ma.e an impression and pour two dies, "3& apply

4l1O3 on a porous duplicate die, "<& heat at (1*

*

5 for 1 hours to dry 4l1O3 , "-& sinter the

coping for (* hours at ((1*

*

5, ",& apply a sodium lanthanum glass slurry mi!ture on the

coping, "7& fire for < hours at ((1*

*

5 to allow infiltration of glass, "3& trim e!cess glass

from the coping with diamond burs, ")& build up the core with dentin and enamel porcelain,

"(*& fire in the oven, grind in the anatomy and occlusion, finish, and glaze.

The advantages of I54 include a moderately high fle!ural strength and fracture

toughness, a metal-free structure, and an ability to be used successfully with conventional

luting agents "Type ( cements&. The collective advantages of the three glass-infiltrated core

materials are their lac. of metal, relatively high fle!ural strength and toughness, and ability to

be successfully cemented using any cement.

In spite of this high fle!ural strength "<1) 'pa&, the Aeibull modulus of I5S is /uite

low "-.7&, which is indicative of a large scatter in the distribution of strength values relative to

the probability of fracture. "Tinschert et al., 1***&. Its marginal adaptation may not be as

good as that achieved with other ceramic products. In one study the mean marginal

discrepancies were 33 m for %rocera 4ll 5eram, ,3 m for I%S 0mpress, and (,(m for In-

5eram 4lumina. Other drawbac.s of I54 include its relatively high degree of opacity,

inability to be etched, techni/ue sensitivity, and the relatively great amount of s.illed labor

re/uired. These disadvantages apply also to In-5eram Girconia. 5ompared with I5', the

opacities of I54 and I5G core ceramics are much greater.

4lthough these newer core ceramics have e!cellent fracture resistance inproper

design of the connector area of a #%$ can significantly reduce the fracture resistance and

clinical survivability of the prosthesis. Shown in fig. 1(-(< is the stress distribution in a three-

unit #%$, which shows relatively high principal tensile stress "red area& at the tissue side of

the interpro!imal connector when an occlusal load of 1-* E is applied to the occlusal surface

of the pontic.

In summary, In-5eram Spinell "I5S& is a glass-infiltrated core ceramic that offers

greater translucency for crowns than either the I54 or I5G core ceramics. owever, I54

has lower strength and toughness compared with I54 and I5G. Thus the use of I5S is

limited to anterior inlays, onlyas, veneers, and anterior crowns. 4lthough I5G is the

strongest and toughest of the three core ceramics, its use is limited to posterior crowns and

#%$s because of its high level of core opacity. I5G is a much stronger and tougher material

and has greater opacity than I54.

-rocera AllCeram:

The %rocera 4ll5eram crown is composed of densely sintered, high-purity aluminum

o!ide core combined with a compatible all5eram veneering porcelain. This ceramic material

contains )).): alumina, and its hardness is one of the highest among the ceramics used in

dentistry. %rocera 4ll5eram can be used for anterior and posterior crowns, veneers, onlays,

and inlyas.

4 uni/ue feature of the %rocera system is the ability of the %rocera Scanner to scan

the surface of the prepared tooth and transmit the data to the milling unit to produce an

enlarged die through a 54$-54' process. The core ceramic form is dry pressed onto the

die, and the core ceramic is then sintered and veneered. Thus the usual (-:-1*:

shrin.age of the core ceramic during sintering will be compensated by constructing an

oversized ceramic pattern, which will shrin. during sintering to the desired size to accurately

fit the prepared tooth.

CAD-CAM Ceramics:

4s shown in the ceramic classification chart in all-ceramic cores can be

produced by processes of condensation and sintering, casting and ceramming,

hotpressing and sintering, sintering and glass infiltration, and 54$-54' processing

for the 5erec $4?-54' system the internal surface of inlays, onlays, or crowns is

ground with diamond dis.s or other instruments to the dimensions obtained from a

scanned inage of the preparation. for some systems, the e!ternal surface must be

ground manually, although some recent 54$-54' systems are capable of forming

the e!ternal surface as well.

4 milling operation within a 5erec 54$-54' unit "Siemens

4.tiengesellschaft, ?ensheim, Bermany &. The ceramic loc. is being ground by a

diamond-coated dis. whose translational movements are guided by computer-

controlled input. 4 cerec 54$-54' ceramic bloc. is shown in #igure 1(-(, before

milling, at an intermediate milling stage, and after completion of the milling operation

for an inlay. These ceramics are supplied as small bloc.s that can be gound into

inlays and veneers in a computer-driven 54E-54' system. 2itablocs 'F II are

feldspathic procelains that are used in the same way as is $icor B5 "machinable

glass-ceramic&. The disadvantages of 54$-54' restorations include the need for

costly e/uipment, the lac. of computer-controlled processing support for occlusal

ad9ustment, and the techni/ue-sensitive nature of surface imaging re/uired for the

prepared teeth. 4dvantages include negligible porosity levels in the 54$-54' core

ceramics, the freedom from ma.ing an impression, reduced assistant time

associated with impression procedures, the need for only a single patient

appointment "with the 5erec system&, and good patient acceptance. 4 list of 54$-

54' and copy-milled ceramics is given in Table 1(-(*.

4n advantage of 54$-54' ceramics is that one can select a core ceramic

either for strength and fracture resistance, for low abrasiveness, or for translucency.

for e!ample, the e!tensive wear of opposing enamel that occurs when it is opposed

by a feldspathic porcelain surface in the absence of posterior occlusion can be

minimized by selscting a core ceramic that is minimally abrasive to enamel.

Cercon an" La5a 6irconia Core Ceramics:

The cercon Girconia system "$estsply 5eramco, ?urlington, EI& consists of

the following procedures for production of zirconia-based prostheses. 4fter preparing

the teeth "1.*mm incisal or occlusal reduction and (.- mm a!ial reduction&, an

impression is made and sent tot he laboratory, where it is poured with a model

material. 4 wa! pattern appro!imately *.3 mm in thic.ness is made for each coping

on the holding appliance on the left side of the scanning and milling unit "5ercon

?rain&. 4 presintered Girconia blan. is attached to the right side of the ?rain unit.

"5ercon ?rain&. 4 presintered zirconia blan. is attached to the right side of the ?rain

unit. The blan. has an attached barcode, which contains the enlargement factor and

other milling parameters for computer control or the milling procedure 4fter the unit is

activated, parameters for computer control of the milling procedure 4fter the unit is

activated, the pattern in scanned and the blan. is rough-milled and fine-milled on

occlusal.

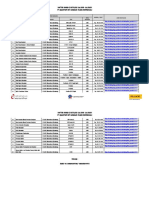

Ceramic

7loc%

Ceramic t,e

Ceramic

5eneer

In"ications Manu.acturer

5er4dapt ighly sintered 4l

1

O

3

4ll cream Implant

superstructure

Eobel ?iocare

5ercon ?ase %resintered GrO

1

J

postsintered after

milling

5oercion

5ream S

5rowns and

#%$s

$entsply 5eramco

$5- Fristen +eucite-base Triceram 5rowns $5S $ental

4B60sprident

$5- Gir.on %resintered GrO

1

hot

isostatic

postcompaction

2itadur $

Triceram

5rowns and

#%$s

$5S $ental

4B62ita60sprident

$enzir %resintered GrO

1

J

hot

isostatic

postcompaction

0mpress1 5rowns and

#%$s

$ecim, Ivoclar

+424 #rame GrO

1

J presintered

and postsntered

+424

5eram

5rowns and

#%$s

3' 0S%0

%ro5ad +eucite-based 'althechni

.

2eneers,

inlays, onlays,

and crowns

Ivoclar

%rocera

4ll5eram

4l

1

O

3

J presintered

and postsintered

4ll5eram 5rowns and

#%$s

Eobel ?iocare

Synthoceram 4l

1

O

3

J reinforcedJ

pressed and

postsintered

Sintagon 5rowns 0lephant

2ita?locs 'ar.

II

#eldspathic

porcelain bloc.

'altechni. 2eneers,

inlays, onlays,

and crowns

2ident

2ita?loc.s

4lumina

Sintered 4l

1

O

3

J

followed by glass

infiltration

2itadur

4lpha

5rowns and

#%$s

5rowns and #%$s 2ident

2ita?locs

Spinell

Sintered

'gO-4l

1

O

3

spinel

followed by glass

infiltration

2itadur

4lpha

5rowns 2ident

2ita?locs

Girconia

Sintered 4l

1

O

3

6GrO

1

followed by glass

infiltration

2itadur

4lpha

5rowns and

#%$s

2ident

Gircogon GrO

1

J presintered

and postsintered

Gircogon 5rowns 0lephant

4nd gingival aspects in an enlarged size to compensate for the 1*:

shrin.age that will occur during subse/uent sintering at (3,*

*

5. the processing

times for milling are appro!imately 3- for a crown and 3* min for a four > unit fi!ed

#%$. The milled are appro!imately 3- min for a crown and 3* min for a four- unit

fi!ed #%$. The milled prosthesis is removed from the and the remaining e!traneous

e!tension are removed. The zircon coping or framewor. is then placed in the 5ercon

furnace and fired at (3-*

*

5 for appro!imately , hours to fully sinter the yttria-

stabilized zirconia core coping or framewor.. The sintering shrin.age is achieved

uniformly and linearly in three > dimensional space by the in targeted process of

scanning, enlarging the pattern design, controlled milling and sintering.

4fter any subse/uent trimming with a water > cooled, hinge- speed diamond

bur the finished ceramic core framewor. is then veneered with a veneering ceramic

"5ercon 5eram S& and stain ceramic

4ll-ceramic prostheses represent the most aesthetically pleasing, but also the

most fracture-prone prostheses. owever, with ade/uate tooth reduction, an

e!cellent /uality impression, a s.illed technician, and a ceramic with reasonably high

fle!ure strength "1-* '%a& and fracture toughness " 1.-'pa.m

(61

&, reasonably high

success rates can be achieved. The material that has the greatest potential fracture

toughness ") '%a.m

K

& and fle!ural strength that has the greatest potential fracture

toughness ") '%a.m

K

& and fle!ural strength ";)** '%a& is pure tetragonal stabilized

zirconia "GrO

1

&. Tinschert et al "1**lb& reported that the fracture resistance of three-

unit ceramic #%$s "(173 E& made of 5ercon zirconia core ceramic "$entspy

5eramco& was more than twice as great as the values reported for In-5eram

4lumina "-(< E& and 0mpress1 ",1( E&. Shown in #igure is a comparison of the

force re/uired to fracture three-unit #%$s cemented to dies with zinc phosphate

cement. The zirconia product "5ercon& would be e!pected to e!hibit less fracture

resistance in this case, but clinical data are needed to confirm this hypotehsis.

To ensure ma!imum survival times, ade/uate occlusal tooth reduction is

essential for posterior teeth. Optimal clinical performance of some ceramic products

re/uire a minimal occlusal reduction of 1 mm for molar tooth preparations. If the

ceramic will be supported by a material with high elastic modulus such as a ceramic

or metal post or an amalgam build-up, less occlusal reduction "(.- mm& may be

possible without compromising the survivability of the crowns. #or patients e!hibiting

e!treme brusism, either metal or metal-ceramic prostheses should be used.

METHODS O3 STRENGTHENING CERAMICS:

Minimi8e t+e e..ect o. stress Raisers

Ahy do dental ceramic prostheses fail to e!hibit the strengths that we would

e!pect from the high bond forces between atomsL The answer is that numerous

minute scratches and other defects are present on the surfaces of these materials.

These surface flaws behave as sharp notches whose tips may be as narrow as the

spacing between several atoms in the material. These stress concentration areas at

the tip of each surface flaw can increase the localized stress to the theoretical

strength of the material even though a relatively low average stress e!ists throughout

the bul. of the structure. Ahen the induced mechanical stress e!ceeds the actual

strength of the material, the bonds at the notch tip brea., forming a crac.. This

stress concentration phenomenon e!plains how materials fail at stresses far below

their theoretical strength.

Stress raisers are discontinuities the ceramic and metal-ceramic structures

and in other brittle materials that cause a stress concentration in these areas. The

design of ceramic dental restorations should also avoid stress raisers in the ceramic.

4brupt changes in shape or thic.ness in the ceramic contour can act as stress

raisers and ma.e the restoration more prone to failure. Thus the incisal line angles

on an anterior tooth prepared for a ceramic crown should be well rounded.

In ceramic crowns, several conditions can cause stress concentration.

5reases or folds of the platinum foil or gold foil substrate that become embedded in

the porcelain leave notches that act as stress raisers. Sharp line angles in the

preparation also create areas of stress concentration in the restoration. +arge

changes in porcelain thic.ness, a factor also determined by the tooth preparation,

can create areas of stress concentration.

4 small particle of porcelain along the internal porcelain margin of a crown

also induces locally high tensile stresses. 4 stray particle that is fused within the

inner surface of a shoulder porcelain margin of a metal-ceramic crown can cause

localized tensile stress concentrations in porcelain when an occlusal force is applied

to the crown.

0ven though a metal-ceramic restoration is generally stronger than most

ceramic crowns of the same size and shape, care must be ta.en to avoid sub9ecting

the porcelain in a %#' to loading the produces large localized stresses. If the

occlusion is not ad9usted properly on a porcelain surface, contact points rather than

contact areas will greatly increase the localized stresses in the porcelain surface as

well as within the internal surface of the crown.

#racture mechanics is a science that allows scientists to analyze the influence

of flaw6stress interactions on the probability of crac. propagation through an elastic

brittle solid. The principles of linear elastic fracture mechanics were developed in the

()-*s by Irwin "()-7&. This pioneering research on fracture phenomena was based

on earlier investigations by Briffth "()1(& and Orowan "()<<, ()<), ()--&. Irwin

found that when a brittle material was sub9ected to tensile stresses, specific crac.

shapes in certain locations were associated with greatly increased stress levels. e

also recognized the importance of determining the fracture toughness of these

materials as a measure of their ability to resist fracture. The fracture toughness "F

I5

&

of a material represents the resistance of a material to rapid crac. propagation. In

contrast, the strength of a material depends primarily on the size of the initiating

crac. that is present. The strength of dental ceramics and other restorative materials

is controlled by the size of the crac.s or defects that are introduced during

processing, production and handling. In this chapter a description is given of the

processing methods used to produce ceramic prostheses and the potential of these

methods to introduce flaws or crac.s that may limit their clinical survival.

The brittle fracture behavior of ceramics and their low tensile strengths

compared with those predicted from bonds between atoms can be understood by

considering stress concentrations around surface flaws. 4s ceramics tends to have

no mechanism for plastically deforming without fracture as do metals, crac.s may

propagate through a ceramic material at low average stress levels. 4s a result,

ceramics and glasses have tensile strengths that are much lower than their

compressive strengths in the oral environment, tensile stresses are usually created

by bending forces, and the ma!imum tensile stress created by the bending forces

occurs at the surface of a prosthesis. It is for this reason that surface flaws are of

particular importance in determining the strength of ceramics.

4s the crac. propagates through the material, the stress concentration is

maintained at the crac., a pore, or a crystalline particle, which reduces the localized

stress. The removal of surface flaws or the reduction of their size and number can

produce a very large increase in strength. 8educing the depth of surface flaws in the

surface of a ceramic is one of the reasons that polishing and glazing of dental

porcelain is so important. The fracture resistance of ceramic prostheses can be

increased through one or more of the following si! options@ "(& select stronger and

tougher ceramicsJ "1& develop residual compressive stresses within the surface of

the material by thermal tempering, "3& develop residual compressive stress within

interfacial regions of wea.er, less tough ceramic layers by properly matching thermal

e!pansion coefficients, "<& reduce the tensile stress in the ceramic by appropriate

selection of stiffer supporting materials, "-& minimize the number of porcelain firing

cycles, ",& design the ceramic #%$ prosthesis with greater bul. and broader radii of

curvature to minimize the magnitude of tensile stresses and stress concentrations of

curvature to minimize the magnitude of tensile stresses and stress concentrations

during function, and "7& adhesively bond ceramic crowns to tooth structure.

De5elo Resi"ual Comressi5e Stresses:

One method of strengthening glasses and ceramics is the introduction of

residual compressive stresses within the veneering ceramic. 5onsider three layers

of porcelain@ the outer two of the same composition and thermal contraction co-

efficient and the middle layer of a different composition and a higher thermal

contraction coefficient. Suppose that the layers are bonded together and the bonded

structure is allowed to cool to room temperature. The inner layer has a higher

coefficient of thermal contraction and thus contracts more as it cools. ence, on

cooling to room temperature, the inner layer produces compressive stresses in the

outer layers as previously described for thermal tempering. This three-layer laminate

techni/ue is used by 5orning Blass wor.s to manufacture dinnerware.

4 similar condition can develop in a veneering porcelain bonding to an alloy

coping used for metal-ceramic crowns and #%$s and ad9acent ceramic layers in all-

ceramic prostheses. The metal and porcelain should be selected with a slight

mismatch in their thermal contraction coefficients "the metal thermal contraction

coefficients "the metal thermal contraction coefficient being slightly larger& so that the

metal contracts slightly more than the porcelain on cooling from the firing

temperature to room temperature. This mismatch leaves the porcelain in residual

compression and provides additional strength for the prosthesis. 0!amples of how

residual tensile stresses can wea.en a metal-ceramic crown or #%$ and how

residual compressive stresses can wea.en a metal-ceramic crown or #%$ and how

residual compressive stresses can increase fracture resistance are shown in #igure.

The same principle applies to ceramic prostheses in which the thermal

contraction coefficient of the core ceramic is slightly greater than that of the

veneering ceramic "such as opaceous dentin or body6gingival porcelain&.

The fabrication of metal-ceramic and all-ceramic prostheses usually involves

processing at high temperature, and the process of cooling to room temperature

affords the opportunity to ta.e advantage of mismatches in coefficients of thermal

contraction of ad9acent materials in the ceramic structure. Ideally, the porcelain

should sustain slight compression in the final restoration. This ob9ective is

accomplished by selecting an alloy that contracts slightly more than the porcelain on

cooling to room temperature.

4 further, yet fundamentally different, method of strengthening glasses and

ceramics is to reinforce them with a dispersed phase of a different material that is

capable of hindering a crac. from propagating through the material. There are two

different types of dispersions used to interrupt crac. propagation. One type relies on

the toughness of the particle to absorb energy from the crac. and deplete its driving

force for propagation. The other relies on a crystal structural change under stress to

absorb energy from the crac.. These methods of strengthening are described

below.

Minimi8e t+e Num!er o. .irin* c,cles:

The purpose of porcelain firing procedures is to densely sinter the particles of

powder together and to produce a relatively smooth, glassy layer "glaze& on the

surface. In some cases, a stain layer is applied for shade ad9ustment or for

characterization such as stain lines or fine crac.s. Several chemical reactions occur

over time at porcelain firing temperatures and of particular importance are increases

in the concentration of crystalline leucite in the porcelain designed for fabrication of

metal-ceramic restorations. +eucite, F1O-4l

1

O

3

<SiO

1

, is a highe-e!pansion crystal

phase, which can greatly affect the thermal contraction coefficient of the porcelain.

5hanges in the leucite content caused by multiple firings can alter the thermal

contraction coefficient of the porcelain. Some porcelains undergo an increase in

leucite crystals after multiple firings that will increase their thermal e!pansion

coefficients. If the e!pansion coefficient increases above the value for the metal, the

e!pansion mismatch between the porcelain and the metal can produce stresses

during cooling that are sufficient to cause immediate or delayed crac. formation in

the porcelain.

Minimi8e Tensile Stress T+rou*+ Otimal Desi*n o. Ceramic -rost+eses:

Tougher and stronger ceramics can sustain higher tensile stresses before

crac.s develops in areas of tensile stress. 5onventional feldspathic porcelains

should not be used as the core of ceramic crowns, especially in posterior areas,

because occlusal forces can easily sub9ect them to tensile stresses that e!ceed the

tensile strength of the core ceramic. Of ma9or concern are tensile stresses that are

concentrated within the inner surface of posterior ceramic crowns. Sharp line angles

in the preparation also will create areas of stress concentration in the restoration,

primarily where a tensile component of bending stress develops. 4 small particle of

ceramic along the internal porcelain margin of a crown will also induce locally high

tensile stresses. Thus the ceramic surface that will be cemented to the prepared

tooth or foundation material should be e!amined carefully when it is delivered from

the laboratory. #urthermore, when grinding of this surface is re/uired for ad9ustment

of fit, one should use the finest grit abrasive that will accomplish the tas..

?ecause the forces on anterior teeth are relatively small, the low to moderate

tensile stresses produced can be supported by ceramic crowns more safely.

owever, if there is a great amount of vertical overlap "overbite& with only a

moderate amount of horizontal overlap "over9et&, high tensile stresses can be

produced. 'etal-ceramic crowns use a metal coping as the foundation of the

restoration to which the porcelain is fused. The stiff, metal coping minimizes fle!ure

of the porcelain structure of the crown that is associated with tensile stresses.

'ost dental restorations containing ceramics should be designed in such a

way as to overcome their wea.nesses, that is their relatively low tensile strength,

their brittleness, and their susceptibility to flaws in the presence of surface flaws.

The design should avoid e!posure of the ceramic to high tensile stresses. It

should also avoid stress concentration at sharp angles or mar.ed changes in

thic.ness. One way to reduce tensile stresses on the cemented surface in the

occlusal region of ceramic inlays or crowns is to use the ma!imum occlusal

thic.ness possible. owever, within practical limits of tooth reduction, this

thic.ness is typically 1.* mm.

4luminous porcelain crowns are contraindicated for restoring posterior teeth

because occlusal forces can induce tensile stresses, which are often concentrated

near the internal surface of the crown. 'etal-ceramic crowns use a metal coping

as the foundation of the restoration to which the porcelain is fused. In an attempt

to overcome these stresses, the strong, stiff, yet ductile metal coping minimizes

fle!ure of the porcelain structure of the crown that is associated with tensile

stresses. ?oth the bonded platinum foil aluminous porcelain corwn techni/ue and

the swaged gold alloy foil techni/ue are also based on this same concept.

The tensile stresses in a ceramic #%$ can be reduced by using a greater

connector height and by broadening the radius of curvature of the gingival

embrasure portion of the interpro!imal connector. owever, a connector height

greater than < mm ma.es the anatomic form in the buccal area of a posterior #%$

too bul.y and unaesthetic.

Ion E9c+an*e:

The techni/ue of ion e!change is one of the more sophisticated and

effective methods of introducing residual compressive stresses into the surface of

a ceramic. The ion-e!change process is sometimes called chemical tempering

"4nusavice et al, ())1& and can involve the sodium ion since sodium is a common

constituent of a variety of glasses and has a relatively small ionic diameter. If a

sodium-containing glass article is placed in a bath of molten potassium nitrate,

potassium ions in the bath e!change places with some of the sodium ions in the

surface of the glass article and remain in place after cooling. Since the potassium

ion is about 3-: larger than the sodium ion, the s/ueezing of the potasium ion

into the place formerly occupied by the sodium ion creates very large residual

compressive stresses.

The product B5 Tuf-5oat "B5 5orp., To.yo, Iapan& was a potassium-rich

slurry that could be easily applied to a ceramic surface and, when heated to <-*

*

5 for 3* min "in any standard porcelain furnace& caused a sufficient. Increases of

(**: or more in fle!ural strength have been achieved with several porcelain

products that contained a significant concentration of small sodium ions. owever,

the depth of the compression zone is less than (** m "anusavic et al. ())<&.

Therefore this strengthening effect could be lost if the porcelain or glass - ceramic

surface is ground, worn, or eroded by long - term e!posure to certain inorganic

acids.

T+ermal Temerin*:

%erhaps the most common method for strengthening glass is by thermal

tempering thermal tempering creates residual surface compressive stresses. ?y

rapidly cooling " /uenching& the surface of the ob9ect while it is hot and in the

softened "molten& state. This rapid cooling produces a s.in of rigid glass

surrounding a soft "molten& core 4s the molten core solidifies, it tends to shrin.,

but the outer s.in remains rigid. The pull of the solidifying molten core, as it

shrin.s, creates residual tensile stresses in the core and residual compressive

stresses within the outer surface.

Thermal tempering is used to strengthen glass for uses such as automobile

windows and windshields, sliding glass doors, and diving mas.s. Often, 9ets of air

directed at the molten glass surface accomplish the rapid cooling of the outer s.in.

If one observes the rear window of an automobile through polarized sunglasses, it

is usually possible to discern a regular pattern of spots over the entire window.

This pattern of spots corresponds to the arrangement of the air 9ets employed by

the manufacturer in the tempering process. #or dental applications, it is more

effective to /uench hot glass phase ceramics in silicone oil or other special li/uids

rather than using air 9est that may not uniformly cool the surface. This thermal

tempering treatment induces a protective region of compressive stress within the

surface " $eoff and anusavic,())1&

Disersion Stren*t+enin*

4 further, yet fundamentally different, method of strengthening glasses and

ceramics is to reinforce them with a dispersed phase of a different material that is

capable of hindering a crac. from propagating through the material. This process

is referred to as dispersion strengthening. 4lmost all of the newer higher- strength

ceramics derive there improved fracture resistance from the crac.- bloc.ing ability

of the crystalline particles. Increasing the crystal containing primarily can

strengthen dental ceramics containing primarily a glass phase can be

strengthened by increasing the crystal content of leucite "F

1

O.4l

1

O

3

.<SiO

1

& lithia

dislocate "+i

1

O.1SiO

1

&, alumina " 4l

1

O

3

& magnesia - alumina spinel "'gO. 4l

1

O

3

&,

zirconia "GrO

1

&, and other types of crystals. Some crystal phase additions are not

as effective as others in toughening the ceramics. Toughening depends on the

crystal type, its size, its volume fraction, the interpartics. Toughening, and its

relative thermal e!pansion coefficient relative to the glass matri!. #or e!ample, the

fracture toughness "F

I5

& of soda lime silica glass is *.7- 'pa . m

(61

If one

disperses 7* vol: of terasilicic flourmill crystals in the glass."$icor 'B5 glass -

ceramic&, the toughness increases only to (.- 'pa. m

(61

. owever, by dispersing

7* vol: if lithia dislocate crystals in the glass matri! " I%S 0mpress1&, F

I5

increased to 3.3 'pa. '

(61

" oland and ?eall, 1**1&.

Ahen a tough, crystalline material such as alumina " 4l

1

O

3

& is added to a

glass the is toughened and strengthened because the crac. cannot pass through

the alumina Mparticles as easily as it can pass through the glass matri!. This

techni/ue has found application in dentistry in the development of alimonies

porcelains " 4l

1

O

3

particles in a glassy porcelain matri!& for porcelain 9ac.et

crowns. 'ost dental ceramics that heave a glassy matri! utilize reinforcement of

the glass by a disposed crystalline substance.

Tinschert et al "1**lb& evaluated the mean strength and standard deviation

values for several ceramics. This mean strength values were as followsJ "'pa N

S$& were 5erec 'ar. II, 3,.3N(1.1J In 5eram 4lumina, <1).3 N 37.1J I%S

0mpress. 33.) N ((.3J 2itadur 4lpha 5ore, (3(.* N ).-J 2itadur 4lpha $entin, ,*.7

N ,.3J 2ita 2'F ,3, 31.7N (*.*@ and Girconia-TG%, )(3.* N -*.1. There was no

statistically significant difference among the fle!ure strength of 5erec 'ar. II,

$icro, I%S 0mpress, 2itadur 4lpha $entin, and 2ita 2'F ,3 ceramics "%;*.*-&.

The highest Aeibull moduli were associated with 5erec 'ar. II and Girconia-TG%

ceramics "13., and (3.<&. $icor glass-ceramic and In-5eram 4lumina had the

lowest values of Aeibull modules "m& "-.- and -.7&, whereas intermediate values

were observed for I%S 0mpress, 2ita 2'F ,3, 2itadur 4lpha $entin, and 2itadur

4lpha 5ore ceramics "3.,, 3.), (*.* and (3.* respectively&.

0!cept for In-5eram 4lumina, 2itadur 4lpha, and Girconia-TG% core

ceramics, the investigated ceramic materials fabricated under the condition of a

dental laboratory were not stronger or more structurally reliable than 2ita 2'F ,3

veneering porcelain. Only 5erec 'ar. II and Girconia-TG% specimens, which were

prepared from an industrially optimized ceramic material, e!hibited m values

greater than (3. ence, we conclude that industrially prepared ceramics are more

structurally reliable materials for dental applications, although 54$-54'

procedures may induce surface and subsurface flaws that may offset this benefit.

Trans.ormation Tou*+enin*:

Ahen small, tough crystals are homogeneously distributed in a glass, the

ceramic structure is toughened and strengthened because crac.s cannot

penetrate the fine particles as easily as they can penetrate the glass. $ental

ceramics are strengthened and toughened by a variety of dispersed crystalline

phases including alumina "2itadur 4lpha, %rocera 4ll5eram, In-5eram alumina&,

leucite "Optec S%, I%S 0mpress, O%5&, tetrasilicic fluormica "$icor, $icor 'B5&,

lithia disilicate "O%5 3B, I%S 0mpress1&, and magnesia-alumina spinel "In-5eram

spinell&. In contrast, dental ceramics based primarily on zirconia crystals "5ercon

and +ava& undergo transformation toughening that involves a transformation of

GrO

1

from a tetragonal crystal phase to a monoclinic phase at the tips of crac.s

that are in regions of tensile stress. The unit cells for tetragonal and monoclinic

lattices are shown.

Ahen pure GrO

1

is heated to a temperature between (<7*

*

and 1*(*

*

5

and it is cooled, its crystal structure begins to change from a tetragonal to a

monoclinic phase at appro!imately ((-*

*

5. $uring cooling to room temperature,

a volume increase of several percentage points occurs when it transforms from

the tetragonal to monoclinic crystal structure. This polymorphic transformation can

be prevented with certain additives such as 3 mol: yttrium o!ide "yttria or O

1

O

3

&.

This material is designated as GrO

1

. TG% "tetragonal zirconia polycrystals&. The

volume increase in this case is constrained if the zirconia crystals are sufficiently

small and the microstructure is strong enough to resist the resulting stresses. This

material is e!tremely strong "fle!ural strength of appro!imately )** '%a& and

tough "fracture tougheness, FI5, of appro!imately ) '%a& and tough "fracture

tougheness, FI5, of appro!imately ) 'pam

(61

&.

The toughening mechanism of crac. shielding results from the controlled

transformation of the metastable tetragonal phase to the stable monoclinic phase.

Several types of crac. shielding processes are possible, including microcrac.ing,

ductile zone formation, and transformation zone formation. ?y controlling the

composition, particle size, and the temperature versus time cycle, zirconia can be

densified by sintering at a high temperature and the tetragonal structure can be

maintained as individual grains or precipitates as it is cooled to room temperature.

The tetragonal phase is not stable at room temperature, and it can transform to

the monoclinic phase with a corresponding volume increase under certain

conditions. Ahen sufficient stress develops in the tetragonal structure and a crac.

in the area begins to propagate, the metastable tetragonal crystals "grains& or

precipitates ne!t to the crac. tip can transform to the stable monoclinic form. In

this process a 3 vol: e!pansion of the GrO

1

crystals or precipitates occurs that

place the crac. under a state of compressive stress and crac. progression is

arrested. #or this crac. to advance further, additional tensile stress would be

re/uired. ?ecause of this strengthening and toughening mechanism, the yttria-

stablilized zirconia ceramic is sometimes referred to as ceramic steel.

A!rasi5eness o. Dental Ceramics:

4 review of the factors and material characteristics that cause e!cessive

wear of enamel by ceramic prostheses is e!tremely important to optimize the

performance of ceramic-based prostheses. 5eramics are generally considered

the most biocompatible, durable, and aesthetic materials available for

rehabilitation of teeth, occlusal function, and facial appearance. 5urrently

available products e!hibit variable mechanical properties "hardeness, fle!ure

strength, fracture toughness, and elastic modulus&, physical properties "inde! of

refraction, color parameters, translucency, chemical durability, and thermally

compatible e!pansion coefficients for the substrates. In spite of their overall

e!cellence in meeting the ideal re/uirements of a prosthetic material, dental

ceramics have one ma9or drawbac.. These materials can cause catastrophic

wear of opposing tooth structure under certain conditions. The most e!treme

damage occurs when a roughened surface contacts tooth enamel or dentin under

high occlusal forces, which may occur because of bru!ing, premaguided

disclusion is ensured, the wear of opposing enamel and dentin will be greatly

reduced. In addition, if the occluding ceramic surface area is periodically

refinished after occlusal ad9ustment or fre/uent e!posure to carbonated beverages

and6or acidulated phosphate fluoride, the abrasive wear of opposing tooth

structure is further reduced.

4brasive wear mechanisms for dental restorative materials and tooth

enamel include "(& adhesion "metal and composites&, in which localized bonding of

two surfaces occurs, resulting in pullout and transfer of matter from one surface to

the other, and "1& microfracture "ceramics and enamel&, which results from

gouging, asperties, impact, and contact stresses that cause crac.s or localized

fracture. #or ceramic and enamel, two-phase brittle strucutres are involved. The

ceramic onsists of a glass matri! that contains variable levels and sizes of

crystals. Tooth enamel consists of a small volume fraction of organic phase matri!

and a high volume fraction of hydro!yapatite crystals. The wear of either material

depends on the ease with which crac.s can propagate through the structure. If

microscopic crac.s are forced to pass around the crystal particles rather than

through them, the material will usually be more fracture and crac.s through the

glass phase, the particles are less fracture resistant than the glass matri!, or

e!cessive voids or other defects e!ist along the pathway. The relative

strengthening effect is dependent on several factors, including the strength of the

glass and crystal phases, the size and spacing of crystalline paricles, the

inferfacial bond strength of the crystal-glass interphase region, and the type and

magnitude of residual stresses in the structure. These factors are beyond the

control of the dentist, although the dentist and laboratory technician can select

ceramics that are highly fracture-resistant.

The microfracture mechanism is the dominant mechanism responsible for

surface brea.down of ceramics and the subse/uent damage that a roughened

ceramic surface can cause to tooth enamel surfaces. eEamel is also susceptible

to this .ind of microfracture through four specific mechanisms@ "(& asperities

e!tending from the ceramic surface that produce high localized stresses and

microfractureJ "1& gouging that results from high stresses and large hardness

differences between two surfaces or particles e!tending from these surfacesJ "3&

impact or erosion that occurs through the action of abrasive particles carried in a

following li/uid such as salivaJ and "<& contact stress microfracture that increases

localized tensile stress and also enhances the damage caused by asperties,

gouging, and impact or erosion. ?ecause of microfracture mechanisms, it may be

necessary to polish the ceramic surface periodically to reduce the height of

asperities and to minimize enamel wear rates. Of ma9or concern is the potential

catastrophic damage that can be incurred by enamel in contact with polycrystalline

asperities having high fracture toughness "F

I5

& values such as alumina "3.--<.*

'pa.m

(61

& or cerium-stabilized zirconia "(*-(, 'pam

(61

&, yttrium-stabilized zirconia

",-)- 'pa.m

(61

&, or cerium--stabilized zirconia "(*-, 'pa.m

(61

&. In contrast glass

has a fracture toughness of only *.7- 'pa.m

(61

and should cause less gouging,

contact stress, and impact damage within contacting enamel surfaces.

The abrasiveness of ceramics against enamel is affected by numerous

factors and properties of the crystal phase particle and the glass matri! "if

present&. These include hardness, tensile strength, fracture toughness, fatigue

resistance, particle glass bonding, particle-glass interface integrity, chemical

durability, e!posure fre/uency to corrosive chemical agents "acidulated phosphate

fluoride, carbonated beverages&, abrasiveness of foods, residual stress,

subsurface /uality "voids or other imperfections&, magnitude and orientation of

applied forces, chewing and bru!ing fre/uency, contacting area, lubrication by

saliva, and wear fre/uency. Thus it is understandable why the hardness of the

ceramic is not a good predictor of the potential wear of enamel surfaces by a

ceramic. owever, the larger the hardness difference between two sliding

surfaces, the greater is the degree of gouging.

:ear o. ceramics Comare" &it+ ot+er Materials

To minimize enamel abrasion by a contacting ceramic structure, we should

use a ceramic that e!hibits uniform surface microfracture at the same rate as tooth

enamel under the same conditions of loading, antagonist structure, food

substance abrasiveness, applied forces, and degree of lubrication. The

brea.down of the ceramic surface should be uniform so that asperities such as

large crystalline inclusions do not pro9ect out from the surface.

These asperities produce high stress concentration areas within the

opposing enamel surface that lead to gouging, troughing, and greater localized

microfracture of the enamel structure. If such nonumiform surface wear of

ceramics occurs duraing oral function, the only solutions available to reduce

enamel wear are to reduce the occlusal load by occlusal ad9ustement or to polish

the ceramic surface periodically to reduce stress concentrations and the height of

these asperities.

Some of the new ultralow-fusing ceramics have a wide range of thermal

e!pansion coefficients as listed. These are appro!imate values estimated for

several low-fusing ceramic products produced by the $ucera company@

$uceragold "73*

*

5& and $uceram +#5 "$entsply 5eramco& were introduced

between ())( and ())1. $uceram +#5 is classified as a hydrothermal ceramic

that was claimed to develop a hydrothermal layer appro!imately (m thic. vitro.

In theory, this property allows a protective layer to seal microscopic surface

crac.s. Its veneer is a low-fusing ceramic that minimizes shrin.age of the core

ceramic during subse/uent firings. $uceram +#5 and $uceragold do not contain

large leucite crystals and therby retain a stable thermal e!pansion coefficient over

several firings. The opalescence the fluorescence are also easier to achieve than

for conventional low-fusing fieldspathic porcelains because of the ability to

maintain very small crystal particles "<**--**nm&. ?ecause of its high e!pansion

coefficient, $uceragold is intended as a veneer for high-e!pansion, low-fusing

porcelains, were subse/uently developed as veneering ceramics for titanium

metals and %rocera 4ll5eram "Eobel ?iocare, Boteborg, Sewden& core ceramics,

respectively. Ti5eram is another ultralow-fusing ceramic and has a firing

temperature of appro!imately 7<*

*

5. The initial veneering porcelain for %rocera

4ll5eram was 2itadur E "2ita Gahnfabri., ?ad Sac.ingen, Bermany&, a large-

particle aluminous porcelain. 5urrently, 4ll5eram porcelain "$egussa $ental& is

used. #inesse, an ultralow-fusing ceramic "P7,*

*

5& that contains larger leucite

crystals, was introduced by $entsply 5eramco, Inc. "0. Aindsor, EI&. 2ita

Omega )** "2ita Gahnfabri.& is another ultralow-fusing ceramic. #or 54$-54'

processing, dicor 'B5 glass-ceramic "5aul.6$entsply, 'ilford, $0&, 2ita 'F I

ceramic "2ita Gahnfabri.&, and 2ita 'F II ceramic "2ita Gahnfabri.& bloc.s are

available, which also offer a small-particle distribution of crystals that may reduce

wear of opposing enamel surfaces.

It is not .nown what effect, if any, thermal mismatch differences will produce

on the surface /uality of these ceramics. 'icrocrac.ing can lead to surface flaws,

loss of surface material, and increased wear of enamel. owever, this effect

should only occur when a gross mismatch occurs between a core ceramic and its

veneering ceramic.

?ased on a study of abrasion by a -**-g slurry of glass "$erand and

2ereby, ()))&, (**g alumina "(** m&, and (1*g water, the mean wear depths "in

microns& after a specified time period for several ceramics and tooth enamel were

as follows@ enamel "1<.3&, #inesse "1*.3&, 2itadur 4lpha "(,.3&, %rocera "(-.3&,

$entsply 5eramco II "(3.,&, 2ita Omega "(3.(&, Ti-5eram "(1.(&, I%S 0mpress

"((.3&, $uceragold "((.-&, and 5reation "(*.3&. The enamel wear was significantly

greater than that of all ceramics tested. The wear depth of 2itadur 4lpha was

significantly than that of all ceramics tested. The wear depth of 2itadur 4plha was

significantly greater than that for I%S 0mpress, $uceragodl, and 5reation

ceramics. It is clear that the relative wear rate of enamel by a highly abrasive

medium is greater than that of most porcelains.

:ear o. Enamel !, Ceramic -ro"ucts an" ot+er restorati5e materials

4nother factor that can increase wear of ceramics against enamel is the

non-uniform distribution or clustering of crystals. I%S 0mpress after hot-pressing

at (3*

*

5 e!hibits clusters of relatively large "--(* m& leucite crystals "F4ISi

1

O

,

&

with crac.s between the crystal agglomerates. This non-interloc.ing arrangement

of elucite crystals also occurs in the veneering ceramic after it is sintered at )(*

*

5.