Académique Documents

Professionnel Documents

Culture Documents

Api 107

Transféré par

Yersin Hernandez Aldan0 évaluation0% ont trouvé ce document utile (0 vote)

26 vues14 pages PIPEUNE MAINTENAI:E W8.DING PRACTS 9 6" (152 mm) minimum 1,4. (3.17-mm) maximum radius on al! comers t Approximately 1. (25. Mm) Wall thickness nes: I. The specimen may be machine or oxygen cut. 2. The weld reinfon:ement shall be removed from both faces flush with the surface of the specimen. 3. The specimen may be flattened at room

Description originale:

Titre original

api 107

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce document PIPEUNE MAINTENAI:E W8.DING PRACTS 9 6" (152 mm) minimum 1,4. (3.17-mm) maximum radius on al! comers t Approximately 1. (25. Mm) Wall thickness nes: I. The specimen may be machine or oxygen cut. 2. The weld reinfon:ement shall be removed from both faces flush with the surface of the specimen. 3. The specimen may be flattened at room

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

26 vues14 pagesApi 107

Transféré par

Yersin Hernandez Aldan PIPEUNE MAINTENAI:E W8.DING PRACTS 9 6" (152 mm) minimum 1,4. (3.17-mm) maximum radius on al! comers t Approximately 1. (25. Mm) Wall thickness nes: I. The specimen may be machine or oxygen cut. 2. The weld reinfon:ement shall be removed from both faces flush with the surface of the specimen. 3. The specimen may be flattened at room

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 14

~

PIPEUNE MAINTENAI:E W8..DING PRACTaS

9

6" (152 mm) minimum

1,4. (3.17-mm)

maximum radius on

al! comers

t

Approximately

1. (25.4 mm)

.

v Wall thickness

Nes:

I. The specimen may be machine or oxygen cut.

2. The weld reinf~t shall be removed from 00th faces flush with the surface of tbe specimen.

3. The specimen may be fIancned at room temperatwe before tcsting.

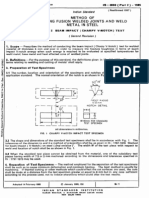

Rgure 7-Root-Bend- and Face-Bend- Test Specimens-Groove Welds

,!!;...

Notes:

1. Radius ofplunger: A=I}; inches (44.45 millimeters): radius ofdie: B=~. inches (58.74 millimeters): width of

die: C=2 inches (50.8 millimeters).

2. Figure is !10( to scale.

Figure 8-Jig for Guided Bend Test

10 API RECOMMENDED PR4CTK;E 1107

.

\ I

\ I

\,.--~

Wall thK:kness

"

'/" (3.17-mm) maximum

j I ~ radius 011 all ~mers

I~-

- t. Wldth 01

1h" (12.7 mm) ~ specimen

6. (152 mm) minimum .1

t

'-1-

'- Wall th~ess

then machined 01' ground srnooth 10 a :l:-iIK:h (12.7-millimeter) widdl. Thc

cut surf~es shalI be smoodl and parallel

3. Thc specimen may be flattened at room temperanae.

Notes:

I. The weld reinfon:ement shall be removed from both f~ f1ush with the

surface of the specimen.

2. The specimen may be machine cut to a ~~ (12.7-millimeter) width. CX"

it may be oxygen cut to approxjmare1y a 'I.-~ (19-mil1imeter) width aDd

Figure 9-Side-Bend- Test Specimen-Groove Welds

weld soundness. The use of optic devices or dye penetrating

materials is not necessary.

2.6.6.3 Acceptance Criteria

enough to assure d1at the welds can be examined. For each

spccimen, at least one face of each cross section is to be

ground smoom and etched with a suitable etchant. such as

ammoniwn persulfate or hydrochloric acid. to give clear def-

inition to the structure of the weld.

In lieu of taking specia1 specimens for macro examina-

tions, the nick-break specimens may be used. Nick-break

specimens used for this purpose are to be examined before

they are nicked.

A visua1 examination of the cross section of the weld

should show d1at it is completely fused at the root and free of

cracks. The fillet weld should have leg lengths that are at

least equal to the lengths specified in the proceduxe specifi-

cation and should not deviate in concavity or convexity by

more than X6 inch (1.59 mi11imeters). The depth of the under-

cutting shou1d not exceed ~ inch (0.79 millimeter) or 12X

percent of the piping wa1l thickness, whichever is sma1ler.

2.6.6.2 Method of Examination

The cross section of tbe weld is to be visUally examined

with lighting that will sufficiently reveal the details of the

Note: Smooth and etCh atleast one face of each weld specirnen cross scction with suitable etchant to give a clear

defmition to the weld stnICtt1Ie.

~E ~ WEl.DtNG PAAcrx;es "

SECTION 3-WELDER QUAURCATION

qualification of a welder is to be conducted in the presence

of a company representative.

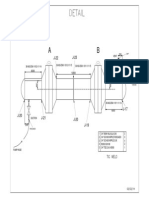

3.2 Welding of Test Assembly

A welder qualifying in accordance with this recom

mended practice is to weld a test assembly simila:i to the one

shown in Figure I or II.. The essential variables associated

with maintenance welding procedure qualification and

welder qualification are not identical. Welder qualifica.tion

is a function of certain essential variables which are set

forth in 3.3.

3.1 Purpose

Tbe welder qua1ification test is meant to detennine

whether a welder has the ability to make sound welds using

a previously qualified welding procedure. Before any main-

tenanc;e welding is perfOmled. a welder must be qua1ified in

accordance with the applicable requirements of 3.1 to 3.6 of

API Standard 1104 or 3.2 to 3.5 ofthis .-m...xIed prac-

tice. We1der qualification f(X circwnferential butt we1ds shall

be in accordance with API Standard 1104.

A welder who successfully welds a test assemb1y for a

procedure qualification test is qualified for that procedure

within the range of essential variables which govem welder

qua1ification. Before starting the qua1ification tests, the

welder should be a1lowed reasonable time to adjust the weld-

ing equipment used in the test. The welder is to use the same

welding technique and to proceed with the sarne speed that

he will use if he passes the test and is peImitted to weld. The

3.3 Essential Variables for Welder

Qualification

If any of the following essential variables OCCUf. the

welder using the new procedure is 10 be requalified.

.

Nace: This test ~iri(X1 qualifies d)e we1der for a1I ~itions. Tests may be perfom1cd in odIer positions wbiclI will

qualify d)e welder for that ~ition only.

Figure 11-Welder Qualification Test Assernbly

API RECOMMENDED PRACnCE 1107

~

3.5.2.1 Tensile- Test Acceptance

Criteria-Groove Welds

Each tensile-test specirnen shou1d meet the acceptance cri-

teria for tensile tests, which are provided in 2.6.2.2. lf any

specimen fails to meet those criteria. the welder is disquali-

fied.

3.5.2.2 Nick-Break- Test Acceptance Criteria

If any nick-break-test specimen shows defects exceeding

those allowed by the acceptance criteria for nick-break tests

provided in 2.6.3.3, the welder is disqualified.

a. A change from one welding process or combination of

processes to any other welding process or combination of

processes.

b. A change in the direction of welding from vertical up to

vertica1 downorvice versa.

c. A change in the filler metal classification from either

Group 1 or Group 2 to Group 3 or from Group 3 to either

Group 1 or Group 2 (see Tab1e 1).

d. A change in the diameter group. A welder qualified on

pipe baving an outside diameter of less than 12Y. inches

(323.8 millirneters) shall be qualified for all diameters less

than or equal to the diameter used in his qualification test. A

welder qualified on pipe having an outside diameter of

greater than orequal to 12Y. incbes (323.8 mil1imeters) shall

be qualified on all pipe diameters.

e. A change in the DOOlinal material wall thickness frorn one

group to another. Some suggested thickness groups are as

folldws:

1. Less than ~6 inch (4.78 millimeters).

2. From ~6 incb to ~ inch (4.76 rnil1imeters to 19.05 mil-

limeters).

3. Greater than ~ inch (19.05 millimeters).

Visual Examination

~

The weld is to present a neat. workmanlike appearance.

Unercutting adjacent to the final bead on the outside of the

pipe should not exceed a depdt of Yn inch (0.79 millimeter)

or 12~ percent of the pipe wall thickness. whichever is

smaller; there should not be more than 2 inches (50.8 mil-

lirneters) of undercutting in any continuous 12-inch (304.8-

millimeter) length of weld or in one sixth the length of the

weld, whichever is smaller. Failure to meet these require-

ments is sufficient cause for e1iminating additional testing.

Performance Qualification

Tests-Destructive Testing

SAMPUNG OF TEST WELDS

T

R8orS8

N8 II

FBorS8 I I

N'

81

Test specimens are to be cut from the test assembly loca-

tions shown in Figure 12. The type and minimwn number of

specimens are given in Table 3. Before testing, test speci-

mens are to be air cooled to ambient temperature.

TENSILE-, NICK-BREAK-, AND

BEND-TESTPROCEDURES

c::::-1

The tensile-, nick-break-, and bend-test specimens for the

procedure qualification tests are to be prepared. and the tests

are to be made as described in 2.6.2 through 2.6.5. The ten-

sile tests may be omitted; if they are omitted, the specimens

designated for the tests are to be subjected to the nick-break

Note: T=tensile; RB=root bend; FB--face bend; NB=nick break; SB=side

bend.

'-

-

PlPEUNE MAwrENAta WElDING PRACT1CES 13

TabJe 3- Type and Number of Test Specimens-WeIder Qualiflcation l\,st

Number of Specimens

Wcld

Typc

Nick

B~

R00[

Bend

Face

~

Side

Bend

Tensile ;);J

Wall

Thickness

l

4'

l

4'

~ 4

4

4

4

>~ inch

2

"Al the owner's option. these specimens may be subrniued !O the ~section test (see 2.6.6) befo~ ~y are

submitted !O the nick-break testo

(;teria section-test specimen does not meet th~ .~.;':Pi:2lh

in 2.6.6.3, the welder is disqualified.

3.6 Retest

If, in the opinion of d1e company, tllt faillU'e of 4t \ \;:der to

pass the test was because of unavoidable conditions or con-

ditions beyond his control, the welder may be given a second

opportunity to qualify. No further retests need to be given

until the welder has submitted proof of subsequent welder

training that is acceptable to the company.

3.5.2.3 Bend- Test Acceptance Criteria-Groove

Welds

If any bend-test specimen shows defects exceeding those

a1lowed by the acceptance criteria for root- and face-bend

tests provided in 2.6.4.3 or for side-bend tests provided in

2.6.5.3. the welder is disqualified. It should be noted. tl1ough.

that a weld in high-test pipe (API Specification 5L. Grades

X42 and above) may not bend to the fu1I U shape. A weld in

high-test pipe is considered acceptable if the cracked speci-

men is broken apart and its exposed swface meets the nick-

break-test acceptance criteria in 2.6.3.3.

If a bend-test specimen fails to meet these criteria and. in

the opinion of the company representative. is not representa-

tive of the weld. the bend-test specimen may be replaced by

an additional specimen cut adjacent to the one that failed.

The welder is disqualified if the additional specimen also

shows defects exceeding the specified 1intS.

.

3.7 Records of Qualified Welders

A record is to be made of the tests given to each welder

and of the detailed results of eacb test. This record should be

developed to suit the needs of d1e individual c001pany and

should be sufficiently det4led to demonsn'ate that the qua1-

ification test embodied tbe various requirements prescribed

by this recommended practice. A list of qualified welders

and the procedures in which they 8IC qualified is to be main-

tained. A welder may be required to requalify if there is a

question about his ability. .

3.5.3 MACRO-SECTlON- TEST PROCEDURES

ANDTESTACCEPTANCE

CRITERIA-FJLLET WELDS

The macro-section-test specimens are to be prepared and

exarnined as described in 2.6.6.1 and 2.6.6.2 If any macro-

SECTION 4-SUGGESTED MAINTENANCE WELDING PRACTICES

4.1 General

For the pipe welding to be in accordance with this recom-

mended ~ce, the .welding is~ ;~",~~b>:.e~ -.

welders usmg quallfied piocedUIeS~aces to be

welded are to be smooth; unifonn; and free of laminations.

te3rs, sca1e, slag, grease. paint. and other deleterious ~

which might adversely affect the welding. The joint design is

to be in accordance with the welding procedure to be used.

Before welding on a piping system which is being or has

been used for the compression. pumping, ttansmission, or

distribution of crude petroleum. petroleum products. or fuel

gases, welders should consider aspects that affect safety.

such as operating pressure. flow conditions, and wall thick-

ness at the location of the welding. All welders performing

repair work sball be familiar with the safety precautions as-

sociated with cutting and welding on piping that contains or

has ~tained liquid petrolewn or fuel gases.

1SartrCUlar considemtion should be given to the fillet weld

used to join a sleeve to a carrier pipe because the fillet weld

is prone to Wlderbead or delayed hydrogen cracking. With

welds on pressurized and flowing piping systems, success

has been achieved using low-hydrogen welding processes or

electrodes with appropriately high-heat input that slows the

cooling rate. The use of low-hydrogen electrodes requires

that special attention be given to electrode care and handling

requirements. The cracking process is related to the hydro-

gen absorbed by the hot weldment. A slow cooling rate is

API R~ PRACTw::e 1107

necessary to pennit diffusion and elimination of the hydro-

gen. Proper attention should be given to fit up and to the car-

bon equivalent factor and chemica1 composition of both the

sleeve and the carrier pipe.

beveled edges are to be smooth and unifonn with dimen-

sions conforming to the procedure specification.

4.4 Weather Conditions

Welding sball not be done when tbe quality of the corn-

pleted weld would be impaired by the prevailing weather

conditions. Weather conditions d1at would cause impairment

include. but are not limited to. airbome moisture. blowing

sands. and high winds. Wmdshields may be used when prac-

tica1. The cornpany representative decides if weather condi-

tions are suitable for welding.

4.2 Alignment

4.2.1 OFFSET ,

The offset between the abutting edges for groove welds

should not exceed X6 inch (1.59 millimeters). To obtain this

alignment. devices .should be used. or misaligned surfaces

can be built up with weld metal.

4.5 Clearance

When bell holes are used. they should be large enough to

provide the welder or welders widl ready access tO the work.

4.2.2 ROOT OPENING (COMPLETE

ENCIRCLEMENT RTTJNGS)

The root opening, d1e space between d1e abutting surfaces,

should be sufficient to pennit 100 percent penetration. Joints

paralleling the axis of the carrier pipe may be fitted with a

suitab1e tape or mild steel backup strip to prevent d1e we1d

metal fi'Om being fused to the surface of the carrier pipe.

4.6 Cleaning

Weld slag, scale. and spatter should be removed from each

weld bead and the adjacent base metal.

4.7 Welding Sequence

Suggested welding sequences for the welding of fittings

are shown in Figures 13 through 18.

4.3 Bevels

Edges o tbe pieces 10 be joined may be beveled by a ma-

chine tool or may be cut by 3D oxygen cutting process. The

~

NOIe: 1bis is the suggested welding sequence; oth= may be followed at the discretion of the company.

PlpEUNE ~ WELDING PRACTa;s

15

~

~

:::'= ~

,

~ ,

-~-- ~ ~

"

~ ~

~ ---' , . I ..

:1 '. 1

Note: This is d1e suggested welding seq\JeIk:e; odIers may be foUowed at tbe ~on oftbe company.

Figure 14-Reinforcing Saddle

ALTERNA11VE

DESJGN

N~ This is Ihe suggesred welding seqIICIx:e: at Ihe discretion o! the compauy. ~ may be !o11owcd and cir-

cumf=tial welds numbets 3 and 4 necd no1 be made.

~

API RECa.o.IENDED PRACT1CE 1107

16

~

NOIes:

1. This is tbe suggested welding sequence: ~ may be followed al the disaetion oftbe company.

2. Wben in operation. tbe fitting is al pipeline ~.

Rgure 16-Encirclement Tee

'~

ALTERNA1lVE

DESIGN

~ Note: This is lile suggested welding sequence; al the di~on of the company. others may be folJowed and cir-

cumferential welds 3 and 4 need not be made.

PtPEUNE ~ WELDING PRACTICES

17

Nore: This is die suggestcd welding sequeuce; ~ may be fonowed at the ~ of die company.

Rgure 18-Encirclement SaddJe

SECTION 5-INSPECTION ANO TESTING OF MAINTENANCE WELOS

5.1 Right of Inspection

The company has the right to inspect all of the welds by

visual and nondestructive testing methods. The inspection

may be made dwing and after the completion of the welding.

The ~ of inspection shall be as specified by the com-

pany.

The nondestructive testing should be done in accordance

with Section 8 of API Standard 1104. The welds shall meet

the standards provided in Section 6 of this recommended

practice.

5.2 Visuallnspection

All welds shaII be visually inspected for geometric confor-

mance widl de procedUIe specificaJ:ion and for conformanCe

widt Section 6.

5.4 Certification of Nondestructive

Testing Personnel

5.4.1 PROCEDURES FOR CERTIFYlNG

NONI)ESTRUCTIVE TESTING PERSONNEl

-~~~,~;~~: :. ,.

For the te5t mediOd tObe ~ nondestructive testing per-

sonnel shall be certified in accordance with the recommen-

dations of ASNT SNT -TC-I A, and only Level II or Level m

personnel shall inteIpret the test results.

5.3 Nondestructive Testing

The company should consider the size, the grade, the op-

erating stress, the location of the piping, the fluid to be n-ans-

~11ed in it, and the inherent limitations of the nondestructive

testing methods when detennining the degree of inspection

and the methods to be used. One or more nondestructive test-

in2 methods mav be used in addition to vi~ual in~~tinn

5.4.2 RECORD OF CERTIFIED

NONDESTRUCTIVETESTINGPERSONNEL

A record of certified nondesb"uctive testing personnel

shall be kent hv thP ~nrn~nv ~n"' thi~ rPI"nrri ~h~1I in~llInp

API ~ PRAcTa 1107

18

ails to comply with the requirements may be disqualified

from further work at the discretion o the company.

the results of the certification tests, d1e agency and person

granting the ceI1ification, and the date of certification. NOD-

desU1lctive testing personnel may need to be recertified if

there is any question about their ability. Also, a1 the option of

the company, they may need to be recertified at tbe begin-

ning of a project or consU1lction schedule. In any event, re-

certification sha],l be required a11east every 3 years.

Right of Rejection 5.5

The company sha1l have the right to accept or reject any

weld that does not meet the requirements of the methods by

which it was inspected. The welder who makes a weld that

5.6 Qualification of Welding Inspectors

Welding inspec~ sha1l be qualified by their experience

with and their training in the specific inspection tBSk they

perform. Their qua1ifications shall be acceptable to the com-

pany. and documentation of d1ese qualifications shall be re-

tained by the company and shall include. but not necessari1y

be limited to. d1e following:

a. Education and experience.

b. Training.

c. Results of any qua1ification examinarions.

SECTION6-STANDARDSOFACCEPTABIUTY:NONDESTRUCTIVETESTING

{INCLUDING VISUAL)

but may be elongated or irregular in shape like piping

(wormhole) porosity. Surface porosity d1at occurs on any

weld pass and. in the opinion of d1e company, is excessive

shall be Iemoved before the dcposition of additional passes.

When measuring the size of d1e radiographic indications that

porosity produces, d1e maximurn dimension of the indica-

tions shal1 apply to this acceptance standaId.

6.1 Introduction

These standards of acceptability apply to the determina-

tion of the s~ and type of defects l~ by visual and DOD-

destructive testing. While circumferential and longitudina1

butt welds sbaIl meet d1e standards of acceptability set forth

in API Standani 1104. fi1Iet welds shall meet tbe standards of

acceptability set forth in this section.

6.4.1 Porosity shall be lmacxeplable wben any o the ol-

lowing conditions exist 6.2 Umitations of Test Methods

Since nondestructive testing metbods give limited indica-

tion, the company may reject welds which appear to meet

~ standards of a=prabi1ity if. in its opinion. d1e depth of

a discontinuity may be detrimental to the weld.

a. The size of an individua1 pore exceeds X incb (3.17 mil-

limeters).

b. The size of an individual pore exceeds 25 perceDt of the

thinnest of tbe DOminal wa11 thicknesses joined.

C. The distribution of scattered porosity exceeds tbe CODcen-

tt'arion pennitted by Figure 19 or 20.

6.3 Incomplete Fusion

Incomplete fusion (1F) is defined as a discontinuity be-

1 tween weld metal and base metal which is open to the exter-

nal surface. Incomplete fusion shal1 be unacceptable when

any of the following conditions exist

a. The length of an individual indication of incornplete fu-

sion exceeds 1 inch (25.4 rnillimeters).

b. The totallength of indicatiODS of incomplete fusion in any

continuous 12-inch (304.8-millimeter) length of weld ex-

ceeds 1 inch (25.4 millimeters).

c. The totallength of indications of incomp1ete fusion ex -

ceeds 8 percent of the weld length of any weld less than 12

inches (304.8 mil1imeters) in length.

6.4.2 C1uster porosity (CP) occurring in any pass except

the finish pass sha11 comply with the requirements of 6.4.1.

Cluster porosity occurring in the finish pass sha11 be unac-

ceptable when any of the following conditions exist

a. The diameter of the cluster exceeds ~ inch ( 12. 7 millime-

ters). .

b. The total accurnulated li1gtbOf cluster porosity in any

continuous 12-inch (304.8-millimeter) length of weld ex-

ceeds ~ inch (12.7 millimeters).

.c. Any individual pore within a cluster exceeds X. inch (1.S9

millimeters ) in size.

Cracks 6.5

6.4 Porosity

Porosity (P), including surface porosity, is caused by gas

b'aDDed by solidifvin~ weld metal. It is 2enerallv SDherical

PlPEI.E MAINTENAta w~ PRACT1CES

19

Large

.

. .

.

.

.

. . .

.

2T

1 T...

~"

Nore: The sizc of die ps pockets is DOt drawn to scale; f(X" die JKOper ~ S 6.4.1.

t.,;

Figure 19-Maximum Distribution of Gas Pockets: Wall Thicknesses

less Than or Equal to ~ (nch (12.7 Millimeters}

,",~

.~".

'~

20 API ~ PRACTa 1107

~-

.

.. .

.

.

.

. .

.

.

Large

.

.

.

.

Medj~

.

.

.

. .

.

.

. . .

.

~

8 8

8 8

8 8

.

.

.

.

.

...

AIigned (It1r8e mae )

1: ." 4T-;.

8 8 8 .2T .8 8 8

I e e e-2T~

I 1T

Nace: 1be sizeofdle gas pockecs is DOt ckawn to scaie; for lile properdimensions, s= 6.4.1.

Rgure 2O-Maxjmum Distribution of Gas Pockets: Wall Thicknesses

Greater Than ~ 1rd1 (12.7 Millimeters)

'-

p~ MAHTENAta WELDtNG PP.ACT1CES 21

weld metal contraction during solidification are not consid.

ered injurious defects unless their length exceeds ~ inch

(3.97 millimeters). With the exception of these shallow

cnter cracks. no weld containing cracks. regardless of their

size or location. shall be acceptable.

Table 4-Undercutting Umits

Depd1 ~gth

6.6

Undercutting

Undercutting is a groove melted into the base metal adja-

cent to the toe or root 9f a weld and left unfilled by weld

metal. Undercutting adjacent to the cover or root bead shall

DOt exceed the limits specified in Table 4.

Over X, inch (0.79 millimeter) (X Not ~e

over 12X peICent of tbe pipe wa1l

dckness.wbicbeverissmaller

Over Y.. inch (0.4 millimeter) 2 inches (SO.8 millimeters) in a

dIroIIgh X, inch (0.79 COIItinUOUS weId of 12 I\clICS

millimeter) oc over 6 percent to (304.8 millimeters) (X X the

12X percent of the pipe wa1l length of dIe weld; whichever is

thickness. whicbever is smaller smaIIer

Y.. inch (0.4 millimeter) (X' 6 percent Acceptable. regard1ess of length

of dIe .wall dckness.

plpe ,

whichever is smaller

SECTION 7-REPAIR OR REMOVAL OF DEFECTS

7.1 Authorization for Repair by Welding

Defects may not be repaired without prior company au-

thorization.

7.2 Removal and Preparation for

Repair of Defects

Before any repairs are made. the defects shall be entirely

rernoved to dte sound metal. and all slag and scale shall be

rernoved. When conditions requiJe it. prehearing should be

perfonned.

7.3 Testing of Repairs

Repaired areas sball be reinspected using the same

method that was previously used. Additional inspection

methods may also be used.

a. The crack is less than 8 ~nt of the weld length.

b. A complete repair procedure has been developed and

documented. The repair procedure shall include the follow-

ing:

1. Method of exploration of the crack area.

2. Method of crack remova1.

3. PIeheat and interpass heat requiremenL

4. Welding procedm'e and type of e1ectrodesc.

5. Post-heat ~ent if req~

c. The repair is made under de supervisi011 of a technician

experienced in repair welding techniques.

d. The weld is made by a qua1ified welder.

e. The newly prepared groove is examined by a magnetic

particle or liquid penetrant test to assure that the crack is

completely removed.

Other cracks are to be e1iminated by removing the section of

piping containing d1eIn.

7.4 Procedure for Repair of Cracks

With the company 's authorization, cracks in or adjacent 10

welds may be ~ if the following conditions exist:

'.

AckttIonaJ copies ~ from API PtbIicatIons and Disb"bJtIon:

(202) 682-8375

Information about API PIHlC8tions, Programa and ServK:es is

8V8I1abie 00 the Workf WIde Web at http://www.api.org

American

Peh"oleum

Institute

1220 L Street, Northwest

Washington, D.C. 20005-4070

202-682-8000

Vous aimerez peut-être aussi

- Storage Tank Inspection API 650Document27 pagesStorage Tank Inspection API 650Pandu Damay Putra92% (12)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsD'EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsÉvaluation : 4.5 sur 5 étoiles4.5/5 (10)

- GMW16215 PDFDocument7 pagesGMW16215 PDFJuanPeriquitanPas encore d'évaluation

- Astm A578 - 07 PDFDocument5 pagesAstm A578 - 07 PDFMuhammad Maulana100% (1)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsD'Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsÉvaluation : 4 sur 5 étoiles4/5 (1)

- Inspection of Storage Tank API - 650Document4 pagesInspection of Storage Tank API - 650Michael Albuquerque0% (1)

- ASME Section IX Welding Qualification RequirementsDocument5 pagesASME Section IX Welding Qualification Requirementskirubha_karan2000Pas encore d'évaluation

- ASME 8 Div 1 Appendix 7 Examination of Steel CastingsDocument3 pagesASME 8 Div 1 Appendix 7 Examination of Steel CastingsSiggy Lai75% (4)

- Storage Tank (API 650)Document20 pagesStorage Tank (API 650)sbmmla83% (6)

- Back To The FutureDocument96 pagesBack To The FutureAlber Sánchez50% (2)

- Welder Performance Qualification AsmeDocument14 pagesWelder Performance Qualification AsmeAhmad RizkiPas encore d'évaluation

- Note 7 - Welder Test - Mechanical Test and X-RayDocument29 pagesNote 7 - Welder Test - Mechanical Test and X-RayMohamad Yusuf HelmiPas encore d'évaluation

- API 1104 2014 EditionDocument17 pagesAPI 1104 2014 EditionekkyPas encore d'évaluation

- 2-Asme BPVC Section Ix-2013Document2 pages2-Asme BPVC Section Ix-2013Reda ElsawyPas encore d'évaluation

- E190 1044228-1Document4 pagesE190 1044228-1mantra2010Pas encore d'évaluation

- API 1104 VT TestDocument2 pagesAPI 1104 VT TestRao Javaid IqbalPas encore d'évaluation

- Pipeline Welding Qualification TestsDocument2 pagesPipeline Welding Qualification TestsKali AbdennourPas encore d'évaluation

- G10 PDFDocument3 pagesG10 PDFSameer Sa100% (1)

- Module 1: Code Basics: Part QW WeldingDocument12 pagesModule 1: Code Basics: Part QW WeldingaliPas encore d'évaluation

- Tensile Stress-Strain of Carbon and Graphite: Standard Test Method ForDocument12 pagesTensile Stress-Strain of Carbon and Graphite: Standard Test Method Forsj19330Pas encore d'évaluation

- 6-15-0003 Rev 4Document9 pages6-15-0003 Rev 4cynidePas encore d'évaluation

- Astm E190 - 97 - Procedimiento de Doblez (Traducción)Document7 pagesAstm E190 - 97 - Procedimiento de Doblez (Traducción)Ivan D100% (1)

- Guided Bend Test For Ductility of WeldsDocument3 pagesGuided Bend Test For Ductility of WeldsErlinawati Bintu SupiyoPas encore d'évaluation

- B 565 - 94 R00 - Qju2ns05nfiwmaDocument3 pagesB 565 - 94 R00 - Qju2ns05nfiwmamalika_00Pas encore d'évaluation

- Bend Test ProcedureDocument9 pagesBend Test ProcedureRavi pandeyPas encore d'évaluation

- Specific Bendability of Pipeline Coatings: Standard Test Method ForDocument3 pagesSpecific Bendability of Pipeline Coatings: Standard Test Method Forvuqar0979Pas encore d'évaluation

- Welder Performance Qualification ProcedureDocument25 pagesWelder Performance Qualification ProceduresajiPas encore d'évaluation

- Ductility of Oriented Electrical Steel: Standard Test Method ForDocument2 pagesDuctility of Oriented Electrical Steel: Standard Test Method Fornvh202148Pas encore d'évaluation

- G 10 - 83 R02 - RzewDocument3 pagesG 10 - 83 R02 - RzewAndres PalacioPas encore d'évaluation

- Storage Tank API 650Document20 pagesStorage Tank API 650jalison07xPas encore d'évaluation

- Hardness of Mineral Aggregate Used On Built-Up Roofs: Standard Test Method ForDocument2 pagesHardness of Mineral Aggregate Used On Built-Up Roofs: Standard Test Method FordaovandongpktPas encore d'évaluation

- This Is Very Common in Tank ConstructionDocument11 pagesThis Is Very Common in Tank ConstructionsbmmlaPas encore d'évaluation

- Asme Sec Ix-WpqDocument47 pagesAsme Sec Ix-WpqKaushal Sojitra100% (1)

- Specific Bendability of Pipeline Coatings: Standard Test Method ForDocument3 pagesSpecific Bendability of Pipeline Coatings: Standard Test Method ForCamilo GuardadoPas encore d'évaluation

- Extracted Pages From Section IX-2015Document78 pagesExtracted Pages From Section IX-2015Jhony ValenciaPas encore d'évaluation

- B 565 - 04 - Qju2nqDocument3 pagesB 565 - 04 - Qju2nqmalika_00Pas encore d'évaluation

- RT Asme IxDocument3 pagesRT Asme Ixhernando gelves100% (1)

- WPQTDocument10 pagesWPQTnike_y2kPas encore d'évaluation

- D 1623 - 78 r95 - Rde2mjmtukveDocument8 pagesD 1623 - 78 r95 - Rde2mjmtukveSiddhesh Umesh MestryPas encore d'évaluation

- 28b. IS 3600 - 2 - 1985 PDFDocument2 pages28b. IS 3600 - 2 - 1985 PDFhhr2412Pas encore d'évaluation

- B769Document4 pagesB769wpwmhatPas encore d'évaluation

- Astm D2290-00Document5 pagesAstm D2290-00T Mathew TholoorPas encore d'évaluation

- QW-162 Guided-Bend Test Procedure: QW-466.1 Figure QW-466.2 Figure QW-463.1 (F)Document2 pagesQW-162 Guided-Bend Test Procedure: QW-466.1 Figure QW-466.2 Figure QW-463.1 (F)Gangadhar SahuPas encore d'évaluation

- D 1052 - 85 R99 - RdewntiDocument4 pagesD 1052 - 85 R99 - RdewntimanthandevPas encore d'évaluation

- ASTM D 2290Document5 pagesASTM D 2290Pablo AlcázarPas encore d'évaluation

- D 2444 - 99 Rdi0ndqDocument8 pagesD 2444 - 99 Rdi0ndqHumberto GutierrezPas encore d'évaluation

- Aluminum Welding ProceedureDocument14 pagesAluminum Welding ProceedureGregEverett2Pas encore d'évaluation

- Degradation of Fine Aggregate Due To Attrition: Standard Test Method ForDocument3 pagesDegradation of Fine Aggregate Due To Attrition: Standard Test Method ForRam Kumar JaiswalPas encore d'évaluation

- Ur-W27rev1 - Cast Steel PropellersDocument9 pagesUr-W27rev1 - Cast Steel PropellersJohnPas encore d'évaluation

- Straight-Beam Ultrasonic Examination of Steel Plates': Standard SpecificationDocument2 pagesStraight-Beam Ultrasonic Examination of Steel Plates': Standard SpecificationRegis KoroivaPas encore d'évaluation

- 5504Document10 pages5504hhr2412Pas encore d'évaluation

- ASTM D 1634-00 Standard Test Method For Compressive Strength of Soil-Cement Using Portions of Beams Broken in Flexure (Modified Cube Method)Document3 pagesASTM D 1634-00 Standard Test Method For Compressive Strength of Soil-Cement Using Portions of Beams Broken in Flexure (Modified Cube Method)Pablo Antonio Valcárcel VargasPas encore d'évaluation

- 01 Samss 022Document6 pages01 Samss 022aamirtec301Pas encore d'évaluation

- Ultrasonic Testing of Steel Plates for DiscontinuitiesDocument6 pagesUltrasonic Testing of Steel Plates for DiscontinuitiesDavid EstradaPas encore d'évaluation

- 12 - Exhibit C Sp-Welding of Pipelines &facilitiesDocument13 pages12 - Exhibit C Sp-Welding of Pipelines &facilitiesMoaatazz Nouisri100% (1)

- Pressuremeter Testing: Methods and InterpretationD'EverandPressuremeter Testing: Methods and InterpretationÉvaluation : 5 sur 5 étoiles5/5 (2)

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingD'EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingPas encore d'évaluation

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyD'EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinPas encore d'évaluation

- English Exercises - Have To - Want To - Need To - Like ToDocument2 pagesEnglish Exercises - Have To - Want To - Need To - Like ToYersin Hernandez Aldan0% (1)

- Anchor Flange DetailDocument1 pageAnchor Flange DetailYersin Hernandez AldanPas encore d'évaluation

- ACI 309R-96 Guide For Consolidation of Concrete: Reported by ACI Committee 309Document39 pagesACI 309R-96 Guide For Consolidation of Concrete: Reported by ACI Committee 309Alexandru Constantinescu100% (1)

- UR Ingdom Inistry: APRIL2014Document8 pagesUR Ingdom Inistry: APRIL2014Yersin Hernandez AldanPas encore d'évaluation

- Adhesion ASTM D 4541 09e1 092613Document2 pagesAdhesion ASTM D 4541 09e1 092613Yersin Hernandez AldanPas encore d'évaluation

- English Exercises - Have To - Want To - Need To - Like ToDocument2 pagesEnglish Exercises - Have To - Want To - Need To - Like ToYersin Hernandez Aldan0% (1)

- Pipeline welding practices guideDocument14 pagesPipeline welding practices guideYersin Hernandez AldanPas encore d'évaluation

- Anchor Flange DetailDocument1 pageAnchor Flange DetailYersin Hernandez AldanPas encore d'évaluation

- API 2201 Hot TapingDocument17 pagesAPI 2201 Hot TapingYersin Hernandez AldanPas encore d'évaluation