Académique Documents

Professionnel Documents

Culture Documents

Wall Climbing Robot by Kartik

Transféré par

Vishal SharmaTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Wall Climbing Robot by Kartik

Transféré par

Vishal SharmaDroits d'auteur :

Formats disponibles

Wall climbing robot

2014

WALL CLIMBING ROBOT

A PROJECT REPORT

Submitted

I n partial fulfillment for the award of the degree

Of

BACHELOR OF TECHNOLOGY

IN

MECHANICAL ENGINEERING

Under The Guidance of Submitted by

Ms Kirti Singh Kartik Arora(11011595)

Assistant Professor Sahil Johri(11113770)

Avinash Kr. Rai(11006690)

Gajendra Kr. Nag(11004799)

Parveen Thakur(11001921)

LOVELY PROFESSIONAL UNIVERSITY

Phagwara-144401, Punjab (India)

Wall climbing robot

2014

ACKNOWLEDGEMENT

I would like to place on record my deep sense of gratitude to Er. Kirti Singh,our Mentor for the

her generous guidance, help and useful suggestions.

I express my sincere gratitude to Mr. Ravinder Singh, Machining operatios guide for his

stimulating guidance, and continuous encouragement .

I am extremely thankful to Prof Gurpreet Singh Phull, HOD, Lovely Professional University

Jalandhar, for valuable suggestions and encouragement .

I am also thankful to my colleagues, family and friend for there continuous encouragement and

support in every possible way

Wall climbing robot

2014

TABLE OF CONTENTS

Chapter 1 Introduction 1

Chapter 2 Tech Rationale And Problem Statement 2

Chapter 3 Components

3.1 Aluminium Strip 3

3.2 Nut And Bolt 3

3.3 DC Servomotors 5

3.3.1 Mechanism 5

3.3.2 Control 6

3.3.3 Servomotors vs Steppermotors 6

3.4 Solenoid 7

3.5 Relays 9

3.5.1 Basic Design and Operation 10

3.5.2 Applications 11

3.6 Suction Cups 11

3.6.1 Calculations 12

3.6.2 Uses 13

3.7 Hose Pipes 13

3.7.1 Applications 13

3.8 Pneumatic Cylinder 15

3.8.1 Operation 16

3.8.2 Specialized functions 16

Wall climbing robot

2014

3.8.3 Fail safe mechanism 16

3.8.4 Types 16

3.8.5 Single Acting Cylinder 16

3.8.6 Double Acting Cylinder 17

3.8.7 Other Types 17

3.8.8 Sizes 18

3.9 Compressor 18

3.9.1 Types Of Air Compressor 18

3.9.2 Positive Displacement 18

3.9.3 Negative Displacement 19

3.9.4 Cooling 19

3.9.5 Applications 19

3.10 Battery 20

3.10.1 Principle of operation 21

3.11 Switches 21

Chapter 4 Processes Used

4.1 Soldering 24

4.1.1 Solder 24

4.1.2 Flux 25

4.1.3 Electronic Components 25

4.1.4 Tools 26

4.2 Drilling 26

4.2.1 Processes 27

Wall climbing robot

2014

4.2.2 Drill 28

4.2.3 Types 28

4.3 Filing 29

4.3.1 Band Filing 29

4.3.2 Reciprocating Filing 29

4.4 Cutting 29

Chapter 5 Work Plan And Flow Chart

5.1 Work Timeline 30

5.2 Flow Chart 31

Chapter 6 Experimental Work Done 33

6.1 Main Cost 35

Chapter 7 Features Of Wall Climbing Robot 36

Chapter 8 Result

8.1 Uses Of Wall Climbing Robot 37

8.2 Drawbacks 38

Chapter 9 Conclusion And Future Scope 39

Refrences

Bibliography

Wall climbing robot

2014

LIST OF FIGURES

Figure 1- Aluminium Strips Page 3

Figure 2- DC Servomotor Page 6

Figure 3- Solenoid valve Page 8

Figure 4- Relay Page 10

Figure 5- Hose Pipe Page 14

Figure 6- Pneumatic Cylinder Page 15

Figure 7- Single Acting Cylinder Page 17

Figure 8- Double Acting Cylinder Page 17

Figure 9- Compressor Page 19

Figure 10- Battery Page 21

Figure 11- Switches Page 23

Figure 12- Soldering Tool Page 24

Wall climbing robot

2014

LIST OF TABLES AND FLOWCHARTS

Table 1- Work Plan Page 30

Table 2- Cost Of Parts Page 35

Flowchart 1-Processes Involved Page 31-32

Wall climbing robot

2014

CHAPTER 1

INTRODUCTION

The main goal for our semester project was to construct a wall climbing robot, which would

be controlled using switches and act according to users will. There are two kind of wall-

climbing robots in the lab. One is called "Flipper" the other is called "Crawler". The restrictions

such as small size, light weight and low power consumption must be complied when designing

the miniature robot. Robots have been created to assist or replace humans in various dangerous

and difficult tasks. Robots have been used in construction, manufacturing, security and etc. This

is because they are able to adapt to different environments and situations. They have conquered

nearly all environments that humans have put them through. Climbing robots can be used on

artificial surfaces like a wall, or on natural surfaces like trees or cave walls. They are desirable

for several applications such as search and rescue. This phenomenon is still a challenge to be

achieved using robotic devices. Climbing robots should have some practical utility to deal with

different surfaces and geometries. This can be achieved by the use of special purpose attachment

devices such as magnets or suction.

Initially we had to figure out what every element did, and to get them to work. The main

components of the climber were the switches , solenoids, pneumatic cylinders, compressor and a

power supply. Throughout the semester we first got every individual component of the climber

to work, and tested the functionality. We also re soldered much of the internal circuitry of the

climber, in order to cut down total amount of wires. We added a two way switch so that the

movements of the robotic arms be modified according to the need. In the end we had made a

climber which was controlled using switches , and pneumatic cylinders actuations.

Wall climbing robot

2014

CHAPTER 2

TECH RATIONALE AND PROBLEM STATEMENT

A wall climbing robot can have many uses. Our robot specifically is useful for going into an

area and being able to view the area without having any humans entering the potentially

dangerous area. The uses of this for military applications are obvious, to send a robot into a

potentially dangerous area to see if there are any enemy soldiers or bombs without endangering

soldiers lives. Another potential use would be to send the robot into areas a human couldnt

physically go like a crawl space or cave of some kind and gather data. Technically the robot is

rather simple, as there are three servomotors, two pneumatic cylinders , two suction cups and

few circuits. One potential downfall is that the robot needs a relatively smooth surface to either

traverse or climb, but in principal the robot shows the ability to gain information remotely. Also

we would have to conduct experiments to see the distance able for the robot to be controlled and

also to send information back to the user.

The main problem faced during the project was of the length and weight of robot. If we

could have been able to reduce the length of the links automatically we would have cut down on

weight also. The suction pressure inside the cups can be increased and decreased which will help

in making us climb heavier bots

Wall climbing robot

2014

CHAPTER 3

COMPONENTS

3.1 Aluminium Strip

Aluminium is a chemical element in the boron group with symbol Al and atomic number 13.

It is a silvery white, soft, ductile metal. Aluminium is the third most abundant

element (after oxygen and silicon), and the most abundant metal, in the Earth's crust. It makes up

about 8% by weight of the Earth's solid surface. Aluminium metal is so chemically reactive that

native specimens are rare and limited to extreme reducing environments. Instead, it is found

combined in over 270 different minerals. The chief ore of aluminium is bauxite.

Length of strips used:

1. Link 1 = Link 4 = 14.8cm

2. Link 2 = Link 3 =17.6cm

3. Total Length = 64.8cm = 0.648m

Figure 1 Aluminium Strips

Wall climbing robot

2014

3.2 Nut And Bolt

A screw, or bolt, is a type of fastener characterized by a helical ridge, known as an external

thread or just thread, wrapped around a cylinder. Some screw threads are designed to mate with a

complementary thread, known as an internal thread, often in the form of a nut or an object that

has the internal thread formed into it. Other screw threads are designed to cut a helical groove in

a softer material as the screw is inserted. The most common uses of screws are to hold objects

together and to position objects. A screw will almost always have a head, (a set screw is an

example of a screw without a head) which is a specially formed section on one end of the screw

that allows it to be turned, or driven. Common tools for driving screws include screw drivers

and wrenches. The head is usually larger than the body of the screw, which keeps the screw from

being driven deeper than the length of the screw and to provide a bearing surface. There are

exceptions; for instance, carriage bolts have a domed head that is not designed to be driven; set

screws often have a head smaller than the outer diameter of the screw; J-bolts have a J-shaped

head which is not designed to be driven, but rather is usually sunk into concrete allowing it to be

used as an anchor bolt. The cylindrical portion of the screw from the underside of the head to the

tip is known as the shank; it may be fully threaded or partially threaded. The distance between

each thread is called the "pitch".

The majority of screws are tightened by clockwise rotation, which is termed a right-hand

thread; a common mnemonic device for remembering this when working with screws or bolts is

"righty-tighty, lefty-loosey." Screws with left-hand threads are used in exceptional cases. For

example, when the screw will be subject to counterclockwise torque (which would work to undo

a right-hand thread), a left-hand-threaded screw would be an appropriate choice. The left

side pedal of a bicycle has a left-hand thread.

More generally, screw may mean any helical device, such as a clamp, a micrometer, a ship's

propeller or an Archimedes' screw water pump

A nut is a type of fastener with a threaded hole. Nuts are almost always used opposite a

mating bolt to fasten a stack of parts together. The two partners are kept together by a

combination of their threads' friction, a slight stretch of the bolt, and compression of the parts. In

applications where vibration or rotation may work a nut loose, various locking mechanisms may

Wall climbing robot

2014

be employed: Adhesives, safety pins orlockwire, nylon inserts, or slightly oval-shaped threads.

The most common shape is hexagonal, for similar reasons as the bolt head - 6 sides give a good

granularity of angles for a tool to approach from (good in tight spots), but more (and smaller)

corners would be vulnerable to being rounded off. Other specialized shapes exist for certain

needs, such as wing nuts for finger adjustment and captive nuts for inaccessible areas.Nuts are

graded with strength ratings compatible with their respective bolts; for example, an ISO property

class 10 nut will be able to support the bolt proof strength load of an ISO property class 10.9 bolt

without stripping. Likewise, an SAE class 5 nut can support the proof load of an SAE class 5

bolt, and so on.

A wide variety of nuts exists, from household hardware versions to specialized industry-specific

designs that are engineered to meet various technical standards.

1. Number of Nuts Used = 37

2. Number of Bolts Used = 20

3.3 DC Servomotors

A servomotor is a rotary actuator that allows for precise control of angular position, velocity

and acceleration. It consists of a suitable motor coupled to a sensor for position feedback. It

also requires a relatively sophisticated controller, often a dedicated module designed

specifically for use with servomotors. Servomotors are not a specific class of motor although

the term servomotor is often used to refer to a motor suitable for use in a closed-loop control

system.

Servomotors are used in applications such as robotics, CNC machinery or automated

manufacturing.

3.3.1 Mechanisms

As the name suggests, a servomotor is a servomechanism. More specifically, it is a closed-

loop servomechanism that uses position feedback to control its motion and final position. The

input to its control is some signal, either analogue or digital, representing the position

commanded for the output shaft. The motor is paired with some type of encoder to provide

position and speed feedback. In the simplest case, only the position is measured. The measured

Wall climbing robot

2014

position of the output is compared to the command position, the external input to the controller.

If the output position differs from that required, an error signal is generated which then causes

the motor to rotate in either direction, as needed to bring the output shaft to the appropriate

position. As the positions approach, the error signal reduces to zero and the motor stops.

The very simplest servomotors use position-only sensing via a potentiometer and bang-bang

control of their motor; the motor always rotates at full speed (or is stopped). This type of

servomotor is not widely used in industrial motion control, but it forms the basis of the simple

and cheap servos used for radio-controlled models.

More sophisticated servomotors measure both the position and also the speed of the output

shaft. They may also control the speed of their motor, rather than always running at full speed.

3.3.2 Control

Most modern servomotors are designed and supplied around a dedicated controller module from

the same manufacturer. Controllers may also be developed around microcontrollers in order to

reduce cost for large volume applications.

3.3.3 Servomotors vs. stepper motors

A servomotor consumes power as it rotates to the commanded position but then the

servomotor rests. Stepper motors run warm to the touch because they continue to consume

power to lock in and hold the commanded position. Servomotors are generally used as a

high performance alternative to the stepper motor. Stepper motors have some inherent

ability to control position, as they have built-in output steps. The stepper motor can only

drive a load that is well within its capacity, otherwise missed steps under load may lead to

positioning errors. The encoder and controller of a servomotor are an additional cost, but

they optimise the performance of the overall system (for all of speed, power and accuracy)

relative to the capacity of the basic motor. With larger systems, where a powerful motor

represents an increasing proportion of the system cost, servomotors have the advantage.

Many applications, such as laser cutting machines, may be offered in two ranges, the low-

priced range using stepper motors and the high-performance range using servomotors.

Wall climbing robot

2014

Figure 2 Servo Motor

Number of Dc servomotors used are 3

3.4 Solenoid Valves

A solenoid valve is an electro-mechanical valve for use with liquid or gas. The valve

is controlled by an electric current through a solenoid in the case of a two-port valve the

flow is switched on or off; in the case of a three-port valve, the outflow is switched

between the two outlet ports. Multiple solenoid valves can be placed together on

a manifold. Solenoid valves are the most frequently used control elements in fluidics. Their

tasks are to shut off, release, dose, distribute or mix fluids. They are found in many

application areas. Solenoids offer fast and safe switching, high reliability, long service life,

good medium compatibility of the materials used, low control power and compact design.

Besides the plunger-type actuator which is used most frequently, pivoted-armature

actuators and rocker actuators are also used.

A solenoid valve has two main parts: the solenoid and the valve. The solenoid converts

electrical energy into mechanical energy which, in turn, opens or closes the valve

mechanically. A direct acting valve has only a small flow circuit, shown within section E of

this diagram (this section is mentioned below as a pilot valve). This diaphragm piloted

Wall climbing robot

2014

valve multiplies this small flow by using it to control the flow through a much larger

orifice.

Solenoid valves may use metal seals or rubber seals, and may also have electrical interfaces

to allow for easy control. A spring may be used to hold the valve opened or closed while

the valve is not activated.

Figure 3 Solenoid Valve

A input side B diaphragm

C pressure chamber D pressure relief conduit

E solenoid F output side

The diagram to the right shows the design of a basic valve. At the top figure is the valve

in its closed state. The water under pressure enters at A. B is an elastic diaphragm and above it is

a weak spring pushing it down. The function of this spring is irrelevant for now as the valve

would stay closed even without it. The diaphragm has a pinhole through its center which allows

a very small amount of water to flow through it. This water fills the cavity C on the other side of

the diaphragm so that pressure is equal on both sides of the diaphragm, however the compressed

spring supplies a net downward force. The spring is weak and is only able to close the inlet

because water pressure is equalized on both sides of the diaphragm.

Wall climbing robot

2014

In the previous configuration the small conduit D was blocked by a pin which is the

armature of the solenoid E and which is pushed down by a spring. If the solenoid is activated by

drawing the pin upwards via magnetic force from the solenoid current, the water in

chamber C will flow through this conduit D to the output side of the valve. The pressure in

chamber C will drop and the incoming pressure will lift the diaphragm thus opening the main

valve. Water now flows directly from A to F.

When the solenoid is again deactivated and the conduit D is closed again, the spring

needs very little force to push the diaphragm down again and the main valve closes. In practice

there is often no separate spring, the elastomer diaphragm is molded so that it functions as its

own spring, preferring to be in the closed shape.

From this explanation it can be seen that this type of valve relies on a differential of pressure

between input and output as the pressure at the input must always be greater than the pressure at

the output for it to work. Should the pressure at the output, for any reason, rise above that of the

input then the valve would open regardless of the state of the solenoid and pilot valve.

In some solenoid valves the solenoid acts directly on the main valve. Others use a small,

complete solenoid valve, known as a pilot, to actuate a larger valve. While the second type is

actually a solenoid valve combined with a pneumatically actuated valve, they are sold and

packaged as a single unit referred to as a solenoid valve. Piloted valves require much less power

to control, but they are noticeably slower. Piloted solenoids usually need full power at all times

to open and stay open, where a direct acting solenoid may only need full power for a short period

of time to open it, and only low power to hold it.

3.5 Relays

A relay is an electrically operated switch. Many relays use an electromagnet to mechanically

operate a switch, but other operating principles are also used, such as solid-state relays. Relays

are used where it is necessary to control a circuit by a low-power signal (with complete electrical

isolation between control and controlled circuits), or where several circuits must be controlled by

Wall climbing robot

2014

one signal. The first relays were used in long distance telegraph circuits as amplifiers: they

repeated the signal coming in from one circuit and re-transmitted it on another circuit. Relays

were used extensively in telephone exchanges and early computers to perform logical operations.

A type of relay that can handle the high power required to directly control an electric motor or

other loads is called a contactor. Solid-state relays control power circuits with no moving parts,

instead using a semiconductor device to perform switching. Relays with calibrated operating

characteristics and sometimes multiple operating coils are used to protect electrical circuits from

overload or faults; in modern electric power systems these functions are performed by digital

instruments still called "protective relays".

Figure 4 Relay

3.5.1 Basic Design and Operation

A simple electromagnetic relay consists of a coil of wire wrapped around a soft iron core, an

iron yoke which provides a low reluctance path for magnetic flux, a movable iron armature, and

one or more sets of contacts (there are two in the relay pictured). The armature is hinged to the

yoke and mechanically linked to one or more sets of moving contacts. It is held in place by

a spring so that when the relay is de-energized there is an air gap in the magnetic circuit. In this

condition, one of the two sets of contacts in the relay pictured is closed, and the other set is open.

Other relays may have more or fewer sets of contacts depending on their function. The relay in

the picture also has a wire connecting the armature to the yoke. This ensures continuity of the

Wall climbing robot

2014

circuit between the moving contacts on the armature, and the circuit track on the printed circuit

board (PCB) via the yoke, which is soldered to the PCB.

When an electric current is passed through the coil it generates a magnetic field that activates the

armature, and the consequent movement of the movable contact(s) either makes or breaks

(depending upon construction) a connection with a fixed contact. If the set of contacts was closed

when the relay was de-energized, then the movement opens the contacts and breaks the

connection, and vice versa if the contacts were open. When the current to the coil is switched off,

the armature is returned by a force, approximately half as strong as the magnetic force, to its

relaxed position. Usually this force is provided by a spring, but gravity is also used commonly in

industrial motor starters. Most relays are manufactured to operate quickly. In a low-voltage

application this reduces noise; in a high voltage or current application it reduces arcing.

When the coil is energized with direct current, a diode is often placed across the coil to dissipate

the energy from the collapsing magnetic field at deactivation, which would otherwise generate

a voltage spike dangerous to semiconductor circuit components. Some automotive relays include

a diode inside the relay case. Alternatively, a contact protection network consisting of a capacitor

and resistor in series may absorb the surge. If the coil is designed to be energized with alternating

current (AC), a small copper "shading ring" can be crimped to the end of the solenoid, creating a

small out-of-phase current which increases the minimum pull on the armature during the AC

cycle.

A solid-state relay uses a thyristor or other solid-state switching device, activated by the control

signal, to switch the controlled load, instead of a solenoid. An optocoupler (a light-emitting

diode (LED) coupled with a photo transistor) can be used to isolate control and controlled

circuits

3.5.2 Applications

Relays are used for:

Amplifying a digital signal, switching a large amount of power with a small operating

power. Some special cases are:

A telegraph relay, repeating a weak signal received at the end of a long wire

Wall climbing robot

2014

Controlling a high-voltage circuit with a low-voltage signal, as in some types

of modems or audio amplifiers,

Controlling a high-current circuit with a low-current signal, as in the starter solenoid of

an automobile,

3.6 Suction cups

A suction cup, also sometimes known as a sucker, is an object that uses negative fluid pressure

of air or water to adhere to nonporous surfaces and in the process creates a partial vacuum. They

exist both as artificially created devices, and as anatomical traits of some animals such

as octopuses and squid.

The working face of the suction cup has a curved surface. When the center of the suction cup is

pressed against a flat, non-porous surface, the volume of the space between the suction cup and

the flat surface is reduced, which causes the fluid between the cup and the surface to be expelled

past the rim of the circular cup. When the user ceases to apply physical pressure to the centre of

the outside of the cup, the elastic substance of which the cup is made tends to resume its original,

curved shape. Because most of the fluid has already been forced out of the inside of the cup, the

cavity which tends to develop between the cup and the flat surface has little to no air or water in

it, and therefore lacks pressure. The pressure difference between the atmosphere on the outside

of the cup, and the low-pressure cavity on the inside of the cup, is what keeps the cup adhered to

the surface.

3.6.1 Calculations

The force required to detach an ideal suction cup by pulling it directly away from the surface is

given by the formula:

Wall climbing robot

2014

where:

F is the force,

A is the area of the surface covered by the cup,

P is the pressure outside the cup (typically atmospheric pressure)

This is derived from the definition of pressure, which is:

For example, a suction cup of radius 2.0 cm has an area of (0.020 m)

2

= 0.0013 square meters.

Using the force formula (F = AP), the result is F = (0.0013 m

2

)(100,000 Pa) = about

130 newtons.

The above formula relies on several assumptions:

The outer diameter of the cup does not change when the cup is pulled.

No air leaks into the gap between the cup and the surface.

The pulling force is applied perpendicular to the surface so that the cup does not slide

sideways or peel off.

3.6.2 Uses

Suction cups have a number of commercial and industrial applications:

In office and household settings, to affix objects (ranging from signs to mugs) to nonporous

vertical surfaces such as refrigerator doors and tiled walls

To move large smooth objects such as panes of glass, automobile windscreens and raised

floor tiles

In toys such as Nerf darts

In toilet plungers

3.7 Hose pipes

Wall climbing robot

2014

A hose is a flexible hollow tube designed to carry fluids from one location to another. Hoses are

also sometimes called pipes (the word pipe usually refers to a rigid tube, whereas a hose is

usually a flexible one), or more generally tubing. The shape of a hose is usually cylindrical

(having a circular cross section). Hose design is based on a combination of application and

performance. Common factors are Size, Pressure Rating, Weight, Length, Straight hose or Coil

hose and Chemical Compatibility. Hoses are made from one or a combination of many different

materials. Applications mostly use nylon, polyurethane, polyethylene, PVC, or synthetic or

natural rubbers, based on the environment and pressure rating needed. In recent years, hoses can

also be manufactured from special grades of polyethylene (LDPE and especially LLDPE). Other

hose materials include PTFE (Teflon), stainless steel and other metals.

3.7.1 Applications

Hoses can be used in water or other liquid environments or to convey air or other gases. Hoses

are used to carry fluids through air or fluid environments, and they are typically used with

clamps, spigots, flanges, and nozzles to control fluid flow.

Figure 5 Hose pipes

Specific applications include the following:-

1. A garden hose is used to water plants in a garden or lawn, or to convey water to a

sprinkler for the same purpose.

Wall climbing robot

2014

2. A Tough Hose is used to water crops in agriculture for drip irrigation

3. A fire hose is used by firefighters to convey water to the site of a fire.

4. Air hoses are used in underwater diving to carry air from a surface compressor or from

air tanks. (See also Snorkeling.) Industrial uses for operating flexible machinery and

worktable tooling such as pneumatic screw drivers, grinders, staplers, etc.

5. In building services, metal or plastic hoses are used to move water around a building;

whilst air ducts are used to move air around (see air conditioning). They can also be used

to take out vibration, and thermal or settlement movement.

6. Automotive hoses are used in automobiles to move fluids around for use in cooling,

lubrication, and/or hydraulics. Hoses are also used to convey pressure or vacuum signals

to control circuits or gauges, as well as conveying vacuum to heating, cooling, brake,

and/or locking systems.

7. In chemistry and medicine, hoses (usually called tubes) are used to move liquid

chemicals or gases around.

8. Beating someone with a rubber hose is a known form of torture. It's sometimes referred

to in a tongue-in-cheek manner such as in Rubber-hose cryptanalysis, a method of

breaking into secured systems by torturing someone to give up a password.

3.8 Pneumatic cylinder:

Pneumatic cylinders (sometimes known as air cylinders) are mechanical devices which

use the power of compressed gas to produce a force in a reciprocating linear motion. Like

hydraulic cylinders, pneumatic cylinders use the stored potential energy of a fluid, in this case

compressed air, and convert it into kinetic energy as the air expands in an attempt to reach

atmospheric pressure. This air expansion forces a piston to move in the desired direction. The

piston is a disc or cylinder, and the piston rod transfers the force it develops to the object to be

Wall climbing robot

2014

moved. Engineers prefer to use pneumatics sometime because they are quieter, cleaner, and do

not require large amounts or space for fluid storage.

Figure 6 Pnuematic cylinder

Single- and Double-Acting Air Cylinders

All models feature high-strength, double rolled Type 304 stainless steel body, aluminum

alloy end caps, Type 303 stainless steel piston rods, and sintered bronze bearings.

Recommended for operating temperatures of -20 Degree to 200 Degree F. 250 psi max.

Operating pressure. Single-acting cylinders are spring loaded.

These are mechanical devices which produce force, often in combination with movement, and

are powered by compressed gas (typically air). To perform their function, pneumatic cylinders

impart a force by converting the potential energy of compressed gas into kinetic energy. This is

achieved by the compressed gas being able to expand, without external energy input, which itself

occurs due to the pressure gradient established by the compressed gas being at a greater pressure

than the atmospheric pressure. This air expansion forces a piston to move in the desired

direction.

3.8.1 Operation

Wall climbing robot

2014

Once actuated, compressed air enters into the tube at one end of the piston and, hence, imparts

force on the piston. Consequently, the piston becomes displaced (moved) by the compressed air

expanding in an attempt to reach atmospheric pressure.

3.8.2 Specialized functions

Depending upon the design of the system, pneumatic cylinders can operate in a variety of

ways. Examples include having the ability to perform multiple strokes without the need for

intermediate intervention, to perform a full stroke with intermediate stopping points, to be

adjusted so as to control the amount of extension and/or retraction of the piston rod once

actuated.

3.8.3 Fail safe mechanisms

Pneumatic systems are often found in settings where even rare and brief system failure is

unacceptable. In such situations locks can sometimes serve as a safety mechanism in case of loss

of air supply (or its pressure falling) and, thus, remedy or abate any damage arising in such a

situation. Due to the leakage of air from i/p or o/p reduces the pressure and so the desired o/p.

3.8.4 Types

Although pneumatic cylinders will vary in appearance, size and function, they generally

fall into one of the specific categories shown below. However there are also numerous other

types of pneumatic cylinder available, many of which are designed to fulfill specific and

specialized functions.

3.8.5 Single acting cylinders

Single acting cylinders (SAC) use the force imparted by air to move in one direction

(usually out), and a spring to return to the "home" position.

Wall climbing robot

2014

Figure 7 Single Acting Cylinder

3.8.6 Double acting cylinders

Double Acting Cylinders (DAC) use the force of air to move in both extend and retract

strokes. They have two ports to allow air in, one for outstroke and one for instroke.

Figure 8 Double Acting Cylinder

3.8.7 Other types

Although SACs and DACs are the most common types of pneumatic cylinder, the

following types are not particularly rare:

Rotary air cylinders: actuators that use air to impart a rotary motion

Rodless air cylinders: actuators that use a mechanical or magnetic coupling to impart

force, typically to a table or other body that moves along the length of the cylinder body,

but does not extend beyond it.

Wall climbing robot

2014

3.8.8 Sizes

Air cylinders are available in a variety of sizes and can typically range from a small

2.5 mm air cylinder, which might be used for picking up a small transistor or other electronic

component, to 400 mm diameter air cylinders which would impart enough force to lift a car.

Some pneumatic cylinders reach 1000 mm in diameter, and are used in place of hydraulic

cylinders for special circumstances where leaking hydraulic oil could impose an extreme hazard.

3.9 Compressor

An air compressor is a device that converts power (usually from an electric motor, a diesel

engine or a gasoline engine) into kinetic energy by compressing and pressurizing air, which, on

command, can be released in quick bursts. There are numerous methods of air compression,

divided into either positive-displacement or negative-displacement types

3.9.1 Types of air compressor

According to the design and principle of operation

1. Reciprocating compressor

2. Rotary screw compressor

3. Turbo compressor

3.9.2 Positive displacement

Positive-displacement air compressors work by forcing air into a chamber whose volume is

decreased to compress the air. Piston-type air compressors use this principle by pumping air into

an air chamber through the use of the constant motion of pistons. They use one-way valves to

guide air into a chamber, where the air is compressed Rotary screw compressors also use

positive-displacement compression by matching two helical screws that, when turned, guide air

into a chamber, whose volume is decreased as the screws turn. Vane compressors use a slotted

rotor with varied blade placement to guide air into a chamber and compress the volume. A type

Wall climbing robot

2014

of compressor that delivers a fixed volume of air at high pressures. Common types of positive

displacement compressors include piston compressors and rotary screw compressors.

3.9.3 Negative displacement

Negative-displacement air compressors include centrifugal compressors. These use centrifugal

force generated by a spinning impeller to accelerate and then decelerate captured air, which

pressurizes it..

Figure 9 Compressor

3.9.4 Cooling

Due to adiabatic heating, air compressors require some method of disposing of waste heat.

Generally this is some form of air- or water-cooling, although some (particularly rotary type)

compressors may be cooled by oil (that is then in turn air- or water-cooled) and the atmospheric

changes also considered during cooling of compressors.

3.9.5 Applications

To supply high-pressure clean air to fill gas cylinders

To supply moderate-pressure clean air for driving some office and school

building pneumatic HVAC control system valves

To supply a large amount of moderate-pressure air to power pneumatic tools, such

as jackhammers

Wall climbing robot

2014

For filling tires

To produce large volumes of moderate-pressure air for large-scale industrial processes (such

as oxidation for petroleum coking or cement plant bag house purge systems).

Most air compressors either are reciprocating piston type, rotary vane or rotary screw.

Centrifugal compressors are common in very large applications. There are two main types of air

compressor's pumps: oil-lubed and oil-less. The oil-less system has more technical development,

but is more expensive, louder and lasts for less time than oil-lubed pumps. The oil-less system

also delivers air of better quality.

3.10 Battery

An electric battery is a device consisting of one or more electrochemical cells that convert stored

chemical energy into electrical energy. Each cell contains a positive terminal, or cathode, and a

negative terminal, or anode. Electrolytes allow ions to move between the electrodes and

terminals, which allows current to flow out of the battery to perform work.

Generally there are two types of batteries namely:-

1. Primary Batteries

2. Secondary Batteries

Primary (single-use or "disposable") batteries are used once and discarded; the electrode

materials are irreversibly changed during discharge. Common examples are the alkaline battery

used for flashlights and a multitude of portable devices. Secondary (rechargeable batteries) can

be discharged and recharged multiple times; the original composition of the electrodes can be

restored by reverse current. Examples include the lead-acid batteries used in vehicles and lithium

ion batteries used for portable electronics. Batteries come in many shapes and sizes, from

Wall climbing robot

2014

Figure 10 Battery

miniature cells used to power hearing aids and wristwatches to battery banks the size of rooms

that provide standby power for telephone exchanges and computer data centers.

3.10.1 Principle of operation

Batteries convert chemical energy directly to electrical energy. A battery consists of some

number of voltaic cells. Each cell consists of two half-cells connected in series by a conductive

electrolyte containing anions and cations. One half-cell includes electrolyte and the negative

electrode, the electrode to which anions (negatively charged ions) migrate; the other half-cell

includes electrolyte and the positive electrode electrode to which cations (positively charged

ions) migrate. Redox reactions power the battery. Cations are reduced (electrons are added) at

the cathode during charging, while anions are oxidized (electrons are removed) at the anode

during discharge. The electrodes do not touch each other, but are electrically connected by the

electrolyte. Some cells use different electrolytes for each half-cell. A separator allows ions to

flow between half-cells, but prevents mixing of the electrolytes.

Wall climbing robot

2014

3.11 Switches

A switch is an electrical component that can break an electrical circuit, interrupting the current

or diverting it from one conductor to another. The most familiar form of switch is a manually

operated electromechanical device with one or more sets of electrical contacts, which are

connected to external circuits. Each set of contacts can be in one of two states: either "closed"

meaning the contacts are touching and electricity can flow between them, or "open", meaning the

contacts are separated and the switch is nonconducting. The mechanism actuating the transition

between these two states (open or closed) can be either a "toggle" (flip switch for continuous

"on" or "off") or "momentary" (push-for "on" or push-for "off") type.

A switch may be directly manipulated by a human as a control signal to a system, such as a

computer keyboard button, or to control power flow in a circuit, such as a light switch.

Automatically operated switches can be used to control the motions of machines, for example, to

indicate that a garage door has reached its full open position or that a machine tool is in a

position to accept another workpiece. Switches may be operated by process variables such as

pressure, temperature, flow, current, voltage, and force, acting as sensors in a process and used to

automatically control a system. For example, a thermostat is a temperature-operated switch used

to control a heating process. A switch that is operated by another electrical circuit is called a

relay. Large switches may be remotely operated by a motor drive mechanism. Some switches are

used to isolate electric power from a system, providing a visible point of isolation that can be

padlocked if necessary to prevent accidental operation of a machine during maintenance, or to

prevent electric shock. An ideal switch would have no voltage drop when closed, and would

have no limits on voltage or current rating. It would have zero rise time and fall time during state

changes, and would change state without "bouncing" between on and off positions.

Practical switches fall short of this ideal; they have resistance, limits on the current and voltage

they can handle, finite switching time, etc. The ideal switch is often used in circuit analysis as it

greatly simplifies the system of equations to be solved, but this can lead to a less accurate

solution. Theoretical treatment of the effects of non-ideal properties is required in the design of

large networks of switches, as for example used in telephone exchanges.

Wall climbing robot

2014

Figure 11 Switches

Wall climbing robot

2014

CHAPTER 4

PROCESSES USED

4.1 Soldering

Soldering is a process in which two or more metal items are joined together by melting and

flowing a filler metal (solder) into the joint, the filler metal having a lower melting point than the

adjoining metal. Soldering differs from welding in that soldering does not involve melting the

work pieces. Soldering is used in plumbing, electronics, and metalwork from flashing to jewelry.

Soldering provides reasonably permanent but reversible connections between copper pipes

in plumbing systems as well as joints in sheet metal objects such as food cans, roof flashing, rain

gutters and automobile radiators. Jewelry components, machine tools and some refrigeration and

plumbing components are often assembled and repaired by the higher temperature silver

soldering process. It can also be used as a semi-permanent patch for a leak in a container or

cooking vessel.

Figure 12 Soldering Tool

Wall climbing robot

2014

4.1.1 Solders

Soldering filler materials are available in many different alloys for differing applications. In

electronics assembly, the eutectic alloy of 63% tin and 37% lead (or 60/40, which is almost

identical in melting point) has been the alloy of choice. Other alloys are used for plumbing,

mechanical assembly, and other applications. Some examples of soft-solder are tin-lead for

general purposes, tin-zinc for joining aluminium, lead-silver for strength at higher than room

temperature, cadmium-silver for strength at high temperatures, zinc-aluminium for aluminium

and corrosion resistance, and tin-silver and tin-bismuth for electronics.Common solder

formulations based on tin and lead are listed below. The fraction represent percentage of tin first,

then lead, totaling 100%:

63/37: melts at 183 C (361 F) (eutectic: the only mixture that melts at a point, instead of

over a range)

60/40: melts between 183190 C (361374 F)

50/50: melts between 185215 C (365419 F)

4.1.2 Flux

The purpose of flux is to facilitate the soldering process. One of the obstacles to a successful

solder joint is an impurity at the site of the joint, for example, dirt, oil or oxidation. The

impurities can be removed by mechanical cleaning or by chemical means, but the elevated

temperatures required to melt the filler metal (the solder) encourages the work piece (and the

solder) to re-oxidize. This effect is accelerated as the soldering temperatures increase and can

completely prevent the solder from joining to the workpiece.

4.1.3 Electronic components (PCB)

Printed circuit boards (PCBs) are mostly wave soldered or reflow soldered, though hand

soldering of production electronics is also still standard practice.

Wall climbing robot

2014

In wave soldering, parts are temporarily kept in place with small dabs of adhesive, then the

assembly is passed over flowing solder in a bulk container. This solder is shaken into waves so

the whole PCB is not submerged in solder, but rather touched by these waves. The end result is

that solder stays on pins and pads, but not on the PCB itself.

Since different components can be best assembled by different techniques, it is common to use

two or more processes for a given PCB. For example, surface mounted parts may be reflow

soldered first, with a wave soldering process for the through-hole mounted components coming

next, and bulkier parts hand-soldered last.

4.1.4 Tools

In principle any type of soldering tool can carry out any work using solder at temperatures it can

generate. In practice different tools are more suitable for different applications.

Hand-soldering tools widely used for electronics work include the electric soldering iron, which

can be fitted with a variety of tips ranging from blunt to very fine, to chisel heads for hot-cutting

plastics rather than soldering. Hot-air guns and pencils allow rework of component packages

which cannot easily be performed with electric irons and guns

A soldering copper is a tool with a large copper head and a long handle which is heated in

a blacksmith's forge fire and used to apply heat to sheet metal for soldering. Typical soldering

coppers have heads weighing between one and four pounds.

Wire brush, wire wool and emery cloth are commonly used to prepare plumbing joints for

connection. Electronic joints are usually made between surfaces that have been tinned and rarely

require mechanical cleaning, though tarnished component leads and copper traces with a dark

layer of oxide passivation (due to aging), as on a new prototyping board that has been on the

shelf for about a year or more, may need to be mechanically cleaned.

Some fluxes for electronics are designed to be stable and inactive when cool and do not need to

be cleaned off, though they still can be if desired, while other fluxes are acidic and must be

removed after soldering to prevent corrosion of the circuits.

Wall climbing robot

2014

4.2 Drilling

Drilling is a cutting process that uses a drill bit to cut or enlarge a hole of circular cross-

section in solid materials. The drill bit is a rotary cutting tool, often multipoint. The bit

is pressed against the workpiece and rotated at rates from hundreds to thousands of revolutions

per minute. This forces the cutting edge against the work piece, cutting off chips (swarf) from the

hole as it is drilled. Exceptionally, specially-shaped bits can cut holes of non-circular cross-

section; a square cross-section is possible

4.2.1 Process

Drilled holes are characterized by their sharp edge on the entrance side and the presence

of burrs on the exit side (unless they have been removed). Also, the inside of the hole usually has

helical feed marks. Drilling may affect the mechanical properties of the workpiece by creating

low residual stresses around the hole opening and a very thin layer of highly stressed and

disturbed material on the newly formed surface. This causes the workpiece to become more

susceptible to corrosion at the stressed surface. A finish operation may be done to avoid the

corrosion. Zinc plating or any other standard finish operation of 14 to 20 m can be done which

helps to avoid any sort of corrosion

The higher the length-to-diameter ratio of the drill bit, the higher the tendency to walk. The

tendency to walk is also preempted in various other ways, which include:

Establishing a centering mark or feature before drilling, such as by:

Casting, molding, or forging a mark into the workpiece

Center punching

Spot drilling (i.e., center drilling)

Spot facing, which is facing a certain area on a rough casting or forging to establish,

essentially, an island of precisely known surface in a sea of imprecisely known surface

Constraining the position of the drill bit using a drill jig with drill bushings

Surface finish in drilling may range from 32 to 500 microinches. Finish cuts will generate

surfaces near 32 microinches, and roughing will be near 500 microinches. Cutting fluid is

Wall climbing robot

2014

commonly used to cool the drill bit, increase tool life, increase speeds and feeds, increase the

surface finish, and aid in ejecting chips. Application of these fluids is usually done by flooding

the workpiece or by applying a spray mist.

In deciding which drill(s) to use it is important to consider the task at hand and evaluate which

drill would best accomplish the task. There are a variety of drill styles that each serve a different

purpose. The subland drill is capable of drilling more than one diameter. The spade drill is used

to drill larger hole sizes. The indexable drill is useful in managing chips

4.2.2 Drill

A drill is a tool fitted with a cutting tool attachment or driving tool attachment, usually a drill

bit or driver bit, used for boring holes in various materials or fastening various materials together

with the use of fasteners. The attachment is gripped by a chuck at one end of the drill and rotated

while pressed against the target material. The tip, and sometimes edges, of the cutting tool does

the work of cutting into the target material. This may be slicing off thin shavings (twist

drills or auger bits), grinding off small particles (oil drilling), crushing and removing pieces of

the workpiece (SDS masonry drill), countersinking, counter boring, or other operations. Drills

are commonly used in woodworking, metalworking, construction and do-it-yourself projects.

4.2.3 Types

There are many types of drills: some are powered manually, others use electricity (electric drill)

or compressed air (pneumatic drill) as the motive power, and a minority are driven by an internal

combustion engine (for example, earth drilling augers). Drills with a percussive action (hammer

drills) are mostly used in hard materials such as masonry (brick, concrete and stone)

or rock. Drilling rigs are used to bore holes in the earth to obtain water or oil. Oil wells, water

wells, or holes for geothermal heating are created with large drilling rigs. Some types of hand-

Wall climbing robot

2014

held drills are also used to drive screws and other fasteners. Some small appliances that have no

motor of their own may be drill-powered, such as small pumps, grinders, etc

A variety of hand-powered drills have been employed over the centuries. Here are a few, starting

with approximately the oldest:

Bow drill

Brace and bit

Gimlet

Hand drill, also known as an "eggbeater" drill

Breast drill, similar to an "eggbeater" drill, it has a flat chest piece instead of a handle

Push drill, a tool using a spiral ratchet mechanism

Pin chuck, a small hand-held jeweler's drill

4.3 Filing

Filing is a material removal process in manufacturing. Similar, depending on use, to both sawing

and grinding in effect, it is functionally versatile, but used mostly for finishing operations,

namely in deburring operations. Filing operations can be used on a wide range of materials as a

finishing operation. Filing helps achieve workpiece function by removing some excess material

and deburring the surface. Sandpaper may be used as a filing tool for other materials, such as

glass.

4.3.1 Band filing

Band Filing takes place on a machine similar to a belt sander, used like a band saw. Band files

are sectioned so that they can be made from stiff material, as they need to be to effectively

remove material, yet still work in a constant feed. A band filing operation can be used to remove

small amounts of material with good accuracy. The cutting teeth of the file are arranged closely

on the file and are used as part of a finishing process

4.3.2 Reciprocating filing

Reciprocating filing takes place on a flat surface where workpieces are fed into the file. The file

Wall climbing robot

2014

teeth are angled so that material is removed on each downstroke of the tool. Chips removed from

the workpiece fall through a cavity in front of the file.

4.4 Cutting

Cutting is the separation of a physical object, or a portion of a physical object, into two or more

portions, through the application of an acutely directed force. Implements commonly used for

cutting are the knife and saw, or in medicine and science the scalpel and microtome. However,

any sufficiently sharp object is capable of cutting if it has a hardness sufficiently larger than the

object being cut, and if it is applied with sufficient force. Even liquids can be used to cut things

when applied with sufficient force.

Cutting is a compressive and shearing phenomenon, and occurs only when the

total stress generated by the cutting implement exceeds the ultimate strength of the material of

the object being cut. The simplest applicable equation is stress = force/area.

Wall climbing robot

2014

CHAPTER 5

WORK PLAN AND FLOW CHART

5.1 Work Timeline

Research on types of similar robots available

21-26 Jan

Study of the different methods for the possibilities

27-31 Jan

Arrange the parts required

3-8 Feb

Cutting of aluminium strips drilling 10-11 Feb

Rivetting 13-14 Feb

Dc Servomotors installed

17-19 Feb

Pistons Installed

24-25 Feb

Suction Cups Fixed 26-28 Feb

Wiring and pneumatic pipe fittings and soldering

10-11 March

Testing of the specimen

12-15 March

Modifications made to support the cups

17-20 March

Project report compilation

24 March- 7 April

Wall climbing robot

2014

Table 1 Work Plan

5.2 FLOW CHART OF THE PROCESSES INVOLVED

Wall climbing robot

2014

Wall climbing robot

2014

Flowchart 1 Process

Wall climbing robot

2014

CHAPTER 6

EXPERIMENTAL WORK DONE

When we first arrived in lab, we were greeted by a smattering of parts. Our mission

throughout the first few weeks was to determine the composition of the robot. Our first goal was

to determine the type of material to be used for sticking the robot to the wall. After a lot of

research we concluded that the possibility of making a robot climb on wall can be with the help

of suction cups only. Our next objective was to find the way for sticking the cups on the wall.

We had two choices either using vaccum pumps or using pneumatic cylinders. Vaccum pumps

are driven using a power supply and pneumatic cylinders using a compressor which inturn

requires a power supply. Both of them have there pros and cons.

After we had decided that for sticking we were going to use a 150 psi compressor driving

a 150cc pneumatic cylinder we had to find ways for its links movement. The best available

motor for this could be DC Servomotors. We used 12V DC supplied Servomotors with 4rpm for

turning the links and to place the cups firmly on the surface. After we were done thinking about

the components required it was now time to start up with the project build up.

Our first step was to look for the material to be used for robot chasis. We choosed

aluminium strips since it was easily available, light weight and provides good strength. We cut

the aluminium strips and drilled holes in them to use fasteners to keep distance between the two

parallel supports. After this a DC Servomotor was planted between the two links.

For setting up the Servomotor we had to use less thickness nuts and to cut the strip

according to the shape of motor head so that the movement of motor can be well transmitted to

the link.

Wall climbing robot

2014

Again a metal strip was cut and bended according to the need of the structure. The metal

was cut for giving space to pneumatic cylinder to be fitted to structure. The process was repeated

for the other leg also. Now the main requirement is to supply power to motors and compressed

air to the pneumatic cylinders. The power to the motors is supplied using a 12V Battery. The

compressor also runs on 12V Dc but the air is supplied to the pistons using pipes. The large lenth

of wires may vary the pressure heads available at the tip of the pipe. Now the solenoid valves are

actuated with the help of switches. These solenloid valve decides the movement of the piston in

the front or backward direction. The front stroke of the cylinder fixes up the robot leg to the

smooth surface. Other leg also brought in contact with the surface. Then again actuating the

other piston helps in sticking the robot firmly to the wall. The suction cup can be removed by

actuating the cylinder to the opposite direction. The motors are operated with the help of

switches and the robot arm is raised above in order to climb the wall.

In terms of assembling the robot, we undid most of the previous wiring and soldered it back

together in a slightly more reasonable manner, having large nodes to which many things could be

connected to. Unfortunately the shortness of some wires limited the usefulness of rearranging

things, and the length of some of the others caused a large mess to be remaining in the end

anyway. In the end, we had two nodes for servomotors which connected to: the terminals of the

battery circuit, and two for the solenoid valves.

As was demonstrated, the project was a success, as we were able to drive the bot via the

switches at different possible angles. We were also able to use the battery monitor and control

the central motor remotely.

Wall climbing robot

2014

6.1 MAIN COSTS

Compressor Rs 1800\-

Battery Rs 900

Solenoid Valves&Relays 4X Rs250

Pneumatic Cylinders 2X Rs650

Dc ServoMotors 3X Rs 350

Table 2 Cost of Parts

Wall climbing robot

2014

CHAPTER 7

FEATURES OF WALL CLIMBING ROBOT

The robot consists of 3 servo motors and 2 robotic feet, in which the functions of motors

are to generate rotary motion of links only which are connected to the robotic feet. These

2 feet motions will operate in a synchronized manner.

The robot has the ability to move in both directions that is forward as well as backward,

this could be achieved by changing the polarity of servo motors. Thus the process is

simpler and doesnt require a microcontroller at all.

The robot has the capabilities to climb walls, walk on ceilings, and transit between

different surfaces. This all could be achieved because we are using suction cups, which

dont get detached easily once the cups are attached to the surface.

The robot can move on virtually any kinds of smooth surfaces which provide a good

chance to create vacuum between the surface and robotic feet consisting of suction cups.

The flipper robot consists of various parts like suction cups, compressor, solenoid valve,

relay, servo motors, pneumatic cylinders actuated using solenoid valves, 12 V battery.

Out of this servo motors are self contained.

Once the battery is fully charged then at a load of 7.2 amperes the battery can operate up

to one hour.

The flipper robot has the ability to carry payloads also; it can carry its self weight of up to

2 kgs as well as other devices like cameras could be mounted on it very easily.

The flipper robot consists of servo motors that have a revolution per minute of 2, and the

length of our robot is approximate 0.65 meters, which means at a full speed it could cover

a distance of 1.3 meters in a minutes. Thus the speed of this robot could be successfully

calculated as 78 meters in an hour.

Wall climbing robot

2014

CHAPTER 8

RESULT

8.1 USES OF WALL CLIMBING ROBOT

Since the end of the 80ties climbing robots are examined for different types of application

scenarios all over the world. E.g at the end of the 80ties and the begin of the 90ties in Japan

several national projects concerning climbing robots for specific application scenarios have been

developed. These include cleaning robots for glass walls, ship hull cleaning robots, rescue robots

for fire brigades, inspection robots for steel tanks and wall. These machine have been developed

for different types of applications like the inspection of pipes and ducts in the petrochemical

industry, maintenance and inspection work in the construction and nuclear industry or cleaning

robots for huge class walls.

Some of the major areas where a wall climbing robot could be used are written below

Nuclear plant inspection

Cleaning and Inspection of glass wall

Steal bridge inspection

Ship cleaning/inspection

Pipe inspection in chemical systems

Airplane cleaning and inspection

Cleaning both the ceramic tile and glass surfaces of high-rise buildings

Wall climbing robot

2014

8.2 DRAWBACKS

The flipper robot that we have made has certain limitations too; we are going to discuss all of

them in a point form.

We are using suction cups which are operated by a pneumatic cylinder actuated by

solenoid valve; this means that the motion of the flipper is dependent upon the suction

generated.

They cannot be used on rough surfaces and the chances of vacuum generation are very

less. The flipper robot could only operate on smooth surfaces or more preferably on glass

surface.

The speed of servo motor is around 2 rpm which means that the speed of our flipper robot

is only 78 meters per hour.

The 12 V battery could operate for approximately one hour only at full load

The aluminum strips that we have used increased the weight of our robot, we could have

used other polymers in place of aluminum but that would have increased the cost of our

project.

The length of flipper is 0.65 meter which could be made short by removing an extra link,

and this way we could remove a extra servo motor also.

The compressor could not be used for long duration as it gets heated up very fast.

The flipper robot that we have made is not remote controlled which means that it cannot

move forward after a certain length, this has been done to ensure the minimum cost for

our project.

CHAPTER 9

Wall climbing robot

2014

CONCLUSION AND FUTURE SCOPE

The design and fabrication of the Wall Climbing Robot has been successfully achieved. This

study has proposed movement step design for wall-climbing robot. In design the robot use

pneumatic system as main unit to move on the wall. During the robot move on the wall, the robot

must remain always the vacuum cups for holding. We can choose parameter to improve the

climbing efficiency for hardware design. The first way, we can change the wall material to

increase s. The second way, we can improve vacuum force or reduce robot weight (Mg), by

using robot light material, example straight plastic. This study is valuable as literature review for

researchers, who want to construct wall-climbing robot. We can choose parameter to improve the

climbing efficiency that the robot can climb much slope. For the first way, we can change the

wall material to increase s and for the second way, we can improve vacuum force by means of

increasing pneumatic system efficiency.

Our next step if we go further with the project should be to make the robot wireless, we have to

focus on increasing the speed of robot, and to increase the suction pressure generated by

compressor. Till now the robot can move in only two directions that is forward and backward we

need to provide more degree of freedom to the links, so that it can go freely in all direction. The

battery used for this purpose could be more powerful. The weight of the flipper could be reduced

by using lighter material than aluminum. The number of servo motors used could be decreased to

2, and finally the length of the flipper could be decreased to ensure a faster movement.

Wall climbing robot

2014

BIBLIOGRAPHY

Journals

D.M. Aslam and G. Dangi, Design, fabrication and testing of a smart robotic foot,

Robotics and Autonomous Sys., vol. 51 (2,3), July 31, 207-214(2005).

T. Yano, S. Tomahiro, M. Murakami, T. Yamamoto, Development of semi-self

contained wall climbing robot with scanning type suction cups, Proceedings IROS

97,1997, pp.900-905.

Nishi, H. Miyagi, Propeller type wall climbing robot for inspection use, Proceedings of

10th International symposium on Automation and robotics in construction (ISARC),

1993, pp.189-196.

M. Fujji, C. Satoo, S. Kajiyama,, and S. Naitoo, Wall surface vehicles for the robots in

hostile environments, Proceedings of the International Topical Meeting on Remote

Systems and Robotics in Hostile environments, 1987, pp 398-403.

Websites

AEM. 2007. Aluminium vs. Plastic. [Online] Advanced Engine Management, Inc, 2007.

http://www.aempower.com/ViewNews.aspx?NewsID=7.

Atmel Corporation. 2004. ATmega64-16AU Datasheet, p327. 2004. Axis. 2008. 207 IP

Camera. http://www.omegacubed.net/axis/axis_207/images/axis_207_large.jpg, s.l. :

2008.

Gates Mectrol Limited. 2008. T10V Tooth Section. Gramlich. 2005. Ansmann.

Ansmann Energy. [Online] 27 12 2005.

http://www.ansmann.de/cms/consumroot/batteries/rechargeable-batteries-nimh/mono-

d/10000-mah.html

Ripmax. 2007. Ripmax, Pro Peak Power Supplies. Ripmax. [Online] Ripmax Ltd2007.

http://www.ripmax.com/item.asp?itemid=O-IP2000&selectedtab=070&Category=070.

Vous aimerez peut-être aussi

- Baja Dyno Capstone Final ReportDocument46 pagesBaja Dyno Capstone Final Reportapi-438671184100% (1)

- Hydraulic Robotic ArmDocument51 pagesHydraulic Robotic ArmAnurag KhotkarPas encore d'évaluation

- Final ReportDocument18 pagesFinal ReportYusha Patel100% (1)

- Wall Climbing RobotDocument5 pagesWall Climbing RobottarasasankaPas encore d'évaluation

- Vijay Halilole.: Fabrication of Vertical Axis Wind TurbineDocument45 pagesVijay Halilole.: Fabrication of Vertical Axis Wind TurbineThaha Refaye0% (2)

- Box Transport MechanismDocument41 pagesBox Transport MechanismsaijanPas encore d'évaluation

- Automatic Pneumatic Punching and Riveting MachineDocument4 pagesAutomatic Pneumatic Punching and Riveting MachineElakkiya Karthic100% (1)

- Project PPT 1Document17 pagesProject PPT 1Dishant PrasadPas encore d'évaluation

- Intelligent Braking System - SynopsisDocument6 pagesIntelligent Braking System - SynopsisTanviPas encore d'évaluation

- 4 Way Hacksaw Machinex (Read-Only)Document34 pages4 Way Hacksaw Machinex (Read-Only)harrysinghPas encore d'évaluation

- Design of Jig and Fixture For Milling Machine, Case Study: Cylindrical PartsDocument24 pagesDesign of Jig and Fixture For Milling Machine, Case Study: Cylindrical PartsRoby MauliansyahPas encore d'évaluation

- Electromagnetic Embossing MachineDocument12 pagesElectromagnetic Embossing Machinesubramanya1982Pas encore d'évaluation

- Design of Walking Mechanism With Straight and Parallel Leg MotionDocument28 pagesDesign of Walking Mechanism With Straight and Parallel Leg MotionKashif MobinPas encore d'évaluation

- FABRICATION OF PNEUMATIC Bearing PullerDocument8 pagesFABRICATION OF PNEUMATIC Bearing PullerAswin KarthickPas encore d'évaluation

- Research On Automatic Bike Starter KitDocument38 pagesResearch On Automatic Bike Starter KitGokul RajaPas encore d'évaluation

- Automatic Garrage SystemDocument11 pagesAutomatic Garrage SystemTalha NayyarPas encore d'évaluation

- Remote Controlled Screw Jack 2014 AcDocument58 pagesRemote Controlled Screw Jack 2014 AcChockalingam AthilingamPas encore d'évaluation

- Project Synopsis: Department of Mechanical Engineering Submitted byDocument10 pagesProject Synopsis: Department of Mechanical Engineering Submitted byMintu VermaPas encore d'évaluation

- Auto Roll Punching MachineDocument42 pagesAuto Roll Punching MachineANAND KRISHNAN100% (1)

- Automatic Floor Cleaning Robot: Mariappan. S Thanga Dhinesh S Esakki Durai M Bala Sathya VDocument20 pagesAutomatic Floor Cleaning Robot: Mariappan. S Thanga Dhinesh S Esakki Durai M Bala Sathya VSmolin ReniPas encore d'évaluation

- Rocker Bogie MechanismDocument6 pagesRocker Bogie MechanismjishnuPas encore d'évaluation

- Design and Fabrication of Paper Cutter 1Document29 pagesDesign and Fabrication of Paper Cutter 1Pát ŔiçkPas encore d'évaluation

- Clutch Inplant Training ReportDocument31 pagesClutch Inplant Training ReportMrityunjay Pathak100% (1)

- Final Four WayDocument35 pagesFinal Four WayRohitsingh JadaunPas encore d'évaluation

- Accident Avoiding of Punching Machine - ReportDocument38 pagesAccident Avoiding of Punching Machine - ReportPrathmeshBhokari0% (1)

- Major Synopsis On Hydraulic ArmDocument7 pagesMajor Synopsis On Hydraulic ArmPrashant Balhara0% (2)

- Development of Wall Painting RobotDocument5 pagesDevelopment of Wall Painting RobotPrakash Kumar SenPas encore d'évaluation

- Design and Analysis Mini CNC Plotter MachineDocument23 pagesDesign and Analysis Mini CNC Plotter MachineUsman BhattiPas encore d'évaluation

- Design and Implementation of Microcontroller Based Controller For Direction and Speed of A RobotDocument65 pagesDesign and Implementation of Microcontroller Based Controller For Direction and Speed of A Robotkhechibakamel100% (1)

- 4 Control StructuresDocument45 pages4 Control StructuresS Rose RazPas encore d'évaluation

- 360 Degree Flexible Drilling MachineDocument26 pages360 Degree Flexible Drilling MachineSATHISH KUMAR SPas encore d'évaluation

- A Project Report: Design and Fabrication of Multi Process Machining Using Scotch Yoke MechanismDocument44 pagesA Project Report: Design and Fabrication of Multi Process Machining Using Scotch Yoke MechanismKali DasPas encore d'évaluation

- 90 Degree Turning Motorized Steering MechanismDocument62 pages90 Degree Turning Motorized Steering MechanismMani Kandan100% (1)

- Smart WiperDocument22 pagesSmart WiperAmit Bakle100% (1)

- Productivity Improvement I N MM540 Steering BoxDocument42 pagesProductivity Improvement I N MM540 Steering BoxVijay JPas encore d'évaluation

- Smart Child Borewell System 3Document44 pagesSmart Child Borewell System 3Venkat nagulapatiPas encore d'évaluation

- Motorized Ramming MachineDocument53 pagesMotorized Ramming Machineilayaraja6100% (1)

- Hydraulic Robotic ArmDocument14 pagesHydraulic Robotic Armj_sachin09100% (1)

- Automatic Pneumatic Bumper For Four Wheeler Final Year Ieee Mech ProjectDocument60 pagesAutomatic Pneumatic Bumper For Four Wheeler Final Year Ieee Mech ProjectAnkit YadavPas encore d'évaluation

- Alcohol Detection System in Vehicle Using Arduino PDFDocument5 pagesAlcohol Detection System in Vehicle Using Arduino PDFMuniyandi LakshmananPas encore d'évaluation

- Automatic Wall Painting MachineDocument9 pagesAutomatic Wall Painting MachineaalekhPas encore d'évaluation

- 2019.03.22 RobotswasherDocument54 pages2019.03.22 RobotswasherJacopo MontalentiPas encore d'évaluation

- PLC Based Automatic Car Washing System-18849Document6 pagesPLC Based Automatic Car Washing System-18849Jok ZamPas encore d'évaluation

- Intelligent Braking System Using MicrocontrollerDocument6 pagesIntelligent Braking System Using Microcontrollermukesh100% (1)

- Nfo ProjectDocument75 pagesNfo Projectankitverma9716Pas encore d'évaluation

- Automatic Pneumatic High Speed Sheet Cutting MachineDocument5 pagesAutomatic Pneumatic High Speed Sheet Cutting MachineIyappanPas encore d'évaluation

- A ProjectDocument14 pagesA Projectajay0% (1)

- Presentation On: Design and Development of Sugarecane Bud Cutting Machine Guided By-Dr. S.S.KULKARNIDocument16 pagesPresentation On: Design and Development of Sugarecane Bud Cutting Machine Guided By-Dr. S.S.KULKARNIVenPas encore d'évaluation

- Automatic Side Stand For Two WheelerDocument84 pagesAutomatic Side Stand For Two Wheelercoolhari0825% (4)

- Minor ProjectDocument23 pagesMinor ProjectDeepak Kumar SinghPas encore d'évaluation

- Internship Report (IIP)Document53 pagesInternship Report (IIP)Mehtab AlamPas encore d'évaluation

- Smart Leaf Infection Identification and FertilizerDocument3 pagesSmart Leaf Infection Identification and FertilizerJiiva GopiPas encore d'évaluation

- "Programmable Logic Controller": Degree of Bachelor of TechnologyDocument42 pages"Programmable Logic Controller": Degree of Bachelor of TechnologyVikas VermaPas encore d'évaluation

- Profile Measurement Full ReportDocument16 pagesProfile Measurement Full ReportAman RedhaPas encore d'évaluation

- Project Report Hybrid Electric VehicleDocument19 pagesProject Report Hybrid Electric VehicleMeet MehtaPas encore d'évaluation

- Pneumatic Sheet Cutting MachineDocument55 pagesPneumatic Sheet Cutting MachineBhushan HadalagiPas encore d'évaluation

- Pune Summer Training ReportDocument34 pagesPune Summer Training ReportGaurav giriPas encore d'évaluation

- Auto Clutch For AutomobileDocument34 pagesAuto Clutch For AutomobileAakash DindigulPas encore d'évaluation

- Specification For Electrical Motor (Rev.a) - ReturnedDocument22 pagesSpecification For Electrical Motor (Rev.a) - ReturnedPanisa BanimaPas encore d'évaluation

- Final ReportDocument28 pagesFinal Reportsnekanvns344Pas encore d'évaluation

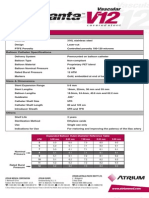

- Advanta V12 Data SheetDocument2 pagesAdvanta V12 Data SheetJuliana MiyagiPas encore d'évaluation

- The Indian Mining Sector: Effects On The Environment & FDI InflowsDocument10 pagesThe Indian Mining Sector: Effects On The Environment & FDI InflowsMehul MandanakaPas encore d'évaluation

- Harmonics PatternsDocument4 pagesHarmonics PatternsIzzadAfif1990Pas encore d'évaluation

- Design and Development of Automatic Pneumatic Jack in Four Wheeler Ijariie5374Document5 pagesDesign and Development of Automatic Pneumatic Jack in Four Wheeler Ijariie5374Saravanan ViswakarmaPas encore d'évaluation

- FRP Handrail Fittings CatalogDocument6 pagesFRP Handrail Fittings CatalogAl Adel MorenoPas encore d'évaluation

- AssessmentDocument9 pagesAssessmentJuan Miguel Sapad AlpañoPas encore d'évaluation

- Lecture 12Document8 pagesLecture 12Mechanical ZombiePas encore d'évaluation

- Niir Integrated Organic Farming Handbook PDFDocument13 pagesNiir Integrated Organic Farming Handbook PDFNataliePas encore d'évaluation

- EPCC Hydrocarbon Downstream L&T 09.01.2014Document49 pagesEPCC Hydrocarbon Downstream L&T 09.01.2014shyaminannnaPas encore d'évaluation

- Chapter 7 - Muscular SystemDocument29 pagesChapter 7 - Muscular SystemlPas encore d'évaluation

- Bomba MixerDocument2 pagesBomba MixerBinelli79Pas encore d'évaluation

- Solutions GoldsteinDocument10 pagesSolutions GoldsteinAnyiPas encore d'évaluation