Académique Documents

Professionnel Documents

Culture Documents

Electroplating Apparatus for Cyanide-Free Silver Coating

Transféré par

ivanjose09Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Electroplating Apparatus for Cyanide-Free Silver Coating

Transféré par

ivanjose09Droits d'auteur :

Formats disponibles

1

Design and construction of electroplating

apparatus for cyanide less silver on

copper plating

NSF Extreme Ultraviolet Engineering Research Center, Colorado State University

Yu-ping Shao, Advisor: Jorge Rocca

2

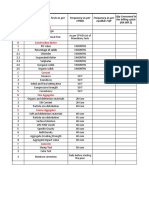

Table of Contents

Abstract ......................... 4

Introduction

Electroplating background ......................... 4

Target device description ......................... 5

Device challenges ......................... 5

Summary of previous work ......................... 6

Project management ......................... 6

Implementation .........................

Experimental setup ......................... 6

Solution level ......................... 7

Apparatus features ......................... 9

Tank construction ......................... 9

Deposition rate ......................... 10

Procedure .........................

Precleaning ......................... 12

Surface preparation ......................... 13

Plating ......................... 13

Operating steps ......................... 13

Soak clean ......................... 14

Electrolytic Clean ......................... 16

Deoxidizing phase ......................... 18

Plating ......................... 20

3

Conclusion ......................... 24

Future work recommendation ......................... 24

Appendix

List of figures and tables ......................... 25

Percentage volume information ......................... 25

Chemical formula and symbol ......................... 26

Original vendor summary ......................... 27

Supplier tank design ......................... 29

4

Abstract

The electroplating of silver on copper is currently performed by an external shop;

therefore, little control is exerted over properties pertaining to electroplating such as thickness,

surface quality, and purity. Therefore, by building a device with controlled electroplating

capability. We can assure that deposition thick goes up to 15m, has a uniform surface finish and

controlled deposition rate. The device should be capable of depositing 10 to 15m of pure silver

on the experiment copper target device.

Introduction

Deposition of silver through electrochemistry

Figure 1: Electroplating tank diagram

Electrodeposition of silver is done through the use of an external electron supply. The

cathode of the setup, in this case the copper target device, and the anode of the setup, in this case

the silver are connected to their perspective ends. The external power supply drives the process

when silver surface is ionized to form cations that are then deposited upon the copper surface.

5

Target Device:

Figure 2: a) Target device. b) Target device dimensions.

The actual target device is made of copper and has parts of the surface removed so that

strips of approximately 2mm in width can be seen spiraling along the surface from top to bottom.

10 strips are found on the surface with each about 1mm spaced from another.

The target device undergoes electroplating through which the silver deposited on the

strips is from 10 to 15 m in thickness. In a high vacuum environment, a EUV laser source

causes the ablation of silver.

Device challenge

Generally, electroplating is performed within a chemically and electrically non-reactive

tank with electrolytic solutions to cause the transfer of ions from anode to cathode. While

electroplating copper unto nickel is almost spontaneous and can be performed with immersion

electroplating, deposition of silver on copper is not. This is due to the ranking of materials in

their electron affinity. The ranking: gold, silver, copper, nickel, shows that copper requires a

striking agent in addition to the electrolytic solution. Industrial electroplating of silver unto

6

copper in 95% of the electroplating shops requires the use of potassium ferrocyanide. Since

ferrocyanide is a highly hazardous material due to high toxicity, an alternative of non-cyanide

plating is adapted. The solution instead contains organosilver complexed with thiosulphate ions

Project management

This is a single effort. The student is responsible for all the phases of the project except

fundraising, which is provided by the CSU Extreme Ultraviolet Engineering Research Center.

Summary of previous work

With 95% of all plating shops adopt a cyanide containing process, effort to conduct

electroplating in a small scale is not well attempted. The primary enabler for this project is based

upon recent work by EPI Chemicals, from which a electronic class, cyanide less chemicals have

been formulated to be used in industrial application.

Main work will be to synthesize the information given by the vendor technical data, and

plating tank norms used by the plating shops. For both the consideration of space and

application, barrel plating and equipment pertaining to barrel plating is investigated.

Implementation

Experimental setup

Due to corrosive vapor produced during the pre-cleaning stage, the entire device must be

kept within a fume hood. In addition, ACS certified respirator must be worn during the plating

procedure to reduce the risk of breathing in corrosive material.

7

Figure 3: Layout of the setup.

The motor is running at 6RPM when supplied with 12V. The electrodes involved in the

plating and electrolytic cleaning require another power source. In this case, Agilent 6632A

power supply is chosen for its high stable voltage capability while running on constant current

mode. In addition, its programmable capability offers a degree of control with proper software

interface.

Solution level

A 4 liter beaker has the height of approximately 9.34. In designing the apparatus, the

positioning of components must fit within component constraints. When filled up to 3L, the

solution level is approximately 7. The chemicals ordered from the supplier are enough to make

3L in the volume of chemicals. Therefore, the shaft that is attached to the cathode and the

extenders that hold the silver anode must extend deep enough to be fully submerged within the

solution. In addition, to eliminate fringe effects on the coating surface, 1.5 is left for extra space

between the surfaces of the cathode to the surface of the anode bars.

8

Figure 4: Illustrating solution level.

9

The Apparatus Features

1. Temperature and chemical resistant tank

2. Rotating target mounting shaft

3. Height adjustable cover

Tank construction:

Due to the rational discussed above in the precleaning procedure, uniform electric fields

distribution is achieved by using a cylindrical tank. Pyrex glass is chosen as the tank material for

reasons pertaining to being chemically and electrically unreactive, and able to withstand high

temperature.

Corrosion

resistant

Electrically

unreactive

Size (8

DIA)

High

temp.

Machinability Cost

Stainless steel Yes Wont

affect

plating

process

Yes Yes

(might get

hot)

Difficult High

Glass Pyrex

(borosilicate)

Yes Yes N/A Yes N/A

(specialized

glassblowing)

Med.

Plastic

Acetal

Yes Yes Yes No Good Med.

Plastic

Polycarbonate

Yes Yes Yes Yes Good High

Plastic -

Polyethylene

Yes Yes Yes No (melts

at 180F

Good Low

Table 1: Materials considered for tank

Since Pyrex glass is not machinable, it is essential to find a glass apparatus in laboratory

ware catalog with the desired dimensions. A beaker with the capacity of 2000mL has 130 x

190mm for height and outer diameter respectively.

A motorized rotator is mounted on the armature and a threaded shaft attaches the motor

output shaft to the cathode sharing the same axial line. Rotating the work piece at the rate of 6

RPM distributes the deposition evenly on the cathode target device. Given 9 in the shaft length,

the height of the tank provides enough head space from the top of the solution to the bottom of

the lid with 2.5 in. in between.

10

Adjustable back for cover height becomes necessary to operate the device within the

fume hood. Since beakers are of different sizes, especially between the ones that kept the plating

solution, and the ones for cold water rinsing. Adjustable cover makes it easier to operate.

Deposition rate:

The rate of deposition is a function dependent upon the metal-solution interface, the

kinetics of the deposition, the nucleation and growth process of the metal lattice and the structure

and properties of the deposits. A good estimation of the deposition rate is as followed

q Na n m Q * * * = 1.1

Q total deposition cathodic charge

m number of gram moles of metal deposited

n number of e

-

in the reaction

Na Avogadros number

q fundamental charge of electron

F - Faradays constant

By definition

q Na F * = 1.2

Given that

1 23

10 022 . 6

= mol N

A

C q

19

10 602 . 1

=

mol

C

. F 44 96473 =

F n

Q

m

*

= 1.3

dt I Q

= 1.4

dt

F n

I

m

=

*

1.5

11

V

w

D = 1.6

D density

m Mw w * = 1.7

Mw molecular weight

A area

T - thickness

T A

w

D

*

= 1.8

dt

D A F n

I

Mw

D A

w

T

= =

* * * *

1.9

Now assume that current is held constant.

D A F n

t I Mw

T

* * *

* *

= 1.10

Mw(silver) = 107.8682 amu

D(silver) = 10490

3

m

kg

Oxidation state(silver) = +1

Ag

+1

+ e

-

Ag

so n = 1

) 10 49 . 10 ( * * ) 44 . 96473 ( * ) 1 (

* * ) 8682 . 107 (

3

=

A

t I

T

A

t I

T

* * 10 07 . 1

7

= 1.11

12

From the supplier specs, the optimal cathode current density (

A

I

) is 1 to 3

2

ft

A

or 1.07 x 10

-7

to

3.22 x 10

-7

2

m

A

For thickness of 16 m and running at 1

2

ft

A

) 10 03 . 1 ( * ) 10 07 . 1 (

) 10 16 (

7 7

6

= t

t = 1.30*10^8 4.36*10^7sec -> 1.5 to 0.5day

Procedure

The entire plating flow can be summarized in four steps.

1. Precleaning

2. Surface preparation

3. Plating

4. Post-cleaning/ polishing

Precleaning

The precleaning process combines both soak cleaning and electrolytic cleaning. For soak

cleaning, the device to be cleaned is immersed under a solution diluted with a mixture of surface

agents, detergents, and suspension agents. While in electrolytic cleaning, the process removes

smut, soil deposits, and prepares the surface for plating. The apparatus used in electrolytic

cleaning should bear similarity to the one used in plating. The process of cleaning achieves the

best result based on the uniform distribution of electric field lines from the anode to the cathode

surface. The quality of the cleaning predicts the success of good electroplating.

Electrolytic cleaning is performed after soak cleaning. The process may cause mild

oxidation on the copper surface visible as darkening spots. These are removed using acidic salts

before the actual plating.

13

Surface preparation

Before plating, the work surface must be activated by immersion in a solution created

from a dry, acidic salt that etches and temporality deoxidizes the copper surface allowing for

greater time for the plating process

Plating

The conventional method of electroplating involves the use of potassium cyanide as a

striking agent, and potassium carbonate as electrolytic solution. The plating solution provided by

the supplier electroplates silver directly onto copper without a striking agent. The elimination of

cyanide reduced cost of waste management. The solution also works in room temperature and is

specified by the supplier to have exceptional covering and throwing power, and produces fine-

grained, smooth, dense, hard deposition layer with low porosity and high luster.

The concentrated liquid must be diluted with deionized water. The solution must operates

within the pH scale of 8.8 to 9.5 and should be adjusted accordingly using KOH or nitric acid.

Keeping the pH below 10 and temperature between 120F is essential in keeping the

effectiveness of the bath.

A ratio of 2 to 1 should be kept between the surface area of pure silver anode to the

copper cathode. While a filtration device using carbon filter is recommended, air agitation alone

provided by aquarium air tank is sufficient due to the small-scale nature.

The best way to run the electroplating apparatus is to divide the operation into several

stages. Before running the machine, titration chemicals for each of the solution tank involved

must be prepared in advance to ensure the flow of the operation without interruption in between.

Running each stage is now organized into lab format to convey the clearest understanding from

the suppliers specifications.

Operating steps

For the actual plating procedure, the procedural steps have been further subdivided into

various stages. Organized as a collection of labs, the manual is meant to convey operational

knowledge as well as calculation as quickly as possible.

Included with each step is also the method of testing involved, as well as pre-quantified

amount of solution chemical mixture used for testing

14

1. Soak cleaning

2. Electrolytic cleaning

3. Cold water rinse

4. Deoxidizing phase

5. Cold water rinse

6. Plating

7. D.I water rinse

8. Dry

Soak Clean

Vendor Operating parameters:

Electrolytic cleaning Soak cleaning

Concentration: 4 to 10 oz/gal. of water 8-16 oz/gal of water

Temperature: 140 to 200F 140 - 200F

Immersion time: 15 seconds to 2 minutes (

zinc and copper)

1 to 5 minutes (steel)

5 10 minutes

Polarity: Anodic (reverse current) N/A

Current Density: 10 to 30 amps. (zinc and

copper)

50 to 100 amps. (steel

N/A

Table 2: Soak clean vendor specs.

Recommended parameters

Bath concentration 8 oz/gal

Bath charge-up

Equipment

125 mL Erlenmeyer flask

25 mL pipet

Clean 2.5 L beaker

Hot plate

15

WARNING: Operate within a fume hood and wear a respirator!

Material is caustic soda

and the vapor produced by heating the solution can cause burn. DO NOT MIX E-Kleen

with acidic material or other chemicals.

Material

E-Kleen pellets

Procedure

1. Fill beaker with water.

2. Heat up the temperature of the beaker content to hot enough (~120 F) to melt the E-Kleen

pellets.

3. Measure out E-Kleen pellets in weight (~180 g).

4. Add the pellets slowly to the warm water to avoid sputtering.

5. Stir the solution with pellets until completely dissolved.

Calculation

1 L = 0.264 gal

1 oz = 28.349 g

Note: Need to fill up to 3 L of E-Kleen solution. This is to make sure that the electrodes will be

completely immersed in a 4 L beaker.

3 (L) x 0.264 (gal/L) x 8 (oz/gal) x 28.349 (gram/oz) = 179.62 g

Testing the bath

Equipment

Clean 1 L beaker

25 mL pipet

Material

-Methyl orange indicator

-1 N HCl

16

Procedure

In an overview, the method described takes a sample of the bath solution, and titrate it with 1 N

HCl. Based on the volume of the HCl (in mL), concentration can be calculated.

1. Allow the solution to cool to room temperature.

2. Take a sample of the solution from the bath using a 25 mL pipet. Transfer to a clean 125

mL Erlenmeyer flask.

3. Add 25 mL of water.

4. Use Methyl orange indicator to produce a yellow colored solution. Add 5 drops. For

strips, hold the strip with a tong.

5. Titrate with 1 N HCl until the indicator turns orange-pink.

Calculation

Concentration of E-Kleen (oz/gal) = (mL of HCL) x (0.3125) x (Normality of HCL)

In this case given that normality is 1 N.

Concentration of E-Kleen (oz/gal) = (ml of HCL) x (0.3125)

Concentration should be 8oz/gal

Running soak cleaning

Equipment

Hot plate

Thermometer

1. Heat up the solution to 160 F on the heat plate.

2. Soak the cathode into the solution for 10 minutes

Electrolytic clean

Vendor Operating parameters:

Electrolytic cleaning Soak cleaning

Concentration: 4 to 10 oz/gal. of water 8-16 oz/gal of water

Temperature: 140 to 200F 140 - 200F

17

Immersion time: 15 seconds to 2 minutes (

zinc and copper)

1 to 5 minutes (steel)

5 10 minutes

Polarity: Anodic (reverse current) N/A

Current Density: 10 to 30 amps. (zinc and

copper)

50 to 100 amps. (steel

N/A

Table 3: Electrolytic clean vendor specs.

Bath charge-up

If steps for charging the soak clean bath have been followed, the used bath can also be used for

electrolytic cleaning

Running the cleaning step

Equipment

DC power supply

Hot plate

Thermometer

Procedure

10 ASF has been selected for copper cleaning

1. Attach the steel anode bars onto the lid of the device.

2. Heat the solution to 160 F.

3. Immerse both the cathode and the steel anodes.

4. Connect the positive terminal to cathode, and negative terminal to anode. This effectively

reverses the current flow for anodic cleaning.

5. Turn on the supply, select current mode and limit it to 0.86 amps. (For detail of the

calculation, refer to running the plating step)

6. Let it run for 2 minutes.

Cold water rinse

Equipment

18

1 L beaker

Procedure

1. Fill the 1 L beaker up to 0.8 L.

2. Submerge the cathode within the cold water for 5 minutes.

3. While rinsing the cathode. Take off the steel bar electrodes.

4. Wash the other electrodes.

Deoxidizing phase

Vendor Operating parameters:

Range Optimum Temperature Time

8-24 oz/gal 16 oz/gallon 65-90F 2-5 minutes

immersion

Table 4: Surface activation vendor specs.

Recommended parameters

Concentration: 16 oz/gal ratio

Temperature: 90 F

Time: 5 minutes immersion

Bath charge-up

Equipment

1 L beaker

WARNING: MUST wear respirator and wear gloves. Material is corrosive.

Material

E-Pik pellets

D.I. water

Procedure

1. Fill the 1 L beaker up to 1 L of D.I. water.

2. Measure out E-Pik pellets. ~ 120 gram.

3. Add salt slowly to the D.I. water

19

4. Stir until the pellets completely dissolve.

Calculation

Fill up the beaker completely to ensure full immersion of the target copper electrode.

1 L x 16 (oz/gal) x 0.264 (gal/L) x 28.349 (g/oz) = 119.7 g

Testing the bath

Equipment

1 L beaker

Pipet

Material

50% Sulfuric acid (H2SO4)

KI/EDTA solution

D.I. water

0.1 N Sodium thiosulfate

Starch indicator

Procedure

1. Take 2 mL of the bath sample.

2. Add 3 mL of 50% sulfuric acid.

3. Add 50 mL of D.I. water.

4. Add 10 mL KI/EDTA until the solution turns rusty red.

5. Titrate with 0.1 N sodium thiosulfate to a pale yellow color.

6. Add 2 mL of starch indicator to turn the solution deep blue. If using strips. Hold the

indicator with a tong.

7. Continue to titrate with sodium thiosulfate until the solution becomes colorless for 30

seconds.

Calculation

Concentration of E-Pik (oz/gal) = (mL of 0.1 N Sodium thiosulfate) x 1.18

This should be around 16 oz/gal

20

Running the deoxidizing phase

Procedure

This is done in room temperature. While the solution does not need to be heated up, it is a

moderately acidic solution.

1. Soak the cathode into the acidic solution for 5 minutes.

Cold water rinse

Equipment

1 L beaker

4 silver anodes

Procedure

1. Fill the 1 L beaker up to 0.8 L.

2. Submerge the cathode within the cold water for 5 minutes.

Plating

Vendor operating parameters:

Optimum Range

Silver Metal 2.4 oz/gal 2-2.5 oz/gal

pH 8.8 8.5-9.5

Temperature 68F 60-75F

Cathode current density 1 3 0.5 5 ASF

Anode current density -- 2-10 ASF

Agitation air agitation on the anodes,

plus cathode rod agitation

or air agitation on the

cathodes.

Table 5: Plating vendor specs.

Recommended parameter:

68F = 20 C

Room temp

Bath charge-up

21

Equipment

4 L beaker

Material

45 % KOH

40% nitric acid (HNO

3

)

E-Brite

D.I. water

pH indicator

Procedure

To make a 3 L solution

1. Pour out 1.8 L of E-Brite solution into the beaker.

2. Add in 1.2 L of D.I. water

3. Use the pH indicator to find the pH of the solution

4. Adjust the pH of the solution to 9.0 with KOH solution or nitric acid.

Calculation

E-Brite contains 4 (oz/gal) of silver, the concentrate must be diluted with D.I. water

Use a percentage of 70% E-Brite, 30% D.I. water

0.264 gal = L

X L x 4 (oz/gal) x 0.264 (gal/L) => (Y oz/3 L) x (L/0.264 gal) => (Z oz/gal)

X = 1.8 L, so Y = (2.4 oz/gal)

Testing the bath

Equipment

25 mL pipet

125 mL Erlenmeyer flask

Material

0.1 N KSCN

22

98% sulfuric acid (H

2

SO

4

)

Nitric acid (HNO

3

)

2% Ferric ammonium

D.I. water

Procedure

1. Transfer 10 mL of solution sample into a 125 mL Erlenmeyer flask

2. Add 50 mL of D.I. water

3. Add 2 mL of nitric acid, 2 mL of sulfuric acid

4. Heat up the solution to boil, and let it boil for 5 minutes.

5. Let cool the solution. Add 5 mL of ferric ammonium sulfate.

6. Titrate with 0.1 N KSCN until the solution turns light orange

Calculation

Concentration of silver = (mL KSCN) x 0.144

Running electroplating

The plating can be done without fume hood. Nevertheless, since the whole setup for pre-

cleaning and deoxidizing should be performed within a fume hood. It is best to plate within the

fume hood as well. Prolonged exposure to E-Brite silver solution can cause the absorption of

silver into the blood stream. Please wear gloves accordingly.

Equipment

DC power supply (up to 1 Amp)

Copper cathode

4 Silver anodes

4 L beaker

Material

E-Brite

23

Procedure

Recommend using 3 ASF for both anode and cathode

Use the bath from the bath charging step. Refer the bath charging-up.

1. Take the target copper cathode from the cold water rinse.

2. Fit the 4 silver anodes onto the plating lid. Submerge all electrodes within the solution.

3. Turn the DC power supply on. Select current mode and switch up to 0.256 A.

4. Wait for the plating to take place. The amount of time required for 15 micron is.

Calculation

Current

ASF ampere per square foot (amp/ft^2)

Going from mm

2

to ft

2

Y ft

2

= (X mm

2

)

x (cm

2

/10 mm

2

) x (in

2

/2.54 cm

2

) x (ft

2

/12 in

2

)

When X = 16000 mm

2

, Y = 0.172 ft

2

Note: The surface area of the anode must be 4 times greater than the surface area of the copper.

3 (amp/ft

2

) x 0.172 ft

2

= 0.258 A

Cold water rinse

Equipment

1 L beaker

Procedure

1. Fill the 1 L beaker up to 0.8 L of cold water.

2. Submerge the cathode within the cold water for 5 minutes.

3. Wash the other electrodes.

D.I. water rinse

Equipment

1 L beaker

Material

24

D.I. water

Procedure

1. Fill the 1 L beaker up to 0.8 L. of D.I. water.

2. Submerge the cathode within the cold water for 5 minutes.

3. Wash the other electrodes.

Dry

Let it sit in the fume hood and let dry.

Conclusion

The plating machine currently produces silver plating albeit at less uniformity than had

expected. When examined under an optical microscope, the thickness of 15m has been achieved

using comparison to a 20 m gold thread. However, the distribution of silver upon the copper

surface has visible bumps. Further testing is required to isolate the cause of uniformity

Through this project, Ive gained the experience of researching, designing,

manufacturing, and operating the device from the start to finish. Ive gained skills in mechanical

machining, Solidworks CADDing, and mixing chemicals. The project has stretched my ability

beyond the bounds of engineering education, and has provided an overview of a challenging

engineering work.

Future work recommendation

The project could be expanded and in fact should incorporate these following elements in

the future to fix the problems of non-uniformity on the plating surface as recently observed on

the optical microscope. The first suggestion is a pH indicator, which could be implemented by

using the current calculation, derive from which, the transfer of ions from the silver anodes to the

cathodes. This will demonstrate the rate of the loss of ions within the solution. In order for this to

be implemented, a calculation needs to be done first to characterize the rate of ion loss, then,

repeated plating to test out the change of pH within the solution as compared to the calculation.

25

The second recommendation of further work is to monitor the plating machine using the

serial communication capability of the Agilent voltage supply. This will involved the use of

LabView and a graphical interface program. It will monitor the loss of ions from the solution, as

well as the thickness of the deposition as predicted by the deposition equation. This is to be

implemented by a repeated trial of depositions and then characterize the deposition by thickness

measurement under the optical microscope, while varying the deposition time, the deposition

current, and the deoxidizing time as variables.

Appendix

List of Figures and Tables

Figure 1: Electroplating tank diagram

Figure 2: a) Target device. b) Target device dimensions

Figure 3: Layout of the setup

Figure 4: Illustrating solution level.

Table 1: Materials considered for tank

Table 2: Soak clean vendor specs.

Table 3: Electrolytic clean vendor specs

Table 4: Surface activation vendor specs.

Table 5: Plating vendor specs.

Table 6: Table of symbols, name, molar mass, and risk phrases

Percentage solution

1. % W/W gram of solute per 100 grams of solution

2. % W/V gram of solute per 100 mL of solution

3. % V/V mL of solute per 100 mL of solution

Molar

gmw of solute per 1 L of solution

26

Normal

gew of solute per 1 L of solution

or

normal = molar x valence

Chemical symbol and rating

It is strongly suggested to obtain the MSDN sheets for the handling of these materials.

Symbol Name Molar mass (g/mol) Risk phrases

HCl hydrochloric acid 36.46 R20 R21 R22 R36 R37 R38

H

2

SO

4

sulfuric acid 98.08 R23 R24 R25 R35 R36 R37

R38 R49

HNO

3

nitric acid 63.01 R8 R23 R24 R25 R34 R41

KI potassium iodide 166.00 R36 R38 R42 R43 R61

KOH potassium hydroxide 56.10564 R20 R21 R22 R35 R41

C

10

H

16

N

2

O

8

ethylenediaminetetraacetic

acid (EDTA)

292.25 R36

KSCN potassium thiocyanate 97.18 R22 R36 R37 R38.

Na

2

S

2

O

3

sodium thiosulfate 158.09774 R36 R37 R38

FeNH

4

(SO

4

)

2

12H

2

O

ferric ammonium sulfate R36 R37 R38

Table 6: Table of symbols, name, molar mass, and risk phrases

R20 Harmful by inhalation.

R21 Harmful in contact with skin

R22 Harmful if swallowed.

R23 Toxic by inhalation.

R24 Toxic in contact with skin.

R25 Toxic if swallowed.

R34 Causes burns.

R35 Causes severe burns.

R36 Irritating to eyes.

R37 Irritating to respiratory system.

R38 Irritating to skin.

R41 Risk of serious damage to the eyes.

R42 May cause sensitization by inhalation.

R43 May cause sensitization by skin contact.

R49 May cause cancer by inhalation.

27

Original vendor summary

28

29

Supplier tank design

Vous aimerez peut-être aussi

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesD'EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášPas encore d'évaluation

- Ta Capacitors With Conductive Polymer Robust To Leadfree ProcessDocument7 pagesTa Capacitors With Conductive Polymer Robust To Leadfree ProcessMauricioSánchezPas encore d'évaluation

- International Journal of Engineering Research and DevelopmentDocument7 pagesInternational Journal of Engineering Research and DevelopmentIJERDPas encore d'évaluation

- Hydrogen Sensing Characteristics of Electrostatically Sprayed Palladium - Doped Tin DioxidesDocument9 pagesHydrogen Sensing Characteristics of Electrostatically Sprayed Palladium - Doped Tin DioxidesInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- Segundo Informe ElectroquímicaDocument30 pagesSegundo Informe ElectroquímicaLUZPas encore d'évaluation

- Design of Copper Electrowinning Circuit Using Conventional CellsDocument59 pagesDesign of Copper Electrowinning Circuit Using Conventional Cellsjoseph kafumbila95% (20)

- Machining of A Film-Cooling Hole in A Single-Crystal Superalloy by High-Speed Electrochemical Discharge DrillingDocument11 pagesMachining of A Film-Cooling Hole in A Single-Crystal Superalloy by High-Speed Electrochemical Discharge Drillingmustafa sertPas encore d'évaluation

- Acme FDocument22 pagesAcme FPhearun PayPas encore d'évaluation

- A Study of Active Screen NitridingDocument8 pagesA Study of Active Screen Nitridingmedane_saad6707Pas encore d'évaluation

- Nuclear Micro Batteries For MEMS DevicesDocument10 pagesNuclear Micro Batteries For MEMS DevicesPardha Saradhi DamarlaPas encore d'évaluation

- A Safe Method For Spot Welding v1.11 5 12Document11 pagesA Safe Method For Spot Welding v1.11 5 12Petar Ivan100% (1)

- Thermal Aging Effect on Oxide Films in Dissimilar Metal WeldsDocument9 pagesThermal Aging Effect on Oxide Films in Dissimilar Metal WeldsOscarCastilloNavaPas encore d'évaluation

- Journal of Nuclear Science and TechnologyDocument6 pagesJournal of Nuclear Science and TechnologyShishir PurohitPas encore d'évaluation

- RAPDDocument4 pagesRAPD123vidyaPas encore d'évaluation

- Chemistry, Relationships and Trouble Shooting of Optical Media Electroforming BathsDocument18 pagesChemistry, Relationships and Trouble Shooting of Optical Media Electroforming BathsKeily VilcarromeroPas encore d'évaluation

- Electrodeposition PDFDocument4 pagesElectrodeposition PDFcb gPas encore d'évaluation

- IV Report KeltronDocument10 pagesIV Report KeltronRijy LorancePas encore d'évaluation

- Processing Window and Evaporation Phenomena For TiDocument8 pagesProcessing Window and Evaporation Phenomena For TiArpan MPas encore d'évaluation

- Electrodeposition of Nickel Coatings On Aluminium Alloy 7075Document262 pagesElectrodeposition of Nickel Coatings On Aluminium Alloy 7075ThaharPas encore d'évaluation

- FinalReport 1 PDFDocument47 pagesFinalReport 1 PDFHITESHBHAI TADVIPas encore d'évaluation

- 1 Artículo CorrosiónDocument16 pages1 Artículo CorrosiónFabiola CovarrubiasPas encore d'évaluation

- 7 Segment Counter using IC 555 and IC 4026 Project ReportDocument22 pages7 Segment Counter using IC 555 and IC 4026 Project ReportGunjan Vyas100% (1)

- Manufacturing Process Crucible FurnaceDocument6 pagesManufacturing Process Crucible FurnaceCristian MosqueraPas encore d'évaluation

- Ahmed Moosa NanoDocument16 pagesAhmed Moosa Nanojojim52Pas encore d'évaluation

- Ee 432 Cymos Final ReportDocument13 pagesEe 432 Cymos Final Reportapi-309959382Pas encore d'évaluation

- VLSI Design Process and Unit ProcessesDocument30 pagesVLSI Design Process and Unit ProcessesVenkata SatishPas encore d'évaluation

- Iwamoto 2019Document7 pagesIwamoto 2019Анна ПетроваPas encore d'évaluation

- LampBook Final LowresDocument40 pagesLampBook Final LowresErickEscobarPas encore d'évaluation

- Ceramic XrayDocument9 pagesCeramic XrayFandi MarcelloPas encore d'évaluation

- Maganet Software MannuelDocument0 pageMaganet Software MannuelKapilachander ThangavelPas encore d'évaluation

- Electrochemical Machining of Metal Plates: J. F. Cooper, M. C. EvansDocument22 pagesElectrochemical Machining of Metal Plates: J. F. Cooper, M. C. EvansNuzhat AmberPas encore d'évaluation

- Er-Bakir's Copper Wire Production ProcessDocument34 pagesEr-Bakir's Copper Wire Production Processmetalurjist90Pas encore d'évaluation

- Design and Testing of a Solar Parabolic Concentrating Collector in SudanDocument5 pagesDesign and Testing of a Solar Parabolic Concentrating Collector in SudanAsepta Surya WardhanaPas encore d'évaluation

- Project Report Phase1Document37 pagesProject Report Phase1Satyam vankayalaPas encore d'évaluation

- HMT Pinjore Industrial Training ReportDocument12 pagesHMT Pinjore Industrial Training ReportAnurag KumarPas encore d'évaluation

- LGP REPORT #3 - SimpasaDocument15 pagesLGP REPORT #3 - SimpasaBeckham ChailePas encore d'évaluation

- A NEW Micro-Four-Point Probe Design FOR Zhang, Dong-Nanotechnology Laboratory, SystemsDocument4 pagesA NEW Micro-Four-Point Probe Design FOR Zhang, Dong-Nanotechnology Laboratory, Systemsobalana tosinPas encore d'évaluation

- EA1-GA3-F-Fairuz Nabilah Binte Muzafar PDFDocument14 pagesEA1-GA3-F-Fairuz Nabilah Binte Muzafar PDFFairuz NabilahPas encore d'évaluation

- Guide to Selecting the Right CapacitorDocument52 pagesGuide to Selecting the Right Capacitorh_878236333Pas encore d'évaluation

- Experimental Research On The Electrochemical Machining of Modern Titanium-And Nickel - Based Alloys For Aero Engine ComponentsDocument17 pagesExperimental Research On The Electrochemical Machining of Modern Titanium-And Nickel - Based Alloys For Aero Engine ComponentsRabindra DashPas encore d'évaluation

- Anodes in Cooling Water Heat Exchangers - GuidelinesDocument12 pagesAnodes in Cooling Water Heat Exchangers - GuidelinesJake SparrowPas encore d'évaluation

- Experimental Investigation On Thermal Performance of Copper With AluminiumDocument6 pagesExperimental Investigation On Thermal Performance of Copper With AluminiumRameshPas encore d'évaluation

- ZNC Varistor Switching SurgeDocument39 pagesZNC Varistor Switching Surgeth3g4m3Pas encore d'évaluation

- Jawaharlal Nehru Technological University Anantapur AndhrapradeshDocument30 pagesJawaharlal Nehru Technological University Anantapur AndhrapradeshJagaPas encore d'évaluation

- Electrochemical Importance of Anode and Cathode Coating in A Membrane Cell Chlor Alkali IndustryDocument8 pagesElectrochemical Importance of Anode and Cathode Coating in A Membrane Cell Chlor Alkali IndustryS Bharadwaj Reddy100% (1)

- Technical - Handbook - OMAN CABLES PDFDocument70 pagesTechnical - Handbook - OMAN CABLES PDFSahul HameedPas encore d'évaluation

- 9479-Physics Apparatus Construction DrawingsDocument64 pages9479-Physics Apparatus Construction DrawingsChris56000Pas encore d'évaluation

- REVIEW PAPER: Design and Investigation On The Reliability of A Ceramic Power PackageDocument11 pagesREVIEW PAPER: Design and Investigation On The Reliability of A Ceramic Power PackageALTHEA JANINE MACAPUNDAGPas encore d'évaluation

- Eem413e Lecture-Week4Document47 pagesEem413e Lecture-Week4Furkan AvcıoğluPas encore d'évaluation

- Radiation Damage and Quantitative Criteria for Accident Tolerant Nuclear FuelsDocument9 pagesRadiation Damage and Quantitative Criteria for Accident Tolerant Nuclear FuelswordssmithPas encore d'évaluation

- Hayfield Report Nace Tm0294-94Document6 pagesHayfield Report Nace Tm0294-94Ricardo Rivas - New GlobalPas encore d'évaluation

- 油式非晶質變壓器 英 PreviewDocument16 pages油式非晶質變壓器 英 PreviewisaacwabbiPas encore d'évaluation

- WR 2009-82 WebDocument45 pagesWR 2009-82 WebMalolan VasudevanPas encore d'évaluation

- Corrosion Prevention and Control Corrosion FundamentalsDocument9 pagesCorrosion Prevention and Control Corrosion FundamentalsbrodyPas encore d'évaluation

- EE432/EE532 Microelectronic Fabrication Techniques: Final Lab ReportDocument28 pagesEE432/EE532 Microelectronic Fabrication Techniques: Final Lab Reportapi-546410997Pas encore d'évaluation

- CDC 10115 DS1Document13 pagesCDC 10115 DS1FernandoPas encore d'évaluation

- Test PlanDocument16 pagesTest PlanAditya NehraPas encore d'évaluation

- Advanced Chlor Alkali Electrolyzer With Cover Page v2Document101 pagesAdvanced Chlor Alkali Electrolyzer With Cover Page v2pmarteenePas encore d'évaluation

- Interfacial Phenomena in ElectrocatalysisDocument391 pagesInterfacial Phenomena in ElectrocatalysisLuis Gerardo CarvajalPas encore d'évaluation

- Corrosion Behavior of Steam Turbine Materials For Geothermal Power PlantsDocument6 pagesCorrosion Behavior of Steam Turbine Materials For Geothermal Power Plantsshare irgaPas encore d'évaluation

- Rules Sensor PlacementDocument40 pagesRules Sensor Placementivanjose09Pas encore d'évaluation

- Chemical Composition of Everyday ProductsDocument220 pagesChemical Composition of Everyday Productsquythanck81% (16)

- Arduino Fungsi SyntaxDocument36 pagesArduino Fungsi Syntaxmul21Pas encore d'évaluation

- Hydrazine Sulfate KetazineDocument4 pagesHydrazine Sulfate Ketazineivanjose09Pas encore d'évaluation

- Fao Specifications and Evaluations For Agricultural PesticidesDocument44 pagesFao Specifications and Evaluations For Agricultural Pesticidesivanjose09Pas encore d'évaluation

- 05Document8 pages05irsgolapPas encore d'évaluation

- QBDocument18 pagesQBMudrikaPas encore d'évaluation

- Assignment Group 13: Sodium Hydroxide Production: CH 1060 Process Engineering FundamentalsDocument61 pagesAssignment Group 13: Sodium Hydroxide Production: CH 1060 Process Engineering FundamentalsHarshil JainPas encore d'évaluation

- Zinky-13 Inorganic Zinc Rich Primer Technical Data SheetDocument4 pagesZinky-13 Inorganic Zinc Rich Primer Technical Data SheetppglPas encore d'évaluation

- Alina Dawood - QS - Long AssignmentDocument11 pagesAlina Dawood - QS - Long AssignmentK AndrePas encore d'évaluation

- U-5 - 2022 - Tecnologías de Tratamientos - BDocument39 pagesU-5 - 2022 - Tecnologías de Tratamientos - BSimón OsésPas encore d'évaluation

- Rheological Properties of Some Oil Based Muds Used in Reservoirs in The Niger Delta, NigeriaDocument6 pagesRheological Properties of Some Oil Based Muds Used in Reservoirs in The Niger Delta, NigeriaNurfatini ChePas encore d'évaluation

- China's First Ministry of Machine-Building Standard for Radiography of WeldsDocument133 pagesChina's First Ministry of Machine-Building Standard for Radiography of Weldsmsiddique1Pas encore d'évaluation

- Figure 1: Basic Design of Fluidized-Bed ReactorDocument3 pagesFigure 1: Basic Design of Fluidized-Bed ReactorElany Whishaw0% (1)

- The Effectiveness of Cassava (Manihot Esculenta) Starch in Creating Biodegradable PlasticDocument3 pagesThe Effectiveness of Cassava (Manihot Esculenta) Starch in Creating Biodegradable PlasticKimi Annika VillarealPas encore d'évaluation

- The University of The South Pacific: Chemistry DivisionDocument10 pagesThe University of The South Pacific: Chemistry DivisionTetzPas encore d'évaluation

- Closures Technical Manual 14nov2008Document37 pagesClosures Technical Manual 14nov2008jjescudero100% (1)

- Assessment PN1096617Document14 pagesAssessment PN1096617Amr TarekPas encore d'évaluation

- Specification For Alloy-Steel and Stainless Steel Bolting Materials For High-Temperature ServiceDocument18 pagesSpecification For Alloy-Steel and Stainless Steel Bolting Materials For High-Temperature ServicesergioprybyszPas encore d'évaluation

- 2019 Y5 Work Book 1 (Practical 3) SolutionsDocument9 pages2019 Y5 Work Book 1 (Practical 3) SolutionsChenluyingPas encore d'évaluation

- AOCS Recommended Practice Ca 12-55 Phosphorus PDFDocument2 pagesAOCS Recommended Practice Ca 12-55 Phosphorus PDFMaximino Alvarez100% (1)

- Dyeing Process of Cotton Fabric With Reactive DyesDocument6 pagesDyeing Process of Cotton Fabric With Reactive DyesMianAbrarAnjumPas encore d'évaluation

- Lecture 3 Coagulation and FlocculationDocument53 pagesLecture 3 Coagulation and FlocculationAbo-Khaled Mohammed100% (1)

- 651 PDFDocument12 pages651 PDFjitendraPas encore d'évaluation

- Class 10 Science Chapter 4 Carbon and Its Compounds Revision NotesDocument30 pagesClass 10 Science Chapter 4 Carbon and Its Compounds Revision NotesNanhe SinghPas encore d'évaluation

- Green Composites: An OverviewDocument11 pagesGreen Composites: An OverviewAyushPas encore d'évaluation

- Quality Tests RequirementDocument6 pagesQuality Tests RequirementSandip PaulPas encore d'évaluation

- Group No 6 - Boge 2 Well Logging and FormationDocument26 pagesGroup No 6 - Boge 2 Well Logging and FormationAlhaj MassoudPas encore d'évaluation

- BS en Iso 9712 Standard CodeDocument17 pagesBS en Iso 9712 Standard CodeVilam Ndt100% (1)

- Carbofill Dec08Document4 pagesCarbofill Dec08Cristian Andres Araya CisternasPas encore d'évaluation

- Automatic Wall Painting MachineDocument9 pagesAutomatic Wall Painting MachineaalekhPas encore d'évaluation

- Hazardous Substance Assessment Checklist Rev 3-1Document5 pagesHazardous Substance Assessment Checklist Rev 3-1Santo WardanaPas encore d'évaluation

- Bfe FM200 Epfs 000 02 V.0Document52 pagesBfe FM200 Epfs 000 02 V.0SajjadPas encore d'évaluation

- Arches: Theory of StructuresDocument20 pagesArches: Theory of StructuresAravind BhashyamPas encore d'évaluation

- Parker Autoclave Engineers: Fluid Componets Product Catalog Feb. 2016Document370 pagesParker Autoclave Engineers: Fluid Componets Product Catalog Feb. 2016mds9185Pas encore d'évaluation

- Housekeeping & Accommodation StudiesDocument15 pagesHousekeeping & Accommodation StudiesCaleb MukaviPas encore d'évaluation

- Why We Die: The New Science of Aging and the Quest for ImmortalityD'EverandWhy We Die: The New Science of Aging and the Quest for ImmortalityÉvaluation : 3.5 sur 5 étoiles3.5/5 (2)

- Summary: Limitless: Upgrade Your Brain, Learn Anything Faster, and Unlock Your Exceptional Life By Jim Kwik: Key Takeaways, Summary and AnalysisD'EverandSummary: Limitless: Upgrade Your Brain, Learn Anything Faster, and Unlock Your Exceptional Life By Jim Kwik: Key Takeaways, Summary and AnalysisÉvaluation : 5 sur 5 étoiles5/5 (8)

- The Fabric of Civilization: How Textiles Made the WorldD'EverandThe Fabric of Civilization: How Textiles Made the WorldÉvaluation : 4.5 sur 5 étoiles4.5/5 (57)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingD'EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingÉvaluation : 5 sur 5 étoiles5/5 (4)

- The Comfort of Crows: A Backyard YearD'EverandThe Comfort of Crows: A Backyard YearÉvaluation : 4.5 sur 5 étoiles4.5/5 (23)

- The Obesity Code: Unlocking the Secrets of Weight LossD'EverandThe Obesity Code: Unlocking the Secrets of Weight LossÉvaluation : 5 sur 5 étoiles5/5 (4)

- Algorithms to Live By: The Computer Science of Human DecisionsD'EverandAlgorithms to Live By: The Computer Science of Human DecisionsÉvaluation : 4.5 sur 5 étoiles4.5/5 (722)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingD'EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (33)

- Sully: The Untold Story Behind the Miracle on the HudsonD'EverandSully: The Untold Story Behind the Miracle on the HudsonÉvaluation : 4 sur 5 étoiles4/5 (103)

- Summary: Outlive: The Science and Art of Longevity by Peter Attia MD, With Bill Gifford: Key Takeaways, Summary & AnalysisD'EverandSummary: Outlive: The Science and Art of Longevity by Peter Attia MD, With Bill Gifford: Key Takeaways, Summary & AnalysisÉvaluation : 4.5 sur 5 étoiles4.5/5 (41)

- Crypt: Life, Death and Disease in the Middle Ages and BeyondD'EverandCrypt: Life, Death and Disease in the Middle Ages and BeyondÉvaluation : 4 sur 5 étoiles4/5 (3)

- The Marshmallow Test: Mastering Self-ControlD'EverandThe Marshmallow Test: Mastering Self-ControlÉvaluation : 4.5 sur 5 étoiles4.5/5 (57)

- Dark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseD'EverandDark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseÉvaluation : 3.5 sur 5 étoiles3.5/5 (69)

- To Explain the World: The Discovery of Modern ScienceD'EverandTo Explain the World: The Discovery of Modern ScienceÉvaluation : 3.5 sur 5 étoiles3.5/5 (51)

- Highest Duty: My Search for What Really MattersD'EverandHighest Duty: My Search for What Really MattersPas encore d'évaluation

- Hero Found: The Greatest POW Escape of the Vietnam WarD'EverandHero Found: The Greatest POW Escape of the Vietnam WarÉvaluation : 4 sur 5 étoiles4/5 (19)

- When the Body Says No by Gabor Maté: Key Takeaways, Summary & AnalysisD'EverandWhen the Body Says No by Gabor Maté: Key Takeaways, Summary & AnalysisÉvaluation : 3.5 sur 5 étoiles3.5/5 (2)

- Brain Rules (Updated and Expanded): 12 Principles for Surviving and Thriving at Work, Home, and SchoolD'EverandBrain Rules (Updated and Expanded): 12 Principles for Surviving and Thriving at Work, Home, and SchoolÉvaluation : 4 sur 5 étoiles4/5 (702)

- All That Remains: A Renowned Forensic Scientist on Death, Mortality, and Solving CrimesD'EverandAll That Remains: A Renowned Forensic Scientist on Death, Mortality, and Solving CrimesÉvaluation : 4.5 sur 5 étoiles4.5/5 (396)

- Masterminds: Genius, DNA, and the Quest to Rewrite LifeD'EverandMasterminds: Genius, DNA, and the Quest to Rewrite LifePas encore d'évaluation

- The Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionD'EverandThe Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionÉvaluation : 4 sur 5 étoiles4/5 (811)

- The Consciousness Instinct: Unraveling the Mystery of How the Brain Makes the MindD'EverandThe Consciousness Instinct: Unraveling the Mystery of How the Brain Makes the MindÉvaluation : 4.5 sur 5 étoiles4.5/5 (93)