Académique Documents

Professionnel Documents

Culture Documents

Condition Monitoring Ensures Against Mechanical Failure

Transféré par

LLCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Condition Monitoring Ensures Against Mechanical Failure

Transféré par

LLDroits d'auteur :

Formats disponibles

Technical Paper

CM1006

SKF Reliability Systems

The advent of miniaturized

electronics to the field of

machinery condition monitoring

has led to efficiency and avoidance

of costly failures only imagined a

decade ago. The premium for

such insurance is becoming more

and more justifiable.

The difference between an efficient profit

generating machine and an expensive

wreck may be only 0.25mm about the

thickness of a fingernail.

That is typical of the clearances between

steam turbine blades and diaphragms that

allows energy to be extracted from

superheated, high-pressure steam to turn

generators and produce condensed steam,

which is returned to the boiler to start the

cycle over. The smaller the internal

clearances, the higher the efficiency but

the greater the risk of catastrophic contact

between rotating and stationary parts. This

risk can be worth over US $500,000 per

day on a 600 MW unit, so the premium

for insurance like machinery condition

monitoring should be easy to justify.

Rotor Motion Required and

Undesirable

A perfect rotor would rotate round a

pinpoint within its bearings, and there

would be no:

1) Lateral (radial) motion

2) Axial (longitudinal) motion

3) Torsional (circular pulsing) motion

These undesirable motions are always

present because perfect rotors do not exist

Condition Monitoring Ensures

Against Mechanical Failure

but as long as they remain within tolerance,

the machine operates within design

efficiency.

Radial Vibration

Increasing radial vibration causes seal and

bearing wear, reducing efficiency. Internal

clearances are no longer as designed so

more energy is wasted. Increased bearing

clearances allow more motion of the rotor

relative to the machine case, ultimately

allowing contact between rotor parts and

casing. Non-contacting displacement

probes mounted in, or adjacent to, the

bearings can monitor this shaft relative

motion precisely.

Axial Motion

Axial motion is typically controlled by

balance pistons or drums, which essentially

equalize pressures throughout a machine.

Thrust bearings absorb normal axial loads

and non-contacting eddy current probes

monitor the axial position of the rotor

relative to the thrust bearing. Excess axial

motion allows blading to strike

diaphragms, and can cause the thrust

bearing to fail. Thrust bearing failure can

occur in seconds and cause a total loss of

the machine.

Torsional Motion

If the combined load and excitation torque

exceed the torsional stress limits of a shaft

or coupling, the shaft can crack and twist-

off in a very recognizable manner.

Frequent electric motor start-ups can cause

torsional failure. Motors generate torsional

vibration at two and four times running

speed.

Other Effects of Rotor Created

Vibration

Even if these undesirable shaft motions are

www.skf.com/reliability

Condition Monitoring Ensures Against Mechanical

Failure

2

below danger limits, they rob energy from the mechanical

system. Additionally, the energy input to the mechanical

system by rotor vibration can loosen bolts, crack

foundations and casing, cause fatigue in piping and (by

transmission through piping and foundations) even damage

the bearings of stationary machines.

Transmitted vibration, which is the response of the system

to input forces generated by shaft displacement, must be

measured with velocity or acceleration transducers mounted

on bearing caps or casings.

Typical Causes

The most common causes of radial vibration are changes in

dynamic balance, coupling misalignment, bearing

instabilities, loose rotor component and bearing parts.

Slow changes in axial position can typically be attributed to

Very Flexible

Bearing Pedestals and

Foundations

High

Bearing Stiffness Low

Casing: Bearing Cap

Seismic (Absolute)

Velocity Pick-Ups Accelerometers

Preferred (API 678)

Bearing Type?

No

Shaft Absolute

Shaft Riders: Accelerometers

and Displacement Probes (Latter

Preferred)

Barrel Compressors Mechanical Drive

Steam Turbines;

Large Motors Pumps;

Package Centrifugal Compressors;

Reciprocating Compressors (Rod Drop)

Shaft Relative

Non-Contacting Displacement

Probes (API 670)

Large Gas Turbines;

Gear Boxes;

Large Fans (FD and ID);

Boiler Feed Pumps (HP)

Large Steam Turbine Generators;

Reactor Coolant Pumps;

Some Gas Turbines (With Damper

Bearings)

Small Gas Turbines;

Small Pumps and Fans;

Hot Gas Expanders;

Cooling Tower Fans

High Casing/Rotor Weight Ratios;

High Damping;

Low Transmissibility

Low Damping:

High Transmissibility

Sleeve Rolling Element

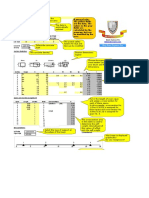

Figure 1. Machinery vibration transducer selection by machinery tape.

thrust bearing and surging and other process changes such

as flow reversal, water slugging, etc.

Machinery Condition Monitoring

The number one requirement of any monitoring project is

the correct placement of the proper transducer for the job.

This requires a basic knowledge of the machines

construction and an understanding of mechanical

transmissibility.

The flow chart (Figure 1) shows that bearing type and

casing-to-rotor weight ratios are the main controlling factors

in the correct choice of transducers. The stiffer thebearing

and the lower the damping, the higher is the transmissibility.

This dictates the use of bearing cap or casing

measurements, which reflect the response of the mechanical

system to input forces from the rotor. Such measurements

www.skf.com/reliability

Condition Monitoring Ensures Against Mechanical

Failure

3

are made with velocity pickups or accelerometers,

depending on the frequency range to be covered. Velocity

pickups typically are limited to vibration frequencies below

2,000 Hz.

Accelerometers are favored over velocity transducers

because of their better frequency response, ruggedness and

price and are preferred by API (American Petroleum

Institute) 678 standards. Rolling element bearings are a

special case of the high transmissibility system, and

accelerometers are useful in detecting small high frequency

signals that are often early warning of internal damage

(Figure 2).

On machines with plain bearings, high casing to rotor

weight ratios and high damping, the non-contacting

displacement probe measures the actual motion of the shaft

relative to the bearing the direction as well as the amount

(Figure 3).

In many cases, both types of transducers should be

employed, because displacement probes respond better than

accelerometers to forces generated by rotor vibrations close

to running speed, whereas casing mounted accelerometers

respond better than displacement probes to the high

frequency forces generated by turbine blades, pump vanes,

gear meshing, etc.

An important third case is that of shaft absolute

measurements. When the displacement probe is mounted in

Accelerometer

Signal Out

A

1 REV

1 REV

Eddy Probes

Signal Out

A

Driver

Driver

Figure 2. Accelerometer used to measure bearing cap motion. Figure 3. Eddy Current Probe used to measure shaft relative motion.

Figure 4. SKF Condition Monitoring M800A monitor keeps track of

turbine RPM, bearing clearances, shaft vibration, thrust, etc.

a bearing, it must be assured the bearing is stable so the

measured shaft relative motion is a fair assessment of the

motion of the rotor relative to the casing. If the bearing

pedestal is moving appreciably in response to forces from

the rotor, there may not be much shaft relative motion to

measure, but motion of the rotor relative to the casing could

be very high. This is often the case with large turbine/

generators and certain designs of boiler feed pumps, and the

internal clearances must be protected by measuring shaft

absolute motion. The preferred way of doing this is to use

displacement probes to measure shaft relative motion and

accelerometers to measure-bearing motion the two signals

are normalized and algebraically summed up in a special

monitor (Figure 4). Shaft absolute measurements were in

www.skf.com/reliability

Condition Monitoring Ensures Against Mechanical

Failure

Casing

Expansion

Key Phasor

Eccentricity

H.P. / I.P. L.P.

Front Standard

Front View of Sliding Feet on

Front Standard

Condenser

Generator

Excitor

Valve Position

Transducer

Differential

Expansion

Figure 5. Typical block diagram of a steam turbine showing turbine supervisory transducer positions.

fact the first vibration measurements taken, and were made

using a Shaft Rider that was, in effect, a plunger riding on

the shaft periphery with a velocity pickup mounted on the

other end.

Special Measurements for Large Steam

Turbine Generators

For maximum efficiency, steam turbine internal clearances

are in the order of 0.125mm 0.750mm radial and 2.500mm

12.500mm axial. Maintaining these clearances during the

tremendous temperature changes of start-up and shutdown

requires special monitoring circuits and transducers.

ECCENTRICITY

First the shaft is so heavy that at rest, it takes on a bend or

bow which must straighten before certain speeds are

reached, or radial rubs occur. The amount of this bow is

monitored by an eddy current probe that measures the peak-

to-peak motion of a small disc, mounted outboard of the

number 1 bearing (Figure 6).

CASING EXPANSION

Turbine casings are pinned to their foundations by the

footing surrounding the exhaust hood. When superheated

4

Driver

Signal Out

Front Standard

Thrust

Bearing

Radial

Bearing

Eccentricity

Wheel

Figure 6. Measurement of shaft eccentricity; the amount of bow or

"bend" in the shaft.

www.skf.com/reliability

Condition Monitoring Ensures Against Mechanical

Failure

5

Figure 7a. Measurement of differential expansion: A perpendicular

collar on the shaft is observed by a long range probe.

Signal

Out

Driver

Comparing

Amp

Driver

Driver

Driver

Driver

Summing

Amp

Figure 7b. Measurement of differential expansion: Complementary

probes method favored by General Electric (USA).

steam enters the casings, they expand by up to 25mm or

more. The front standard (including the thrust bearing and

front bearing assembly) are keyed to the foundation on

sliding feet, to allow expansion without buckling the casing.

To ensure this movement occurs correctly, an LVDT

transducer is mounted to the foundations with its plunger

fastened to the front standard (Figure 5).

DIFFERENTIAL EXPANSION

During start-up the rotor must expand at the same rate as the

casing to prevent axial rubs. Depending on the design of the

turbine, there are currently three ways to monitor

differential expansion, all using eddy current probes.

Figure 7a, shows a long-range probe observing a

perpendicular collar on the shaft.

Figure 7b, shows two normal range probes (25mm)

observing a perpendicular target so that it is never out of

range of one or the other probes (typical of General Electric

(USA) turbines).

Figure 7c, shows the ramp method (typical of Westinghouse

turbines) where the range of the probes is artificially

amplified by the ramp. All of these methods have some

serious drawbacks, and other methods are being pursued so

that accuracy will not suffer so much from temperature,

environment, radial shaft movement, etc.

VALVE POSITION INDICATION

To determine how much steam is being fed to the turbine, a

rotary potentiometer is used to measure the position of the

cam that operates the steam control valve (on GE units).

Westinghouse units usually require individual transducers

Figure 7c. Measurement of differential expansion: Ramp method

favored by Westinghouse.

for each governor valve (up to eight), and the output of each

potentiometer is gauged with the others to provide a

percentage of total valve openings.

SPEED, PHASE AND RATE OF CHANGE OF SPEED

Speed is best measured by an eddy current probe that

observes a notch on the shaft, usually referred to as a one-

per-rev event (Figure 8). A speed monitor automatically

converts this to rev/min and the same signal serves as a

fixed reference point on the shaft to measure the phase or

direction of the vibration. This is essential for dynamically

www.skf.com/reliability

Condition Monitoring Ensures Against Mechanical

Failure

6

balancing turbines, and also assists in the

diagnosis of mechanical problems. Rate of

change of speed is also derived from the

same signal, and is necessary to maintain the

maximum permissible start-up rates and

provide smooth transmission from soak-

point to soak-point.

OTHER NECESSARY MEASUREMENTS

Bearing metal temperatures, thrust position,

lube oil pressures and temperatures

(absolute and differential) are advisable on

all machinery and no less so on large steam

turbines. The value of these measurements

is multiplied synergistically when combined

with vibration, phase, etc., for

troubleshooting and control.

DATA ACQUISITION, ANALYSIS AND DISPLAY

Once the correct transducers are in place, the

choice of information usage and display

become part of the operating philosophy of

the plant. If simple manual control by the

operator is all that is required, then a rack of standard

monitors is sufficient. This monitor rack provides clear

visual indication of present status, and can give audible and

visual alarms, or even automatic shutdown, when acceptable

levels are exceeded. Tape recorders, balance analyzers and

spectrum analyzers can be easily connected to the signals

via buffered front panel outputs.

Due to the shortage of control panel space, and the fact that

individual meters are expensive and only used on rare

occasions, more advanced microprocessor controlled

devices that print out records of alarms, store history and

compute trends are coming into general usage. Such

devices typically manage multiple channels of mixed inputs

in a very compact volume and are much less expensive on a

per channel basis than standard monitors.

Modern machinery monitoring systems, such as the

powerful SKF Condition Monitoring M800A system have

standard computer interfaces that allow connection to

process control systems and/or desktop computers for

machinery information, analysis, and reporting. The

M800A system also contains embedded spectrum modules

for fast fourier transform monitoring and alarm windowing.

Combined with the desktop-based machinery diagnostic

workstations, this capability provides the most powerful

condition monitoring package available.

A typical system provides protection, analysis and diagnosis

over 1,000 channels. The computer and spectrum

1 REV

Signal Out

Eddy Probe

Key Phasor Notch

Driver

Figure 8. Key phasor signal generation; an eddy probe observes the key phasor notch on

the shaft to measure speed, rate of change of speed and phase.

monitoring modules work together to perform high-speed

on-line spectrum monitoring, comparison and analysis.

Every 5-12 seconds, the vibration signals are analyzed,

compared to baseline, and a warning issued if the spectrum

has changed. This is a very sensitive method of detecting

mechanical problems, sometimes months before they

become serious. Valuable start-up and coast-down data can

also be taken automatically by such systems, and the data

post-processed for a variety of different displays that

provide different insights. Such systems can be viewed as

resident machinery analysts in plant control rooms, 24

hours a day, every day.

The Future

Although the origins of machinery condition monitoring can

be traced back several decades, it really only started as a

viable technology about 30 years ago, with the introduction

of reliable transducers, especially non-contacting

displacement probes. API 670 (the first industrial standard

for vibration monitoring) was published in 1976 and laid

down basic standards for transducer and monitor accuracies

and reliabilities, installation practice and voting logic

considerations so that nuisance alarms were reduced to a

minimum and industry could entrust automatic shutdown of

expensive processes to this relatively unfamiliar technology.

Since the advent of microprocessors and electronic

memories, machinery condition monitoring can encompass

mechanical vibration, process parameters, efficiency

SKF Reliability Systems

5271 Viewridge Court

San Diego, California 92123

USA

Telephone (+1) 858-496-3400

FAX (+1) 858-496-3531

Web: www.skf.com/reliability

Although care has been taken to

assure the accuracy of the data

compiled in this publication, SKF

does not assume any liability for

errors or omissions. SKF

reserves the right to alter any part

of this publication without prior

notice.

SKF is a registered trademark

of SKF.

All other trademarks are the

property of their respective

owners.

CM1006 (Revised 6-04)

Copyright 2004 by

SKF Reliability Systems

ALL RIGHTS RESERVED

"Condition

Monitoring

Ensures Against

Mechanical

Failure"

calculations and diagnostic capability that

was only imagined a decade ago.

As with most problems in a competitive

free market system, machinery

manufacturers are self-regulating and must

cure the problems to stay in business. To

assist the process, organizations such as the

API (American Petroleum Institute) write

standards not only for machinery condition

monitoring equipment, but for various

types of machinery. For example, API 617

deals with centrifugal compressor design

and sets standards for rotor unbalance and

other vibration. More importantly, API

617 sets limits on the rotor Amplification

Factor at critical speeds. This in effect

sets limits on maximum response, or

conversely minimum damping in the rotor

bearing system.

This is a very significant step, because less

damping means higher efficiency the goal

of the designer. But the users goal is also

reliability, and API 617 (and its steam

turbine equivalent API 612) is essentially

telling designers that efficiency must be

compromised in the interests of reliability.

The Electrical Power Research Institute

(EPRI), a nonprofit organization in Palo

Alto, California, funded by utilities in the

USA, has a charter to finance and manage

research projects on behalf of the power

generation industry. An increasing number

of their projects are now concerned with

machinery condition monitoring and design

improvements that can result from these

studies. Recommendations on monitoring

boiler feed pumps, study programs on

hydroturbines and vertical pumps,

evaluation of computerized vibration

analysis and diagnosis systems, and most

recently, a study on how to detect cracks in

shafts are some of the condition monitoring

related programs that have been funded.

Insurance companies such as Travelers and

Hartford Steam Boiler not only have a

vested interest in vibration technology, but

use it themselves for surveying clients

machinery.

The interest of these organizations is vital

considering most power generation plants

are well over 30 years old and run at 65 per

cent availability, compared to over 90 per

cent in the hydrocarbon processing

industries. Their efforts to improve and

ensure machinery availability constitutes

not only an investment in vibration

measurement but an affirmation that the

technology does work, and has a

measurably healthy return on investment

by protecting those few hundredths of a

millimeter between turbine blades whirling

at transonic speeds and a motionless

casing.

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Master Gears UsaDocument6 pagesMaster Gears UsaLLPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- IEEE1068 Repair & Rewinding of MotorsDocument28 pagesIEEE1068 Repair & Rewinding of MotorsjojeecaresPas encore d'évaluation

- IEEE1068 Repair & Rewinding of MotorsDocument28 pagesIEEE1068 Repair & Rewinding of MotorsjojeecaresPas encore d'évaluation

- Motor bearings: understanding common problems and proper handlingDocument8 pagesMotor bearings: understanding common problems and proper handlinghozipek5599100% (1)

- Motor bearings: understanding common problems and proper handlingDocument8 pagesMotor bearings: understanding common problems and proper handlinghozipek5599100% (1)

- Defects and Discontinuities GuideDocument68 pagesDefects and Discontinuities GuideRahulKumarPas encore d'évaluation

- Lubrication Guide - Ultrasonic Condition-Based LubricationDocument7 pagesLubrication Guide - Ultrasonic Condition-Based LubricationLLPas encore d'évaluation

- Automatic Oil Bath Air FilterDocument22 pagesAutomatic Oil Bath Air FilterLLPas encore d'évaluation

- Che 3G04 Winter 2004 Mcmaster UniversityDocument33 pagesChe 3G04 Winter 2004 Mcmaster UniversityAris Koreya100% (2)

- AS/NZS 5100.6, Design of Steel and Composite Bridges: April 2017Document9 pagesAS/NZS 5100.6, Design of Steel and Composite Bridges: April 2017Krish ChandPas encore d'évaluation

- Process Engineers Checklist HAZOPDocument4 pagesProcess Engineers Checklist HAZOPashumishra007Pas encore d'évaluation

- Catalytic ReactorsDocument40 pagesCatalytic ReactorsClinton Thomson100% (1)

- Din 6885Document1 pageDin 6885Riadini Anis Hade50% (2)

- SteelsDocument72 pagesSteelsLLPas encore d'évaluation

- Llo See DD Gts v3 W en 02Document428 pagesLlo See DD Gts v3 W en 02LLPas encore d'évaluation

- Ilchmann GMBH EDocument6 pagesIlchmann GMBH ELLPas encore d'évaluation

- Mam71 Prod Ref GuideDocument167 pagesMam71 Prod Ref Guidee305050Pas encore d'évaluation

- Ingersoll CAT-009 HoleM TechDocument30 pagesIngersoll CAT-009 HoleM TechLLPas encore d'évaluation

- FACOM - Hand Tools - 2004Document899 pagesFACOM - Hand Tools - 2004Евгений АнатольевичPas encore d'évaluation

- KVR UkDocument4 pagesKVR UkLLPas encore d'évaluation

- Falk Metric Key KeywayDocument2 pagesFalk Metric Key KeywayMAXPas encore d'évaluation

- Material Grades EN PDFDocument30 pagesMaterial Grades EN PDFnechitamariusPas encore d'évaluation

- GBSP 47Document3 pagesGBSP 47LLPas encore d'évaluation

- Goodyear Hydraulics Adapters Catalog PDFDocument165 pagesGoodyear Hydraulics Adapters Catalog PDFpsolutions.franciscoPas encore d'évaluation

- l0820300 Stacker Reclaimer ChainsDocument2 pagesl0820300 Stacker Reclaimer ChainsLLPas encore d'évaluation

- Hardox Uk 400Document2 pagesHardox Uk 400Jackson VuPas encore d'évaluation

- FACOM - Hand Tools - 2004Document899 pagesFACOM - Hand Tools - 2004Евгений АнатольевичPas encore d'évaluation

- Heat LineDocument1 pageHeat LineLLPas encore d'évaluation

- Price List - Fluke Precision Measurements - End Users - October 2006Document29 pagesPrice List - Fluke Precision Measurements - End Users - October 2006LLPas encore d'évaluation

- Standard - Manual - Low - Voltage - EN Rev G Web PDFDocument26 pagesStandard - Manual - Low - Voltage - EN Rev G Web PDFTuấn Anh CaoPas encore d'évaluation

- BG70 SNDocument2 pagesBG70 SNLLPas encore d'évaluation

- Motor Donot Just Fail... Do They - A Guide To Preventing FailureDocument70 pagesMotor Donot Just Fail... Do They - A Guide To Preventing FailuresurawutwijarnPas encore d'évaluation

- Installation, Operation and Maintenance Manual for Ex d Asynchronous MotorsDocument101 pagesInstallation, Operation and Maintenance Manual for Ex d Asynchronous MotorsberkahharianPas encore d'évaluation

- Standard - Manual - Low - Voltage - EN Rev G Web PDFDocument26 pagesStandard - Manual - Low - Voltage - EN Rev G Web PDFTuấn Anh CaoPas encore d'évaluation

- TST18 MLE Install Brochure LRDocument24 pagesTST18 MLE Install Brochure LRLLPas encore d'évaluation

- First Term SS 2 Chemistry Scheme of WorkDocument74 pagesFirst Term SS 2 Chemistry Scheme of Workangus ogwuchePas encore d'évaluation

- REMF-197 Design and Fabrication of Pulse Tube Refrigeration SystemDocument4 pagesREMF-197 Design and Fabrication of Pulse Tube Refrigeration SystemretechPas encore d'évaluation

- Projectile Driving Band Interaction With Gun BarrelsDocument6 pagesProjectile Driving Band Interaction With Gun Barrelsjitendra25252Pas encore d'évaluation

- Lecture 18Document8 pagesLecture 18فردوس سليمانPas encore d'évaluation

- Division 23 Hvac: 230548: Vibration Isolation / 230549: Seismic/Wind Restraints Section 230548: Vibration IsolationDocument10 pagesDivision 23 Hvac: 230548: Vibration Isolation / 230549: Seismic/Wind Restraints Section 230548: Vibration IsolationTengku Azaha Tengku IsmailPas encore d'évaluation

- Elements of Earthquake SeismologyDocument8 pagesElements of Earthquake SeismologylevyaiiPas encore d'évaluation

- Review On Fused Deposition ModelingDocument11 pagesReview On Fused Deposition ModelingM Ali HaiderPas encore d'évaluation

- Ce2202 - Mechanics of FluidsDocument3 pagesCe2202 - Mechanics of FluidsPrashant GaradPas encore d'évaluation

- Beam Express Pro TutorialDocument596 pagesBeam Express Pro Tutorialvrajan1988Pas encore d'évaluation

- Hurricane Pumps - 4SD2 - 14 Single Phase Borehole Pump 220V 0 PDFDocument2 pagesHurricane Pumps - 4SD2 - 14 Single Phase Borehole Pump 220V 0 PDFSiziba NhlanhlaPas encore d'évaluation

- Ador Welding Revised Price List for Welding ElectrodesDocument16 pagesAdor Welding Revised Price List for Welding ElectrodesBhaskar AnandPas encore d'évaluation

- Autonomous HVAC CFD - IntroductionDocument31 pagesAutonomous HVAC CFD - IntroductionPraveen Kumar RPas encore d'évaluation

- Deformation of The CrustDocument11 pagesDeformation of The CrustSayno, Samantha Jade C.Pas encore d'évaluation

- Projectiles I MD I RnsDocument4 pagesProjectiles I MD I RnsKhabi Nada50% (2)

- CR - Installation and Operating InstructionsDocument48 pagesCR - Installation and Operating InstructionsHusniPas encore d'évaluation

- RooftankDocument1 pageRooftankwennycantikPas encore d'évaluation

- Haze Meter 3color® HM-300 SeriesDocument4 pagesHaze Meter 3color® HM-300 SeriesbugajonesPas encore d'évaluation

- Catalog 2023 FinalDocument55 pagesCatalog 2023 FinalHana VũPas encore d'évaluation

- QT 16Cr Technical Data SheetDocument1 pageQT 16Cr Technical Data SheethafsaPas encore d'évaluation

- Thin andDocument43 pagesThin andAnnisa TurrahmahPas encore d'évaluation

- Unit 2 Ground Improvement TechniquesDocument33 pagesUnit 2 Ground Improvement Techniquessandesh negiPas encore d'évaluation

- Electro ChemistryDocument5 pagesElectro ChemistrySush ReddyPas encore d'évaluation

- Water CycleDocument3 pagesWater CycleChong Xue ErPas encore d'évaluation

- Pages From Combined QP - Unit 1 Edexcel Physics A-Level-8Document2 pagesPages From Combined QP - Unit 1 Edexcel Physics A-Level-8ieswaheedPas encore d'évaluation

- Electric Log PDFDocument1 pageElectric Log PDFAyu FadhilahPas encore d'évaluation