Académique Documents

Professionnel Documents

Culture Documents

1.65 DST Packer Test Tool

Transféré par

Kim MissonTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

1.65 DST Packer Test Tool

Transféré par

Kim MissonDroits d'auteur :

Formats disponibles

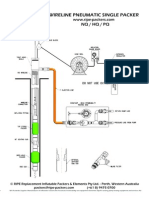

NO42LP16SE0.

5

Perm bility Packer Test Procedure

2.752 51.918

W EI G H T ( 113 ) VOLUME ( G al)

F 1 9 . 1 5 1

O D ( i n c h )

TEST ZO NE

E

27-1 /k 16ft0

I D ( i n c h )

NO 2.3 74

GEO -Packers TM

D ST PACKER TEST TO O L

G E O - P A C K E R 165"

NO D ST SINGLE PACKER TESTING TO O L

NF LATIO N I WIRELINE

SEALING TIGHT HEAD

1 .

I NJECT I ON H OSE 2

RIG WIRELINE

SU RF ACE

CO ND U CTO R

r.

omplete deflate the packer.

r is fully deflated before movin

e.

1 3. U ndo comp si in tight head andremove rubbe

seals and stee shers.

1 4. Reinstall the co pression cap andremove the packs

1 5 . Remove the seal ng tight head andthen lower the

inner tube assembl into position.

1 6. Connect the dr' I rods, lowering the drill string t

the hole botto and restart drilling.

7. O HS procedu es must be followed.

1 8flation an use of packers and packer equip

a h op rators own risk.

SMALL BORE 3-

NYLO N INF LATIO N LIM O .

5 .

r .

Pull th inneYTe assembly from the core barrel,

leaving the drill string in place.

Elevate the drill strin9 off the drill hole bottom and

I expose th per meaBli ty zone.

Secure/ st bilise the drill)ktring in place.

Install the sealing tight head.

Lower the packer through the sealing tight head

and driiPtring, positioning into the core barrel.

Install steel washers andrubber s l o p in the tight

ead and tighten the compression cap.

7. Co ect the nylon inflation tube to the g s/air supply.

8. Slow inflate the permeability packer in i rements

of until e desired pressure is met.

0 DRI LL RODS

i n jec t wa r through the tight head asse

I

ak, packer into he test zone.

1 0. ermeability est is run in under instruction b

oject engin

1

1" L.,

O nce testing is

1 2. M ake suds pack

from the drill ho

WIREL O RING D IAM O ND BI

D IAM O ND CO RED

EN HO LE

Bi t set O D

2.97-

Bi . ti et I D CORED H O SI Z E

1. 8" 2.98"

NO DRI LL ROD SPECCAT I ONS

Max W or ki n g pr essur e vs h ole di ameter

Bor eh oles di ameter ( i n ) 1.8 - 2- 2.2- 2.4- 2.6- 2.8 - 3 " 3 .2 - 3 .4" 3 .5- 3 .7-

Per c en tage i n flati on di ameter 9 21.2 3 3 .3 45.5 57.6 69.7 81.8 93 .9 106 112.1 124.2

I n flati on pr essur e ( PSI ) 2100 1800 1500 1200 1150 1100 1000 650 580 500 43 5

Non c on fi n ed Fr ee ai r I n flati on

Di ameter ( i n ) 1.8" 2" 2.2" 2.4" 2.6" 2.8" 3 " 3 .2" 3 .4" 3 .5" 3 .T

I n flati on pr essur e ( PSI ) 22 3 0 3 6 48 61 73 87 96 123 13 8 160

Replacement Inflatable Packers and Elements Pty Ltd

29 Wheeler St Belmont 61 04, Perth Western Australia

Tel: (+61 (08) 9 475 0700F ax: +61 (08) 9 475 0770packers@ripe-packers. com www. ripe-packers. com

W A Austr ali a Suppli er Man ufac tur er of i n flatable Pac ker s for DST W ell Pac ker T esti n g Per meabi li ty si n gle/ double pac ker testi n g equi pmen t andSer vi c es AU.

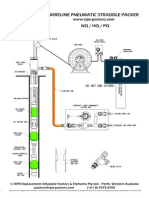

Perm bility Packer Test Procedure

51.918 1 9 . 1 5 1

GEO-Packers T M

DST PACKER T EST T OOL

GEO-PACKER 0 165"

NO DST DOUBLE PACKER T EST ING T OOL

INFLATION / WIRELINE

SEALING TIGHT HEAD

NO42LP1 6SE0. 5

RIG WIRELINE

WATER

.SECTION HOS

1. Pull th inneYTe assembly fromthe core barrel,

leaving the drill string in place.

MALL BORE

2. Elevate the drill strin9 off the drill hole bottomand

NYLON INFLAT LINE

expose th permeaBlity zone.

3. Secure/ st bilise the drill )1,tring in place.

Install the sealing tight head.

Lower the packer through the sealing tight head

and drllPtring, positioning into the core barrel.

0 DRILL ROES

Install steel washers and rubber s l o p in the tight

ead and tighten the compression cap.

fi kk 7. Co ect the nylon inflation tube to the g s/air supply.

8. Slow inflate the permeability packer in i rements

O C

of until e desired pressure is met.

. Inject wa r through the tight head asse

packer into he test zone.

lo. ermeability est is run in under instruction b

----ROD STEM PACKER

)

oject engin er.

1

1Once

testing is omplete deflate the packer.

12. Make suds pack r is fully deflated before movin

fromthe drill ho e.

13. Undo comp si in tight head and remove rubbe

seals and stee shers.

14. Reinstall the co pression cap and remove the pack r.

15. Remove the seal ng tight head and then lower the

inner tube assembl into position.

16. Connect the dr' I rods, lowering the drill string t

the hole botto and restart drilling.

7. OHS procedu es must be followed.

flation an use of packers and packer equip

rators own risk.

0 WIRELINE CORING DIAMOND BIT SPEC

Bit set ID

1.884,1_

CORED HOLE SIZE

2.98 -

NO DRILL ROD SPE CATIONS

WEIGHT ) VOL r E (Gal)

Max Working pressure vs hole diameter

Boreholes diameter (in) 1.8 - 2 2.T 2.4- 2.6- 2.8 - 3- 3.2- 3.4" 3.5 - 3.7-

Percentage inflation diameter 9 21.2 33.3 45.5 57.6 69.7 81.8 93.9 106 112.1 124.2

Inflation pressure (PSI) 2100 1800 1500 1200 1150 1100 1000 650 580 500 435

Non confined Free air Inflation

Diameter (in) 1.8" 2" 2.2" 2.4" 2.6" 2.8" 3" 3.2" 3.4" 3.5" 3.T

Inflation pressure (PSI) 22 30 36 48 61 73 87 96 123 138 160

Replacement Inflatable Packers and Elements Pty Ltd

29 Wheeler St Belmont 61 04, Perth Western Australi a

T el: (+61 (08)9 475 0700 Fax: +61 (08)9 475 0770 packers@ri pe-packers. comwww. ri pe-packers. com

WA Australia Supplier Manufacturer of Inflatable Packers for DSTWell Packer Testing Permeability single/ double packer testing equipment and Servi ces AU.

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- OrificeDocument13 pagesOrificexjaf01Pas encore d'évaluation

- Antique Vaseline Glass - Collectors WeeklyDocument9 pagesAntique Vaseline Glass - Collectors WeeklyRobertJimenezPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- SNAMPROGETTI UREA PROCESS STEPSDocument23 pagesSNAMPROGETTI UREA PROCESS STEPSTu Hai50% (2)

- Introduction to Flow Assurance and OLGA SoftwareDocument10 pagesIntroduction to Flow Assurance and OLGA SoftwareG Vengat VinayagamPas encore d'évaluation

- State of The Art CCS Technologies 2022Document81 pagesState of The Art CCS Technologies 2022reda100% (1)

- VOC PlanDocument132 pagesVOC PlanBoris PetrovicPas encore d'évaluation

- Wireline Hydraulic Straddle PackerDocument1 pageWireline Hydraulic Straddle PackerKim MissonPas encore d'évaluation

- Wireline Pneumatic Single PackerDocument1 pageWireline Pneumatic Single PackerKim MissonPas encore d'évaluation

- Wireline Hydraulic Single PackerDocument1 pageWireline Hydraulic Single PackerKim MissonPas encore d'évaluation

- Wireline Pneumatic Straddle PackerDocument1 pageWireline Pneumatic Straddle PackerKim MissonPas encore d'évaluation

- Replacements and RebuildsDocument1 pageReplacements and RebuildsKim MissonPas encore d'évaluation

- RIPE K-Packers: Water Bore Monitoring Well Completion ApplicationsDocument1 pageRIPE K-Packers: Water Bore Monitoring Well Completion ApplicationsKim MissonPas encore d'évaluation

- Mini Hydrualic Frac PackersDocument1 pageMini Hydrualic Frac PackersKim MissonPas encore d'évaluation

- Permeability TestingDocument1 pagePermeability TestingKim MissonPas encore d'évaluation

- Hydraulic Fracturing Inflatable PackersDocument1 pageHydraulic Fracturing Inflatable PackersKim MissonPas encore d'évaluation

- Ripe K Packers and Telescopic SealsDocument1 pageRipe K Packers and Telescopic SealsKim MissonPas encore d'évaluation

- Kpackers MetricDocument1 pageKpackers MetricKim MissonPas encore d'évaluation

- K PackersDocument1 pageK PackersKim MissonPas encore d'évaluation

- Grab Packer MetricDocument1 pageGrab Packer MetricKim MissonPas encore d'évaluation

- 73 DST Packer Test ToolDocument2 pages73 DST Packer Test ToolKim MissonPas encore d'évaluation

- Drill Able Bridge PlugsDocument1 pageDrill Able Bridge PlugsKim MissonPas encore d'évaluation

- 83 Standard Wireline Packer System ReplacementsDocument1 page83 Standard Wireline Packer System ReplacementsKim MissonPas encore d'évaluation

- 30 Bridge Plug Metric Fixed EndDocument1 page30 Bridge Plug Metric Fixed EndKim MissonPas encore d'évaluation

- Grab Packer ImperialDocument1 pageGrab Packer ImperialKim MissonPas encore d'évaluation

- 54 DST Packer Test ToolDocument2 pages54 DST Packer Test ToolKim MissonPas encore d'évaluation

- 60 Standard Wireline Packer System ReplacementsDocument1 page60 Standard Wireline Packer System ReplacementsKim MissonPas encore d'évaluation

- 72 DST Packer Test ToolDocument2 pages72 DST Packer Test ToolKim MissonPas encore d'évaluation

- 30 Bridge Plug Metric Sliding EndDocument1 page30 Bridge Plug Metric Sliding EndKim MissonPas encore d'évaluation

- 30 Bridge Plug Imperial Sliding EndDocument1 page30 Bridge Plug Imperial Sliding EndKim MissonPas encore d'évaluation

- 56 DST Packer Test ToolDocument2 pages56 DST Packer Test ToolKim MissonPas encore d'évaluation

- 43 DST Packer Test ToolDocument2 pages43 DST Packer Test ToolKim MissonPas encore d'évaluation

- 42 DST Packer Test ToolDocument2 pages42 DST Packer Test ToolKim MissonPas encore d'évaluation

- 42 Standard Wireline Packer System ReplacementsDocument1 page42 Standard Wireline Packer System ReplacementsKim MissonPas encore d'évaluation

- 30 Bridge Plug Imperial Fixed EndDocument1 page30 Bridge Plug Imperial Fixed EndKim MissonPas encore d'évaluation

- 26 Bridge Plug Imperial Sliding EndDocument1 page26 Bridge Plug Imperial Sliding EndKim MissonPas encore d'évaluation

- 26 Bridge Plug Metric Sliding EndDocument1 page26 Bridge Plug Metric Sliding EndKim MissonPas encore d'évaluation

- Executive SummaryDocument36 pagesExecutive SummaryUdomsin WutigulpakdeePas encore d'évaluation

- Compression and Expansion of GasesDocument5 pagesCompression and Expansion of GasesmishraenggPas encore d'évaluation

- A12.P50 (4) Code of Practice For The Storage of Liquefied Petroleum Gas at Fixed InstallationsDocument52 pagesA12.P50 (4) Code of Practice For The Storage of Liquefied Petroleum Gas at Fixed InstallationsminhyPas encore d'évaluation

- Spitzglass EquationDocument8 pagesSpitzglass EquationCHANADASPas encore d'évaluation

- تصميم لتجميع مياة الامطارDocument4 pagesتصميم لتجميع مياة الامطارfawazbakerPas encore d'évaluation

- Fluid MechDocument10 pagesFluid MechPetForest Ni JohannPas encore d'évaluation

- Somasila ProjectDocument2 pagesSomasila ProjectDarsi SuhasPas encore d'évaluation

- Earth SpheresDocument18 pagesEarth Spheresdani_0227Pas encore d'évaluation

- Water Cycle Lesson 3Document5 pagesWater Cycle Lesson 3api-247794398Pas encore d'évaluation

- Pump installation diagrams and total dynamic head explainedDocument3 pagesPump installation diagrams and total dynamic head explainedMichaelPas encore d'évaluation

- 004 PumpsDocument8 pages004 PumpsHamdanPas encore d'évaluation

- Calculate Catchment Area of Gandao DamDocument9 pagesCalculate Catchment Area of Gandao DamOmer MehsudPas encore d'évaluation

- GE-310-312 FDA Plastic Flow SwitchesDocument2 pagesGE-310-312 FDA Plastic Flow Switchessales1068Pas encore d'évaluation

- Production LoggingDocument82 pagesProduction LoggingAnkit SharmaPas encore d'évaluation

- LED and induction street lights cut energy bills 87Document11 pagesLED and induction street lights cut energy bills 87Zain NadeemPas encore d'évaluation

- Portable Water Filtration System: Importance of The StudyDocument7 pagesPortable Water Filtration System: Importance of The StudyJohn Michael Z. CatayloPas encore d'évaluation

- Main Components of Francis Turbine: 1. Spiral CasingDocument3 pagesMain Components of Francis Turbine: 1. Spiral CasingaliriazPas encore d'évaluation

- Nor R3Document29 pagesNor R3grsPas encore d'évaluation

- Vapour Compression Refrigeration System Manual FinalDocument3 pagesVapour Compression Refrigeration System Manual FinalRaiwat KanasakarPas encore d'évaluation

- Wastewater Recycling 2018-A4Document2 pagesWastewater Recycling 2018-A4SohailPas encore d'évaluation

- Wastewater EngineeringDocument2 pagesWastewater Engineeringharry_chemPas encore d'évaluation

- Gaseous State (Ideal Gases) Exercise With Sol.Document25 pagesGaseous State (Ideal Gases) Exercise With Sol.mikcPas encore d'évaluation

- Learn About Oil and Gas SeparatorsDocument2 pagesLearn About Oil and Gas SeparatorsOlivier Whettem0% (1)

- RAC AssignmentDocument7 pagesRAC AssignmentSoumikSabyasachi50% (2)