Académique Documents

Professionnel Documents

Culture Documents

Electrical Manhole and Handhole Design Guide

Transféré par

lilama45-1100%(1)100% ont trouvé ce document utile (1 vote)

2K vues8 pagesThe minimum inside dimensions for a manhole is 12' x 6' wide, and 6'6" high. The sump pit is to be 18 inches as shown on Manhole Detail Drawing. All concrete used in the construction of the manholes shall contain steel reinforcing bars.

Description originale:

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentThe minimum inside dimensions for a manhole is 12' x 6' wide, and 6'6" high. The sump pit is to be 18 inches as shown on Manhole Detail Drawing. All concrete used in the construction of the manholes shall contain steel reinforcing bars.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

100%(1)100% ont trouvé ce document utile (1 vote)

2K vues8 pagesElectrical Manhole and Handhole Design Guide

Transféré par

lilama45-1The minimum inside dimensions for a manhole is 12' x 6' wide, and 6'6" high. The sump pit is to be 18 inches as shown on Manhole Detail Drawing. All concrete used in the construction of the manholes shall contain steel reinforcing bars.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 8

ELECTRICAL MANHOLE AND HANDHOLE

1. Materials for Manhole

1.1. Cast-in-Place or Pre-Cast concrete may be used.

1.2. The minimum 28 day concrete compressive strength for concrete shall be

4,000psi.

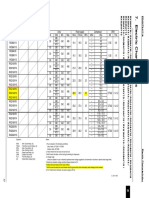

1.3. The minimum inside dimensions for a manhole is 12 x 6 wide, and 66 high.

1.4. Only ready mixed concrete shall be used. Ready mixed concrete shall be mixed

and transported to the job site in accordance with ASTM C94 Specifications for

Ready Mixed Concrete.

1.5. Manholes shall be designed in compliance with ASTM C857-87, Standard

Practice for Minimum Structural Design Loading for Underground Pre-cast

Concrete Utility Structures. Wheel loading shall be HS-20.

1.6. Manholes shall be manufactured in accordance with ASTM C858-83, Standard

Specifications for Underground Pre-cast Concrete Utility Structures.

1.7. Shall be designed per ACI 318-02 Building code Requirements for Structural

Concrete.

1.8. Design loads shall consist of dead load, live load, impact, surcharge load, and any

other loads which may be imposed upon the structure

1.9. Sump

1.9.1. The sump shall have a concrete bottom and shall be 18 inches as shown on

Manhole Detail Drawing.

1.9.2. The manhole floor is to be sloped to the sump pit.

1.9.3. Sump pit is to be located in the middle of the floor below the entry hole.

1.9.4. There is to be no grating over the sump pit.

1.10. Reinforcement

1.10.1. All concrete used in the construction of the manholes shall contain steel

reinforcing bars to conform to all applicable building codes. All reinforcing steel

shall conform to ASTM 432 and ASTM A305 Specifications.

1.11. Accessories

1.11.1. Cable pulling-in irons Provides a strong and easy-to-get-at attachment for the

pulling-in blocks when installing or removing cables. Pulling-in irons are set into

the brick or concrete walls of street vaults opposite all duct entrances. Hot dip

galvanized. Shall be Cooper Power Systems Catalog No. DU1T1; Joslyn

Manufacturing and Supply Company Catalog No. J8120; Hubbell/Chance

Catalog No. 8120; or approved equal.

1.11.2. Manhole Covers and Frames

1.11.2.1. Manhole access is to be in the middle of the manhole ceiling, with the sump

pit located directly underneath (see Manhole Detail.dwg for reference).

1.11.2.2. Manhole covers shall consist of a solid circular gravity lid and frame. The lid

and frame shall be heavy duty type, fabricated from gray cast iron.

1.11.2.3. Manhole lids shall have a checkered design with the word ELECTRIC cast

into the top surface.

1.11.2.4. Manhole frames shall provide a 36-inch diameter opening. The opening

through the concrete roof of each manhole shall be 40.5 inches in diameter.

1.11.2.5. Manhole frames and covers shall be Neenah Foundry Company Catalog No.

R-1640-D, or approved equal. The cover shall have two (2) pick holes

located 180apart.

1.11.2.6. Vent cover and frame shall 8-1/2 clear opening, cast iron, heavy duty,

Neenah R-5901-A with open grate lid.

1.11.3. Conduit End Bells

1.11.3.1. Conduit end bells provide a smooth transition from conduit to open

conductors, preventing sheath or insulation damage while pulling cables.

1.11.3.2. Conduit end bells for PVC conduit shall be polyvinyl chloride (PVC) type

glued to the end of each PVC conduit. Conduit end bells shall be Carlon

Electrical Products Catalog No. E297_, or approved equal by Condux

International, Inc., Certainteed Products Corp. or Can-Tex Industries.

1.11.3.3. Conduit end bells for rigid galvanized steel conduit shall be hot-dipped

galvanized malleable iron or steel, threaded to the end of the rigid galvanized

steel conduit and cast in place in the concrete wall of the manhole and shall

be O-Z/Gedney Company Type TNS or approved equal by Appleton Electric

or Crouse-Hinds.

1.11.4. Cable Racks

1.11.4.1. Cable racks shall be heavy duty type fabricated from 50% glass-reinforced

nylon or a non-metallic material having equal mechanical strength, thermal

resistance, chemical resistance, dielectric strength and physical properties.

1.11.4.2. Stanchions

1.11.4.2.1. Size of stanchions shall be coordinated with Energy Management Electric

Distribution Engineer.

1.11.4.2.2. Stanchions shall incorporate multiple arm mounting holes that are 4

inches apart and recessed attachment bolt mounting holes.

1.11.4.2.3. Stanchions shall be Model CR__-B as manufactured by Underground

Devices, Inc. or approved equal.

1.11.4.3. Cable Support Arms

1.11.4.3.1. Cable support arms shall be heavy duty type fabricated from 50% glass-

reinforced nylon or a non-metallic material having equal mechanical

strength, thermal resistance, chemical resistance, dielectric strength and

physical properties. Cable support arms shall be 14 inches in length, with

5 slots for cable wire ties.

1.11.4.3.2. Provide a positive locking clip for each and every cable support arm

supplied to prevent disengagement of the cable support arm from the

cable rack due to upward force on the support arm.

1.11.4.3.3. Cable support arms shall be Model RA14 with Model HDL lock as

manufactured by Underground Devices, Inc. or approved equal.

1.11.5. Cable Support Insulators

1.11.5.1. Cable support insulators shall be fabricated from high-grade electrical

porcelain and shall have rounded corners and edges to prevent cable sheath

damage.

1.11.5.2. Cable support insulators shall be Model DE11U1 as manufactured by Cooper

Power Systems, or approved equal.

1.11.6. Cable Ties

1.11.6.1. Cable ties shall be weather resistant self-locking high strength UV-resistant

black nylon, having a minimum length of 15 inches and a minimum loop

tensile strength of 120 lbs, meeting Military Specifications MS 3367-3-0.

Cable ties shall be Ty-Rap Catalog No. TY5275MX; 3M Catalog No. 06277;

W.H. Brady Company Series CTUN-400HBK; or approved equal.

1.11.7. Grounding

1.11.7.1. Grounding rods shall be -inch diameter, 10 feet long, high strength solid

steel rod with a bonded copper jacket, and UL listed.

1.11.7.2. Grounding rods shall be manufactured by Copperweld Steel Company, ITT

Weaver; Thomas & Betts; Blackburn; Joslyn Mfg. and Supply Co.; or

approved equal.

1.12. Waterproofing

1.12.1. All manholes shall be waterproofed.

1.12.2. Sheet membrane waterproofing system shall be Bituthene 3000/Low

Temperature Membrane by Grace Construction Products, or Carlisle CCW

MiraDRI 860/861. Membrane shall be a self-adhesive, cold-applied composite

sheet consisting of a thickness of 1.4 mm (0.056 in.) of rubberized asphalt and

0.1 mm (0.004 in.) of cross-laminated, high density polyethylene film. Provide

rubberized asphalt membrane covered with a release sheet which is removed

during installation. No special adhesive or heat shall be required to form laps.

1.12.3. Protection board shall be expanded polystyrene board 1 thick for vertical

application with the following characteristics. Adhere to waterproofing

membrane with Bituthene Protection Board Adhesive.

1.12.4. Asphaltic hardboard shall be Bituthene Asphaltic Hardboard by Grace

Construction Products; a pre-molded semi-rigid protection board consisting of

bitumen, mineral core and reinforcement. Provide two (2) layers of 3 mm (0.125

in.) thick hardboard on horizontal surfaces.

1.12.5. Waterstops for use in manholes shall be sodium bentonite clay type by 3/8

thick, Volcay Waterstop RX-102.

2. Installation for Manholes

2.1. Cast-in-Place Concrete Manholes

2.1.1. Concrete work excavations shall not be backfilled until the concrete has cured,

or a minimum of seven (7) days after concrete placement.

2.1.2. The subgrade walls, roof, and risers of all new manholes shall be waterproofed.

2.1.3. All concrete work for the manholes shall be formed, using proper concrete

forms.

2.1.4. The inside surfaces of manhole walls and ceilings shall have a smooth finish.

Manhole floors shall have a non-slip broom finish.

2.1.5. Furnish and install all required appurtenances for each manhole, such as cast

iron cable pulling-in irons, cast iron frame and cover, conduit end bells, cable

racks, grounding rods, etc. Set them into position in forms before pouring

concrete.

2.1.6. Cable rack stanchions shall be installed on each wall of every manhole.

Maximum spacing of stanchions shall be 30 on center. Stanchions shall be

bolted to manhole walls using stainless steel expansion anchors in accordance

with the cable rack manufacturers recommendations.

2.1.7. Provide a minimum of three (3) cable support arms for every stanchion

supplied.

2.1.8. Cable Support Insulators

2.1.8.1. Each insulator with cables shall be tied to the cable support arm when

installing the cables by wrapping two cable ties, in opposite directions,

completely around the cables, the insulator, and the cable support arm.

Cable ties shall be long enough to accomplish this.

2.1.9. Pulling-in Irons

2.1.9.1. Furnish and install the pulling-irons opposite each duct-bank entry.

2.2. Pre-cast Concrete Manholes

2.2.1. The sub-grade walls, roof, and risers of all new manholes shall be

waterproofed.

2.2.2. Pre-cast concrete manholes shall be installed in accordance with the manhole

manufacturers instructions.

2.3. Waterproofing

2.3.1. Cleaning and Protection: Remove any masking materials after installation.

Clean any stains on materials which would be exposed in the completed work.

2.4. Grounding

2.4.1. Manhole shall have two grounding rods in each electric manhole. Grounding

rods shall be driven into the soil beneath the manhole and cast in place with the

installation of the concrete floor of the manhole. Grounding rods shall be located

in diagonally opposite corners of the manhole, located 5 inches out from each

wall, and projecting 6 inches above the finished floor level.

2.4.2. Manhole shall have a size 4/0 bare stranded copper conductor around the

inside perimeter of each electric manhole. The conductor shall be fastened to

the manhole concrete wall every 4 linear feet at a height of 6 inches above the

finished floor using two-hole copper tubing straps.

2.4.3. The copper grounding conductor shall be connected to each grounding rod by

means of exothermic welding.

2.5. Sump

2.5.1. Provide a concrete sump in the center of the floor of each manhole for the

collection of any water which might enter the manhole. The manhole floor shall

slope towards the sump with a minimum slope of 1/8 inch per foot. A sump

pump is not required.

3. Commissioning

3.1. All soil and debris shall be removed from manholes.

3.2. Verify all pull strings and caps are installed.

3.3. All soil and debris shall be removed from manholes and equipment pads where

duct banks terminate.

3.4. Verify all pull strings and caps are installed.

Vous aimerez peut-être aussi

- Underground Electrical Service ManualDocument7 pagesUnderground Electrical Service ManualAwotiku AbimbolaPas encore d'évaluation

- Cable Raceway and Installation GuideDocument20 pagesCable Raceway and Installation GuidePERVEZ AHMAD KHANPas encore d'évaluation

- Electrical Manhole StandardsDocument13 pagesElectrical Manhole StandardsMohammad JaradehPas encore d'évaluation

- Design Standard: Electrical ManholesDocument4 pagesDesign Standard: Electrical ManholesDiana MakarudzePas encore d'évaluation

- ABB (Pro-E Type Test) - PanelDocument16 pagesABB (Pro-E Type Test) - Panelari bowoPas encore d'évaluation

- Minimum clearances for busduct installationsDocument1 pageMinimum clearances for busduct installationsNethajiPas encore d'évaluation

- Neutral Grounding Resistors: Installation and Maintenance InstructionsDocument7 pagesNeutral Grounding Resistors: Installation and Maintenance Instructionsks_ramachandra7017Pas encore d'évaluation

- Electrical Conduit Installation Method StatementDocument6 pagesElectrical Conduit Installation Method StatementSopi Labu0% (1)

- Safety Clearance Recom For TransformerDocument10 pagesSafety Clearance Recom For TransformerhanlovePas encore d'évaluation

- DG BusductDocument16 pagesDG BusductanandpurushothamanPas encore d'évaluation

- Busway DesignDocument97 pagesBusway DesignJOHN PAUL JAVIER100% (3)

- 11 KV RMU-Tech. Spec PDFDocument23 pages11 KV RMU-Tech. Spec PDFMohsin ElgondiPas encore d'évaluation

- GRC-ES005 - r2 - Lighting & Power Distribution BoardDocument13 pagesGRC-ES005 - r2 - Lighting & Power Distribution BoardAdityaPas encore d'évaluation

- Module 5 MV Switch TestingDocument68 pagesModule 5 MV Switch TestingSuresh K Krishnasamy100% (1)

- IEC 61439 type testsDocument12 pagesIEC 61439 type testsSharif Khan100% (2)

- Catalog MV PDFDocument58 pagesCatalog MV PDFJS Engineering100% (1)

- 7 Typical Layout Designs of 11kV Indoor Distribution SubstationDocument15 pages7 Typical Layout Designs of 11kV Indoor Distribution SubstationmostafaPas encore d'évaluation

- Standard ListDocument8 pagesStandard ListSreeram PanigrahiPas encore d'évaluation

- Guidelines 11 KV 33KV OUTDOOR TRANSFORMERS PDFDocument89 pagesGuidelines 11 KV 33KV OUTDOOR TRANSFORMERS PDFSwaroop Biswas100% (1)

- Kahrama Standards Drawings ListDocument2 pagesKahrama Standards Drawings Listmanojj6575% (4)

- All NEIS StandardsDocument2 pagesAll NEIS Standardsdelmar02Pas encore d'évaluation

- Checklist For Electrical DesignDocument8 pagesChecklist For Electrical DesignJd100% (1)

- Method Statement For Concealed PVC Conduit-CDocument5 pagesMethod Statement For Concealed PVC Conduit-CJanePas encore d'évaluation

- DSR Electrical 2012Document78 pagesDSR Electrical 2012জেত বন100% (2)

- Electrical Specification SummaryDocument5 pagesElectrical Specification SummaryRaymundo Delfin100% (2)

- Distribution Planning StandardDocument182 pagesDistribution Planning Standardsan_misus100% (2)

- 35kv Xlpe Phelps DodgeDocument2 pages35kv Xlpe Phelps DodgeCommercial One100% (2)

- 5 - SMDBDocument4 pages5 - SMDBKhyle Laurenz DuroPas encore d'évaluation

- Acsr Tree Wire 15KV PDFDocument1 pageAcsr Tree Wire 15KV PDFbertovalenPas encore d'évaluation

- Switchboards, Distribution Boards and Control PanelsDocument45 pagesSwitchboards, Distribution Boards and Control PanelsRachel IngramPas encore d'évaluation

- Technical Specifications 11kvDocument106 pagesTechnical Specifications 11kvprasanthvenkatesh60% (5)

- MEW Specification For LED Street Lighting Luminaires - April 2018Document16 pagesMEW Specification For LED Street Lighting Luminaires - April 2018minjut50% (2)

- 11kv SWGR SpecsDocument87 pages11kv SWGR SpecsstalinPas encore d'évaluation

- TES-P-119-25-R2-Lighting and Receptacles For Substation Yard Building-1Document20 pagesTES-P-119-25-R2-Lighting and Receptacles For Substation Yard Building-1Salman YounasPas encore d'évaluation

- 4 Pole DesignDocument102 pages4 Pole Designashutosh2009100% (1)

- Type of Drawout PDFDocument58 pagesType of Drawout PDFrantaroPas encore d'évaluation

- IS 8130 - Classes of Conductors - 2013 - Reaffiremed 2018Document12 pagesIS 8130 - Classes of Conductors - 2013 - Reaffiremed 2018piyush guptaPas encore d'évaluation

- 630A MCC BUSBAR SIZING CALCULATIONDocument42 pages630A MCC BUSBAR SIZING CALCULATIONAnonymous OKkHA0NzPas encore d'évaluation

- Hyundai Electric BrochureDocument36 pagesHyundai Electric BrochurebadbenzationPas encore d'évaluation

- COMPLIANCE STATEMENT FOR CABLE TRAY SPECIFICATIONSDocument3 pagesCOMPLIANCE STATEMENT FOR CABLE TRAY SPECIFICATIONSvtalexPas encore d'évaluation

- Lumped Load Editor - Short-Circuit PDFDocument3 pagesLumped Load Editor - Short-Circuit PDFNMulyonoPas encore d'évaluation

- 0422R - Standard Specifications (Part 1)Document339 pages0422R - Standard Specifications (Part 1)louie100% (1)

- Earthing and Lightning Protection Systems PDFDocument88 pagesEarthing and Lightning Protection Systems PDFSky LightPas encore d'évaluation

- Technical Specifications - Cable LayingDocument48 pagesTechnical Specifications - Cable LayingShkelzen GoxhajPas encore d'évaluation

- Power Transformer Specification PDFDocument42 pagesPower Transformer Specification PDFamulya00428100% (1)

- SEC underground distribution network construction standardDocument52 pagesSEC underground distribution network construction standardvinoth100% (6)

- External Electrical - BOQDocument41 pagesExternal Electrical - BOQroy_nhp100% (1)

- Check List LT PanelDocument1 pageCheck List LT PanelAnil PatelPas encore d'évaluation

- Kindergarten Electrical BoxesDocument2 pagesKindergarten Electrical BoxesSaad AkramPas encore d'évaluation

- Sec-09 Electrical Works and InstallationDocument6 pagesSec-09 Electrical Works and InstallationOmer HayatPas encore d'évaluation

- WST CorGal SPEC 0803-WT-CHRDocument4 pagesWST CorGal SPEC 0803-WT-CHRAlejandro TrujilloPas encore d'évaluation

- Duct and PVC in ConcreteDocument6 pagesDuct and PVC in ConcreteAli AimranPas encore d'évaluation

- 330513S01 - MANHOLES AND STRUCTURES - Electrical Manholes and CoversDocument2 pages330513S01 - MANHOLES AND STRUCTURES - Electrical Manholes and CoversDuy Phạm VănPas encore d'évaluation

- SECTION 16116 Cable Trunking: Part 1 - General Related DocumentsDocument4 pagesSECTION 16116 Cable Trunking: Part 1 - General Related DocumentsAhmed GamalPas encore d'évaluation

- National Greenhouse Specifications Series E 11 2008Document8 pagesNational Greenhouse Specifications Series E 11 2008G.Senthil KumaranPas encore d'évaluation

- DO Fuse UnitDocument8 pagesDO Fuse UnitImran KhanPas encore d'évaluation

- Insulator: PackingDocument8 pagesInsulator: PackingZeeshan SubhaniPas encore d'évaluation

- Insulator: PackingDocument8 pagesInsulator: PackingZeeshan SubhaniPas encore d'évaluation

- Specifications: I. General Technical ConditionDocument3 pagesSpecifications: I. General Technical ConditionCel Marie SanchezPas encore d'évaluation

- 9 InsulatorDocument39 pages9 InsulatorLeo KhkPas encore d'évaluation

- TCVN 7957 2008 FullDocument96 pagesTCVN 7957 2008 FullThanh Ngoc TtntPas encore d'évaluation

- How We Calculate MCA and MOPDocument1 pageHow We Calculate MCA and MOPnaffcopumpsPas encore d'évaluation

- Catalogue Imatek - VN EditionDocument18 pagesCatalogue Imatek - VN Editionlilama45-1Pas encore d'évaluation

- Extracted Pages From Daikin VRV-A Engineering DataDocument2 pagesExtracted Pages From Daikin VRV-A Engineering Datalilama45-1Pas encore d'évaluation

- VRV - Daikin Vs LG PDFDocument1 pageVRV - Daikin Vs LG PDFlilama45-1Pas encore d'évaluation

- MCA & MOP of CircuitsDocument7 pagesMCA & MOP of CircuitsMiko QuijanoPas encore d'évaluation

- How We Calculate MCA and MOPDocument1 pageHow We Calculate MCA and MOPnaffcopumpsPas encore d'évaluation

- My New Year's Resolutions: Part OneDocument2 pagesMy New Year's Resolutions: Part Onelilama45-1Pas encore d'évaluation

- Reliable Tunnel Spray NozzleDocument3 pagesReliable Tunnel Spray Nozzlelilama45-1Pas encore d'évaluation

- Hawaii Five-0: The VenturesDocument4 pagesHawaii Five-0: The Ventureslilama45-1Pas encore d'évaluation

- Differences Between Ductile Iron and Gray Cast IronDocument2 pagesDifferences Between Ductile Iron and Gray Cast Ironlilama45-1Pas encore d'évaluation

- National Pipe Thread - WikipediaDocument4 pagesNational Pipe Thread - Wikipedialilama45-1Pas encore d'évaluation

- MSB Electrical Cupboard Load ScheduleDocument2 pagesMSB Electrical Cupboard Load Schedulelilama45-1Pas encore d'évaluation

- Energy Usage For RestaurantsDocument26 pagesEnergy Usage For RestaurantsGayathri VasuPas encore d'évaluation

- Grounding Cases and Covers: ApplicationsDocument2 pagesGrounding Cases and Covers: Applicationslilama45-1Pas encore d'évaluation

- Dimension in RevitDocument24 pagesDimension in Revitlilama45-1Pas encore d'évaluation

- FT Plate Base Support enDocument2 pagesFT Plate Base Support enlilama45-1Pas encore d'évaluation

- Selection of Relay For Incoming and Outgoing Feeders For MV and LV MCC SwitchgearsDocument11 pagesSelection of Relay For Incoming and Outgoing Feeders For MV and LV MCC Switchgearslilama45-1Pas encore d'évaluation

- (2017) 42 - 2017 - ND-CP - Sua Doi ND 59 - 2015 - OriginDocument21 pages(2017) 42 - 2017 - ND-CP - Sua Doi ND 59 - 2015 - Originlilama45-1Pas encore d'évaluation

- Ghost Rider in The SkyDocument5 pagesGhost Rider in The Skylilama45-1Pas encore d'évaluation

- Specification of 1500v 5.1mva Solar Ware Station - RevaDocument15 pagesSpecification of 1500v 5.1mva Solar Ware Station - Revalilama45-1Pas encore d'évaluation

- Data, Voice and Structured Cabling SpecificationDocument7 pagesData, Voice and Structured Cabling Specificationlilama45-1Pas encore d'évaluation

- Indoor Cassette PDFDocument56 pagesIndoor Cassette PDFlilama45-150% (2)

- Model Number Structure: Floatless Level Switch (Basic Type)Document15 pagesModel Number Structure: Floatless Level Switch (Basic Type)Umar MajeedPas encore d'évaluation

- WSP UK Building Services - BIM Protocol (Autodesk Revit)Document40 pagesWSP UK Building Services - BIM Protocol (Autodesk Revit)lilama45-1Pas encore d'évaluation

- WSP Revit ManualDocument18 pagesWSP Revit Manuallilama45-1100% (3)

- OVR - F - 0301 - MẶT BẰNG CHỮA CHÁY - TẦNG HẦM PDFDocument1 pageOVR - F - 0301 - MẶT BẰNG CHỮA CHÁY - TẦNG HẦM PDFlilama45-1Pas encore d'évaluation

- Spec ELE Section 22 Painting and FinishingDocument1 pageSpec ELE Section 22 Painting and Finishinglilama45-1Pas encore d'évaluation

- Spec ELE Section 14 Power Factor CorrectionDocument6 pagesSpec ELE Section 14 Power Factor Correctionlilama45-1Pas encore d'évaluation

- 7F Concrete Rigid FramesDocument14 pages7F Concrete Rigid FramesMadalina AntohePas encore d'évaluation

- TCVN 1651.2008 Steel For The Reinforcement of Concrete - Part 1Document8 pagesTCVN 1651.2008 Steel For The Reinforcement of Concrete - Part 1Ngo Tien VinhPas encore d'évaluation

- Concrete Structures DesignDocument66 pagesConcrete Structures Designmadkik100% (1)

- Reinforced Concrete Design by Professor Anthony Kwame DansoDocument131 pagesReinforced Concrete Design by Professor Anthony Kwame DansoBadu Evans NyiayePas encore d'évaluation

- National Structural Code of The Philippines KeyDocument8 pagesNational Structural Code of The Philippines KeyMia ListaPas encore d'évaluation

- Combined FootingDocument48 pagesCombined FootingGunjan KolarkarPas encore d'évaluation

- 350.2R-04 - Concrete Structures For Containment Hazardous Materials PDFDocument17 pages350.2R-04 - Concrete Structures For Containment Hazardous Materials PDFEduardo Quezada Larenas100% (1)

- Guidelines For Retrofitting of BuildingsDocument45 pagesGuidelines For Retrofitting of Buildingsferdie macaranasPas encore d'évaluation

- BBS T5a P01 STR 2100Document31 pagesBBS T5a P01 STR 2100Franklyn GenovePas encore d'évaluation

- Technical SpecificationDocument123 pagesTechnical SpecificationMarvin SironPas encore d'évaluation

- "Study of Natural Fibers As An Admixture For Concrete Mix Design" (Chapter 2)Document9 pages"Study of Natural Fibers As An Admixture For Concrete Mix Design" (Chapter 2)JOHN FHILIP ORIT100% (4)

- TERMS Concrete Plant Visit Technical ReportDocument7 pagesTERMS Concrete Plant Visit Technical ReportDave Vendivil SambranoPas encore d'évaluation

- Application of 3D Printing Technology in The Construction Industry and Its Development ProspectsDocument7 pagesApplication of 3D Printing Technology in The Construction Industry and Its Development Prospects2JH19CV015 Mohammedasjadraza MullaPas encore d'évaluation

- 7.chapter 5 Column PDFDocument73 pages7.chapter 5 Column PDFSeventh SkyPas encore d'évaluation

- Crack width calculations sheet no projectDocument1 pageCrack width calculations sheet no projectAmanda SmithPas encore d'évaluation

- Concrete 3d MSWDocument28 pagesConcrete 3d MSWManu S NadesanPas encore d'évaluation

- RCC Notes Made Easy (IES VIVEK Sir) PDFDocument345 pagesRCC Notes Made Easy (IES VIVEK Sir) PDFJack Mano88% (8)

- Foundation Technical SpecificationDocument13 pagesFoundation Technical SpecificationwaliPas encore d'évaluation

- 2016 Book NewApproachesToBuildingPatholo PDFDocument214 pages2016 Book NewApproachesToBuildingPatholo PDFCarlos Augusto Sanchez RondonPas encore d'évaluation

- Tek 10-03Document4 pagesTek 10-03Thai DamPas encore d'évaluation

- Estimation techniques and bill of quantitiesDocument14 pagesEstimation techniques and bill of quantitiesKalees KaleesPas encore d'évaluation

- Precast Concrete Components PresentationDocument49 pagesPrecast Concrete Components PresentationCt NaSihah100% (1)

- MasterSeal 940 TDSDocument4 pagesMasterSeal 940 TDSbayuargad100% (1)

- Ce6601 Sve QBDocument28 pagesCe6601 Sve QBLogeshwariPas encore d'évaluation

- Constructing Concrete Forms CourseDocument27 pagesConstructing Concrete Forms CourseRakesh ParaliyaPas encore d'évaluation

- IS 13920 - 1993vs2016Document14 pagesIS 13920 - 1993vs2016RonakShahPas encore d'évaluation

- Construction Method For Jetty English R3 1Document69 pagesConstruction Method For Jetty English R3 1Elsa Ardiansyah93% (15)

- KDU Auditorium Field Visit ReportDocument14 pagesKDU Auditorium Field Visit ReportTharindu DissanayakePas encore d'évaluation

- Bill of Quantities Civil and Specialist's Works For Rehabilitation of High School of Economics and Trade in ParaćinDocument26 pagesBill of Quantities Civil and Specialist's Works For Rehabilitation of High School of Economics and Trade in ParaćinOscarKonzultPas encore d'évaluation

- ISIS Educational Module on FRP Strengthening of Concrete StructuresDocument107 pagesISIS Educational Module on FRP Strengthening of Concrete StructuresOmar100% (1)