Académique Documents

Professionnel Documents

Culture Documents

Risk Asses 116 - Boiler Hydro Test LP3

Transféré par

Rochdi Bahiri0 évaluation0% ont trouvé ce document utile (0 vote)

359 vues5 pagesHazard Identification and Risk Analysis Procedure (Risk Management) to be undertaken by OCIA and all Subcontractors in order to initiate, act on, review and effectively manage project-related risks.

Description originale:

Titre original

Risk Asses 116- -Boiler Hydro Test LP3

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentHazard Identification and Risk Analysis Procedure (Risk Management) to be undertaken by OCIA and all Subcontractors in order to initiate, act on, review and effectively manage project-related risks.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

359 vues5 pagesRisk Asses 116 - Boiler Hydro Test LP3

Transféré par

Rochdi BahiriHazard Identification and Risk Analysis Procedure (Risk Management) to be undertaken by OCIA and all Subcontractors in order to initiate, act on, review and effectively manage project-related risks.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 5

Location: TERGA Date of Assessment:

Assessor(s): A.FRIDI System/Activity:

INTRODUCTION

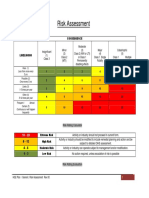

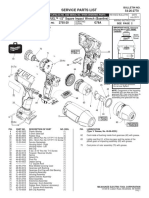

The table below provides a simplified representation of the methodology used and the processes

Management) to be undertaken by OCIA and all Subcontractors in order to initiate, act on,

IDENTIFICATION - Pre planning, Method

statement , Job safety analysis.

ASSESSMENT

Mitigation measure, Residual risk

Identify activities , Identify hazards Assess Impacts, Analyze Risk ,

Establish Mitigation Measures.

P

r

o

b

a

b

i

l

i

t

y

&

F

r

e

q

u

e

n

c

y

Definite 5 5 10 15 20

High 4 4 8 12 16

Moderate 3 3 6 9 12

Low 2 2 4 6 8

Negligible 1 1 2 3 4

1 2 3 4

Minor Serious Major Catastrophic

Severity

Key to Priorities

Medium Priority (5

days)

High Priority (2-3 days) Immediate

RISK ASSESSMENT FORM

Date of Assessment: 01-08-2010 Assessment No:

System/Activity: Boiler Hydro Test LP3

The table below provides a simplified representation of the methodology used and the processes involved in this Hazard Identification & Risk Analysis Procedure (Risk

Management) to be undertaken by OCIA and all Subcontractors in order to initiate, act on, review and effectively manage project-related risks

ASSESSMENT Impact, Risk factor,

Mitigation measure, Residual risk

IMPLEMENTATION &

COMMUNICATION

REVIEW & UP DATE

Assess Impacts, Analyze Risk ,

Establish Mitigation Measures.

Communication & Training Audit, Inspection & Up dating of Log.

Page 2 of 6

116 Rev: 0

involved in this Hazard Identification & Risk Analysis Procedure (Risk

related risks throughout the Construction Phase.

REVIEW & UP DATE

Audit, Inspection & Up dating of Log.

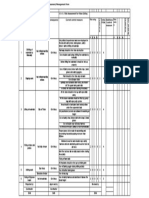

Tasks Hazards Identified (include

the exposed groups)

Probability

1 - 5

Hydrostatic testing

Up to 15 bar

Of weld and welded

part

4

Rupture Ejected parts

Hit of persons by

Persons hit by high

pressure water

projected parts

RISK ASSESSMENT FORM

Probability Severity

1 - 4

Risk

1 - 20

Control Measures to be

Implemented

Probability

1 - 5

3 12 The conformity of welded point

and parts

2

Test area must be cleared and

safety walk down carried out on

all levels of test areas and

ground level barricades and

signs and erected. A list of

authorised personnel aloud in

the area posted and erected prior

to test.

place the specific safety signs

Notify and evacuate all

personnel in the area 20 minutes

prior to test starting.

Provide only one guarded

access.

Barricade area authorised

personnel only no by sanders

Signs in place English French

Arabic Hydrostatic test in

progress with Duration and

pressure In Bar or PSI

Remove all loose objects in area

prior to test walk down the

whole area prior to test be

engineer and HSE Supervisor

Page 3 of 6

Probability Severity

1 - 4

Risk

1 - 20

Residual

Risk

Date

Action

Completed

1 2

Tasks Hazards Identified (include

the exposed groups)

Probability

1 - 5

Rupture Electrocution

Of water

Fire

4

RISK ASSESSMENT FORM

Probability Severity

1 - 4

Risk

1 - 20

Control Measures to be

Implemented

Probability

1 - 5

3 12 Forbid all the work all around

the test area.

isolate all electrical distribution

points in local area and areas

below hydro test area prior to

hydro test

Put at the access the list of the

responsible of the test and the

authorised people. At controlled

access point, radio

communication with stand by

man at the inlet valve. (ready to

switch off or de energize water

scours/ supply

Clear the test area from

electrical panel, installation,

cables and equipment.

Prepare pumping material.

2

Page 4 of 6

Probability Severity

1 - 4

Risk

1 - 20

Residual

Risk

Date

Action

Completed

1 2

Tasks Hazards Identified (include

the exposed groups)

Probability

1 - 5

Leaks from Blanks,

spades and flanges

Leaks from welds

RISK ASSESSMENT FORM

Probability Severity

1 - 4

Risk

1 - 20

Control Measures to be

Implemented

Probability

1 - 5

Safety walk down, tightening

tests, visual inspection.

QA Conformity inspection and

testing prior to Hydro static test

P&ID Drawings attached with

Permit to work.

NDT testing of welds and

conformity certificates prior to

testing

All blanks and spades to

conform to pressure test

No home made blanks and

spades to be used all must

conform to pressure testing

standards

Have read and understand the

OCI Hydrostatic testing

procedure and hold a copy on

site ( Available from site HSE

Manager Orascom)

Page 5 of 6

Probability Severity

1 - 4

Risk

1 - 20

Residual

Risk

Date

Action

Completed

Tasks Hazards Identified (include

the exposed groups)

Probability

1 - 5

Environmental

Pollution the air:

Exhaust gas, The dust

Leaking oil or diesel

machines on soil

3

Assessor Print :

RISK ASSESSMENT FORM

Probability Severity

1 - 4

Risk

1 - 20

Control Measures to be

Implemented

Probability

1 - 5

3 9

Checking the condition of

equipments before beginning

the work

ventilation Workstation

2

Sign: Date:

Page 6 of 6

Probability Severity

1 - 4

Risk

1 - 20

Residual

Risk

Date

Action

Completed

2 4

Vous aimerez peut-être aussi

- HSE PLAN Generic RA PDFDocument5 pagesHSE PLAN Generic RA PDFテレブリコ ジェファーソン100% (1)

- Risk Assess - 98-Installation Fuel Oil ConditioniDocument4 pagesRisk Assess - 98-Installation Fuel Oil ConditioniRochdi BahiriPas encore d'évaluation

- App-16.2 - Risk Assessment For Traffic Signal SystemDocument13 pagesApp-16.2 - Risk Assessment For Traffic Signal Systemloveson709100% (2)

- Job Hazard Analysis: Format For JHA WorksheetDocument3 pagesJob Hazard Analysis: Format For JHA WorksheetWaseem AhmadPas encore d'évaluation

- SRB-JSA-41-Thrust Boring - 01 Febr 2010 - 56PL - KM 1+578Document9 pagesSRB-JSA-41-Thrust Boring - 01 Febr 2010 - 56PL - KM 1+578kkalvi100% (1)

- Ra02 - Container OffloadingDocument3 pagesRa02 - Container OffloadingSamPas encore d'évaluation

- Safety Training PassportDocument2 pagesSafety Training PassportAbhaySnghPas encore d'évaluation

- PM 01 Hira For Excavation of Boiler FoundationDocument3 pagesPM 01 Hira For Excavation of Boiler FoundationSyed Shariq Hassan100% (1)

- Risk Assessment For General ActivitiesDocument25 pagesRisk Assessment For General Activitiesabou bakar67% (3)

- Safety Alert 260 - Unsafe Cradle Installation and UsageDocument2 pagesSafety Alert 260 - Unsafe Cradle Installation and UsageAbdulKatherPas encore d'évaluation

- 340AJ Risk AssessmentDocument7 pages340AJ Risk AssessmentMyaIdzaharPas encore d'évaluation

- Job Hazard Analysis For Desalination of First Effect RetubingDocument7 pagesJob Hazard Analysis For Desalination of First Effect Retubingmc chesterPas encore d'évaluation

- Baseline Risk Assessment: Phindile Kula (Project Coordinator)Document9 pagesBaseline Risk Assessment: Phindile Kula (Project Coordinator)EmilPas encore d'évaluation

- HIRA No. 02-Use of Access Scaffolding SBDDocument2 pagesHIRA No. 02-Use of Access Scaffolding SBDVenkadesh Periathambi25% (4)

- GIS-RA-4061E-002 Risk Assessment For Lifting (Rev.00)Document6 pagesGIS-RA-4061E-002 Risk Assessment For Lifting (Rev.00)Ajas AjuPas encore d'évaluation

- Self Leveling - Epoxy Work (R-A)Document3 pagesSelf Leveling - Epoxy Work (R-A)anisaanPas encore d'évaluation

- Structural Excavation Method StatementDocument3 pagesStructural Excavation Method StatementNikolay DrumevPas encore d'évaluation

- Risk Assessment for Dewatering Worksمعدل الخطرRiskRatingActivity:األرحجيةLikelihoodAssessment location :Description of workLocations for dewatering at site.العواقبConsequencesDocument8 pagesRisk Assessment for Dewatering Worksمعدل الخطرRiskRatingActivity:األرحجيةLikelihoodAssessment location :Description of workLocations for dewatering at site.العواقبConsequencesloveson709100% (1)

- De-Com - For Existing 8 12 Inch - Pipeline - TRA1Document6 pagesDe-Com - For Existing 8 12 Inch - Pipeline - TRA1Darius DsouzaPas encore d'évaluation

- Risk Assessment-Pnuematic Test. DraftDocument3 pagesRisk Assessment-Pnuematic Test. DraftKono Nor AtanPas encore d'évaluation

- A002 C NightclubDocument6 pagesA002 C NightclubBlas de LezoPas encore d'évaluation

- HSE-RA-019 Steel Fixing - Rev 0Document15 pagesHSE-RA-019 Steel Fixing - Rev 0عمروPas encore d'évaluation

- Adverse Weather PolicyDocument10 pagesAdverse Weather Policyvlad100% (1)

- JSA Format Erection of Column 903-C-02,03Document5 pagesJSA Format Erection of Column 903-C-02,03sakthi venkat100% (1)

- Confined Space Entry Program 11 2021Document16 pagesConfined Space Entry Program 11 2021zaka ullahPas encore d'évaluation

- HSE PresentationDocument10 pagesHSE PresentationjeffPas encore d'évaluation

- Job Safety Analysis - Clinker StorageDocument4 pagesJob Safety Analysis - Clinker StorageMohammed MinhajPas encore d'évaluation

- JSA For Refurbishing and Repainting 23oct2017 (Woqod LPG Plant) UpdatedDocument13 pagesJSA For Refurbishing and Repainting 23oct2017 (Woqod LPG Plant) UpdatedJoseph PerezPas encore d'évaluation

- Construction Site Inspection Check List ALMCDocument2 pagesConstruction Site Inspection Check List ALMCAmeerHamzaWarraichPas encore d'évaluation

- 13.2.11 RA SWP For Installation of Instruments and Instrument Tubing at DCLDocument17 pages13.2.11 RA SWP For Installation of Instruments and Instrument Tubing at DCLkeertiraj09100% (1)

- Ref: Section / Dept: Civil Activity: Risk Assessment For False CeilingDocument1 pageRef: Section / Dept: Civil Activity: Risk Assessment For False CeilingJack P100% (2)

- HMRC risk assessment form reviewDocument8 pagesHMRC risk assessment form reviewmkmusaPas encore d'évaluation

- SOP SOP0022 Concrete Core DrillDocument3 pagesSOP SOP0022 Concrete Core Drillkristian08Pas encore d'évaluation

- JHA Handling Materials - ROMODocument3 pagesJHA Handling Materials - ROMOazroyremyPas encore d'évaluation

- SH-F43 - PTW Format - R02Document2 pagesSH-F43 - PTW Format - R02vini100% (1)

- CIVE3707 Risk Assessment Steel Beam LiftingDocument1 pageCIVE3707 Risk Assessment Steel Beam LiftingJosh Booth100% (2)

- Task Risk Assessment Engineering Kinetics (PVT.) LTD: Risk Evaluation (Refer To Evaluation Form)Document3 pagesTask Risk Assessment Engineering Kinetics (PVT.) LTD: Risk Evaluation (Refer To Evaluation Form)andrePas encore d'évaluation

- JSO Cable Drum (02 Sept.'07)Document2 pagesJSO Cable Drum (02 Sept.'07)Francis Enriquez TanPas encore d'évaluation

- Risk Assessment: Project Manager Project Engineer HSE Officer/engineer First AiderDocument5 pagesRisk Assessment: Project Manager Project Engineer HSE Officer/engineer First AiderOvais FarooqPas encore d'évaluation

- Abdul Rahman Al-Otaishan Group Safety Presentation June 2015Document14 pagesAbdul Rahman Al-Otaishan Group Safety Presentation June 2015jaydeePas encore d'évaluation

- Job Safety Analysis: Trench Preparation & Thrust Boring Activity Required References Jsa ReviewDocument4 pagesJob Safety Analysis: Trench Preparation & Thrust Boring Activity Required References Jsa ReviewMoaatazz Nouisri100% (1)

- 9 - Risk Assessment - PaintingDocument8 pages9 - Risk Assessment - Paintingmahmoud nadaPas encore d'évaluation

- CRA - Structural Steel Staircase Fabrication Works at Leighton Plant YardDocument4 pagesCRA - Structural Steel Staircase Fabrication Works at Leighton Plant YardRiyas Mangodan100% (1)

- SS JSP - 013 Foundation and Ground Shuttering Forms and Rebar WorksDocument6 pagesSS JSP - 013 Foundation and Ground Shuttering Forms and Rebar WorksFarhat SetharPas encore d'évaluation

- Hazard Identification and Risk Control-TemplateDocument2 pagesHazard Identification and Risk Control-TemplateShristika Pradhan100% (1)

- 15.tube Bundle Puller.Document3 pages15.tube Bundle Puller.Mohammad Fazal Khan100% (1)

- JSA - Suface Preparationand Brush PaintingDocument5 pagesJSA - Suface Preparationand Brush PaintingAzad pravesh khanPas encore d'évaluation

- Light Material Loading Safety PracticesDocument6 pagesLight Material Loading Safety PracticesFarhat SetharPas encore d'évaluation

- JSA For MobilizationDocument3 pagesJSA For MobilizationHossain amjad Hossain100% (1)

- IM-08-B HSE Wall Grinding For Finishing WorkDocument2 pagesIM-08-B HSE Wall Grinding For Finishing WorkAnsari HarisPas encore d'évaluation

- Job Safety Analysis (Jsa) : CONTRACT N° .Document1 pageJob Safety Analysis (Jsa) : CONTRACT N° .ghazi kallelPas encore d'évaluation

- Risk Assessment For Braket Scaffolding: Construction of Lubricating Oil Blending Plant (LOBP)Document3 pagesRisk Assessment For Braket Scaffolding: Construction of Lubricating Oil Blending Plant (LOBP)AmeerHamzaWarraichPas encore d'évaluation

- HIRA (Hazard Identification and Risk Assessment)Document6 pagesHIRA (Hazard Identification and Risk Assessment)Nathan Naelz SandyPas encore d'évaluation

- Risk Assessment Installation of Aluminium Cladding Work For Ducting & Piping.Document16 pagesRisk Assessment Installation of Aluminium Cladding Work For Ducting & Piping.Mohsin MohdPas encore d'évaluation

- Hazardous Substances PlanDocument4 pagesHazardous Substances Planفواد جانPas encore d'évaluation

- Construction Site HSE PlanDocument33 pagesConstruction Site HSE Planyoga barataPas encore d'évaluation

- Man Machine InterfaceDocument22 pagesMan Machine Interfaceamdarrif3723100% (1)

- Risk Asses 53-GPR Fitting AssemblyDocument6 pagesRisk Asses 53-GPR Fitting AssemblyRochdi BahiriPas encore d'évaluation

- Assessment No 47 Demolition Basin E40Document4 pagesAssessment No 47 Demolition Basin E40Rochdi Bahiri0% (1)

- RISK ASSES-105-Erection of Steel Structure BuildinDocument4 pagesRISK ASSES-105-Erection of Steel Structure BuildinRochdi Bahiri75% (8)

- Audit of Power Purchase AgreementsDocument6 pagesAudit of Power Purchase AgreementsRochdi BahiriPas encore d'évaluation

- Project Finance and Merchant PowerDocument76 pagesProject Finance and Merchant Powersimplyanks_5100% (2)

- A Case Study of 3-MW Scale Grid-Connected Solar Photovoltaic Power Plant at Kolar, KarnatakaDocument38 pagesA Case Study of 3-MW Scale Grid-Connected Solar Photovoltaic Power Plant at Kolar, KarnatakaAnant Joshi67% (3)

- Risk Asses23 - Generator RotorDocument3 pagesRisk Asses23 - Generator RotorRochdi BahiriPas encore d'évaluation

- What Is Quadrature Axis Reactance PDFDocument11 pagesWhat Is Quadrature Axis Reactance PDFRochdi BahiriPas encore d'évaluation

- Evaluate economic feasibility of power plant projectsDocument7 pagesEvaluate economic feasibility of power plant projectsfundu123Pas encore d'évaluation

- Epc Contracts in The Power SectorDocument30 pagesEpc Contracts in The Power SectorIwan Anggara100% (2)

- Risk Asses 116 - Boiler Hydro Test LP3Document5 pagesRisk Asses 116 - Boiler Hydro Test LP3Rochdi BahiriPas encore d'évaluation

- Primavera: Contract Manager Functional OverviewDocument22 pagesPrimavera: Contract Manager Functional OverviewIgor ČučekPas encore d'évaluation

- TSA Appendices State - 16 09 2014 - WPDocument24 221 pagesTSA Appendices State - 16 09 2014 - WPRochdi BahiriPas encore d'évaluation

- Pump Efficiency For Single Stage Centrifugal PumpsDocument8 pagesPump Efficiency For Single Stage Centrifugal PumpsPerrobast100% (1)

- Power Electronics For Modern Wind Turbines-Frede Blaabjerg Zhe ChenDocument68 pagesPower Electronics For Modern Wind Turbines-Frede Blaabjerg Zhe Chennelber_xPas encore d'évaluation

- Readme 1 STDocument1 pageReadme 1 STRochdi BahiriPas encore d'évaluation

- Risk Asses 118-Transformers Oil TreatmentDocument5 pagesRisk Asses 118-Transformers Oil TreatmentRochdi BahiriPas encore d'évaluation

- Financing and Performance Contracting For EE Projects OutlineDocument1 pageFinancing and Performance Contracting For EE Projects OutlineRochdi BahiriPas encore d'évaluation

- Financial Analysis of Projects I - OutlineDocument2 pagesFinancial Analysis of Projects I - OutlineRochdi BahiriPas encore d'évaluation

- Project and O&M CostDocument2 pagesProject and O&M CostRochdi BahiriPas encore d'évaluation

- Dampers ExplanationDocument7 pagesDampers ExplanationRochdi BahiriPas encore d'évaluation

- 308 BeheraDocument6 pages308 BeheraRajneesh VachaspatiPas encore d'évaluation

- Install NotesDocument1 pageInstall NotesRochdi BahiriPas encore d'évaluation

- Risk Assesment 16 - Pre - Assembly and Erection ofDocument7 pagesRisk Assesment 16 - Pre - Assembly and Erection ofRochdi BahiriPas encore d'évaluation

- Primavera Project Planner p3Document300 pagesPrimavera Project Planner p3MARIANO100% (19)

- P6 Reference ManualDocument550 pagesP6 Reference Manualsaluthomas100% (22)

- Lettre Recommandation Orascom ConstructionDocument1 pageLettre Recommandation Orascom ConstructionRochdi BahiriPas encore d'évaluation

- BRD - Lean Manufacturing CaseDocument62 pagesBRD - Lean Manufacturing CaseRochdi BahiriPas encore d'évaluation

- Hawk 4000 Controls: HAWK 4000 Boiler Control System Sample SpecificationsDocument4 pagesHawk 4000 Controls: HAWK 4000 Boiler Control System Sample SpecificationsRochdi BahiriPas encore d'évaluation

- Wmu 2013 - PPT - FinalDocument103 pagesWmu 2013 - PPT - FinalRochdi BahiriPas encore d'évaluation

- Risk Asses23 - Generator RotorDocument3 pagesRisk Asses23 - Generator RotorRochdi BahiriPas encore d'évaluation

- 750-326 OM Blowdown Separator 04-10Document8 pages750-326 OM Blowdown Separator 04-10Rochdi BahiriPas encore d'évaluation

- Boiler Design StepDocument3 pagesBoiler Design StepRochdi BahiriPas encore d'évaluation

- API 5l Grade l245 PipesDocument1 pageAPI 5l Grade l245 PipesMitul MehtaPas encore d'évaluation

- IES 2012 Exam Civil Engineering Paper II Solved With Answer KeyDocument21 pagesIES 2012 Exam Civil Engineering Paper II Solved With Answer KeyPratik Nayak0% (2)

- Basics of GD&T TrainingDocument3 pagesBasics of GD&T TrainingShajil SPas encore d'évaluation

- Dynamometer - 1Document3 pagesDynamometer - 1Vishal BhattPas encore d'évaluation

- Satellite 2755dvdDocument2 pagesSatellite 2755dvdeduinnPas encore d'évaluation

- Hospital Management SystemDocument63 pagesHospital Management Systemsanjay yadavPas encore d'évaluation

- Industrial Sliding DoorsDocument40 pagesIndustrial Sliding DoorsAnonymous CPEha1db7UPas encore d'évaluation

- Pages From RCJ SpecificationsDocument1 pagePages From RCJ Specificationsarch ragabPas encore d'évaluation

- Fix Canon Pixma MP287 Printer Error CodesDocument7 pagesFix Canon Pixma MP287 Printer Error CodesBen BennyPas encore d'évaluation

- Jtm45plus Wiring DiagramDocument1 pageJtm45plus Wiring DiagramSarah Ladeira LucasPas encore d'évaluation

- Reaffirmed Indian Standards for Water Resources DepartmentDocument2 pagesReaffirmed Indian Standards for Water Resources Departmentjamjam75Pas encore d'évaluation

- Analysis of 3PL and 4PL ContractsDocument8 pagesAnalysis of 3PL and 4PL ContractsGoutham Krishna U BPas encore d'évaluation

- Asme Sa 234 Grade WPC PipesDocument1 pageAsme Sa 234 Grade WPC PipesFerroPipEPas encore d'évaluation

- JeppView - LGSA (7 Charts)Document18 pagesJeppView - LGSA (7 Charts)Roshan UppalPas encore d'évaluation

- Reliable Ni-Cd batteries keep railroads running smoothlyDocument8 pagesReliable Ni-Cd batteries keep railroads running smoothlyJesus LandaetaPas encore d'évaluation

- Lean & Environment ToolkitDocument96 pagesLean & Environment Toolkittinyplankton100% (7)

- Tensile Test AnalysisDocument8 pagesTensile Test AnalysisNazmul HasanPas encore d'évaluation

- Katalog Menadzer 2013 EnglDocument119 pagesKatalog Menadzer 2013 EnglMarko MiladinovićPas encore d'évaluation

- 20 Things To Know About The Jeepney Modernization ProgramDocument2 pages20 Things To Know About The Jeepney Modernization ProgramMark Julius MaravilloPas encore d'évaluation

- Hazardous Area ClassificationDocument15 pagesHazardous Area ClassificationpmnasimPas encore d'évaluation

- 2755 22 (G78A) Milwaukee PBDocument2 pages2755 22 (G78A) Milwaukee PBZeckPas encore d'évaluation

- Installation Manual: Automatic TWIN Greasing SystemDocument62 pagesInstallation Manual: Automatic TWIN Greasing SystemWill FrontPas encore d'évaluation

- Philips Chassis Lc7-1e La PDFDocument91 pagesPhilips Chassis Lc7-1e La PDFcomphomePas encore d'évaluation

- Construction EstimateDocument42 pagesConstruction EstimateAngelica GicomPas encore d'évaluation

- Richard GrisenthwaiteDocument25 pagesRichard GrisenthwaitecaarthiyayiniPas encore d'évaluation

- En 818-6 PDFDocument5 pagesEn 818-6 PDFlub007Pas encore d'évaluation

- BTS3900 GSM Site Maintenance Terminal User Guide - (V300R008 - 06)Document160 pagesBTS3900 GSM Site Maintenance Terminal User Guide - (V300R008 - 06)engrvinzzPas encore d'évaluation

- Catalogo General KOBA 1000 - e - 2012revDocument21 pagesCatalogo General KOBA 1000 - e - 2012revTECNIMETALPas encore d'évaluation

- Digital VLSI System Design Prof. Dr. S. Ramachandran Department of Electrical Engineering Indian Institute of Technology, MadrasDocument30 pagesDigital VLSI System Design Prof. Dr. S. Ramachandran Department of Electrical Engineering Indian Institute of Technology, MadrasPronadeep BoraPas encore d'évaluation

- Faa Gleim Outlines Instrument PilotDocument130 pagesFaa Gleim Outlines Instrument PilotTalaat SalehPas encore d'évaluation