Académique Documents

Professionnel Documents

Culture Documents

Ff4.2 Transportation

Transféré par

sridhartksCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Ff4.2 Transportation

Transféré par

sridhartksDroits d'auteur :

Formats disponibles

Resource Management 4.2.

1

4-2 TRANSPORTATION

INTRODUCTION

A scooter production company produces scooters at the units situated at various places (called origins)

and supplies them to the places where the depot (called destination) are situated.

Here the availability as well as requirements of the various depots are finite and constitute the limited

resources.

This type of problem is known as distribution or transportation problem in which the key idea is to

minimize the cost or the time of transportation.

MATHEMATICAL FORMULATION OF TRANSPORTATION PROBLEM

Some Definitions

The following terms are to be defined with reference to the transportation problems:

(A) Feasible Solution (F.S.): A set of non-negative allocations xij 0 which satisfies the row and

column restrictions is known as feasible solution.

(B) Basic Feasible Solution (B.F.S.): A feasible solution to a m-origin and n-destination problem is

said to be basic feasible solution if the number of positive allocations are (m+n1).

If the number of allocations in a basic feasible solutions are less than (m+n1), it is called degenerate

basic feasible solution (DBFS) (otherwise non-degenerate).

(C) Optimal Solution: A feasible solution (not necessarily basic) is said to be optimal if it minimizes

the total transportation cost.

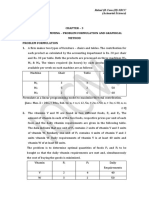

PRACTICAL PROBLEMS

THE TRANSPORTATION PROBLEM

Q 1:

Depot/ Unit B1 B2 B3 B4 Stock

A1 (2) (3) (5) (1) 8

A2 (7) (3) (4) (6) 10

A3 (4) (1) (7) (2) 20

Requirement 6 8 9 15 38

(All terms are in hundreds)

In order to find the solution of this transportation problem we have to follow the steps given below.

(A) Initial basic feasible solution

(B) Test for optimization.

Let us consider these steps one by one.

(A) Initial Basic Feasible Solution:

(I) North-West corner rule

Transportation 4.2.2

(II) Lowest cost entry method

(III) Vogels approximation method

A1: (A) Initial Basic Feasible Solution

(I) North-West corner rule

Depot/ Unit B1 B2 B3 B4 Stock

A1 6(2) 2(3) (5) (1) 8

A2 (7) 6(3) 4(4) (6) 10

A3 (4) (1) 5(7) 15(2) 20

Requirement 6 8 9 15 38

From the above table, the cost of transportation is calculated:

62 + 23 + 63 + 44 + 57 + 152

= 12 + 6 + 18 + 16 + 35 + 30 = 117 i.e., 11700.

(II) Lowest cost entry method

Depot/ Unit B1 B2 B3 B4 Stock

A1 (2) (3) (5) 8(1) 8

A2 1(7) (3) 9(4) (6) 10

A3 5(4) 8(1) (7) 7(2) 20

Requirement 6 8 9 15 38

From the above facts, calculate the cost of transportation as

81 + 17 + 94 + 54 + 81 + 72

= 8 + 7 + 36 + 20 + 8 + 14= 93 i.e., 9300.

(III) Vogels approximation method

Depot/ Unit B1 B2 B3 B4 Stock RP1 RP2 RP3 RP4

A1 6(2) (3) (5) 2(1) 8 1 2

2

- -

A2 (7) 1(3) 9(4) (6) 10 1 1 1 1

A3 (4) 7(1) (7) 13(2) 20 1 1 1 6

4

Requirement 6 8 9 15 38

CP1 2

1

2 1 1

CP2 - 2 1 1

CP3 - 2 1 4

3

CP4 - 2 3 -

From the above facts calculate the cost of transportation as

62 + 21 + 13 + 94 + 71 + 132

= 12 + 2 + 3 + 36 + 7 + 26 = 86 i.e., 8600.

Resource Management 4.2.3

(B) Test for Optimization

Definition: A basic feasible solution of an (m n) transportation problem is said to be non-

degenerate if it has following two properties:

(a) Initial basic feasible solution must contain exactly m+n1 number of individual allocations.

(b) These allocations must be in independent positions. Independent positions of a set of allocations

mean that it is always impossible to form any closed loop through these allocations.

The following theorem is also helpful in testing the optimality.

Theorem: If we have a B.F.S. consisting of m+n1 independent positive allocations and a set of

arbitrary number u

i

and v

j

(i=1,2,...m; j=1,2,...n) such that c

rs

= u

r

+v

s

for all occupied cells (r,s) then

the evaluation d

ij

corresponding to each empty cell (i, j) is given by

d

ij

= c

ij

(u

i

+v

j

)

Algorithm for optimality test

In order to test for optimality we should follow the procedure as given below:

Step 1: Start with B.F.S. consisting of m+n1 allocations in independent positions.

Step 2: Determine a set of m+n numbers:

u

i

(i=1,2,....m) and v

j

(j=1,2,...n)

such that for each occupied cells (r,s)

c

rs

= u

r

+v

s

Step 3: Calculate cell evaluations (unit cost difference)

d

j

for each empty cell (i,j) by using the formula

d

ij

= c

ij

(u

i

+v

j

)

Step 4: Examine the matrix of cell evaluation d

ij

for negative entries and conclude that

i. If all d

ij

> 0 then Solution is optimal and unique.

ii. (ii)If all d

ij

0 then At least one d

ij

= 0 then Solution is optimal and alternate solution also

exists.

iii. If at least one d

ij

< 0 then Solution is not optimal.

If it is so, further improvement is required by repeating the above process.

Step 5:

i. See the most negative cell in the matrix [d

ij

].

ii. Allocate to this empty cell in the final allocation table. Subtract and add the amount of

this allocation to other corners of the loop in order to restore feasibility.

iii. The value of , in general is obtained by equating to zero the minimum of the allocations

containing (not + ) only at the corners of the closed loop.

iv. Substitute the value of and find a fresh allocation table

Step 6: Again, apply the above test for optimality till you find all d

ij

0

Computation for optimality test from the initial basic feasible solution as obtained by VAM

Step 1: (i) In this table number of allocations = 3+41=6

Step 2: Determine a set of (m+n), i.e., (3+4) numbers u1, u2, u3, and v1, v2, v3, and v4 for each

occupied cells by taking u

1

as an arbitrary constant (say zero) then by using c

ij

= u

i

+v

j

try to find all u

i

and v

j

as

Transportation 4.2.4

B1 B2 B3 B4 u

i

A1 2 1 0

A2 3 4 3

A3 1 2 1

v

j

2 0 1 1

Step 3: Cost matrix for the empty positions

c

ij

u

i

+v

j

d

ij

=[c

ij

][u

i

+v

j

]

B1 B2 B3 B4 u

i

B1 B2 B3 B4 u

i

B1 B2 B3 B4 u

i

A1 3 5 A1 0 1 0 A1 3 4

A2 7 6 A2 5 4 3 A2 2 2

A3 4 7 A3 3 2 1 A3 1 5

v

j

v

j

2 0 1 1 v

j

Step 4: Here all d

ij

> 0 then Solution obtained by Vogels approximation method is an optimal

solution

Q2: Where IBFS is not optimal: Data for the transportation problem

Warehouse/

Factory

W1 W2 W3 W4 Factory

Capacity

F1 (19) (30) (50) (10) 7

F2 (70) (30) (40) (60) 9

F3 (40) (8) (70) (20) 18

Warehouse

Requirement

5 8 7 14 34

Find out the initial basic feasible solution by Vogels approximation method and test optimality.

A2:

Warehouse/

Factory

W1 W2 W3 W4 Factory

Capacity

RP1 RP2 RP3 RP4

F1 5(19) (30) (50) 2(10) 7 9 9 40 40

F2 (70) (30) 7(40) 2(60) 9 10 10 20 20

F3 (40) 8(8) (70) 10(20) 18 12 20 50

3

-

Warehouse

Requirement

5 8 7 14 34

CP1 21 22

1

10 10

CP2 21

2

- 10 10

CP3 - - 10 10

CP4 - - 10 50

4

Resource Management 4.2.5

Cost = 519 + 210 + 740 +260 + 88 +1020 = 779

Step 1: Number of allocations = 3+41=6 and they are in independent position.

Step 2: Assumed v

4

= 0

Warehouse/

Factory

W1 W2 W3 W4 Capacity u

i

F1 (19) (10) 10

F2 (40) (60) 60

F3 (8) (20) 20

Requirement v

i

[v

4

=0] 9 -12 -20 0

Step 3: Cost matrix for the empty positions

c

ij

u

i

+v

j

d

ij

=[c

ij

][u

i

+v

j

]

W1 W2 W3 W4 W1 W2 W3 W4 u

i

W1 W2 W3 W4

F1 30 50 F1 -2 -10 10 F1 32 60

F2 70 30 F2 69 48 60 F2 1 -18

F3 40 70 F3 29 0 20 F3 11 70

v

j

v

j

9 -12 -20 0 v

j

Step 4: Since one d

ij

< 0, therefore, the solution is not optimal.

Step 5:

Warehouse/

Factory

W1 W2 W3 W4 Factory

Capacity

F1 5(19) (30) (50) 2(10) 7

F2 (70) + (30) 7(40) - 2(60) 9

F3 (40) - 8(8) (70) + 10(20) 18

Warehouse

Requirement

5 8 7 14 34

(iii)

Warehouse/

Factory

W1 W2 W3 W4 Factory

Capacity

F1 5(19) (30) (50) 2(10) 7

F2 (70) 2 (30) 7(40) (60) 9

F3 (40) 6 (8) (70) 12(20) 18

Warehouse

Requirement

5 8 7 14 34

This improved basic feasible solution gives the cost for this solution as

5(19)+2(10)+2(30)+7(40)+6(8)+12(20) = 743.

Step 6: Test this improved solution for optimality by repeating steps 1,2,3 and 4. In each step,

following matrices are obtained:

Transportation 4.2.6

Step 1: Number of allocations = 3+41=6 and they are in independent position.

Step 2: Assumed u

3

= 0

Warehouse/

Factory

W1 W2 W3 W4 Capacity u

i

u

3

=0

F1 (19) (10) -10

F2 (30) (40) 22

F3 (8) (20) 0

Requirement v

i

29 8 18 20

Step 3: Cost matrix for the empty positions

c

ij

u

i

+v

j

d

ij

=[c

ij

][u

i

+v

j

]

W1 W2 W3 W4 u

i

W1 W2 W3 W4 u

i

W1 W2 W3 W4

F1 30 50 F1 -2 8 -10 F1 32 42

F2 70 60 F2 51 42 22 F2 19 18

F3 40 70 F3 29 18 0 F3 11 52

v

j

v

j

29 8 18 20 v

j

29 8 18 20

Step 4: Since all d

ij

< 0, therefore, the solution is optimal with minimum cost = 743.

Q3: A manufacturer has distribution centres X, Y, and Z. These centres have 40, 20 and 40 units of

his product. His retail outlets at A, B, C, D and E require 25,10,20,30 and 15 units respectively. The

transport cost in (Rupees/Unit) between each centre and each outlet is given in the following table:

Distribution Centre

\Retail outlets

A B C D E

X 55 30 40 50 40

Y 35 30 100 45 60

Z 40 60 95 35 30

Find out the optimum distribution cost.

A3:

A B C D E Supply RP1 RP2 RP3 RP4 RP5

X (55) 10(30) 20(40) (50) 10(40) 40 10 10

2

10

3

- -

Y 20(35) (30) (100) (45) (60) 20 5 5 10 10 10

5

Z 5(40) (60) (95) 30(35) 5(30) 40 5 5 5 5 5

Demand 25 10 20 30 15 100

CP1 5 0 55

1

10 10

CP2 5 0 - 10 10

CP3 5 - - 10 10

CP4 5 - - 10 30

4

CP5 5 - - 10 -

Cost = 1030 + 2040 + 1040 + 2035 + 540 + 3035 + 530 = 3600

Resource Management 4.2.7

Step 1: Number of allocations = 3+51=7 and they are in independent position.

Step 2: Assumed u

1

= 0

A B C D E u

i

[u

1

=0]

X (30) (40) (40) 0

Y (35) -15

Z (40) (35) (30) -10

v

i

50 30 40 45 40

Step 3: Cost matrix for the empty positions

c

ij

u

i

+v

j

d

ij

=[c

ij

][u

i

+v

j

]

A B C D E u

i

A B C D E u

i

A B C D E

X 55 50 X 50 45 0 X 5 5

Y 30 100 45 60 Y 15 25 30 25 -15 Y 15 75 15 35

Z 60 95 Z 20 30 -10 Z 40 65

v

j

v

j

50 30 40 45 40 v

j

Step 4: Since all d

ij

> 0, therefore, the solution is optimal.

Q4: (Unbalanced Problem) A company requires for the next month 300, 260 and 180 tones of stone

chips for its three constructions C1, C2 and C3 respectively. Stone chips are produced by the

company at three mineral fields. All the available boulders must be crushed into chips. Any excess

chips over the demands at sites C1, C2 and C3 will be sold ex-fields.

The fields are M1, M2 and M3 which will yield 250, 320 and 280 tones of stone chips respectively.

Transportation costs from mineral elds to construction sites vary according to distances, which are

given below in monetary unit (MU).

From\To C1 C2 C3

M1 8 7 6

M2 5 4 9

M3 7 5 5

(i) Determine the optimal plan for the company and the overall transportation cost in MU.

(ii) What are the quantities to be sold from M1, M2 and M3 respectively?

A4:

From\To C1 C2 C3 D1 To RP1 RP2 RP3 RP4

M1 (8) (7) 140(6) 110(0) 250 6

1

1 1 1

M2 300(5) 20(4) (9) (0) 320 4 1 5

3

-

M3 (7) 240(5) 40(5) (0) 280 5 0 0 0

From 300 260 180 110 850

CP1 2 1 1 0

CP2 2

2

1 1 -

CP3 - 1 1 -

CP4 - 2

4

1 -

Transportation 4.2.8

Cost = 1406 + 3005 + 204 +2405 +405 = 3,820

Step 1: Number of allocations = 3+41=6 and they are in independent position.

Step 2: Assumed u

1

= 0

Warehouse/

Factory

W1 W2 W3 W4 Capacity u

i

U

1

=0

F1 (6) (0) 0

F2 (5) (4) 0

F3 (5) (5) 1

Requirement v

i

5 4 6 0

Step 3: Cost matrix for the empty positions

c

ij

u

i

+v

j

d

ij

=[c

ij

][u

i

+v

j

]

W1 W2 W3 W4 u

i

W1 W2 W3 W4 u

i

W1 W2 W3 W4 u

i

F1 (8) (7) F1 5 4 0 F1 3 3

F2 (9) (0) F2 6 0 0 F2 3 0

F3 (7) (0) F3 6 1 1 F3 1 0

v

j

v

j

5 4 6 0 v

j

Step 4: Since all d

ij

> 0, therefore, the solution is optimal.

Q5: Unbalanced, Degenerated and Maximization Problem

Ladies Fashion Shop wishes to purchase the following quantity of summer dresses:

Dress Size I II III IV

Quantity 100 200 450 150

Three manufacturers are willing to supply dresses. The quantities given below are the maximum that

they are able to supply of any given combination of orders for dresses: Manufacturers A, B and C, can

supply total quantity of 150, 450 and 250. The shop expects the profit per dress to vary with the

manufacturer as given below:

Size I II III IV

A 2.5 4.0 5.0 2.0

B 3.0 3.5 5.5 1.5

C 2.0 4.5 4.5 2.5

Required:

a) Use the transportation technique to solve the problem of how the orders should be placed with the

manufacturers by the fashion shop in order to maximize profit.

b) Explain how you know there is no further improvement possible.

A5: Profit Maximization Problem

From\To I II III IV To

A (2.5) (4.0) (5.0) (2.0) 150

B (3.0) (3.5) (5.5) (1.5) 450

Resource Management 4.2.9

C (2.0) (4.5) (4.5) (2.5) 250

D1 (0) (0) (0) (0) 50

From 100 200 450 150 900

Profit maximization problem converted into minimization problem (Highest Profit in the cell Profit

in the cells)

From\To I II III IV To RP1 RP2 RP3

A 100(3) (1.5) (0.5) 50(3.5) 150 1 1.5 .5

B (2.5) (2) 450(0) (4) 450 2

1

- -

C (3.5) 200(1) (1) 50(3) 250 0 2

2

.5

D1 (5.5) (5.5) (5.5) 50(5.5) 50 0 0 0

From 100 200 450 150 900

CP1 .5 .5 .5 .5

CP2 .5 .5 - .5

CP3 .5

3

- - .5

Maximum Profit = 1002.5 + 502 + 4505.5 +2004.5 + 502.5 + 500 = 3,850

Step 1: Number of allocations < 4+41=7 and the problem is de-generated. Hence is introduced in

the least cost empty cell to test its optimality

Step 2: Assumed u

1

= 0

From\To I II III IV u

i

A (3) (0.5) (3.5) 0

B (0) -0.5

C (1) (3) -0.5

D1 (5.5) -2

v

j

3 1.5 0.5 3.5

Step 3: Cost matrix for the empty positions

c

ij

u

i

+v

j

d

ij

=[c

ij

][u

i

+v

j

]

I II III IV To I II III IV u

i

W1 W2 W3 W4 u

i

A 1.5 A 1.5 0 F1 0

B 2.5 2 4 B 2.5 1 3 -0.5 F2 0 1 1

C 3.5 1 C 2.5 0 -0.5 F3 1 1

D1 5.5 5.5 5.5 D1 1 .5 1.5 -2 4.5 5 4

v

j

3 1.5 0.5 3.5 v

j

Step 4: Since all d

ij

> 0, therefore, the solution is optimal.

Transportation 4.2.10

[CWA RTP D11]

Q6: A company has three plants F1, F2 F3 from which it supplies to 4 markets: A, B, C & D.

Determine the optimal transportation plan from the following table giving the plant to market

shipping costs, quantities available at each plant and quantities required at each market.

Plant Markets

Available

at plant A B C D

F

1

13 11 15 20 2

F

2

17 14 12 13 6

F

3

18 18 15 12 7

Requirement 3 3 4 5 15

A6: The problem is balanced transportation problem because the demand and supply both are equal to

15. Now obtain the initial feasible solution by Vogels method. The cost matrix and the penalties for

given problem are as under:

From\To A B C D A RP1 RP2 RP3

F

1

2(13) (11) (15) (20) 2 2 - -

F

2

(17) 3(14) 3(12) (13) 6 1 1 1

F

3

1(18) (18) 1(15) 5(12) 7 3 *3 3

R 3 3 4 5 15

CP1 4

1

3 3 1

CP2 1 4

2

3 1

CP3 1 - *3

3

1

*In CP3, column 3 and in RP3 row 3 has same penalty and cost in its concerned column or row also

12. Hence column 3 in CP3 is taken for arbitrary assignment.

Minimum Cost = 213+314+312+118+115+512 = 197

Step 1: Number of allocations is equal to m+n-1 [4+31 = 6] and the problem is generated.

Step 2: Assumed u

1

= 0

From\To A B C D u

i

F

1

(13) 0

F

2

(14) (12) 2

F

3

(18) (15) (12) 5

v

j

13 12 10 7

Resource Management 4.2.11

Step 3: Cost matrix for the empty positions

c

ij

u

i

+v

j

d

ij

=[c

ij

][u

i

+v

j

]

A B C D To A B C D u

i

A B C D u

i

F

1

11 15 20 F

1

12 10 7 0 F

1

-1 5 13

F

2

17 13 F

2

15 9 2 F

2

2 4

F

3

18 F

3

17 5 F

3

1

v

j

13 12 10 7 v

j

Step 4: Since all d

ij

is not positive, therefore, the solution is not optimal.

As the cell [F

1

.A] is negative, it is the new occupied cell

Step 5:

F\T A B C D A F\T A B C D A

F

1

- 2(13) + (11) (15) (20) 2 F

1

1(13) 1(11) (15) (20) 2

F

2

(17) - 3(14) + 3(12) (13) 6 F

2

(17) 2(14) 4(12) (13) 6

F

3

+ 1(18) (18) - 1(15) 5(12) 7 F

3

2(18) (18) (15) 5(12) 7

R 3 3 4 5 15 R 3 3 4 5 15

This improved basic feasible solution gives the cost for this solution as

Minimum Cost = 113+111+214+412+218+512 = 196

Step 6: Test this improved solution for optimality by repeating steps 1, 2, 3 and 4. In each step,

following matrices are obtained

Step 1: Number of allocations is equal to m+n-1 [4+31 = 6] and the problem is generated.

Step 2: Assumed u

1

= 0

From\To A B C D u

i

F

1

(13) (11) 0

F

2

(14) (12) 3

F

3

(18) (12) 5

v

j

13 11 9 7

Step 3: Cost matrix for the empty positions

c

ij

u

i

+v

j

d

ij

=[c

ij

][u

i

+v

j

]

A B C D To A B C D u

i

A B C D u

i

F

1

15 20 F

1

9 7 0 F

1

6 13

F

2

17 13 F

2

16 10 3 F

2

1 3

F

3

18 15 F

3

16 14 5 F

3

2 1

v

j

13 11 9 7 v

j

Step 4: Since all d

ij

is positive, therefore, the solution is optimal.

Transportation 4.2.12

[CWA INTER D02]

Q7: Comprehensive Formulation and Profit Maximization Problem

A Company has 4 factories F1, F2, F3and F4, manufacturing the same product. Production and raw

material costs differ from factory to factory and are given in the table below in the first two rows. The

transportation costs from the factories to the sales depots S1, S2 and S3 are also given. The last two

columns in the table below give the sales price and total requirements at each depot and the

production capacity of each factory is given in the last row.

F

1

F

2

F

3

F

4

S.P/p.u. () Requirement

Production Cost/Unit () 15 18 14 13

Raw Material Cost/Unit () 10 9 12 9

Transportation Cost/Unit ()

S

1

3 9 5 4 34 80

S

2

1 7 4 5 32 120

S

3

5 8 3 6 31 150

Production capacity 10 150 50 100

Determine the optimal solution and the associated profit by using the Vogels Approximation Method

A7: Profit matrix

Profit of each cell = Sale price (Production cost + Raw material cost + Transportation cost)

Maximization model

From\To S

1

S

2

S

3

A

F

1

6 6 1 10

F

2

(2) (2) (4) 150

F

3

3 2 2 50

F

4

8 5 3 100

Dummy 0 0 0 40

R 80 120 150 350

From\To S

1

S

2

S

3

A RP1 RP2 RP3 RP4

F

1

(2) 10(2) (7) 10 0 5

2

- -

F

2

(10) (10) (12) 150 0 2 2

F

3

(5) (6) (6) 50 1 0 0 1

F

4

80(0) 20(3) (5) 100 3

1

2 2 -

Dummy (8) (8) (8) 40 0 0 0 0

R 80 120 150 350

CP1 2 1 1

CP2 - 1 1

Resource Management 4.2.13

CP3 - 3

3

1

CP4 - 2 2

Q8: Unbalanced and Profit Maximization Problem

Departmental store wishes to purchase the following quantities of Sprees:

Types A B C D E

Quantity 150 100 75 250 200

Tenders are submitted by 4 different manufacturers who undertake to supply not more than the

quantities mentioned below (all types of sprees combined):

Manufacturer W X Y Z

Total Quantity 300 250 150 200

The store estimates that its profit/spree will vary with the manufacturer as shown in the following

matrix.

Sprees

Manufacturers A B C D E

W 275 350 425 225 150

X 300 325 450 175 100

Y 250 350 475 200 125

Z 325 275 400 250 175

How should the orders be placed?

Q9: Unbalanced and Minimization Problem with Alternative Solution

The products of three plants F1, F2 and F3 are to be transported to 5 ware houses W1, W2, W3, W4

and W5. The capacities of plants, demand of warehouses and the cost of transportation from one plant

to various warehouses are indicated in the following table:

W1 W2 W3 W4 W5 Plant Capacity

F1 74 56 54 62 68 400

F2 58 64 62 58 54 500

F3 66 70 52 60 60 600

Warehouse Demand 200 280 240 360 320 1500/1400

a) Find out a distribution plan of products from plants to the warehouses at a minimum cost. What

is the minimum cost?

b) Is there any surplus capacity of the plants? If so, in which plant should we associate that surplus

capacity?

Transportation 4.2.14

c) Is there any alternate solution for the optimum solution achieved in?

Q10: Basic Formulation, Unbalanced and Minimization Problem

The Bombay Transport Company has trucks available at four different sites in the following numbers:

Site A 5 Trucks

Site B 10 Trucks

Site C 7 Trucks

Site D 3 Trucks

Customers W, X and Y require trucks as shown below.

Customer W 5 Trucks

Customer X 8 Trucks

Customer Y 10 Trucks

Variable Costs of getting trucks to the Customers are given below:

From A to W 7, to X 3, to Y 6

From B to W 4, to X 6 to Y 8

From C to W 5, to X 8 to Y 4

From D to W 8 to X 4 to Y 3

Solve the above transportation problem.

Vous aimerez peut-être aussi

- Capital Gains (Income Tax)Document110 pagesCapital Gains (Income Tax)sridhartks100% (1)

- Cover LetterDocument7 pagesCover Letterrohan guptaPas encore d'évaluation

- G1 6.4 Partnership - Amalgamation and Business PurchaseDocument15 pagesG1 6.4 Partnership - Amalgamation and Business Purchasesridhartks100% (2)

- G1 6.3 Partnership - DissolutionDocument15 pagesG1 6.3 Partnership - Dissolutionsridhartks100% (2)

- Decision Theory Elements and EnvironmentsDocument41 pagesDecision Theory Elements and EnvironmentsMhmd Karam100% (1)

- Transportation ProblemDocument30 pagesTransportation ProblemYash JunejaPas encore d'évaluation

- 1 Eoq PDFDocument12 pages1 Eoq PDFLyber PereiraPas encore d'évaluation

- cs4l 2 0 en PDFDocument84 pagescs4l 2 0 en PDFmishka123Pas encore d'évaluation

- Unit 2 - Network Crashing NumericalsDocument26 pagesUnit 2 - Network Crashing NumericalsKartik Gupta100% (1)

- Double Storeyed Building Estimation and Costing by 7th Sem Students of Assam Engineering CollegeDocument241 pagesDouble Storeyed Building Estimation and Costing by 7th Sem Students of Assam Engineering CollegeNafisa Nazneen Choudhury100% (6)

- FormulationDocument40 pagesFormulationNitin KumarPas encore d'évaluation

- School Action Plan in Science (S.Y. 2018-2019)Document2 pagesSchool Action Plan in Science (S.Y. 2018-2019)Jorie Cardaño Cacho75% (4)

- Chapter 8: Leverage and EBIT–EPS AnalysisDocument51 pagesChapter 8: Leverage and EBIT–EPS AnalysisNikita AggarwalPas encore d'évaluation

- DC1 Guide To Dark Conspiracy (1st Edition) (2085857)Document10 pagesDC1 Guide To Dark Conspiracy (1st Edition) (2085857)James StevensPas encore d'évaluation

- Happy Startup EbookDocument72 pagesHappy Startup EbookLucca CinquarolliPas encore d'évaluation

- Problems On Accept or Reject Special of Er DecisionDocument9 pagesProblems On Accept or Reject Special of Er DecisionJBPas encore d'évaluation

- OG1 9 Branch AccountingDocument25 pagesOG1 9 Branch AccountingsridhartksPas encore d'évaluation

- UNIT 4 Tronportation ProblemDocument28 pagesUNIT 4 Tronportation ProblemN . pavan0% (1)

- Ratios Solved ProblemsDocument8 pagesRatios Solved ProblemsYasser Maamoun100% (1)

- Mental Math Magic 6212 Practice Problems, Tips, and Hacks To Help You Calculate FasterDocument465 pagesMental Math Magic 6212 Practice Problems, Tips, and Hacks To Help You Calculate FasterKindman KindmanPas encore d'évaluation

- EOQ With DiscountsDocument18 pagesEOQ With DiscountsprashullpPas encore d'évaluation

- (Discrete Mathematics and Its Applications (Boca Raton. Print) ) Gerbner, Dániel - PatDocument352 pages(Discrete Mathematics and Its Applications (Boca Raton. Print) ) Gerbner, Dániel - PatOmar Perez Veloz100% (1)

- Solution of AssignmenDocument38 pagesSolution of AssignmenNikunj Patel75% (8)

- Case Problem 4 WorkforceDocument4 pagesCase Problem 4 WorkforceTú PhạmPas encore d'évaluation

- Product Mix ProblemsDocument11 pagesProduct Mix ProblemsSiegfred Laborte100% (1)

- Budgeting2 PDFDocument88 pagesBudgeting2 PDFPoojaPas encore d'évaluation

- Transportation ProblemDocument63 pagesTransportation ProblemlulughoshPas encore d'évaluation

- Labour Costing Practical Questions With Answers: SolutionDocument7 pagesLabour Costing Practical Questions With Answers: SolutionDeepsak0% (1)

- MAKE and BUY DECISIONDocument14 pagesMAKE and BUY DECISIONAkriti Prasad50% (2)

- 6.transportation ProblemsDocument66 pages6.transportation ProblemsAparna SinghPas encore d'évaluation

- OR Assignment GroupDocument3 pagesOR Assignment Groupamir83% (6)

- Indian Accounting Standards (One Pager)Document29 pagesIndian Accounting Standards (One Pager)sridhartks100% (1)

- 171 Studymat 1 Final Eve-Morn SolutionDocument13 pages171 Studymat 1 Final Eve-Morn SolutionSneha Angre100% (1)

- OR CH 3,4&5Document93 pagesOR CH 3,4&5sami damtew67% (3)

- Chapter V Transportation and Assignment ProblemsDocument56 pagesChapter V Transportation and Assignment ProblemsErit AhmedPas encore d'évaluation

- X X X X: Answer: 300Document4 pagesX X X X: Answer: 300zohaibPas encore d'évaluation

- Optimal Cement DistributionDocument4 pagesOptimal Cement DistributionSoumendra Roy100% (2)

- Lecture 5 Cost PDFDocument39 pagesLecture 5 Cost PDFAmir Kan67% (3)

- Operations Research - 2013Document106 pagesOperations Research - 2013vinit557% (7)

- Chapter One Cost-Volume-Profit (CVP) Analysis: Unit OutlineDocument15 pagesChapter One Cost-Volume-Profit (CVP) Analysis: Unit OutlinebojaPas encore d'évaluation

- Chapter - 3 Linear Programming - Problem Formulation and Graphical Method Problem Formulation 1. A Firm Makes Two Types of Furniture - Chairs and Tables. The Contribution ForDocument11 pagesChapter - 3 Linear Programming - Problem Formulation and Graphical Method Problem Formulation 1. A Firm Makes Two Types of Furniture - Chairs and Tables. The Contribution ForYamica ChopraPas encore d'évaluation

- Chapter Two - PPTX FinalDocument61 pagesChapter Two - PPTX Finalsemetegna she zemen 8ተኛው ሺ zemen ዘመንPas encore d'évaluation

- Financial Leverage QuestionsDocument2 pagesFinancial Leverage QuestionsjeganrajrajPas encore d'évaluation

- Operation Research Assignment - Transportation ProblemsDocument5 pagesOperation Research Assignment - Transportation ProblemsjeganrajrajPas encore d'évaluation

- 1 Linear Programming Problems 2010Document17 pages1 Linear Programming Problems 2010Jasmeet Singh86% (7)

- Advertising Campaign Optimization Using Simplex MethodDocument9 pagesAdvertising Campaign Optimization Using Simplex MethodAgumas AlehegnPas encore d'évaluation

- Chapter 4 Overhead ProblemsDocument5 pagesChapter 4 Overhead Problemsthiluvnddi100% (1)

- Operation Research - QuestionDocument15 pagesOperation Research - QuestionLeo Tech100% (3)

- Transportation ProblemDocument17 pagesTransportation ProblemHarjeet Kaur100% (2)

- Introduction to Linear Programming ModelsDocument20 pagesIntroduction to Linear Programming Modelstemedebere100% (1)

- 1st Semester Accounts Selected Question PDFDocument32 pages1st Semester Accounts Selected Question PDFVernon Roy100% (1)

- CHAPTER 3 Transportatiofor Night ClassDocument10 pagesCHAPTER 3 Transportatiofor Night ClassHACHALU FAYE100% (1)

- TransportationDocument10 pagesTransportationVikram MulikPas encore d'évaluation

- OM Assignment NewDocument37 pagesOM Assignment NewBisrat nigusuPas encore d'évaluation

- OR Chapter 1&2Document91 pagesOR Chapter 1&2sami damtewPas encore d'évaluation

- Chapter 4: LeverageDocument15 pagesChapter 4: LeverageSushant MaskeyPas encore d'évaluation

- Assignment Chapter 5Document2 pagesAssignment Chapter 5Nati AlexPas encore d'évaluation

- (Yard) Individual ASSIGNMENT (Qantitative)Document2 pages(Yard) Individual ASSIGNMENT (Qantitative)Agat40% (5)

- CA - IPCC PAPER 3 PART A COST ACCOUNTINGDocument92 pagesCA - IPCC PAPER 3 PART A COST ACCOUNTINGRahul ShendePas encore d'évaluation

- ch5 PDFDocument164 pagesch5 PDFBeri Z Hunter75% (4)

- MEA AssignmentDocument13 pagesMEA Assignmentankit07777100% (1)

- All Sums CostingDocument14 pagesAll Sums Costingshankarinadar100% (1)

- Problems and SolutionsDocument7 pagesProblems and SolutionsMohitAhujaPas encore d'évaluation

- Master of Business Administration: Quantitative Analysis For Management DecisionsDocument75 pagesMaster of Business Administration: Quantitative Analysis For Management DecisionsDawit TesfayePas encore d'évaluation

- Introduction to Linear Programming OptimizationDocument37 pagesIntroduction to Linear Programming OptimizationWonde Biru67% (3)

- Managerial Economics Optimization TechniquesDocument21 pagesManagerial Economics Optimization TechniquesSaurabh SharmaPas encore d'évaluation

- Maximizing profit from TV set productionDocument10 pagesMaximizing profit from TV set productionAkkama100% (1)

- Tme 601Document14 pagesTme 601dearsaswatPas encore d'évaluation

- A 5 SDocument15 pagesA 5 SBinyam KebedePas encore d'évaluation

- Chapter 2 - Transportation ProblemsDocument15 pagesChapter 2 - Transportation ProblemsRoster Guard100% (1)

- MC0079Document38 pagesMC0079verma_rittika1987100% (1)

- Test 2 QMTDocument4 pagesTest 2 QMTNurulMadihahPas encore d'évaluation

- Assignment ProblemsDocument9 pagesAssignment ProblemsTharaka MethsaraPas encore d'évaluation

- International TaxationDocument46 pagesInternational TaxationsridhartksPas encore d'évaluation

- Capital Gains 20151224 (Cmaj15 & Can15)Document111 pagesCapital Gains 20151224 (Cmaj15 & Can15)sridhartksPas encore d'évaluation

- Department AccountsDocument9 pagesDepartment Accountssridhartks100% (1)

- G1 6.1 Partnership - FundamentalDocument7 pagesG1 6.1 Partnership - Fundamentalsridhartks100% (1)

- Content New PDFDocument1 pageContent New PDFsridhartksPas encore d'évaluation

- G1 6.2 Partnership - ReconstitutionDocument55 pagesG1 6.2 Partnership - Reconstitutionsridhartks100% (1)

- Content New PDFDocument1 pageContent New PDFsridhartksPas encore d'évaluation

- DR Cma T K Sridhar: Department Accounting Branch Accounting Partnership AccountingDocument2 pagesDR Cma T K Sridhar: Department Accounting Branch Accounting Partnership AccountingsridhartksPas encore d'évaluation

- Content New PDFDocument1 pageContent New PDFsridhartksPas encore d'évaluation

- 1 OmDocument32 pages1 OmsridhartksPas encore d'évaluation

- G1 4 Accounting For Depreciation (D01-J14)Document37 pagesG1 4 Accounting For Depreciation (D01-J14)sridhartksPas encore d'évaluation

- Financial Accounting Paper-2Document58 pagesFinancial Accounting Paper-2mknatoo1963Pas encore d'évaluation

- RTP BVM D12Document53 pagesRTP BVM D12sridhartksPas encore d'évaluation

- 12 RatioDocument19 pages12 RatiosridhartksPas encore d'évaluation

- Financial Accounts ConceptDocument191 pagesFinancial Accounts ConceptsridhartksPas encore d'évaluation

- 2.banker CustomerDocument42 pages2.banker CustomersridhartksPas encore d'évaluation

- Inter RTP P-10 NewDocument38 pagesInter RTP P-10 NewsridhartksPas encore d'évaluation

- Singar Information BookletDocument1 pageSingar Information BookletsridhartksPas encore d'évaluation

- Inter P-5 New Dec-08 PaperDocument6 pagesInter P-5 New Dec-08 PaperSudhir RanjanPas encore d'évaluation

- 1.banking Into Duct IonDocument52 pages1.banking Into Duct IonsridhartksPas encore d'évaluation

- Accounting StandardsDocument45 pagesAccounting StandardsBhavin PathakPas encore d'évaluation

- SPACEPLACE: ART IN THE AGE OF ORBITIZATION - ZKM Germany 2005-8Document55 pagesSPACEPLACE: ART IN THE AGE OF ORBITIZATION - ZKM Germany 2005-8Philip Pocock100% (1)

- Higher Unit 06b Check in Test Linear Graphs Coordinate GeometryDocument7 pagesHigher Unit 06b Check in Test Linear Graphs Coordinate GeometryPrishaa DharnidharkaPas encore d'évaluation

- PSA Maintenace in SAP BIDocument11 pagesPSA Maintenace in SAP BImath_mallikarjun_sapPas encore d'évaluation

- Dbms FileDocument25 pagesDbms FileKanika JawlaPas encore d'évaluation

- The Role of International Organisations in World PoliticsDocument8 pagesThe Role of International Organisations in World PoliticsAnonymous i7InXpWAbJPas encore d'évaluation

- MobileMapper Office 4.6.2 - Release NoteDocument5 pagesMobileMapper Office 4.6.2 - Release NoteNaikiai TsntsakPas encore d'évaluation

- Famous Scientist Wanted Poster Project 2014Document2 pagesFamous Scientist Wanted Poster Project 2014api-265998805Pas encore d'évaluation

- TQM MCQ'S FOR SECOND MID-TERMDocument4 pagesTQM MCQ'S FOR SECOND MID-TERM17-550 Priyanka MaraboinaPas encore d'évaluation

- KART STEERING SYSTEM OPTIMIZATION AND SIMULATIONDocument7 pagesKART STEERING SYSTEM OPTIMIZATION AND SIMULATIONgame_freakerboy_8346Pas encore d'évaluation

- The Bright Side of TravellingDocument6 pagesThe Bright Side of TravellingFatin Amirah AzizPas encore d'évaluation

- Board of Education Meeting Observation ReportDocument3 pagesBoard of Education Meeting Observation ReportBidita RahmanPas encore d'évaluation

- Math 221 AssignmentsDocument25 pagesMath 221 AssignmentsSiddhant SharmaPas encore d'évaluation

- Legal Theory - Young Chapter 1: Displacing The Distributive Paradigm & Chapter 2: Five Faces of OppressionDocument5 pagesLegal Theory - Young Chapter 1: Displacing The Distributive Paradigm & Chapter 2: Five Faces of OppressionJlyne TrlsPas encore d'évaluation

- Classical PhysicsDocument3 pagesClassical PhysicsJami HasanPas encore d'évaluation

- The Appreciative Inquiry - The Appreciative Inquiry BookDocument4 pagesThe Appreciative Inquiry - The Appreciative Inquiry Book'Personal development program: Personal development books, ebooks and pdf100% (1)

- 4 Listgarten M. Electron Microscopic Study of The Gingivodental Junction of Man. Am J Anat 1966 119-147 (HWN)Document31 pages4 Listgarten M. Electron Microscopic Study of The Gingivodental Junction of Man. Am J Anat 1966 119-147 (HWN)Benjamin NgPas encore d'évaluation

- Raiseplus Weekly Plan English Subject - Sample Only Region 5Document4 pagesRaiseplus Weekly Plan English Subject - Sample Only Region 5Jenelyn Ramos SantiagoPas encore d'évaluation

- Dosha NakshatrasDocument3 pagesDosha NakshatrasNeo RagPas encore d'évaluation

- Distributed Flow Routing: Venkatesh Merwade, Center For Research in Water ResourcesDocument20 pagesDistributed Flow Routing: Venkatesh Merwade, Center For Research in Water Resourceszarakkhan masoodPas encore d'évaluation

- Open NebulaDocument7 pagesOpen NebulaNaresh KumarPas encore d'évaluation

- Plagiarism: Giving Credit Where Credit Is DueDocument16 pagesPlagiarism: Giving Credit Where Credit Is DueAshish GuptaPas encore d'évaluation

- SRS For VCSDocument14 pagesSRS For VCSKartikay SharmaPas encore d'évaluation