Académique Documents

Professionnel Documents

Culture Documents

Project Design

Transféré par

Gunjan SolankiCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Project Design

Transféré par

Gunjan SolankiDroits d'auteur :

Formats disponibles

AIM:

Assuming loses 1) Reactor 0.5 % of COS carbonyl sulfide

2) Absorber 1 % of COS carbonyl sulfide

3) Stripper 1 % of CS

2

carbon disulfide

Molecular weight of compounds used in the process:

1 Carbon monoxide CO 28.01 kg/kmol

2 Carbon dioxide CO

2

44.01 kg/kmol

3 Sulphur Dioxide SO

2

64.066 kg/kmol

4 Carbon disulfide CS

2

76.139 kg/kmol

5 Carbonyl sulfide COS 60.075 kg/kmol

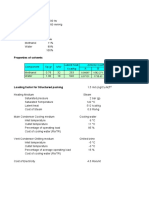

Unit 1: shell and tube reactor

Reaction:

Feed:

CO 37.31 kmol/hr

1045.0531 kg/hr

SO

2

12.43666667 kmol/hr

796.7674867 kg/hr CO COS

Product: CO2

COS 11.81483333 kmol/hr

709.7761125 kg/hr SO2

CO

2

23.62966667 kmol/hr

1039.94163 kg/hr

23.51152 kmol/hr

1034.742 kg/hr

COS output after loss 11.75576 kmol/hr

706.2272 kg/hr

To design carbon disulfide plant of 100 TPD

3CO + SO

2

COS + 2CO

2

CO

2

output after loss

Conversion rate = 95 %

Shell and tube reactor

Second unit: Reactor cum absorber:

Reaction:

Feed: 1) CO

2

23.51152 kmol/hr

1034.742 kg/hr

2) COS 11.75576 kmol/hr

706.2272 kg/hr

Note: Conv 95% factor(Mole ): 0.5

Product 1) CS

2

5.583986 kmol/hr

425.1591 kg/hr

2) CO

2

5.583986 kmol/hr

245.7512 kg/hr

Product after loss 1) Carbon disulfide 5.528145748 kmol/hr

420.9074891 kg/hr

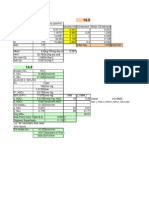

Third Unit: Stripping section()

Feed: Carbon Monoxide CO 5% more then required in first reactor

39.1755 kmol/hr 0.010882

1097.306 kg/hr 0.013863

carbon disulfide CS

2

5.528146 kmol/hr

420.9075 kg/hr

Final CS

2

After Losses CS

2

5.472864 kmol/hr

416.6984 kg/hr

2COS CS

2

+ CO

2

Stripping Section(No reaction takes place here)

Considering plant operation of 24 HR 24 hr

Total production of CS2 131.348743 kmol/day

10000.76194 kg/day

10.00076194 TPD

1) Temperature of reactor 200 Celsius 473.15 Kelvin

2) log Kp 22.58819

1 CO -110.53 KJ/mol

2 CO2 -393.5 KJ/mol

3 COS -141.5 KJ/mol

4 CS2 -116.9 KJ/mol

5 SO2 -296.81 KJ/mol

1 CO 29.2 KJ/kmol C 817.892

2 CO2 37.4 KJ/kmol C 0.013409

3 COS 41.5 KJ/kmol C

4 CS2 45.66 KJ/kmol C 3476.507

5 SO2 42 KJ/kmol C

6

Ethylene

GLYCOL 176 KJ/kmol C 176.08

3)

m(CO) 37.31 Kmol/hr Cp(CO) 0.0292 KJ/Kmol C 29.2 KJ/kmol C

m(SO2) 12.43667 Kmol/hr CP(SO2) 0.042 KJ/Kmol C 42 KJ/kmol C

temp T1 25 C 298.15 K

T2 200 C 473.15 K

Heat Capacity datas at constant pressure Cp

Energy require to take CO and SO2 from 25 C to 200C

Energy Balance Across UNIT 1: Shell and tube Reactor.

Heat of formation at 25 Degree

19 . 10 )

1

( 15509 log

T

Kp

Heat required m*Cp*T

282063.6 KJ/hr

6769526 KJ/day

4) Heat of reaction for first reaction in catalytic reactor:

Reaction:

Hr -48.1 KJ/mol -48100 KJ/Kmol -568293.483 KJ/hr

-565.452016 KJ/hr -13639043.6 KJ/day

-13570.8484 KJ/day

4.1) Heat removed to get 100C

T1 200 energy needed 177664.7883 KJ/hr

T2 100

Cp(CO2) 39.94

Cp(COS) 71.25

If we use ethylene glycol in our HE Cp(Ethylen gylcol) 150.6

flowrate 235.9246

Inlet temp 0

Outlet Temp 50

Energy 1776513

5) Reaction:

Hr -227.4 KJ/mol -227400 KJ/Kmol

-1257.10034 KJ/hr

-30170.4082 KJ/day

5.1) Energy to heat the CO from 25 to 100

T1 25

T2 100

energy required 85794.35 KJ/hr

Taking ethylene glycol as a cooling agent in HE flowrate 113.928 Kmol/hr

3CO + SO

2

COS + 2CO

2

2COS CS

2

+ CO

2

T1 0 C

T2 50 C

857878

6)

T2 25 C Cp(CS2) 45.6

T1 100 C Cp(CO) 29.2

heat 104700.6 KJ/hr

150.6 KJ/Kmol C

flowrate required to achieve cooling 155.7769

inlet temp 0

outlet temp 50

1173000

Total Energy requirement 80672.75 KJ/hr

1936146 KJ/Day

Taking ethylene gycol in heat exchanger Cp(ethylene glycol)

Temperature required

Heat balance around the condensor

CS

2

+ CO

2

Solvent back to absrober

CO (For stripping)

COS absorbed in Solvent

Stripper

CO2

Dissolved COS to stripper

COS + CO

2

5% more then required in first reactor density of overall mass flow kg/m3 1.153 CO

kmol/s kg/m3 1.261 CS2

kmol/m2 s silicone oil 55.28146 960 silicone oil

oil+CS2 60.8096 kmol/hr

0.016892 kmol/s 1.182942 mixed

0.021518 kmol/m2 s

1518.2132

ratio

CS2 1

CO 0.722761

Solvent(From Stripper)

Reactor cum absorber

CO 37.31 kmol/hr

COS 11.81483 kmol/hr

CO2 23.62967 kmol/hr

SO2 12.43667 kmol/hr

KJ/kmol C

kmol/hr

C

C

KJ/Kmol C

KJ/Kmol C

kmol/hr

C

C

KJ/hr

flowrates kg/hr mol/hr

CO 1045.053 37.31

SO2 796.7675 12.43783

density kg/m3 mol/m3

CO 1.153 0.041164

SO2 2.707 0.042257

Volumetric

flowrate m3/hr

CO 906.3774 Fao 49.74783

SO2 294.336

Total

volume F 1200.713 m3/hr

0.333531 m3/s

Partial pressure 200 C

CO 13.35606

SO2 12.47547

k at 200 C

6455438140

For PFR

rate of the reaction is given by

From the kinetic of a reaction , assume residence time to be 1 minute

60 seconds

Volume of a reactor = 20.01189 m3

For design V = 21 m3

k(CO)3(SO2)

The reactor is Tubular

consider a tube of 4 inch OD and 3.84 inch ID

10.16 cm 9.7536 cm

0.1016 m 0.097536 m

Considering the length of standard tube be 4.88 m

Allowing the tube length thickness 4.83 m

Volume of one tube Vi = 0.03607 m3

So total tube for consideration Nt 582.2006 tube

600 tubes(lets say)

Design of a stripper

Let the number of tray = 33.33333

Tray efficiency = 0.3 (30% efficient)

So no. Of effective tray = NE

= 10

Let the diamter of tower = 1 m

so the area will be = 0.785 m2

Flow rate data:

flow rate of CO = 39.1755 kmol/hr

flow on cs2 in oil = 5.528146 kmol/hr

flow of oil in cs2 = 55.28146 kmol/hr

flow rate of CS2+ H/C Oil = 60.8096 kmol/hr

At the bottom of the tower

Flow rate of Carbon monoxide = 0.013863 Kmol/m2 s G

Mole ratio of CS2 with CO = Y1 0

Mole ratio of CS2 with Oil = X1 0.0001

At the top of the tower

flow rate of oil = 0.021518 Kmol/m2 s L

exit CO composition = Y2 0.3

inlet oil composition' = X2 0.1

The minimum CO consuption takes place when exit CO stream is in equilibrium with the inlet oil

Assume that the equlibrium relationship of the system be taken as Y=3X

so Ye2 = (3*X2) = 0.3

now using the equation

If Y1 be 0 , that means the inlet stream is CS2 free

So (G/L) minimum = 0.333

Now we may use the formula of absorption factor to find the number of trays

where the A is given by L/mG 3

SO A = 0.517412

For the stripping column we have the equation

so

no of effective trays = 10

LHS 0.999 = 0.999336

Consider the tower design to be sieve tray column.

Liquid flow pattern

= (molar flowrate in kmol/s)/(density in kg/m3)

= 0.000176 m3/s density of oil 960

if we assume m=

volumetric liquid rate

1 ) 517412 . 0 / 1 (

) 517412 . 0 / 1 ( ) 517412 . 0 / 1 (

) 3 / 0 ( 1 . 0

0001 . 0 1 . 0

) 1 (

) 1 (

N

N

kg/m3

vapour viscosity 100 373.15 C1 C2 C3 C4

CO 2.85568E-05 1.21E-06 0.5338 94.7

CS2 1.25319E-05 5.82E-08 0.9262 44.581

total 2.41118E-05

HC 33.75066 mols

HC 1555.125108 Kg

vapour thermal onductivity 100 373.15 c1 c2 c3

CO 0.030234902 0.00059882 0.6863 57.13

CS2 0.011758979 0.0003467 0.7345 479

Total 0.025111528

C5

c4

501.12

Heat Exchanger design

Process design

is

is

4.186 KJ/kg K ratio

46.2 KJ/kg K CS

2

0.27723872

1.04 KJ/kg K CO 0.72276128

Overall Heat capacity of gas mixture 13.5601 KJ/kg K

flow rate on tube side 1518.213244 kg/h

Tube side

Shell side

38.8296984 C

KW

Kg/s

R

S

0.81

heat capacity of water

Tube side fluid mixture of Carbon monoxide and carbon disulfide

Shell side fluid water

LMTD

Heat Load ((flowrate *heat capacity of CS2(inlet - oulet))/(3600))

heat capacity of CS

2

Heat capacity of CO

Inlet temp Outlet temp

100 25

(0-40)/(25-100)

Inlet temp Outlet temp

10 20

428.8984163

Flow of water Heat load/ (Heat capacity of methanol(outlet-inlet))

10.24602046

Use one shell pass and two tube pass

0.133333333

(25-100)/(40-100)

0.9375

From the below graph we obtain Ft

C

450 W/m2 K U

Provsional Area A Heat load/((Delta Tm)*U)

30.30350707 m2

Choose 20 mm O.D. and 16 mm I.D. with 4.88 CU-ni Long tube length

0.02 m 0.016 m

Allowing for tube length thickness use length 4.83 m

Area of one tube 4.83*20* Pi * (10^(-3)) = 0.303324 m2

No of tube are provisional area/area of one tube 99.9047457 =

Db

= mm

= mm

= 55 mm

= 310+55 = 365 mm

302.5672122

Delta Tm LMTD * Ft

31.45205568

Overall Heat Transfer coeff of the process

As the shell side fluid are relatively clean use 1.25 triangular pitch

Bundle diameter 20*(146/.249)^(1/2.207)

310

Use split ring floating heat type

From the below figure, bundle diametrical clearance

Shell diameter

Tube side co-efficient

= (Inlet+Outlet)/2 = 62.5 C

= (pi/4)*(16)^2 = 200.96 mm2

Tubes per pass = 100/2 = 50 tubes

Total Flow area = tubes per pass * tube cross sectional area in m2

= 0.010048 m2

= Flow of methanol / total flow area

= 1019.7074 Kg/m2 s

= 1.1813834 kg/m3 1.2632 CS2

1.15 CO

= gas mass velocity/density

863.14691 m/s

Reynold number =

=

0.0029

= (Cp* viscosity )/Kf

Using the above equation and neglecting the (Mu/Mu w)

hi = 985.5636342 W/m2 C

= Ds/5 73 mm

= 1.25*20 25 mm

= ((25-20)/20)*(365)*(73*(10^(-6)))

= 0.0066613 m2

=

Kg/m2 s

9.07E+05

Mean CS2+CO temperature

Tube cross sectional area

Gas mixture mass velocity

Density of gas mixture

Gas mixture linear velocity

(Density* velocity*diameter)/viscosity

Heat transfer factor from the graph

Prandtle number

0.013020268

Shell side co-efficient

Choose baffle spacing

Tube pitch

Cross Flow area As

Mass Velocity Gs (10.246/0.006661)

1538.152818

de =

= 14.201 mm

= (10+20)/2 15 C

= 998 kg/m3

= 1.084 mNs/m2

= 4.186 KJ/kg C

= 0.592 W/m C

= (Gs*de)/mu

= 20150.653

= (Cp*mu)/Kf

= 7.6649054

jh = 0.0042

hs = 2201.7354 W/m2 C

= 62.5-15

= 47.5 C

= (U/h0)*(delta T)

= 9.70825 C

Mean wall temperature =

= C

= 50 W/m C

= 5000 W/m2 C

= 4000 W/m2 C

Mean Shell Side temperature

Equivalent Diameter

(47.5)-(9.708251)

Density of water

Viscosity

heat capacity

thermal conductivity

Reynold number

Prandtle number

Choose 25 % baffle cut, from graph find jh

Without the viscosity correction term, find hs

Estimate the wall temperature

mean temperature difference across all resistence

across the water film

37.79174905

Overall HT Coefficient

Thermal Conductivity of cupro-nikle alloy

Fouling co-efficient of water

Fouling co-efficient of gas mixture

so 1/U0 =

= 0.002139511

U0 = 467.3966288 W/m2 C

The assumed value was 450 W/m2 c

Little above the assumed value

From the graph Re = 9.07E+05

So friction factor is jf = 0.0029

Neglecting the viscosity term

delta Pt =

= 8364575.2 N/m2

= 8364.5752 K Pa

Linear velocity = Gs/ rho

= 1.541235288

jf = 0.0046

Delta Ps

= 74179.6 N/m2

= 74.1796 K Pa

Tube Side

Shell Side

From the figure, at Re at 20150.15

Neglect the correction factor

Pressure Drop

c1

27722677 j/kmol 3.496

27722.68 KJ/Kmol 34960000

364.0057 kj/kg

heat of vaporization of CS2

m long tube of cupper-nikle

CU-ni Long tube length 4.88 m long tube of cupper-nikle

100 Tubes

Density

co 1.15

so2 2.71

Overall 1.58 kg/m3

Velocity 863 m/s

viscosity 0 Pa.s

Diameter 0.02 m

Thermal

conductivity 0.03 W/m C

1 2 3 4 5

0.001 0 4.46287E-05 0.000313 0.000568

c2 c3 c4 Tr tc t

0.2986 0 0 0.540127 552 298.15

m long tube of cupper-nikle

Vous aimerez peut-être aussi

- Classification of Igneous RocksDocument23 pagesClassification of Igneous RocksAdit8450100% (1)

- Advances in Chemical Engineering Volume 36 Photocatalytic TechnologiesDocument364 pagesAdvances in Chemical Engineering Volume 36 Photocatalytic Technologiesale alvarezPas encore d'évaluation

- Manufacture of Oxygen by Linde Frankl's ProcessDocument60 pagesManufacture of Oxygen by Linde Frankl's ProcessAhmed Ali100% (1)

- Trident P&C PayslipDocument2 pagesTrident P&C PayslipGunjan SolankiPas encore d'évaluation

- Batch Still Volume OptimizationDocument15 pagesBatch Still Volume Optimizationinvincible111100% (1)

- Shell Diameter Calculation and Heat Exchanger DesignDocument26 pagesShell Diameter Calculation and Heat Exchanger Designpavan100% (1)

- Boiler CalculationDocument4 pagesBoiler Calculationmohsin husen BargirPas encore d'évaluation

- Unit conversion program for engineering processesDocument9 pagesUnit conversion program for engineering processesAnubhav KhandelwalPas encore d'évaluation

- MODEL: PFTA 1500-4: Ratings & Performance DataDocument4 pagesMODEL: PFTA 1500-4: Ratings & Performance DataAnonymous izGbhcPas encore d'évaluation

- Chemistry Lesson 1Document8 pagesChemistry Lesson 1Vinod Varadan SPas encore d'évaluation

- Che 2Document25 pagesChe 2Jaynie Lee VillaranPas encore d'évaluation

- Design Equipment Distillation TowersDocument72 pagesDesign Equipment Distillation TowersG Vamsee KrishnaPas encore d'évaluation

- (Kern Metode) Design Data: Shell and Tube Heat Exchanger SizingDocument32 pages(Kern Metode) Design Data: Shell and Tube Heat Exchanger SizingLisa SeptidianaPas encore d'évaluation

- Coal Gasifier ProcessesDocument28 pagesCoal Gasifier ProcessesH Janardan PrabhuPas encore d'évaluation

- Final Ventury Working For Wet Alkaline ScrubberDocument11 pagesFinal Ventury Working For Wet Alkaline ScrubberNanasaheb JagtapPas encore d'évaluation

- Tripple Effect Evaporator Design CalculationDocument6 pagesTripple Effect Evaporator Design CalculationCathal McKeownPas encore d'évaluation

- H&M CalculationsDocument14 pagesH&M CalculationsNITINPas encore d'évaluation

- Mass Transfer MaterialDocument133 pagesMass Transfer MaterialYumnaPas encore d'évaluation

- Bio Reactor Design CalculationsDocument6 pagesBio Reactor Design CalculationsDr Narayana Saibaba K.V.Pas encore d'évaluation

- Combustion CalculationsDocument6 pagesCombustion CalculationsMauro FerraresePas encore d'évaluation

- Boiler Steam CostingDocument10 pagesBoiler Steam CostingSomnath SinghPas encore d'évaluation

- Bestway Cement Limited heat balance and WHR analysisDocument4 pagesBestway Cement Limited heat balance and WHR analysisKiran Veerubhotla100% (1)

- Reaction mass balance and energy analysisDocument4 pagesReaction mass balance and energy analysisparthPas encore d'évaluation

- Monoethanolamine Design 2520of 2520equipmentsDocument54 pagesMonoethanolamine Design 2520of 2520equipmentsbhaskar5377Pas encore d'évaluation

- Energy BalanceDocument11 pagesEnergy BalanceBharat VaajPas encore d'évaluation

- Thermal design of a 2-effect forward-feed evaporatorDocument4 pagesThermal design of a 2-effect forward-feed evaporatorAristya KurniawanPas encore d'évaluation

- Evaporator Design CalculationDocument58 pagesEvaporator Design CalculationManoj BPas encore d'évaluation

- Mass Balance 3Document22 pagesMass Balance 3barbadosiyPas encore d'évaluation

- 11.3 KernDocument78 pages11.3 KernChou ChouPas encore d'évaluation

- Perhitungan Dan Disain HeaterDocument19 pagesPerhitungan Dan Disain HeatersehonoPas encore d'évaluation

- 1X 66 Mwkohinoor Power Pvt. Ltd. CNT 5110122 Stack Height SizingDocument4 pages1X 66 Mwkohinoor Power Pvt. Ltd. CNT 5110122 Stack Height SizingPriyanathan ThayalanPas encore d'évaluation

- Ammonia Design 2520of 2520equipmentsDocument32 pagesAmmonia Design 2520of 2520equipmentsapi-3714811100% (1)

- Shell Side Fluid Heat Load and Tube Side Fluid Heat Transfer CalculationsDocument6 pagesShell Side Fluid Heat Load and Tube Side Fluid Heat Transfer CalculationsrajachemPas encore d'évaluation

- Coal CombustionDocument3 pagesCoal CombustionRahul ChandrawarPas encore d'évaluation

- SI Units Hukum Gas Ideal Turbin Efis Power Pressure Tcompress Flow Mdot Vnormal Mol RDocument3 pagesSI Units Hukum Gas Ideal Turbin Efis Power Pressure Tcompress Flow Mdot Vnormal Mol RAhmad ZaenudinPas encore d'évaluation

- Venturi Scrubber Theory & ExperimentDocument6 pagesVenturi Scrubber Theory & ExperimentTian Fung Wang100% (1)

- Biomass Combustion ManojDocument16 pagesBiomass Combustion Manojsugandaraj522Pas encore d'évaluation

- Boiler efficiency and flue gas analysis calculationsDocument50 pagesBoiler efficiency and flue gas analysis calculationsDilip MishraPas encore d'évaluation

- Evaporator Design CalculationDocument20 pagesEvaporator Design CalculationDaniyal HashmiPas encore d'évaluation

- Thermopack Heat Generation CalculationDocument8 pagesThermopack Heat Generation CalculationAyush AgrawalPas encore d'évaluation

- Calculate Boiler Efficiency Using Direct MethodDocument53 pagesCalculate Boiler Efficiency Using Direct Methoddineshkbunker08Pas encore d'évaluation

- EvapDocument7 pagesEvapwestewrPas encore d'évaluation

- Mass ConverterDocument18 pagesMass ConverterDinesh CR7Pas encore d'évaluation

- BLR Efficiency CalculatorDocument2 pagesBLR Efficiency CalculatorPratik Ray ChaudhuryPas encore d'évaluation

- Thermal vapor-compression system design and performance analysisDocument8 pagesThermal vapor-compression system design and performance analysisBagus HutomoPas encore d'évaluation

- Typical Process / Facility Water Balance CalculationDocument5 pagesTypical Process / Facility Water Balance CalculationYesi CeballosPas encore d'évaluation

- Crystallizer Thickness CalculationDocument8 pagesCrystallizer Thickness CalculationAmritRoshniKaurPas encore d'évaluation

- Calculation Sheet For Flares: User Supplied Inputs (Grey Cells)Document1 pageCalculation Sheet For Flares: User Supplied Inputs (Grey Cells)VishalPas encore d'évaluation

- Ammonium 2520sulphate Material 2520balance.Document9 pagesAmmonium 2520sulphate Material 2520balance.AgadmatorPas encore d'évaluation

- Specifition-Sheet For Evaporator 1. Customer Details A. B. C. D. E. 2. Data Required For EvaporatorDocument2 pagesSpecifition-Sheet For Evaporator 1. Customer Details A. B. C. D. E. 2. Data Required For EvaporatorTowfiq Hossain TaskuPas encore d'évaluation

- Design of Flash DrumDocument7 pagesDesign of Flash DrumJonathan OrPas encore d'évaluation

- Juice HeatersDocument3 pagesJuice HeatersqqyukiPas encore d'évaluation

- Distillation Column OptimizationDocument14 pagesDistillation Column OptimizationLovely TarunPas encore d'évaluation

- Perhitungan Basis MolDocument384 pagesPerhitungan Basis MolalmengarunPas encore d'évaluation

- Material Balance ADocument8 pagesMaterial Balance ATheepa SubramaniamPas encore d'évaluation

- Expt. 5 Calandria EvaporatorDocument5 pagesExpt. 5 Calandria EvaporatorPradeep Diwakar100% (1)

- CEB 2063 Evaporation Process Design and AnalysisDocument28 pagesCEB 2063 Evaporation Process Design and AnalysisScorpion RoyalPas encore d'évaluation

- MNT Design 2520of 2520equipmentsDocument32 pagesMNT Design 2520of 2520equipmentsshamsabbasPas encore d'évaluation

- MATERIAL BALANCE TITLEDocument46 pagesMATERIAL BALANCE TITLEG Vamsee KrishnaPas encore d'évaluation

- Material BalanceDocument6 pagesMaterial BalanceMehran Rasheed GorayaPas encore d'évaluation

- Ch. 14 Answer Key 2012Document11 pagesCh. 14 Answer Key 2012tmtennisPas encore d'évaluation

- Components Molar Flowrate (Kmole/hr) Mass Flowrate (KG/HR) : Composition of The Incoming GasDocument12 pagesComponents Molar Flowrate (Kmole/hr) Mass Flowrate (KG/HR) : Composition of The Incoming GasIsmail JamaluddinPas encore d'évaluation

- Power Plant Emissions CalculationsDocument9 pagesPower Plant Emissions CalculationsDanialPas encore d'évaluation

- Thermodynamics, Fluid and Process Engineering C106 Combustion Theory Sae 1 Combustion by MassDocument6 pagesThermodynamics, Fluid and Process Engineering C106 Combustion Theory Sae 1 Combustion by MasscataicePas encore d'évaluation

- CASE 6: Hanover Bates Chemical Corporation: Group 5Document1 pageCASE 6: Hanover Bates Chemical Corporation: Group 5Gunjan SolankiPas encore d'évaluation

- Case 6-7 Questions For Advance Preparation and Group Submission On Campus 360Document1 pageCase 6-7 Questions For Advance Preparation and Group Submission On Campus 360Gunjan SolankiPas encore d'évaluation

- Project WorkDocument3 pagesProject WorkGunjan SolankiPas encore d'évaluation

- SDM - 2016-18 - Course OutlineDocument22 pagesSDM - 2016-18 - Course OutlineGunjan SolankiPas encore d'évaluation

- Product MixDocument191 pagesProduct MixGunjan SolankiPas encore d'évaluation

- Raghuram Rajan in 3 YearsDocument4 pagesRaghuram Rajan in 3 YearsGunjan SolankiPas encore d'évaluation

- 507419143 (1)Document2 pages507419143 (1)Gunjan Solanki0% (1)

- Floor Pricing of "Plasto Cover" Floor Cover: 140 Price of "Plasto Cover" For Time of 5 Year in Case of Optimistic SellingDocument4 pagesFloor Pricing of "Plasto Cover" Floor Cover: 140 Price of "Plasto Cover" For Time of 5 Year in Case of Optimistic SellingGunjan SolankiPas encore d'évaluation

- IntroductionDocument1 pageIntroductionGunjan SolankiPas encore d'évaluation

- R 1Document11 pagesR 1Gunjan SolankiPas encore d'évaluation

- Mont BlancDocument1 pageMont BlancGunjan SolankiPas encore d'évaluation

- 17th August 9 PMDocument1 page17th August 9 PMGunjan SolankiPas encore d'évaluation

- IntroductionDocument1 pageIntroductionGunjan SolankiPas encore d'évaluation

- Online Admissions 2016-2018 IIFTDocument2 pagesOnline Admissions 2016-2018 IIFTGunjan SolankiPas encore d'évaluation

- Farewell LetterDocument1 pageFarewell LetterGunjan SolankiPas encore d'évaluation

- Work ExDocument2 pagesWork ExGunjan SolankiPas encore d'évaluation

- XlriDocument1 pageXlriGunjan SolankiPas encore d'évaluation

- Incoming IlluminationsDocument1 pageIncoming IlluminationsGunjan SolankiPas encore d'évaluation

- Body BoiloutDocument1 pageBody BoiloutGunjan SolankiPas encore d'évaluation

- Receipt 888915766442Document1 pageReceipt 888915766442Gunjan SolankiPas encore d'évaluation

- Nmat 2015-16Document2 pagesNmat 2015-16Gunjan SolankiPas encore d'évaluation

- MomentDocument1 pageMomentGunjan SolankiPas encore d'évaluation

- Evaporator 1st Effect Body Change Over - Rev01Document3 pagesEvaporator 1st Effect Body Change Over - Rev01Gunjan SolankiPas encore d'évaluation

- Gunjan Solanki ResumeDocument3 pagesGunjan Solanki ResumeGunjan SolankiPas encore d'évaluation

- XLRi InterviewDocument6 pagesXLRi InterviewGunjan SolankiPas encore d'évaluation

- State Bank of India ReciptDocument1 pageState Bank of India ReciptGunjan SolankiPas encore d'évaluation

- ESP Internal Cleaning & CheckingDocument2 pagesESP Internal Cleaning & CheckingGunjan SolankiPas encore d'évaluation

- Recovery Boiler 2 Cold ShutDocument5 pagesRecovery Boiler 2 Cold ShutGunjan SolankiPas encore d'évaluation

- Recovery Boiler 2 Cold ShutDocument5 pagesRecovery Boiler 2 Cold ShutGunjan SolankiPas encore d'évaluation

- How Cells Move Materials Against Concentration GradientsDocument11 pagesHow Cells Move Materials Against Concentration GradientsDARLENE JANE MAYNESPas encore d'évaluation

- Institutional Training Report 2Document22 pagesInstitutional Training Report 2Madhumitha PPas encore d'évaluation

- Mebendazole Uv1Document13 pagesMebendazole Uv1SukadevPas encore d'évaluation

- Internship Report FACTDocument16 pagesInternship Report FACTBennetHailinkPas encore d'évaluation

- Introduction To Chemistry FacCh 101Document116 pagesIntroduction To Chemistry FacCh 101lolo.moussa159Pas encore d'évaluation

- 9701 Nos Ps 2Document6 pages9701 Nos Ps 2Hubbak Khan0% (1)

- (2019) Synthesis and Characterization of Nanodiamond-Anticancer Drug ConjugatesDocument14 pages(2019) Synthesis and Characterization of Nanodiamond-Anticancer Drug Conjugatesس-ح- رPas encore d'évaluation

- Tarnish & CorrosionDocument18 pagesTarnish & CorrosionPreeti AgarwalPas encore d'évaluation

- Chem Lab Report 4Document2 pagesChem Lab Report 4Nor Ashikin IsmailPas encore d'évaluation

- Cell Communication 1Document10 pagesCell Communication 1api-277471896Pas encore d'évaluation

- Corrosion ReviewDocument25 pagesCorrosion ReviewtoddPas encore d'évaluation

- Lipidomic Analysis of Bacteria by Thin-Layer Chromatography and Liquid Chromatography/Mass SpectrometryDocument15 pagesLipidomic Analysis of Bacteria by Thin-Layer Chromatography and Liquid Chromatography/Mass SpectrometryololadePas encore d'évaluation

- 056 Set 1 C ChemistryDocument16 pages056 Set 1 C ChemistryEepen JohnPas encore d'évaluation

- List of Mineral AbbreviationsDocument14 pagesList of Mineral AbbreviationsLeonardo OlartePas encore d'évaluation

- Understanding Equilibrium Shifts with Le Chatelier's PrincipleDocument4 pagesUnderstanding Equilibrium Shifts with Le Chatelier's PrincipleJennifer HuPas encore d'évaluation

- UV SpectrosDocument4 pagesUV SpectrosCarlton GrantPas encore d'évaluation

- CHEMISTRY PROJECT On Content of Cold Drinks AvailableDocument20 pagesCHEMISTRY PROJECT On Content of Cold Drinks AvailableVipul KumarPas encore d'évaluation

- Regulasi CA, MG and PO4Document16 pagesRegulasi CA, MG and PO4siskaPas encore d'évaluation

- Complexation NotesDocument6 pagesComplexation NotesDeepak PradhanPas encore d'évaluation

- Lesson 6 Changes in The State of Matter CW 1 Drop BoxDocument6 pagesLesson 6 Changes in The State of Matter CW 1 Drop BoxrBdPas encore d'évaluation

- Subject: Pharmacognosy: PHD Admission Test 2017 Question PaperDocument10 pagesSubject: Pharmacognosy: PHD Admission Test 2017 Question PaperManish BudhrajaPas encore d'évaluation

- Notes - Unit of Acid and Bases - Answer Key PacketDocument47 pagesNotes - Unit of Acid and Bases - Answer Key PacketLizeth PautaPas encore d'évaluation

- Catalase (CAT) : From Bovine LiverDocument4 pagesCatalase (CAT) : From Bovine Liver幸福Pas encore d'évaluation

- Ranitidine NewDocument9 pagesRanitidine NewSabhaya ChiragPas encore d'évaluation

- 1 BhattiAcademy - Com Chemistry 7. ILmi (Objective)Document17 pages1 BhattiAcademy - Com Chemistry 7. ILmi (Objective)Muhammad RizwanPas encore d'évaluation

- CeramicsDocument3 pagesCeramicsjannat00795Pas encore d'évaluation

- High-Entropy Materials For CatalysisDocument24 pagesHigh-Entropy Materials For Catalysisemerson_kohlPas encore d'évaluation