Académique Documents

Professionnel Documents

Culture Documents

E1221

Transféré par

LLCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

E1221

Transféré par

LLDroits d'auteur :

Formats disponibles

ROBUST Series

High-Speed Precision Angular Contact

Ball Bearings for Machine Tool Spindles

ITemperature tol erance and l ow heat generati on

ISmooth runni ng even duri ng sudden rapi d accel erati on

IHi gher speed and l onger l i fe

1

High-Speed Precision Angular Contact Ball Bearings

1. Features

These bearings are designed for motorized and non-motorized spindles and feature the

optimal internal structure for minimizing heat generation and improving seizure resistance.

The H type can be lubricated with grease at speeds where conventional bearings require

oil/air lubrication (Fig. 1). Additionally, both the S type and H type are capable of speeds 20%

higher than conventional precision angular contact ball bearings.

While this hybrid ceramic bearing has the same design as the S and H types, its rings are

made of SHX steel, a new steel developed by NSK. SHX has excellent seizure and wear

resistance during critical lubrication shortages. Also, its heat resistance is nearly equal to

M50 steel, which is widely used in bearings for jet aircraft engines. With the X type, grease

lubrication is feasible at even higher speeds than the H type (Fig. 1). In terms of both

surface and subsurface fatigue, SHX steel provides longer life (Figs. 3 ~ 6).

H type angular contact ball bearings

S type (balls and rings: bearing steel) H type (balls: silicon nitride, Si

3

N

4

/rings: bearing steel)

X type (balls: silicon nitride, Si

3

N

4

/rings: SHX steel)

A major trend in the machine tool industry is for higher maximum spindle speeds. In addition, machines are

being required to perform a wider variety of tasks and undergo frequent tool changes. Under such conditions,

excellent high-speed performance is imperative and spindles must accelerate and decelerate faster. During

periods of rapid acceleration or deceleration, spindle bearings are subjected to severe thermal load conditions.

These conditions are caused by drastic changes in the ambient environment that result from heat generated

by the motor, housing cooling and other factors. Performing well under such conditions and being capable of

higher speeds than conventional precision bearings, the ROBUST Series bearings provide solutions for high-

speed spindles of the 21st century.

Bearing features indispensable to motorized main spindles

temperature tolerance, seizure resistance and low heat

generationhave been improved to enable higher speeds

with minimal thermal deformation.

2

Notes: 1. Special heat-resistant, high-strength polyimide resin cages are used in the X and EX types for extremely high speeds. In the S and H types

and the X and EX types at low to moderate speeds, phenolic or polyamide cages are used.

2. For X and EX type bearings with outside diameters exceeding 150, please consult NSK.

EX bearings have the same specifications as the X type, but employ NSKs exclusive

Spinshot

lubrication system (Fig. 7). While previously only oil jet lubrication has been

feasible at speeds exceeding 2,000,000 dmn, the Spinshot

lubrication system utilizes

a mixture of oil and air to enable the EX type to sustain such speeds (Fig. 1). The use

of oil/air instead of oil jets reduces overall costs by allowing the structure of the

spindle to be simplified and cutting down on the consumption of oil, an added

environmental benefit.

Please note that the EX type is not dimensionally interchangeable with conventional

precision angular contact ball bearings.

ROBUST Series

EX type (balls: silicon nitride, Si

3

N

4

/rings: SHX steel/Spinshot

Technology)

H type

X type

ROBUST Series

Conventional

Bearings

EX type

d

m

n 2. 0 1. 0 3. 0 4. 0 x10

6

Ceramic balls

Steel balls

S type

Position preload Constant-pressure preload

Gr ease

Gr ease

Oi l / ai r

Oi l / ai r

Gr ease

Oi l / ai r

Gr ease

Oi l / ai r

Gr ease

Oi l / ai r

Oi l / ai r

Fig. 1 Comparison of application ranges of conventional and ROBUST Series bearings under position preload

Note: Limiting speeds vary depending not only on the bearing and lubrication method used, but also on the main

spindle driving system, cooling method, structure and other factors. Consider the above as a general

reference guide and consult NSK for limiting speeds of specific applications.

High-Speed Precision Angular Contact Ball Bearings

3

Optimal Internal Design

Today, machining involves various cutting conditions within a wide range of speeds. Consequently, spindle temperatures vary

widely and cause changes in internal bearing load. The unique design of the ROBUST Series bearings minimizes the adverse

effect temperature variation has on internal bearing load.

Fig. 2 Analysis results on bearing dynamics

With a lower PV value* and less heat generation,

ROBUST Series bearings operate with greater

stability than conventional precision bearings.

I Minimal heat generation

I Improved temperature tolerance

To ensure the accuracy of spindles by minimizing thermal displacement, suppression of bearing dynamic frictional loss is vital.

The ROBUST Series design controls dynamic frictional loss, reducing heat generation by approximately 20% when compared to

conventional bearings operating at the same speed.

H

e

a

t

g

e

n

e

r

a

t

i

o

n

,

W

0 5 10 15 20

Speed, rpm (10

3

)

100

120

140

80

60

40

20

0

0 5 10 15 20

Speed, rpm (10

3

)

T

e

m

p

e

r

a

t

u

r

e

r

i

s

e

o

f

o

u

t

e

r

r

i

n

g

,

C

50

40

30

20

10

0

Temperature difference between inner and outer rings

H

e

a

t

g

e

n

e

r

a

t

i

o

n

P

V

v

a

l

u

e

*

Conventional bearings

ROBUST Series

Heat generation- Calculated values

(bore diameter: 65 mm; grease lubrication)

Temperature rise of outer ring- Measured values

(bore diameter: 65 mm; grease lubrication)

Conventional bearings

ROBUST Series

Conventional bearings

ROBUST Series

* PV value measures the relationship between ball and

raceway surface pressure and ball sliding speed.

4

SHX Steel Used for Inner and Outer Rings of X and EX Types

SHX steel has heat resistance nearly equivalent to that of M50 steel and is superior to M50 in wear resistance, seizure

resistance and durability. As such, SHX is highly suited for use in machine tool spindles, which must run at high speeds

with a minimum supply of lubricant.

Fig. 3.1 Tempering temperature and hardness

Tempering temperature,C

400 300 200 100

H

a

r

d

n

e

s

s

,

H

V

900

850

800

750

700

650

600

550

500

SUJ2

SHX

M50

Temperature, C

H

a

r

d

n

e

s

s

,

H

v

500 400 300 200 100 0

900

800

700

600

500

400

300

SHX

SUJ2

M50

2000 1500 500 1000 0

SUJ2

SHX

M50

0

0.01

0.02

0.03

0.04

0.05

0.06

0.07

Sliding distance, m

A

m

o

u

n

t

o

f

w

e

a

r

,

g

Load

Lubricant

7 rpm

10 rpm

Fig. 4 Wear resistance (2-cylinder wear test)

Test conditions

Surface pressure: 880 MPa

Sliding ratio: 30%

Lubrication: Spindle oil (2 cm

3

/min)

Temperature: Room temperature

ROBUST Series

Heat resistance

Fig. 3.2 High-temperature hardness

Wear resistance

High-Speed Precision Angular Contact Ball Bearings

5

These tests confirm that SHX is superior to M50 in seizure resistance. Silicon nitride balls offer even higher

seizure resistance.

Life, h

C

u

m

u

l

a

t

i

v

e

f

a

i

l

u

r

e

p

r

o

b

a

b

i

l

i

t

y

,

%

Clean lubrication

10 10

2

10

3

10

4

99.9

99

90

50

10

5

1

SUJ2

SHX

Test conditions

Bearing: 6206

P/C: 0.71

Temperature: 160C

Speed: 4,900 rpm

Oil film parameter, : 5

Life, h

C

u

m

u

l

a

t

i

v

e

f

a

i

l

u

r

e

p

r

o

b

a

b

i

l

i

t

y

,

%

1 10 10

2

10

3

99.9

99

90

50

10

5

1

Contaminated lubrication

Test conditions

Bearing: 6206

P/C: 0.28

Temperature: 140C

Speed: 4,900 rpm

Foreign debris:

Hardness: Hv540

Size: 74 ~ 147 m

SUJ2

SHX

M50

Fig. 6.1 Life test for subsurface-originated flaking

Fig. 6.2 Life test for surface-originated flaking

Long life

Seizure resistance

Fig. 5.1 Dry seizure test (4-ball test) Fig. 5.2 Seizure limit test (4-ball test)

500

600

400

300

200

100

0

-100

M50 SHX

Material

T

i

m

e

u

n

t

i

l

s

e

i

z

u

r

e

,

s

e

c1600

1200

800

400

SUJ2 M50 SHX

Material

P

V

v

a

l

u

e

,

(

k

g

f

/

m

m

2

m

/

s

)

Test conditions

Lubrication: None

Sliding condition: PV = 3,720N

mm

2

m/s

(380 kgf

mm

2

m/s)

Test conditions

Lubrication: Oil bath

Speed: 6,000 rpm (constant)

Rotating

Fixed

Load

Notes: (1) Oil shut-off point

(2) M50 seized before the oil shut-off point was reached.

(1)

(2) 4-ball test

6

ROBUST Series

Spinshot

Lubrication System

The EX type features the widely accepted Spinshot

lubrication system for machine tool main spindles. This system ensures a

steady supply of lubricating oil to the bearing and excellent high-speed performance.

The Spinshot

lubrication system is illustrated in Fig. 7. Oil/air (a mixture of the minimum necessary amount of oil and

compressed air) is fed from the lubrication device to the bearing via nozzles and oil scoops in the spacer. The nozzles in the

spacer are inclined outward so that centrifugal force makes the oil flow into the bearing with greater velocity as speed increases.

With the Spinshot

lubrication system, the steady supply of lubrication and the cooling effect of the oil/air mixture greatly

increase the limiting speed of the bearing.

Please note that the EX type is not dimensionally interchangeable with conventional precision angular contact ball bearings.

Oil scoop Spinshot spacer

Oil/air

Oil/air

Oil/air

Spinshot spacer

Fig. 7 Spinshot

lubrication system

Fig. 8 Example of bearing arrangement (position preload)

A

View of outer ring spacer from A

3. Test Results

H type

Fig. 9 Comparison of temperature rise with grease lubrication

H type

Conventional hybrid bearing

W

i

t

h

o

u

t

c

o

o

l

e

d

h

o

u

s

i

n

g

W

i

t

h

c

o

o

l

e

d

h

o

u

s

i

n

g

O

u

t

e

r

r

i

n

g

t

e

m

p

e

r

a

t

u

r

e

r

i

s

e

,

C

40

30

20

10

0

0.5 1 2

20 15 10 5

0 1.5

Bearing: 90BNR10TDB

Preload when assembled: 382N (40 kgf)

Lubrication: VG22, 0.03 cm

3

/16 min

d

m

n (10

6

)

Speed, rpm (10

3

)

Thermocouple

Thermocouple

Fig. 10 Comparison of temperature rise with oil/air lubrication

20 25 15 10 5 0

O

u

t

e

r

r

i

n

g

t

e

m

p

e

r

a

t

u

r

e

r

i

s

e

,

C

40

50

30

20

10

0

H type

Conventional hybrid bearing

Bearing: 65BNR10TDBB

Preload when assembled: 196N (20 kgf)

Lubrication: Grease

Speed, rpm (10

3

)

0.5 1 2 1.5

d

m

n (10

6

)

2. Bearing Materials and Construction

High-Speed Precision Angular Contact Ball Bearings

7

Testing machine structure

Testing machine structure

Type

Material

Bearing construction

Inner ring Outer ring Balls

S SUJ2 SUJ2 SUJ2

H SUJ2 SUJ2 Si

3

N

4

X SHX SHX Si

3

N

4

EX SHX SHX Si

3

N

4

Note: SUJ2 is equivalent to ASTM 52100.

40 30 20 10 0

Speed, rpm (10

3

)

T

e

m

p

e

r

a

t

u

r

e

r

i

s

e

o

f

c

y

l

i

n

d

e

r

,

C

60

40

50

30

20

10

0

0.5 1

dmn

2 3 3.5 1.5 2.5

Rear bearings

Front bearings

Bearing: 65BNRE110T62DT

55BNRE95T62DT

Preload (constant-pressure): 755N (77 kgf)

Lubrication: Under race oil/air lubrication (Spinshot)

Lubrication is provided one shot at

a time by one of 3 nozzles

(10

6

)

Testing machine structure

Testing machine structure

ROBUST Series

EX type

Thermocouple

dmn (10

6

)

Bearing: 65BNRE110T62DB

Preload when assembled: 98N (10 kgf)

Lubrication: Under race oil/air lubrication (Spinshot)

VG22, 0.03 cm

3

/4 min (2 nozzles)

EX type

O

u

t

e

r

r

i

n

g

t

e

m

p

e

r

a

t

u

r

e

r

i

s

e

,

C

40

30

35

45

25

15

5

20

10

0

0.5 1 2 1.5 2.5

Speed, rpm (10

3

)

30 20 10 5 15 25 0

X type

Fig. 11 Comparison of temperature rise with grease lubrication

Thermocouple

O

u

t

e

r

r

i

n

g

t

e

m

p

e

r

a

t

u

r

e

r

i

s

e

,

C

30

35

40

25

20

15

5

10

20 25 15 10 5 0

0

X type

Conventional

hybrid bearing

0.5 1 2 1.5

d

m

n (10

6

)

Speed, rpm (10

3

)

Bearing: 65BNRX10TDBB

Preload when assembled: 49N (5 kgf)

Lubrication: VG32, 0.03 cm

3

/8 min

Bearing: 65BNRX10TDBB

Preload when assembled: 196N (20 kgf)

Lubrication: Grease

O

u

t

e

r

r

i

n

g

t

e

m

p

e

r

a

t

u

r

e

r

i

s

e

,

C

40

50

60

30

20

10

20 25 15 10 5 0

0

X type

Conventional hybrid bearing

Speed, rpm (10

3

)

0.5 1 2 1.5

d

m

n (10

6

)

Fig. 12 Comparison of temperature rise with oil/air lubrication

Testing machine structure

8

Testing machine structure

Fig. 13 Temperature rise with oil/air lubrication and position preload

Fig. 14 Temperature rise with oil/air lubrication and constant-pressure preload

Nominal bearing bore

Preload symbol

EL: Extra light

L: Light

CP: Preload (negative clearance)

(CP10: -10 m)

CA: Axial clearance (CA10: +10 m)

Cage symbol

T: Phenolic cage

TY: Polyamide cage

Example:

Indicates type of bearing

BNRS: 18

BARS: 30

BTRS: 40

Arrangement symbol

DB: Back-to-back arrangement

DT: Tandem

DBB: 4-row arrangement

10

Size series no.

10: Bore, outside diameter and width are same as 70 series

19: Bore, outside diameter and width are same as 79 series

10X: Bore and outside diameter are same as 70 series

(width is a special dimension)

65 BNRS TY L

Accuracy symbol

P4: ISO Class 4

P4A: NSK tolerance for BARS and BTRS

P3: Dimensions- ISO Class 4

Running accuracy- ISO Class 2

P2: ISO Class 2

P4 DB

Indicates type of bearing-BNR: 18

Size series no.

10: Bore, outside diameter and width are same as 70 series

19: Bore, outside diameter and width are same as 79 series

See above

Nominal bearing bore

Example:

10 65 BNR TY L P4 DB

4. Bearing Nomenclature

S type (balls and rings: bearing steel)

X type (balls: silicon nitride, Si

3

N

4

/rings: SHX steel)

H type (balls: silicon nitride, Si

3

N

4

/rings: bearing steel)

High-Speed Precision Angular Contact Ball Bearings

EX type (balls: silicon nitride, Si

3

N

4

/rings: SHX steel/Spinshot

Technology)

9

Example:

10 65 BNRX T L P4 DB

Indicates type of bearing-BNRX: 18

See above

Size series no.

10: Bore, outside diameter and width are same as 70 series

19: Bore, outside diameter and width are same as 79 series

Nominal bearing bore

Cage symbol

T: Phenolic cage

T62: Polyimide cage

Indicates type of bearing

Nominal bearing outside diameter

See above

Example:

110 65 BNRE T62 L P4 DB

Nominal bearing bore

ROBUST Series

5. Tolerances for Boundary Dimensions and Running Accuracy

For most tolerances, i.e., P2, P3 and P4, refer to NSK catalog number E124, Precision Rolling Bearings for Machine-

Tool Spindles. However, for the tolerances of BARS10X and BTRS10X series, which have Class 4A tolerance, refer to

Tables 1.1 and 1.2. Class 4A tolerance is an NSK specification. In Class 4A, all of the tolerances are the same as ISO

Class 4 except for those related to the outside diameter.

Brg outside Single plane Deviation

Outside dia. variation

Mean outside

Radial runout

Variation of brg Assembled brg

Outer ring

diameter mean outside of a single

in a single

dia. variation

of assembled

outside surface outer ring

width variation

D dia. deviation outside dia.

radial plane

brg outer ring

generatrix inclination face runout

VCs

(mm) Dmp Ds

VDp

Kea

with outer ring face with raceway

Diameter series

VD

mp

SD Sea

9 0

over incl high low high low max max max max max max max

80 -30 -37 -30 -37 7 5 3.5 5 4 5 3

80 120 -40 -48 -40 -48 8 6 4 6 5 6 4

120 150 -50 -59 -50 -59 9 7 5 7 5 7 5

150 180 -50 -60 -50 -60 10 8 5 8 5 8 5

180 250 -50 -61 -50 -61 11 8 6 10 7 10 7

Brg bore

Single plane Deviation

Bore dia. variation

Mean bore

Radial runout Inner ring

Assembled brg

Inner ring

Deviation of a

mean bore of a single

in a single

dia. variation

of assembled reference face

inner ring

widthvariation

single inner

d dia. deviation bore dia.

radial plane

Vdmp

brg inner ring runout with bore

face runout

VBs

ring width

(mm) dmp ds

Vdp

Kia Sd

with raceway

Bs (Cs)

Diameter series

Sia

9 0

over incl high low high low max max max max max max max high low

50 0 -6 0 -6 6 5 3 4 4 4 3 0 -300

50 80 0 -7 0 -7 7 5 3.5 4 5 5 4 0 -500

80 120 0 -8 0 -8 8 6 4 5 5 5 4 0 -500

120 150 0 -10 0 -10 10 8 5 6 6 7 5 0 -750

Table 1.2 Outer ring tolerances of BARS10X and BTRS10X series

Table 1.1 Inner ring tolerances of BARS10X and BTRS10X series

10

Units: m

Units: m

High-Speed Precision Angular Contact Ball Bearings

11

6. Preloads for Duplex Bearings

When determining the appropriate preload for your application, please consult NSK.

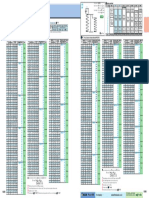

Table 2.1 BNRS19, BNR19 and BNRX19 Series

Table 2.2 BNRS10, BNR10 and BNRX10 Series

Axial Preload (N)

Bearing bore

diameter BNRS19 ( = 18) BNR19, BNRX19 ( = 18)

EL L EL L

35 49 147 49 157

40 49 147 49 157

45 49 157 49 176

50 49 167 49 176

55 49 167 49 186

60 49 176 49 196

65 49 186 49 206

70 49 186 49 206

75 49 186 49 206

80 49 196 49 215

85 49 196 49 215

90 98 294 98 314

95 98 294 98 314

100 98 343 98 372

105 98 343 98 412

110 98 392 98 461

120 98 412 98 471

130

Axial Preload (N)

Bearing bore

diameter BNRS10 ( = 18) BNR10, BNRX10 ( = 18)

EL L EL L

35 49 108 49 118

40 49 118 49 127

45 49 118 49 127

50 49 118 49 127

55 49 118 49 137

60 49 127 49 137

65 49 137 49 147

70 49 235 49 265

75 49 245 49 274

80 98 343 98 372

85 98 343 98 372

90 98 343 98 372

95 98 343 98 392

100 98 343 98 392

105 98 441 98 490

110 98 539 98 637

120 98 588 98 637

130

ROBUST Series

12

Note: is the contact angle

Table 2.3 BARS10X and BTRS10X Series

Axial Preload (N)

Bearing bore

diameter BARS10X ( = 30) BTRS10X ( = 40)

EL L EL L

35

40 196 441 294 686

45 196 441 294 735

50 245 490 343 784

55 245 637 343 784

60 245 637 392 882

65 245 686 392 931

70 245 931 392 1 570

75 245 931 392 1 670

80 343 1 130 539 1 860

85 343 1 130 539 1 910

90 392 1 670 539 2 890

95 392 1 760 539 2 990

100 392 1 810 588 3 090

105 392 1 860 588 3 190

110 392 1 910 588 3 280

120 392 2 060 588 3 530

130 392 2 600 588 4 510

High-Speed Precision Angular Contact Ball Bearings

13

Material

Inner rings Outer rings Balls

BNRS19 SUJ2 SUJ2 SUJ2

BNR19 SUJ2 SUJ2 Si

3

N

4

BNRX19 SHX SHX Si

3

N

4

BNRS19

BNR19

BNRX19

Contact angle 18

Boundary Dimensions Basic Load Ratings

(mm) (N) {kgf}

d D B r r

1

C

r

C

or

C

r

C

or

min min

35 55 10 0.6 0.3 8 300 4 600 845 470

40 62 12 0.6 0.3 10 300 5 900 1 050 600

45 68 12 0.6 0.3 11 000 6 700 1 120 685

50 72 12 0.6 0.3 11 700 7 500 1 190 765

55 80 13 1 0.6 13 300 8 900 1 350 905

60 85 13 1 0.6 13 500 9 400 1 380 955

65 90 13 1 0.6 14 100 10 300 1 440 1 050

70 100 16 1 0.6 19 500 13 900 1 990 1 420

75 105 16 1 0.6 19 900 14 600 2 030 1 490

80 110 16 1 0.6 20 300 15 400 2 060 1 570

85 120 18 1.1 0.6 27 000 20 300 2 750 2 070

90 125 18 1.1 0.6 29 000 23 000 2 950 2 350

95 125 18 1.1 0.6 29 500 24 000 3 000 2 450

100 140 20 1.1 0.6 35 000 27 100 3 550 2 760

B

r1

a

D

d

r

r

r

D

a

d

a

ra

ra

ROBUST Series

14

Dynamic Equivalent Load

Nominal

Contact

Angle

C

or

*

iF

a

e

Single, DT DB or DT

X Y X Y X Y X Y

F

a

/F

r

e F

a

/F

r

e F

a

/F

r

>e F

a

/F

r

>e

18 0.57 1 0 0.43 1 1 1.09 0.70 1.63

Static Equivalent Load

Nominal

Contact

Angle

Single, DT DB or DF

X

0

Y

0

X

0

Y

0

18 0.5 0.42 1 0.84

*For i, use 2 for DB and DF and 1 for DT.

Single or DT mounting

when

F

r

>0.5F + Y

0

F

a

use P

0

= F

r

P = XF

r

+ YF

a

P

0

= X

0

F

r

+ Y

0

F

a

Eff. Load Center

Abutment and Fillet Dimensions

Mass Internal Free

Bearing Numbers

(mm)

(mm)

(kg) Space

a

d

a

D

a

D

b

r

a

r

b

min max max max max

approx (cm

3

/row)

35BNRS19

35BNR19 12.3 40 50 52.5 0.6 0.3 0.074 3

35BNRX19

40BNRS19

40BNR19 14.3 45 57 59.5 0.6 0.3 0.109 4.8

40BNRX19

45BNRS19

45BNR19 15.2 50 63 65.5 0.6 0.3 0.129 5.2

45BNRX19

50BNRS19

50BNR19 15.9 55 67 69.5 0.6 0.3 0.130 5.9

50BNRX19

55BNRS19

55BNR19 17.5 61 74 75 1 0.5 0.182 7.4

55BNRX19

60BNRS19

60BNR19 18.3 66 79 80 1 0.5 0.195 7.2

60BNRX19

65BNRS19

65BNR19 19.1 71 84 85 1 0.5 0.208 8.6

65BNRX19

70BNRS19

70BNR19 21.8 76 94 95 1 0.5 0.338 14

70BNRX19

75BNRS19

75BNR19 22.6 81 99 100 1 0.5 0.358 15

75BNRX19

80BNRS19

80BNR19 23.4 86 104 105 1 0.5 0.377 16

80BNRX19

85BNRS19

85BNR19 25.7 92 113 115 1 0.6 0.534 24

85BNRX19

90BNRS19

90BNR19 26.5 97 118 120 1 0.6 0.568 24

90BNRX19

95BNRS19

95BNR19 27.3 102 123 125 1 0.6 0.597 23

95BNRX19

100BNRS19

100BNR19 29.5 107 133 135 1 0.6 0.800 31

100BNRX19

D

b

d

a

ra

rb

High-Speed Precision Angular Contact Ball Bearings

15

BNRS10

BNR10

BNRX10

Contact angle 18

Boundary Dimensions Basic Load Ratings

(mm) (N) {kgf}

d D B r r

1

C

r

C

or

C

r

C

or

min min

35 62 14 1 0.6 9 150 5 500 935 560

40 68 15 1 0.6 9 650 6 150 985 630

45 75 16 1 0.6 10 700 6 950 1 090 710

50 80 16 1 0.6 11 200 7 700 1 140 785

55 90 18 1.1 0.6 13 900 9 800 1 420 995

60 95 18 1.1 0.6 14 500 10 700 1 480 1 090

65 100 18 1.1 0.6 15 100 11 600 1 540 1 180

70 110 20 1.1 0.6 20 500 15 200 2 090 1 550

75 115 20 1.1 0.6 20 800 16 000 2 120 1 630

80 125 22 1.1 0.6 24 500 19 000 2 500 1 940

85 130 22 1.1 0.6 24 800 19 900 2 530 2 030

90 140 24 1.5 1 32 500 25 800 3 300 2 630

95 145 24 1.5 1 33 000 26 900 3 350 2 740

100 150 24 1.5 1 33 500 28 000 3 400 2 860

a

D

d

r

r

r

B

r1

D

a

d

a

ra

ra

Material

Inner rings Outer rings Balls

BNRS10 SUJ2 SUJ2 SUJ2

BNR10 SUJ2 SUJ2 Si3N4

BNRX10 SHX SHX Si3N4

ROBUST Series

16

Dynamic Equivalent Load

Nominal

Contact

Angle

C

or

*

iF

a

e

Single, DT DB or DT

X Y X Y X Y X Y

F

a

/F

r

e F

a

/F

r

e F

a

/F

r

>e F

a

/F

r

>e

18 0.57 1 0 0.43 1 1 1.09 0.70 1.63

Static Equivalent Load

Nominal

Contact

Angle

Single, DT DB or DF

X

0

Y

0

X

0

Y

0

18 0.5 0.42 1 0.84

*For i, use 2 for DB and DF and 1 for DT.

Single or DT mounting

when

F

r

>0.5F + Y

0

F

a

use P

0

= F

r

P = XF

r

+ YF

a

P

0

= X

0

F

r

+ Y

0

F

a

Bearing Numbers

Eff. Load Center

Abutment and Fillet Dimensions

Mass Internal Free

(mm)

(mm)

(kg)

a

d

a

D

a

D

b

r

a

r

b

Space

min max max max max

approx (cm

3

/row)

35BNRS10

35BNR10 14.9 41 56 57 1 0.5 0.162 5.3

35BNRX10

40BNRS10

40BNR10 16.3 46 62 63 1 0.5 0.204 7

40BNRX10

45BNRS10

45BNR10 17.7 51 69 70 1 0.5 0.259 8.9

45BNRX10

50BNRS10

50BNR10 18.6 56 74 75 1 0.5 0.281 9.9

50BNRX10

55BNRS10

55BNR10 20.8 62 83 85 1 0.6 0.418 13

55BNRX10

60BNRS10

60BNR10 21.6 67 88 90 1 0.6 0.453 13

60BNRX10

65BNRS10

65BNR10 22.4 72 93 95 1 0.6 0.476 15

65BNRX10

70BNRS10

70BNR10 24.6 77 103 105 1 0.6 0.649 22

70BNRX10

75BNRS10

75BNR10 25.4 82 108 110 1 0.6 0.684 24

75BNRX10

80BNRS10

80BNR10 27.7 87 118 120 1 0.6 0.928 29

80BNRX10

85BNRS10

85BNR10 28.5 92 123 125 1 0.6 0.972 31

85BNRX10

90BNRS10

90BNR10 30.7 99 131 134 1.5 0.8 1.25 41

90BNRX10

95BNRS10

95BNR10 31.5 104 136 139 1.5 0.8 1.3 43

95BNRX10

100BNRS10

100BNR10 32.3 109 141 144 1.5 0.8 1.35 45

100BNRX10

D

b

d

a

ra

rb

High-Speed Precision Angular Contact Ball Bearings

17

BARS10X

Contact angle 30

BTRS10X

Contact angle 40

Boundary Dimensions Basic Load Ratings

(mm) (N) {kgf}

d D 2B r r

1

C

a

C

oa

C

a

C

oa

min min

40 68 27 1 0.6

11 700 17 200 1 200 1 760

14 100 19 600 1 440 2 000

45 75 28.5 1 0.6

13 000 19 500 1 330 1 980

15 600 22 200 1 590 2 260

50 80 28.5 1 0.6

13 600 21 400 1 390 2 190

16 300 24 400 1 660 2 490

55 90 33 1.1 0.6

16 900 27 300 1 720 2 790

20 200 31 000 2 060 3 150

60 95 33 1.1 0.6

17 600 29 800 1 800 3 050

21 100 34 000 2 150 3 450

65 100 33 1.1 0.6

18 300 32 500 1 870 3 300

21 900 37 000 2 230 3 750

70 110 36 1.1 0.6

24 800 42 500 2 530 4 350

29 700 48 500 3 050 4 950

75 115 36 1.1 0.6

25 300 44 500 2 570 4 550

30 000 50 500 3 100 5 150

80 125 40.5 1.1 0.6

29 700 53 000 3 050 5 400

35 500 60 500 3 600 6 150

85 130 40.5 1.1 0.6

30 000 55 500 3 050 5 650

36 000 63 000 3 650 6 450

90 140 45 1.5 1

39 500 72 000 4 000 7 350

47 000 82 000 4 800 8 350

95 145 45 1.5 1

40 000 75 000 4 100 7 650

48 000 85 500 4 900 8 700

100 150 45 1.5 1

40 500 78 500 4 150 8 000

48 500 89 000 4 950 9 050

105 160 49.5 2 1

46 000 89 500 4 700 9 100

55 000 102 000 5 600 10 400

110 170 54 2 1

52 000 102 000 5 300 10 400

62 000 116 000 6 350 11 800

120 180 54 2 1

53 500 110 000 5 450 11 200

64 000 125 000 6 550 12 700

130 200 63 2 1

67 500 133 000 6 850 13 500

80 500 151 000 8 200 15 400

Material

Inner rings Outer rings Balls

BARS10X SUJ2 SUJ2 SUJ2

BTRS10X SUJ2 SUJ2 SUJ2

Note: These bearings are only available in Class 4A tolerance (Tables 1.1 and 1.2, page 10).

ROBUST Series

18

D

b

d

a

rb

r1

r

r

2B

D

d

r1

Bearing Numbers

Abutment and Fillet Dimensions

Mass Internal Free

(mm)

(kg)

d

a

D

b

r

b

Space

min max max

approx

(cm

3

/row)

40BARS10X

50 63 0.5 0.200 6.1

40BTRS10X

45BARS10X

56 70 0.5 0.255 7.4

45BTRS10X

50BARS10X

61 75 0.5 0.272 8

50BTRS10X

55BARS10X

68 84 0.6 0.412 13

55BTRS10X

60BARS10X

73 89 0.6 0.433 12

60BTRS10X

65BARS10X

78 94 0.6 0.472 14

65BTRS10X

70BARS10X

85 104 0.6 0.637 20

70BTRS10X

75BARS10X

90 110 0.6 0.671 21

75BTRS10X

80BARS10X

97 117 0.6 0.912 28

80BTRS10X

85BARS10X

102 122 0.6 0.971 29

85BTRS10X

90BARS10X

109 132 0.8 1.27 40

90BTRS10X

95BARS10X

113.5 137 0.8 1.32 42

95BTRS10X

100BARS10X

119 142 0.8 1.37 43

100BTRS10X

105BARS10X

125 151 1 1.74 56

105BTRS10X

110BARS10X

132 159 1 2.23 67

110BTRS10X

120BARS10X

142 169 1 2.39 72

120BTRS10X

130BARS10X

156 188 1 3.57 110

130BTRS10X

CAT. No. E1221 1999 G -11 Printed in Japan NSK Ltd. 1999

NSK LTD.-Headquarters http://www.nsk.com

Japan: Tokyo

AMERICAS & EUROPE DEPARTMENT Phone: 03-3779-7120

ASIA MARKETING & SALES DEPARTMENT Phone: 03-3779-7121

NSK AMERICAS, INC.

[AMERICAN HEADQUARTERS]

U.S.A.: Ann Arbor Phone: 734-761-9500

NSK CORPORATION

U.S.A.: Ann Arbor Phone: 734-761-9500

[Precision Products Business Unit]

U.S.A.: Chicago Phone: 630-924-8000

[TECHNICAL CENTER]

U.S.A.: Ann Arbor Phone: 734-668-0877

[BRANCHES and DISTRIBUTION CENTERS]

U.S.A.: Los Angeles Phone: 562-926-2975

NASTECH

U.S.A.: Vermont Phone: 802-442-5448

NSK SAFETY TECHNOLOGY, INC.

U.S.A.: Detroit Phone: 248-338-4959

NSK-RHP AMERICAN DISTRIBUTION CENTER, INC.

U.S.A.: Miami Phone: (305) 261-7824

NSK-RHP CANADA INC.

Canada: Toronto Phone: 905-890-0740

NSK RODAMIENTOS MEXICANA, S.A. DE C.V.

Mexico: Mexico City Phone: 5-301-2741

NSK DO BRASIL INDUSTRIA E COMERCIO

DE ROLAMENTOS LTDA.

Brazil: So Paulo Phone: 011-269-4700

NSK-RHP EUROPE LTD. [European Headquarters]

England: Ruddington Phone: 0115-936-6464

NSK-RHP EUROPE LTD. WARSAW LIAISON OFFICE

Poland: Warsaw Phone: 022-645-1525, 1526

NSK BEARINGS EUROPE LTD.

England: Peterlee Phone: 0191-586-6111

NSK-RHP EUROPEAN TECHNOLOGY CO., LTD.

England: Ruddington Phone: 0115-940-5409

NSK-RHP UK LTD.

England: Ruddington Phone: 0115-936-6600

NSK-RHP DEUTSCHLAND GMBH.

Germany: Dsseldorf Phone: 02102-481-0

NSK-RHP FRANCE S.A.

France: Paris Phone: 01 30 57 39 39

NSK-RHP NEDERLAND B.V.

Netherlands: Amsterdam Phone: 020-6470711

NSK-RHP EUROPEAN DISTRIBUTION CENTRE B.V.

Netherlands: Amsterdam Phone: 020-6470711

NSK-RHP ITALIA S.P.A.

Italy: Milano Phone: 02-995191

NSK-RHP IBERICA, S.A.

Spain: Barcelona Phone: 93-575-1662

NSK ISKRA S.A.

Poland: Kielce Phone: 041-366-61-11

NSK-RHP BEARINGS MIDDLE EAST TRADING CO., LTD.

Turkey: Istanbul Phone: 216-463-6150

NSK-RHP SOUTH AFRICA (PTY) LTD.

South Africa: Johannesburg Phone: 011 (458) 3600

NASTECH EUROPE LTD.

England: Coventry Phone: 01203-854500

NSK INTERNATIONAL (SINGAPORE) PTE LTD.

Singapore: Singapore Phone: 2730357

NSK SINGAPORE (PRIVATE) LTD.

Singapore: Singapore Phone: 2781711

NSK-RHP AUSTRALIA PTY. LTD.

Australia: Melbourne Phone: 03-9764-8302

NSK Ltd. has a basic policy not to export any products or technology that have

been designated as controlled items by export related laws.

When exporting such products that are shown in this pamphlet, the laws of the

exporting country must be observed.

For more details, please contact any of the following NSK offices.

Worldwide Manufacturing and Marketing Organization

Specifications are subject to change without notice and without any obligation on the part of the manufacturer. Every care has been taken to ensure accuracy of the data contained

in this catalog, but no liability can be accepted for any loss or damage suffered through errors or omission. We will gratefully acknowledge any additions or corrections.

NSK-RHP BEARINGS NEW ZEALAND LTD.

New Zealand: Auckland Phone: 09-276-4992

NSK BEARINGS (THAILAND) CO., LTD.

Thailand: Bangkok Phone: 02-6412150~58

NSK SAFETY TECHNOLOGY (THAILAND) CO., LTD.

Thailand: Chonburi Phone: (038) 214-317-8

SIAM NASTECH CO., LTD.

Thailand: Chachoengsao Phone: 038-522-343~350

PT. NSK BEARINGS MANUFACTURING INDONESIA

Indonesia: Jakarta Phone: 021-898-0155

NSK BEARINGS (MALAYSIA) SDN. BHD.

Malaysia: Kuala Lumpur Phone: 03-758-4396

NSK MICRO PRECISION (M) SDN. BHD.

Malaysia: Kuala Lumpur Phone: 03-961-6288

RANE NASTECH LTD.

India: Madras Phone: 4114-65313, 65314

Phone: 4114-65365, 66002

NSK KOREA CO., LTD.

Korea: Seoul Phone: 02-3287-0300

NSK-RHP HONG KONG LTD.

China: Hong Kong Phone: 2739-9933

KUNSHAN NSK HS CO., LTD.

China: Kunshan Phone: 0520-7305654

GUIZHOU HS NSK BEARINGS CO., LTD.

China: Anshun Phone: 0853-3521505

TAIWAN NSK PRECISION CO., LTD.

Taiwan: Taipei Phone: 02-2591-0656

NSK REPRESENTATIVE OFFICES

India: Chennai Phone: 044-4334732

China: Beijing Phone: 010-6590-8161~3

RHP BEARINGS LIMITED

England: Newark Phone: 01636-605123

Vous aimerez peut-être aussi

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsD'EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsÉvaluation : 4 sur 5 étoiles4/5 (1)

- NIS Bearing Units Cataloguexsx BgsssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssDocument162 pagesNIS Bearing Units Cataloguexsx BgsssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssEsca Dwi Nugroho33% (3)

- 442Document76 pages442smhcnr88Pas encore d'évaluation

- Timken Corrosion Resistant Deep Groove Ball Bearing Catalog 01 2023 11267 1Document20 pagesTimken Corrosion Resistant Deep Groove Ball Bearing Catalog 01 2023 11267 1Đỗ Xuân TùngPas encore d'évaluation

- Fyh Unit Bearings Catalog 3310 Us89Document1 pageFyh Unit Bearings Catalog 3310 Us89rozzaq dhmgroupPas encore d'évaluation

- VCP A11-0507Document32 pagesVCP A11-0507Dan PascaruPas encore d'évaluation

- Bearing Design CalculationsDocument42 pagesBearing Design Calculationsarunurs1100% (1)

- EXCEL High Performance Parts For GP Cone-CrusherDocument4 pagesEXCEL High Performance Parts For GP Cone-CrusherGires TochePas encore d'évaluation

- Ball Screw B3115eDocument6 pagesBall Screw B3115eseregePas encore d'évaluation

- Backstop P84-CN-110930Document116 pagesBackstop P84-CN-110930Alice SunPas encore d'évaluation

- SNT Plummer Block Mini Catalog 1Document44 pagesSNT Plummer Block Mini Catalog 1Anonymous y4YLeR2mUPas encore d'évaluation

- Super Precision Bearing PDFDocument204 pagesSuper Precision Bearing PDFMikel1020Pas encore d'évaluation

- Power LockDocument88 pagesPower Lockash remoPas encore d'évaluation

- NSK Ball BearingDocument42 pagesNSK Ball BearingJeya Vijaya Naveen VijayPas encore d'évaluation

- ABT Precision Bearings CatalogDocument56 pagesABT Precision Bearings CatalogEduardo RateikePas encore d'évaluation

- NSK Electrically Insulated Bearings 1306Document2 pagesNSK Electrically Insulated Bearings 1306Leroy AraoPas encore d'évaluation

- Top Drive Spare Parts Catalog-2023Document11 pagesTop Drive Spare Parts Catalog-2023dove4suppliesPas encore d'évaluation

- Deep Groove Ball BearingDocument32 pagesDeep Groove Ball BearingFernando PadillaPas encore d'évaluation

- FYH ZK - EnglishDocument17 pagesFYH ZK - EnglishRicardo TurlaPas encore d'évaluation

- SKF ConCentra Ball BearingDocument40 pagesSKF ConCentra Ball BearingdaviqperezPas encore d'évaluation

- Us - Tsubaki - Sprocket - Catalog 2Document199 pagesUs - Tsubaki - Sprocket - Catalog 2Jairo Andrés FAPas encore d'évaluation

- SNT Plummer Block CatalogDocument120 pagesSNT Plummer Block CatalogRickson PhilipPas encore d'évaluation

- Automatic Injection Pump 038 130 107 J PDFDocument6 pagesAutomatic Injection Pump 038 130 107 J PDFJavi Rodríguez HermidaPas encore d'évaluation

- Taneks Deutz CatalogueDocument123 pagesTaneks Deutz CatalogueeCommerce SAJID AutoPas encore d'évaluation

- FYH New Stainless - EnglishDocument16 pagesFYH New Stainless - EnglishRicardo TurlaPas encore d'évaluation

- Barford TR5048 Manual + Parts List 2021 WITH MULCHDocument62 pagesBarford TR5048 Manual + Parts List 2021 WITH MULCHpggmarquesPas encore d'évaluation

- CTP Water PumpsDocument4 pagesCTP Water PumpsMert KaygusuzPas encore d'évaluation

- Listado de Grasas y Aceites CATDocument11 pagesListado de Grasas y Aceites CATJonnyMonroyPas encore d'évaluation

- Archer Octubre 2019 - VendedoresDocument4 pagesArcher Octubre 2019 - VendedoresLARRY MENDEZPas encore d'évaluation

- Bringing valuable water solutions to various applicationsDocument32 pagesBringing valuable water solutions to various applicationsAhmadMoaazPas encore d'évaluation

- Stieber Clutches Maincatalog en 2010Document92 pagesStieber Clutches Maincatalog en 2010Alice SunPas encore d'évaluation

- Spinning Into Infinity: Sales Catalogue - BearingsDocument113 pagesSpinning Into Infinity: Sales Catalogue - BearingsBlashko GjorgjievPas encore d'évaluation

- Timken Fafnir Super Precision Bearings For Machine Tool Applications - 5918 PDFDocument252 pagesTimken Fafnir Super Precision Bearings For Machine Tool Applications - 5918 PDFEdwin RodriguezPas encore d'évaluation

- Unirol CatalogDocument22 pagesUnirol CatalogDerlan MarzelaPas encore d'évaluation

- KMP Brand 2017 Starter Motors and Alternators Catalogue (Agricultural Division)Document2 pagesKMP Brand 2017 Starter Motors and Alternators Catalogue (Agricultural Division)Андрей Кулешов0% (1)

- Metal Polymer Bearings General CatalogDocument95 pagesMetal Polymer Bearings General Catalogwe427Pas encore d'évaluation

- Bearing Housing Data WeightDocument20 pagesBearing Housing Data Weightgoelabhishek90Pas encore d'évaluation

- Bombas Peerless FarecoDocument12 pagesBombas Peerless Farecoac030476Pas encore d'évaluation

- 6 Different Excavator Types & Their Uses - BigRentzDocument11 pages6 Different Excavator Types & Their Uses - BigRentzShuvoVattPas encore d'évaluation

- Shaft Mounted Speed Reducers SMSR & SMSR Plus SeriesDocument32 pagesShaft Mounted Speed Reducers SMSR & SMSR Plus SeriesAmit KumarPas encore d'évaluation

- WCB Cross Roller Ladle Turret Tower Crane Slewing Bearings CatalogDocument56 pagesWCB Cross Roller Ladle Turret Tower Crane Slewing Bearings CatalogWCB BEARINGPas encore d'évaluation

- Grid-Lign Fl4011 1209 WebDocument2 pagesGrid-Lign Fl4011 1209 WebRenzo Jo LaurentPas encore d'évaluation

- Sumitomo HGJJKKDocument1 pageSumitomo HGJJKKDilan MarvePas encore d'évaluation

- Barden/Fag Cronidur® 30 Hybrid Spindle BearingsDocument2 pagesBarden/Fag Cronidur® 30 Hybrid Spindle BearingssgwilliamsPas encore d'évaluation

- GGB CatalogueDocument35 pagesGGB CatalogueRajaSekarsajjaPas encore d'évaluation

- Estimasi b13.02Document3 pagesEstimasi b13.02JujuPas encore d'évaluation

- Misumi Spring Catologue PDFDocument1 pageMisumi Spring Catologue PDFAkshay JagdalePas encore d'évaluation

- Maximum Retail Price List: Moving The Wheels of IndustryDocument22 pagesMaximum Retail Price List: Moving The Wheels of IndustryAlexander David Pino SalazarPas encore d'évaluation

- Guia de Intecambio de FabricantesDocument20 pagesGuia de Intecambio de FabricantesDavid DelgadoPas encore d'évaluation

- Insert Ball BearingsDocument26 pagesInsert Ball BearingsJason ZhouPas encore d'évaluation

- Catalogue Amp 1000Document52 pagesCatalogue Amp 1000wasco plant100% (1)

- DCW - Zoomlion Technical Specs of 6m3 Truck Mixer PDFDocument8 pagesDCW - Zoomlion Technical Specs of 6m3 Truck Mixer PDFjacques Perron0% (1)

- Timken Deep Groove Ball Bearings Catalog 10857Document32 pagesTimken Deep Groove Ball Bearings Catalog 10857dunghtvcPas encore d'évaluation

- Journal BearingDocument7 pagesJournal BearingNur AfifahPas encore d'évaluation

- Cojinetes de Generador Renk Manual de AplicacionesDocument39 pagesCojinetes de Generador Renk Manual de AplicacionesMiguel Angel PoncePas encore d'évaluation

- Journal BearingDocument7 pagesJournal BearingFarhan TalibPas encore d'évaluation

- Waukesha Bearings - Modular TPT Bearings - MS - A4Document32 pagesWaukesha Bearings - Modular TPT Bearings - MS - A4rafay0saeedPas encore d'évaluation

- Bnr/Ber Robust Series: High-Speed Precision Angular Contact Ball Bearings For Machine Tool SpindlesDocument16 pagesBnr/Ber Robust Series: High-Speed Precision Angular Contact Ball Bearings For Machine Tool SpindlesMEPRO Chiriac C.Pas encore d'évaluation

- E 1236Document7 pagesE 1236LLPas encore d'évaluation

- Journal Bearing LubricationDocument5 pagesJournal Bearing LubricationYorman Hernandez100% (1)

- Ilchmann GMBH EDocument6 pagesIlchmann GMBH ELLPas encore d'évaluation

- IEEE1068 Repair & Rewinding of MotorsDocument28 pagesIEEE1068 Repair & Rewinding of MotorsjojeecaresPas encore d'évaluation

- FACOM - Hand Tools - 2004Document899 pagesFACOM - Hand Tools - 2004Евгений АнатольевичPas encore d'évaluation

- Mam71 Prod Ref GuideDocument167 pagesMam71 Prod Ref Guidee305050Pas encore d'évaluation

- Heat LineDocument1 pageHeat LineLLPas encore d'évaluation

- Lubrication Guide - Ultrasonic Condition-Based LubricationDocument7 pagesLubrication Guide - Ultrasonic Condition-Based LubricationLLPas encore d'évaluation

- KVR UkDocument4 pagesKVR UkLLPas encore d'évaluation

- Ingersoll CAT-009 HoleM TechDocument30 pagesIngersoll CAT-009 HoleM TechLLPas encore d'évaluation

- Goodyear Hydraulics Adapters Catalog PDFDocument165 pagesGoodyear Hydraulics Adapters Catalog PDFpsolutions.franciscoPas encore d'évaluation

- Falk Metric Key KeywayDocument2 pagesFalk Metric Key KeywayMAXPas encore d'évaluation

- Master Gears UsaDocument6 pagesMaster Gears UsaLLPas encore d'évaluation

- FACOM - Hand Tools - 2004Document899 pagesFACOM - Hand Tools - 2004Евгений АнатольевичPas encore d'évaluation

- Material Grades EN PDFDocument30 pagesMaterial Grades EN PDFnechitamariusPas encore d'évaluation

- l0820300 Stacker Reclaimer ChainsDocument2 pagesl0820300 Stacker Reclaimer ChainsLLPas encore d'évaluation

- GBSP 47Document3 pagesGBSP 47LLPas encore d'évaluation

- Hardox Uk 400Document2 pagesHardox Uk 400Jackson VuPas encore d'évaluation

- Motor bearings: understanding common problems and proper handlingDocument8 pagesMotor bearings: understanding common problems and proper handlinghozipek5599100% (1)

- Price List - Fluke Precision Measurements - End Users - October 2006Document29 pagesPrice List - Fluke Precision Measurements - End Users - October 2006LLPas encore d'évaluation

- Standard - Manual - Low - Voltage - EN Rev G Web PDFDocument26 pagesStandard - Manual - Low - Voltage - EN Rev G Web PDFTuấn Anh CaoPas encore d'évaluation

- Installation, Operation and Maintenance Manual for Ex d Asynchronous MotorsDocument101 pagesInstallation, Operation and Maintenance Manual for Ex d Asynchronous MotorsberkahharianPas encore d'évaluation

- Motor bearings: understanding common problems and proper handlingDocument8 pagesMotor bearings: understanding common problems and proper handlinghozipek5599100% (1)

- Standard - Manual - Low - Voltage - EN Rev G Web PDFDocument26 pagesStandard - Manual - Low - Voltage - EN Rev G Web PDFTuấn Anh CaoPas encore d'évaluation

- Motor Donot Just Fail... Do They - A Guide To Preventing FailureDocument70 pagesMotor Donot Just Fail... Do They - A Guide To Preventing FailuresurawutwijarnPas encore d'évaluation

- Llo See DD Gts v3 W en 02Document428 pagesLlo See DD Gts v3 W en 02LLPas encore d'évaluation

- IEEE1068 Repair & Rewinding of MotorsDocument28 pagesIEEE1068 Repair & Rewinding of MotorsjojeecaresPas encore d'évaluation

- Automatic Oil Bath Air FilterDocument22 pagesAutomatic Oil Bath Air FilterLLPas encore d'évaluation

- BG70 SNDocument2 pagesBG70 SNLLPas encore d'évaluation

- Din 6885Document1 pageDin 6885Riadini Anis Hade50% (2)

- SteelsDocument72 pagesSteelsLLPas encore d'évaluation

- TST18 MLE Install Brochure LRDocument24 pagesTST18 MLE Install Brochure LRLLPas encore d'évaluation

- Plate Bending Element Formulation and Stiffness Matrix DevelopmentDocument6 pagesPlate Bending Element Formulation and Stiffness Matrix DevelopmentSeyhan ÖzenPas encore d'évaluation

- A Study of The Effect of Blasting Vibration On Green ConcreteDocument160 pagesA Study of The Effect of Blasting Vibration On Green ConcreteNattHemat HulinPas encore d'évaluation

- Expt 01Document10 pagesExpt 01Kathleen De Vera BarrilPas encore d'évaluation

- How retinal adaptation maintains visual perception despite illumination changesDocument1 pageHow retinal adaptation maintains visual perception despite illumination changesAkicaPas encore d'évaluation

- Pore Structure of Air-Entrained Hardened Cement PasteDocument9 pagesPore Structure of Air-Entrained Hardened Cement Paste1mattelliottPas encore d'évaluation

- Mathematics - Ijmcar - An Approach For Continuous Method For The GeneralDocument12 pagesMathematics - Ijmcar - An Approach For Continuous Method For The GeneralTJPRC PublicationsPas encore d'évaluation

- WBUT Btech 2nd Sem 2011 ThemodynamicsDocument7 pagesWBUT Btech 2nd Sem 2011 ThemodynamicsBapi SarkarPas encore d'évaluation

- OAT Bootcamp Physics Equation Sheet PDFDocument11 pagesOAT Bootcamp Physics Equation Sheet PDFjon100% (2)

- Refraction Through Spherical Surfaces and LensesDocument2 pagesRefraction Through Spherical Surfaces and LensesOrbit MBBS PreparationPas encore d'évaluation

- Culvert DesignDocument18 pagesCulvert Designseagull700% (1)

- Molecular Partition Function ExplainedDocument18 pagesMolecular Partition Function ExplainedAnimasahun Olamide HammedPas encore d'évaluation

- Chapter 3 Linear KinematicsDocument26 pagesChapter 3 Linear KinematicsKuldeep SinghPas encore d'évaluation

- Stepper Motor Driven Solar Tracker SystemDocument4 pagesStepper Motor Driven Solar Tracker SystemFAHMY RINANDA SAPUTRI (066629)Pas encore d'évaluation

- Working of Steam Turbines and Its AuxillariesDocument48 pagesWorking of Steam Turbines and Its AuxillariesbalajigandhirajanPas encore d'évaluation

- MCAT Formula SheetDocument3 pagesMCAT Formula SheetYank AzharPas encore d'évaluation

- Ansys Fluent 12.0 Theory Guide - 7.1Document3 pagesAnsys Fluent 12.0 Theory Guide - 7.1Tg DgPas encore d'évaluation

- A AjouterDocument3 pagesA Ajouter00JoPas encore d'évaluation

- Ansys APDLDocument3 pagesAnsys APDLradhePas encore d'évaluation

- Synperonic EthoxylatesDocument2 pagesSynperonic Ethoxylatesjacky ye100% (1)

- Diaphragm Design PDFDocument50 pagesDiaphragm Design PDFManoj JaiswalPas encore d'évaluation

- Laser Dismantling of PHWR Spent Fuel Bundles and De-Cladding of Fuel Pins in The Highly Radioactive Hot CellsDocument6 pagesLaser Dismantling of PHWR Spent Fuel Bundles and De-Cladding of Fuel Pins in The Highly Radioactive Hot CellsK. JayarajanPas encore d'évaluation

- Particulate Matter Sampling PDFDocument62 pagesParticulate Matter Sampling PDFAshitPas encore d'évaluation

- Sample Lesson Plan in Science V Using Explicit InstructionDocument6 pagesSample Lesson Plan in Science V Using Explicit InstructionKrimson Mike DolorzoPas encore d'évaluation

- POMFriction AssessmentDocument11 pagesPOMFriction AssessmentJoãoAraújoPas encore d'évaluation

- Mijlocul Cerului in SinastrieDocument2 pagesMijlocul Cerului in SinastrieKali KaliPas encore d'évaluation

- ACET208 Theodolite PresentationDocument6 pagesACET208 Theodolite Presentationsilverm_4Pas encore d'évaluation

- Ising ModelDocument5 pagesIsing Modeldecerto252Pas encore d'évaluation

- Gujarat Technological University: W.E.F. AY 2018-19Document3 pagesGujarat Technological University: W.E.F. AY 2018-19SURAJ NAKUMPas encore d'évaluation

- Probe PH Meter Ultraglass For Orion STARA2115Document33 pagesProbe PH Meter Ultraglass For Orion STARA2115chaerul.anwar554Pas encore d'évaluation

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideD'EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideÉvaluation : 2 sur 5 étoiles2/5 (1)

- Fire in the Night: The Piper Alpha DisasterD'EverandFire in the Night: The Piper Alpha DisasterÉvaluation : 4.5 sur 5 étoiles4.5/5 (5)

- Asset Integrity Management for Offshore and Onshore StructuresD'EverandAsset Integrity Management for Offshore and Onshore StructuresPas encore d'évaluation

- Flow Analysis for Hydrocarbon Pipeline EngineeringD'EverandFlow Analysis for Hydrocarbon Pipeline EngineeringPas encore d'évaluation

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryD'EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryPas encore d'évaluation

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionD'EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionÉvaluation : 4.5 sur 5 étoiles4.5/5 (16)

- Industrial Piping and Equipment Estimating ManualD'EverandIndustrial Piping and Equipment Estimating ManualÉvaluation : 5 sur 5 étoiles5/5 (7)

- Pipeline Integrity: Management and Risk EvaluationD'EverandPipeline Integrity: Management and Risk EvaluationÉvaluation : 4.5 sur 5 étoiles4.5/5 (6)

- Well Control for Completions and InterventionsD'EverandWell Control for Completions and InterventionsÉvaluation : 4 sur 5 étoiles4/5 (10)

- Pocket Guide to Flanges, Fittings, and Piping DataD'EverandPocket Guide to Flanges, Fittings, and Piping DataÉvaluation : 3.5 sur 5 étoiles3.5/5 (22)

- Risk Management in the Oil and Gas Industry: Offshore and Onshore Concepts and Case StudiesD'EverandRisk Management in the Oil and Gas Industry: Offshore and Onshore Concepts and Case StudiesPas encore d'évaluation

- Black Gold Stranglehold: The Myth of Scarcity and the Politics of OilD'EverandBlack Gold Stranglehold: The Myth of Scarcity and the Politics of OilPas encore d'évaluation

- Deepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology ApplicationD'EverandDeepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology ApplicationÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Hydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisD'EverandHydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisPas encore d'évaluation

- Practical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsD'EverandPractical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsÉvaluation : 5 sur 5 étoiles5/5 (1)

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesD'EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesÉvaluation : 4 sur 5 étoiles4/5 (2)

- Oil & Gas Design Engineering Guide Book: Useful Practices and Equipment & SystemsD'EverandOil & Gas Design Engineering Guide Book: Useful Practices and Equipment & SystemsPas encore d'évaluation

- Subsea Valves and Actuators for the Oil and Gas IndustryD'EverandSubsea Valves and Actuators for the Oil and Gas IndustryÉvaluation : 5 sur 5 étoiles5/5 (1)

- Petroleum Rock Mechanics: Drilling Operations and Well DesignD'EverandPetroleum Rock Mechanics: Drilling Operations and Well DesignÉvaluation : 5 sur 5 étoiles5/5 (1)

- Compression Machinery for Oil and GasD'EverandCompression Machinery for Oil and GasKlaus BrunÉvaluation : 4 sur 5 étoiles4/5 (4)