Académique Documents

Professionnel Documents

Culture Documents

Storage Tank Design Calculations and Summary

Transféré par

ace1205Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Storage Tank Design Calculations and Summary

Transféré par

ace1205Droits d'auteur :

Formats disponibles

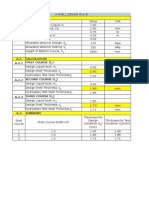

D

c

1000

kg/m

3

G 1.00 -

G' 1.00 -

F

Ymin

250 MPa

F

Tmin

400 MPa

E 195000 MPa

T

max

N/A

o

C

T

min

N/A

o

C

S

d

160 MPa

S

t

171 MPa

P

i

0.00

kN/m

2

( kPa )

P

e

0.00

kN/m

2

( kPa )

f 0

kN/m

2

( kPa )

H

1

1.0 m

CA 3.0 mm

CA 3.0 mm

CA 3.0 mm

CA 3.0 mm

CA 3.0 mm

CA 3.0 mm

tmin 6.0 mm

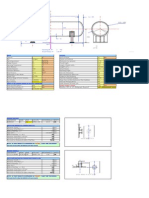

Outside Dia. Do 1.012 m

Inside Dia. Di 1.000 m

Nominal Dia. ( Inside Dia. + Shell Thk. ) Dn 1.006 m

Total Height H 1.3 m

10.016 kN

F

Ystructure

250 MPa

Den. 7850

kg/m

3

Width

Press.

Head

HL

1

' t

d

t

t

Max( t

d

,t

t

) t

smin

t

smin

m m m mm mm mm mm mm

3.6.1.2 3.6.3.2 3.6.3.2 3.6.3.2 3.6.1.1 A.4.1

pg pg A-1

1 1.800 0.00 1.00 3.02156613 0.02017883 3.02 5 3.03

t

s1

(mm) = 6

Yield Strength - Structural Parts

Density

S H E L L D E S I G N

C

o

u

r

s

e

#

Fluid Hold Down Weight

Allowable Hydrostatic Test Stress at Design Temperature

Internal Pressure

External Pressure

Smallest of the allowable tensile stresses (Roof, Shell, Ring)

High Liquid Level

Bottom

Shell

Roof

Structure

Anchor Bolts

Nozzles, etc.

Allowable Product Design Stress at Design Temperature

Purpose Rapid Mix Tank

Density of Contents

Specific Gravity of Contents

Specific Gravity of Contents (For Appendix A Only)

Material Group Group IV

Minimum Yield Strength

Minimum Tensile Strength

Modulus of Elasticity

Maximum Design Temperature

Minimum Design Temperature

m kN kg mm kN kg

1 1.800 2.63 267.94 3.0 1.31 133.97

1.800 2.629 267.942 1.31 133.97

Width of

plate t

bmin

CA t

b-req'd

mm mm mm mm

3.4.1 3.4.1

1800 6 3.0 9.0

Min shell-to-bottom fillet weld size 3.1.5.7

Min. width of overlapping 3.1.3.5

Min. distance between 3- plate laps in tank bottom 3.1.5.4

Min. widith of plate 3.4.1

Min. width projected outside of shell 3.4.2

Nominnal Dc 1.006 m

Total Height of tank shell Ht 1.3 m

Ht from bottom shell to COG of tank, Xs Xs

Maximum Design level Liqiuid H 1.0 m

Total weight of tank shell 7850 kg/m3 Ws 2628.514 N

Total weight of tank rook Wr 0 N

Total weight of tank contents 1000 kg/m3 Wt 10136.74 N

12765.25 N

Ration of D/H 0.77384615

Overturning Moment

B O T T O M P L A T E D E S I G N

S H E L L W E I G H T S U M M A R Y

Course #

Width

3.6.1.2

Shell Wt.

(Uncorroded) Thk. - CA

Shell Wt.

(Corroded)

t

smin

*t

used

S

dmax

S

tmax

W

tr

mm mm MPa MPa m

J.3.3 3.9.7.2 & V.8.1.4

5.00 6 1.15 0.58 1.800

S H E L L D E S I G N

Use

Projection

mm mm

3.4.2

10 25

8

25

300.00 mm

- mm

25.00 mm

http://www.slideshare.net/yahasani/above-surface-storage-tanks-asts

http://www.slideshare.net/ledzung/storage-tanks-basic-training-rev-2

Overturning Moment

B O T T O M P L A T E D E S I G N

Service WATER

Sp.Gr of liquid (G) 1

Capacity ( m3 ) 0.79

Dia of tank (D) 1.000 m 3.280 ft

Ht of tank (H) 1.000 m 3.280 ft

Type of Roof -

Type of Bottom Flat

Slope of Roof 1:6 1 : 6 For Self Supported

Slope of Bottom

Corrosion Allow (CA) 1.6 mm 0.063 in

Wind Velocity (V) 100 miles/hr 160920 m/sec 161 Km/hr

Live Load on Roof 25 lbs/ft 122 Kg/m

Joint Efficiency 0.85

Plate Width 2.438 m 8.000 ft

Plate Height 1.219 m 3.999 ft

Allowable Design Stress ( s ) PSI 15000 See Section 3.3

SHELL DESI GN CALCULATI ONS

No of Courses from Liquid Level in tank Height of Shell Course Design Shell Thk

Shell Bottom (mm) (mm) (mm)

1 1000 1000.0 1.656

2 0 0 0

3 0 0 0

4 0 0 0

5 0 0 0

6 0 0 0

7 0 0 0

8 0 0 0

9 0 0 0

10 0 0 0

11 0 0 0

12 0 0 0

13 0 0 0

14 0 0 0

15 0 0 0

16 0 0 0

17 0 0 0

18 0 0 0

19 0 0 0

20 0 0 0

A 2

B 3

C 4

D 5

Full coarse Full width A

Full coarse Partial width B

Partial coarse Full width C

Partial coarse Partial width D

No of Full Plates 1

No of Partial Plate 1

Width of Partial Plate 0.703

Ht of Partial Plate 1

Butt Welding at the Bottom of each Course

No of Courses

A B

1 0 0

2 0 0

Course # Course thk Course Width Unstiffened Shell

Ht ( mm )

1 5 1000 1000

4 5 0 0

5 5 1000 1000

6 5 0 0

7 0 0 0

8 0 0 0

9 0 0 0

10 0 0 0

11 0 0 0

12 0 0 0

No of plates

All.Design Stress (Sd) 15000 Psi 103386028 N/m

All.Test Stress (St) 22500 Psi 155079043 N/m

Roof Plate Thk 0.242 in 6.1517 mm

Bottom Plate Thk 0.313 in 7.9500 mm

Density of Material 7850 Kg/Cu.m 491 lbs/Cu.ft

Wind Pressure 18.00 Psf

Min Thk as per 3.10.1 Adopted Shell Thk Thk Selected Weight of each Course Adopted Shell Thk

(mm) (mm) (mm) (Kg) (in)

5 5.0 5 123.31 0.197

5 0.0 5 0.00 0.000

5 0.0 0.00 0.000

5 0.0 0.00 0.000

5 0.0 0.00 0.000

5 0.0 0.00 0.000

5 0.0 0.00 0.000

5 0.0 0.00 0.000

5 0.0 0.00 0.000

5 0.0 0.00 0.000

5 0.0 0.00 0.000

5 0.0 0.00 0.000

5 0.0 0.00 0.000

5 0.0 0.00 0.000

5 0.0 0.00 0.000

5 0.0 0.00 0.000

5 0.0 0.00 0.000

5 0.0 0.00 0.000

5 0.0 0.00 0.000

5 0.0 0.00 0.000

0.123 Tons

1219.203677 2438.407354 2.972915213

1219.203677 703.1852994 0.857326103

1000 2438.407354 2.438407354

1000 703 0.703185299

1.288378928 1 0.288378928

0.52836903 0 0.52836903

1

0.8202075 0.8202075

Thickness Vertical Weld Length Horizental Weld Length

C D (mm) (m) (m)

1 1 5.000 2.00 Fillet Welding

0 0 0 0.00 0.00

All Shell Ht (H1) All Shell Ht (H1)Remarks Section Modulus (in3)

(mm) ( ft ) When required

520849.85 1708.39 Not required 1.838

520849.85 1708.39 Not required 1.838

#DIV/0! #DIV/0! #DIV/0! #DIV/0!

#DIV/0! #DIV/0! #DIV/0! #DIV/0!

#DIV/0! #DIV/0! #DIV/0! #DIV/0!

#DIV/0! #DIV/0! #DIV/0! #DIV/0!

#DIV/0! #DIV/0! #DIV/0! #DIV/0!

#DIV/0! #DIV/0! #DIV/0!

#DIV/0! #DIV/0! #DIV/0!

#DIV/0! #DIV/0! #DIV/0!

No of plates

Ht upto bottom Ht of C.G of Long. X-Sec Area X C.G

of course each Course area

500 5000 2500000

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

5000 500

1.64 ft

Horizental Weld Length

Height of C.G of Shell

The tank will be designed in accordance with the following criteria:-

Circular in shape

For non-pressurize storage

Tank is subjected to hydrostatic head only (i.e. uniformly increasing load

from top to bottom and normal to its plane

No external pressure

Design Temperature

Corrosion allowance to be included in the design

Fluid Properties Metric Imperial

Fluid height, H 1.000 m 3.281 ft

Density of water, r 1000 kg/m 62 lb/ft

Specific gravity of water 1 1

Acceleration due to gravity , g 9.8 m/s 32.2 ft/s

Maximum hydrostatic pressure, P

(internal pressure) 9.8 kN/m/s 1.4 PSI

Ring tension

Material and Condition

Material Specs A36

Material Grade C

Nominal diamter of tank 1.000 m 3.281 ft

Corrosion allowance, C 2 0.079 in

Joint efficiency (usually 85%) 0.85 0.85

All.Bending Stress (dall) 103421359.350 15000

All.Design Stress (Sd) 103421359.350 15000

All.Test Stress (St) 103421359.350 15000

Plate Width 2.43902439 8

Plate Height 1.219512195 4

P

=

= (

2

)

Bottom Plate Thk w/o CA 0.394 10

Bottom Plate Thk with CA 0.394 10

Density of Material 7850 490.5199998

Bottom Overlap Percent 0.05

Min Yield Strength 30000

Min Tensile Strength 55000

Corrosion Allow for Bottom 0 0

Corrosion Allow for Roof 0 0

Hydrostatic Shell Thickness 0.0000 mm 0.0 in

Design Shell Thickness 2.0 mm 0.0809 in

Adopted shell thickness 6.0 mm 0.25 in

Height of shell course 1.000 m 3.281 ft

No. fo courses 1 1 1

No. of plates

AWWA shell plate thickness calculation

Basic formula =

2.6

+CA

Where:

t= Plate thickness for course under consideration

h

p

= Liquid height from top capacity level to bottom of course under

consideration

D = Nominal diameter

G = Specific gravity

s = Allowable design stress

E = Joint efficiency

CA = Corrosion allowance

Maximum allowable working

stress 34473786450

Thickness of the shell,t

Circumferential = #VALUE! mm

Longitudinal = #VALUE! mm

Allowance = 2 mm

No. of plates = 1

Total circumference with 1 plate = 0.0 mm

Length of each plate = 0.0 mm

The size of the plate selected from :

Edge supported; uniform load

At center:

(max)

r

=

t

=

1.24

2

=

0.695

4

3

Hydrostatic Pressure at Tank Bottom

The hydrostatic pressure can be expressed as:

P (psi) = maximum hydrostatic pressure

(internal pressure)

= 0.4336 h

where

=

2

+ C

Butt joints are provided for welding the vertical joints between plates to

form the lowest laye of the shell. An allowance of 2 mm is amde between

two adjacent plates to facilate welding.

=

4

+ C

Dimensions:

Outside diameter, Do = 18

Nominal wall thickness, t = 0.25

Length, L = 24

Corrosion allowance, Corr = 0.01

Material =

Allowable stress, S = 20,000

Long seam efficiency, El = 0.70

Circ seam efficiency, Ec = 0.85

Under tolerance allowance = 0.00

Interior pressure, P = 201.4

1lbf =32.174 lbm.ft/s2

,.

mm

mm

mm

mm

psi

%

%

%

psi

The tank will be designed in accordance with the following criteria:-

Circular in shape

For non-pressurize storage

Tank is subjected to hydrostatic head only (i.e. uniformly increasing load

from top to bottom and normal to its plane

No external pressure

Design Temperature

Corrosion allowance to be included in the design

Fluid Properties Metric Imperial

Fluid height, H 1.000 m 3.281 ft

Density of water, r 1000 kg/m 62 lb/ft

Specific gravity of water 1 1

Acceleration due to gravity , g 9.8 m/s 32.2 ft/s

Maximum hydrostatic pressure, P

(internal pressure) 9810.0 kg/m/s 1.4 PSI

1000.0 kg/m 204.8 lb/ft

Material and Condition

Material Specs A36

Material Grade -

Nominal diamter of tank 1.000 m 3.281 ft

Corrosion allowance, tc 1.5875 0.0625 in

Joint efficiency (usually 85%) 0.85 0.85

Yield strength palte,Fy 248.2 MPa 36000 PSI

Ring tension 500.0 kg/m 2.601 lb/in

Allowable tensile stress, Ft=0.6*Fy 148.9 MPa 21600 PSI

Thickness of the shell,ts(min) 3.94982946 0.00014168

Required thickness = ts+tc 5.53732946 0.06264168

Use ts 5 0.1875

P

=

= (

2

)

if ts>ts(min +tc) NOT ACCEPTED OK

0.02709583 0.002610023

Bottom Plate Thk w/o CA 0.394 10

Bottom Plate Thk with CA 0.394 10

Density of Material 7850 490.5199998

Bottom Overlap Percent 0.05

Min Yield Strength 30000

Min Tensile Strength 55000

Corrosion Allow for Bottom 0 0

Corrosion Allow for Roof 0 0

Hydrostatic Shell Thickness 0.0232 mm 0.0 in

Design Shell Thickness 1.6 mm 0.0634 in

Adopted shell thickness 6.0 mm 0.25 in

Height of shell course 1.000 m 3.281 ft

No. fo courses 1 1 1

No. of plates

4.9Dc ( [H+Hi] - 0.3 ).G

AWWA shell plate thickness calculation

Basic formula =

2.6

+CA

Where:

t= Plate thickness for course under consideration

h

p

= Liquid height from top capacity level to bottom of course under

consideration

D = Nominal diameter

G = Specific gravity

s = Allowable design stress

E = Joint efficiency

CA = Corrosion allowance

Maximum allowable working

stress 1316.60982

Thickness of the shell,t

Circumferential = #VALUE! mm

Longitudinal = #VALUE! mm

Allowance = 2

No. of plates = 1

Total circumference with 1 plate = 0.0

Length of each plate = 0.0

The size of the plate selected from :

Edge supported; uniform load

At center:

(max)

r

=

t

=

1.24

2

=

0.695

4

3

Hydrostatic Pressure at Tank Bottom

The hydrostatic pressure can be expressed as:

P (psi) = maximum hydrostatic pressure (internal

pressure)

= 0.4336 h

where

=

2

+ C

Butt joints are provided for welding the vertical joints between plates to form the

lowest laye of the shell. An allowance of 2 mm is amde between two adjacent plates

to facilate welding.

=

4

+ C

Dimensions:

Outside diameter, Do =

Nominal wall thickness, t =

Length, L =

Corrosion allowance, Corr =

Material =

Allowable stress, S =

Long seam efficiency, El =

Circ seam efficiency, Ec =

Under tolerance allowance =

Interior pressure, P =

3

,.

0.00219

mm

mm

mm

18 mm

0.25 mm

24 mm

0.01 mm

20,000 psi

0.70 %

0.85 %

0.00 %

201.4 psi

Reference Output

Dimensions:

Pressure at top of vessel, P = 200 psi

Fluid height, h = 3.31 ft

Fluid specific gravity, SG = 1

Static head = 1.43 psi

Pdesign = 201.43 psi

Dimensions:

Outside diameter, Do = 18 in

Nominal wall thickness, t = 0.25 in

Length, L = 24 in

Corrosion allowance, Corr = 0.01 in

Material and Conditions:

Material =

Allowable stress, S = 20,000 psi

Long seam efficiency, El = 0.70 %

Circ seam efficiency, Ec = 0.85 %

Under tolerance allowance = 0.00 %

Interior pressure, P = 201.4 psi

Calculated Properties

Volume,V

= 5772.68 in3

= 3.34067 ft3

Weight, W

Calculations

= (

2

t)

2

h

= ( )

Cirumferential Joint (Longitudinal Stress)

F

PL

=

PL

.A

Pressure force = P.D

2

/4

Resisting force = S.Dt

By equating two (2) forces,

P.D

2

/4 = S.Dt

=

4

PL

Longitudinal Joint (Cirumferential-hoop Stress)

F

PL

=

PH

.A

Pressure force = P.L.D

Resisting force = S.2Lt

By equating two (2) forces,

P.L.D = S.2Lt

=

2

Thickness of shells under Internal Pressure ( interms of inside diameter)

Where, t = Min. required thickness of shell, in

R = Insider radius of shell, in

P = Internal design pressure or max. allowable working

pressure (taking into consideration the static head of

fluid), psi

S = Max. allowable stress of shell material, psi

E = Min. joint efficiency, percent

1. Circumferential (hoop) Stress (Longitudinal Joints) t < 0.5 R or P < 0.385 SE

=

0.6

2. Longitudinal Stress(Circumferential Joints) t < 0.5 R or P < 1.25 SE

=

2 +0.4

The tank will be designed in accordance with the following criteria:-

Circular in shape

For non-pressurize storage

Tank is subjected to hydrostatic head only (i.e. uniformly increasing load

from top to bottom and normal to its plane

No external pressure

Design Temperature

Corrosion allowance to be included in the design

Fluid Properties

Fluid height, H = 1 m

Density of water, r = 1,000.00 kg/m

Acceleration due to gravity , g = 9.81 m/s

2

Maximum hydrostatic pressure, P

(internal pressure)

= 9.81 kN/m

2

Material

Nominal diamter of tank = 1 m

Joint efficiency (usually 85%) = 0.85

Corrosion allowance, C = 2 mm

Permissible stress, f = 15,000 psi

Permissible stress, f = 103421.3594 kN/m

2

Maximum allowable working

stress = 34473.78645

Thickness of the shell,t

Circumferential = 2.167390613 mm

Longitudinal = 2.083695306 mm

P

=

=

2

+ C

=

4

+ C

Allowance = 2 mm

No. of plates = 1

Total circumference with 1 plate = 3.1 mm

Length of each plate = 3.1 mm

The size of the plate selected from :

Dimensions:

Outside diameter, Do = 18 mm

Nominal wall thickness, t = 0.25 mm

Length, L = 24 mm

Corrosion allowance, Corr = 0.01 mm

Material =

Allowable stress, S = 20,000 psi

Long seam efficiency, El = 0.70 %

Circ seam efficiency, Ec = 0.85 %

Under tolerance allowance = 0.00 %

Interior pressure, P = 201.4 psi

Edge supported; uniform load

At center:

(max)

r

=

t

=

1.24

2

=

0.695

4

3

Hydrostatic Pressure at Tank Bottom

The hydrostatic pressure can be expressed as:

P (psi) = maximum hydrostatic pressure

(internal pressure)

= 0.4336 h

where

Butt joints are provided for welding the vertical joints between plates to form

the lowest laye of the shell. An allowance of 2 mm is amde between two

adjacent plates to facilate welding.

,.

Value Units

Water tank capcity

Nominal diamter of water tank,D

Nominal height of water tank,Ht

Water storage height in the tank, H 1 m

Rood slope Rise to Run

Minimum free board

Bottom Plate diameter of water tank, Db

Yield strength fo structural steel, plate and pipe, Fy 36000 psi

Portland Cement for concrete construction Type I

Specified compressive strength of concrete, fc' 4000 psi

Specfied yield strength of reinforcement, fy 60,000 psi

Specified yield strength of welded wire fibre, fy 65,000 psi

Density of reinforced concrete, Dc 150 psf

Density of steel plate, Dst

Density of water, Dw 62.4 pcf

Specfic gravity of water, G 1

Min. allowance for corrosion layer 0.0625 inch

Bottom plates

Bottom plates shall conform to API Standard 650 (Ref page 3-5 and 3-6)

3.4.1 Minimum nominal thickness 6 mm

pg 3-5 Corrosion allowance 0.0625 mm

Minimum thickness of the bottom plate

inclusive corrosion allowance,tb 6.0625 mm

It is selected that thickness of the bottom plate is 8 mm

1303.44 mm

Parameter

Annular bottom plate width required:

()

.

where

tb = thickness of the annular plate, in mm

H = maximum design liquid level, m

Cylindrical Tank Shell

Wath Depth, H 1 mm

Hydro- pressure, p = Dw*H* 9.81 kN/m

2

Ring tension, Th = p*(D/2)

Allowable tensile stress, Ft = 0.6*Fy

Welded joint efficiency factor, E 0.85

Thickness of shell

Corrosion allowance,tc

Required thickness of shell

250 MPa A36

2400 kg/m

3

7850 kg/m

3

1000 kg/m

3

0.25 in

API 650

Appendix A

AWWA

D100-84

metric imperial

hp 1 m 3.28083 ft

G 1 1

D 1 m 3.28083 ft

Table 4 AWWA s 103.4 Mpa 15000 psi

Table 9 AWWA E 0.85 0.85

Table 14 pg 27 CA(Shell 1 mm 0.03937 in

CA(Floor) 2 mm 0.07874 in

t 1.05574 mm 0.08093 mm

=

4.9

+CA

Tank data

Material

Metric Imperial

D 1 m 3.28083 ft

G 1 1

s 103.421 psi 15000 psi

E 0.85 0.85

CA 2 mm 0.07874 in

H 1 m 3.28083 ft

The calculated plate thickness requirements are as follows:

The minimum allowable is = 0.1875 inch

Course 1 = 0.00219

AWWA shell plate thickness calculation

AWWA shell plate thickness calculation

Basic formula =

2.6

+CA

Where:

t= Plate thickness for course under consideration

h

p

= Liquid height from top capacity level to bottom of course

under consideration

D = Nominal diameter

G = Specific gravity

s = Allowable design stress

Nozzle Service Cant Diameter (inch) Weigh (lb) Weigh (kg) Material

N1 Water inlet 1 8 48.50 31.75 A-105

N2 Service Water Oulet 1 4 20.00 9.07 A-105

N3 fire fighting Water Oulet 1 16 173.00 78.47 A-105

N6 Fire Fighting water recirculation inlet 1 8 48.50 22.00 A-105

Service Water

Sp.Gr of liquid (G) 1

Capacity ( m3 ) 1200

Dia of tank (D) 1.000 m 3.281 ft

Ht of tank (H) 1.000 m 3.281 ft

Type of Roof None

Type of Bottom None

Slope of Roof - -

Slope of Bottom - -

Corrosion Allow (CA) 3.0 mm 0.120 in

Wind Velocity (V) - -

Live Load on Roof - -

H/D Ratio 0.53333

Vapour Pressure ( Bar abs )

Seismic Zone 2A

D

c

1000

kg/m

3

G 1.00 -

G' 1.00 -

F

Ymin

250 MPa

F

Tmin

400 MPa

E 195000 MPa

T

max

N/A

o

C

T

min

N/A

o

C

S

d

160 MPa

S

t

171 MPa

P

i

0.00

kN/m

2

( kPa )

P

e

0.00

kN/m

2

( kPa )

f 0

kN/m

2

( kPa )

H

1

1.0 m

CA 3.0 mm

CA 3.0 mm

CA 3.0 mm

CA 3.0 mm

CA 3.0 mm

CA 3.0 mm

tmin 6.0 mm

Outside Dia. Do 1.012 m

Inside Dia. Di 1.000 m

Nominal Dia. ( Inside Dia. + Shell Thk. ) Dn 1.006 m

Total Height H 1.3 m

10.016 kN

F

Ystructure

250 MPa

Den. 7850

kg/m

3

Width

Press.

Head

HL

1

' t

d

t

t

Max( t

d

,t

t

) t

smin

t

smin

m m m mm mm mm mm mm

3.6.1.2 3.6.3.2 3.6.3.2 3.6.3.2 3.6.1.1 A.4.1

pg pg A-1

1 1.800 0.00 1.00 3.02156613 0.02017883 3.02 5 3.03

t

s1

(mm) = 6

Shell

Fluid Hold Down Weight

Yield Strength - Structural Parts

Density

S H E L L D E S I G N

C

o

u

r

s

e

#

Rapid Mix Tank

Group IV

Allowable Product Design Stress at Design Temperature

Allowable Hydrostatic Test Stress at Design Temperature

Internal Pressure

Purpose

Density of Contents

Specific Gravity of Contents

Specific Gravity of Contents (For Appendix A Only)

Material Group

Minimum Yield Strength

Bottom

Minimum Tensile Strength

Modulus of Elasticity

Maximum Design Temperature

Minimum Design Temperature

External Pressure

Smallest of the allowable tensile stresses (Roof, Shell, Ring)

High Liquid Level

Roof

Structure

Anchor Bolts

Nozzles, etc.

m kN kg mm kN kg

1 1.800 2.63 267.94 3.0 1.31 133.97

1.800 2.629 267.942 1.31 133.97

t

bmin

CA t

b-req'd

mm mm mm

3.4.1 3.4.1

6 3.0 9.0

kN kgs kN kgs kN kg

0.000087 0.01 2.63 267.94 2.63 267.95

0.000061 0.01 1.31 133.97 1.31 133.98

DL Corroded Uncorroded

SHELL 0.00 0.00 kN

1.31 2.63 kN

0.00 kN

0.00 kN

0.00 kN

0.00 kN

1.31 2.63 kN

#VALUE! #VALUE!

kN/m

2

( kPa )

ALL #REF! #REF! kN

#REF! #REF!

kN/m

2

( kPa )

Superimposed L

r

1.5

kN/m

2

( kPa )

Snow Load S 0

kN/m

2

( kPa )

External Pressuer P

e

0.00

kN/m

2

( kPa )

Top Angle

Course(s)

Wind Girders

Ladder

Insulation

Others

W E I G H T S U M M A R Y

Bottom Plt. Wt. Shell Plt. Wt. Total Weight

S H E L L W E I G H T S U M M A R Y

Course #

Width

3.6.1.2

Shell Wt.

(Uncorroded) Thk. - CA

Shell Wt.

(Corroded)

B O T T O M P L A T E D E S I G N

t

smin

*t

used

S

dmax

S

tmax

W

tr

mm mm MPa MPa m

J.3.3 3.9.7.2 & V.8.1.4

5.00 6 1.15 0.58 1.800

S H E L L D E S I G N

Use

Projection

mm mm

3.4.2

10 25

W E I G H T S U M M A R Y

B O T T O M P L A T E D E S I G N

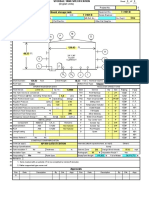

DESIGN CODE API 650 1998

TANK

Roof None

Tank support (Self-supported / Column-supported / NA) NA

GEOMETRIC DATA

Inside diameter , Di ( corroded ) (@ 1,000 mm ) 1,006 mm

Nominal diameter, Dn ( new ) ( based on 1st shell course ) 1,005 mm

Nominal diameter, Dc ( corroded ) ( based on 1st shell course ) 1,008 mm

Tank height (tan/tan), H 1,000 mm

Specific gravity of operating liquid , S.G. (Actual) 1.000

Specific gravity of operating liquid , S.G. (Design) 1.00

Nominal capacity , V 0.794851 m

Maximum design liquid level, HL 1,000 mm

Component Material Tensile Yield Corrosion

Stress Stress Allowance

Sd(N/mm) St(N/mm) c.a.(mm)

PLATE

Shell Plate A36 160.00 171.00 3.000

Annular Plate A36 160.00 171.00 3.000

Bottom Plate A36 160.00 171.00 3.000

Roof Plate A36 160.00 171.00 3.000

STRUCTURE MEMBERS

Roof structure (rafter,bracing,etc ) A36 160.00 171.00 3.00

Top Curb Angle A36 160.00 171.00 3.00

Intermediate Wind Girder A36 160.00 171.00 3.00

SPECIFIED MINIMUM SHELL THICKNESS

Specification API 650 1998

Minimum thickness as per API 650 cl 5.6.1.1 5 mm

Design shell thickness, (in mm)

=

4. . 9

0.3

+ CA

Hydrostatic test shell thickness

=

4. . 9

0.3

Calculation & Results

td 3.02 mm

tt 0.02 mm

Recall tmin (as per API 650) 5.0 mm

Thickness selected and used 5.00 mm

Ht up to bottom of course 0 mm

Ht of CG of each course 500 mm

Long X-sec Area 5000 mm2

Area X C.G 2500000 mm3

Ht of Center of gravity 500 mm

BOTTOM & ANNULAR PLATE DESIGN

BOTTOM PLATE & ANNULAR PLATE DESIGN

Annular plate used ? ( yes/no ) No

BOTTOM PLATE

Minimum thickness as per API 650 Clause 5.4.1 6.00 mm

Minimum thickness required (@ 3.00 mm c.a )

Therefore, use thickness of 9.00 mm (tb) is satisfactory.

Min. shell-to-bottom fillet weld size (cl. 3.1.5.7) 6.00 mm

Should not be more than 1/2 inch & should not be less than thk of thinner of the two plates joined.

Min. width of overlapping (cl. 5.1.3.5) 25.00 mm

300.00 mm

Min. width of plate (cl. 5.4.1) 1800.00 mm

Min. width projected outside of shell (cl. 3.4.2) 25.00 mm

Intermediate wind girder

API.650 Minimum required size as per API 650 clause 5.9.3.2 64 x 64 x 6.4

12th Min. nominal thickness of plate 6.00 mm

or Section modulus,Z min 6.77

cm

3

API 650 Unstiffened height 1 m

3.9

H1 105.0886693 m

If H1 is greater than the Unstiffened shell height, wind girders are not required

Hence Not Required

The maxmum height of the unstiffened shell shall be calcualted as follows

1

= 9.47

3

TANK CONSTRAINT CALCULATIONS

Seismic zone 2B

Seismic zone factor, Z 0.2

Importance factor, I (max 1.25) 1.00

Nominal diameter of tank, D 1.0 m

Total height of tank shell, Ht 1.0 m

Ht.from bottom shell to COG of shell,Xs 0.5 m

Maximum design liquid level, H 1.0 m

Density of water 1000 kg/m

Density of steel (shell,bottom) 7850 kg/m

Total weight of tank shell, Ws 1219.3 N

Total weight of tank bottom, Wb 553.1 N

Sum 1772.4 N

Total weight of tank contents, W

T

7828.5 N

Ht from bottom of Shell to C.G 500 mm

W

T

7828.5 N

Overturning Moment

Effective Mass of Tank contents

Ratio Dc/H 1.008

W1/WT 0.8

W2/WT 0.25

W1 6262.820146 N

W2 1957.131296 N

X1/H 0.4

X2/H 0.72

=

.

12

.9.81

1000

. 9.81

=

7850 9.81

X1 400 mm

X2 720 mm

c1 0.6

k 0.59

T 1.07 s

When T <=4.5 C2 1.05

When T >45 C2 4.40

Site coefficient,S 1.5

Therefore C2 1.05

Overturning moment,M 702.7 N-m

Yield strength 250 Mpa

WL (1) 14087.9 N/m

WL (2)

196.98 N/m

If WL(1)>WL(2), use WL(2) for Resistance to Overturning 196.98 N/m

Wt of Tank Components 423.3 N/m

M/D(wt+wl) 1.121617275

From Figure E-5 :

'(b+wl)/(wt+wl) 3.2

Max Longtudinal comp. Force at the bottom of shell, b 1787.871135 N/m

b/12t 16.55436236

A = GHD/t 0.028224 mm3/m2

GHD2/t2 is less than 44 so

Max Long. Comp stress in shell, Fa =83t/2.5D+7.5(GH)^0.5 205 MPa

Max Long. Comp stress in shell, Fa =0.5Fy 125 MPa

Fa shall not be greater than 0.5Fty,hence Fa 125 MPa

Fa = maximum allowable longitudinal compressive stress in the shell, in MPa.

= 99

= 196

For stablity b/12t < Fa Stable, No Anchoring required

TOP CURB ANGLE

See Section 3.1.5.9 ( e ) of API 650 page 3-4

The tank shall be supplied with top angles of not less than the following sizes:

For tank with diameter <= to 11 m (35 ft)

51 x 51 x 4.8 mm (2 x 2 x 3/16 in) Use

For tank with diameter 11 m (35 ft) > = 18 m (60 ft)

51 x 51 x 6.4 mm (2 x 2 x 1/4 in) No

For tank with diameter > 18 m (60 ft)

76 x 76 x 9.5 mm (3 x 3 x 3/8 in) No

Length of Curb Angle 3.2 m

CURB ANGLE kg/m AREA IN cm

(51 x 51 x 4.8 mm) 3.77 4.79

(51 x 51 x 6.4 mm) 4.5 5.68

(75 x 75 x 9.5 mm) 11 14.02

TOTAL WEIGHT (kg ) 11.9386

TOTAL WEIGHT ( N ) 117.117

WIND OVERTURNING CALCULATION

3.11.1 Wind Velocity 160 km/hour

Wind Pressure on Cylindrical Surfaces 0.86 kPa

Wind Pressure on Conical Surfaces 0 kPa

Roof Weight 0 kg

Shell Weight 124 kg

Net Weight 124 kg

Roof Height 0.000 m

Shell Surface Area 3.167 m2

COG 0.500 m

Wind Moment

Lateral force #REF! lbs

Over turning moment "M" #REF! lbs-ft

Stabilizing Moment #REF! lbs-ft

Remarks

No Material Specified Specified Yield stress Max. allow Max. allow

used min. tensile min. yield reduction fac design hydro.test

stress stress ( App. M ) stress stress

St (N/mm) Sy (Nmm) k Sd (N/mm) St (N/mm)

A36 160.00 171.00 1.000 64.00 68.57

Should not be more than 1/2 inch & should not be less than thk of thinner of the two plates joined.

Corrosion

allowance

c.a (mm)

0.00

Vous aimerez peut-être aussi

- Design As Per APIDocument82 pagesDesign As Per APINeeraj BhallaPas encore d'évaluation

- Storage Tank Design Calculation - Api 650: Close Floating RoofDocument31 pagesStorage Tank Design Calculation - Api 650: Close Floating RoofNguyễn Duy HưngPas encore d'évaluation

- Diesel Tank TaluksangayDocument70 pagesDiesel Tank TaluksangayBert EngPas encore d'évaluation

- Premium TankDocument26 pagesPremium TankAnonymous p0iwBoPas encore d'évaluation

- API 650 Tank Design 5Document44 pagesAPI 650 Tank Design 5Inamullah Khan93% (14)

- Anchor Chair Design FinalDocument26 pagesAnchor Chair Design FinalLe Bacha Bacha100% (4)

- API 650 Design TanksDocument34 pagesAPI 650 Design TanksSyedZainAli100% (13)

- Tank Design As Per IS803 and API650Document36 pagesTank Design As Per IS803 and API650Vikash Kumar Singh100% (1)

- Tank Design As Per IS803 and API650Document36 pagesTank Design As Per IS803 and API650Vikk Suriya100% (1)

- Tank Calc - Api650Document90 pagesTank Calc - Api650kamleshyadavmoney100% (3)

- API 650 Tank DesignDocument29 pagesAPI 650 Tank DesignBerk Koç100% (11)

- API 650 Tank Design 1foot MethodDocument4 pagesAPI 650 Tank Design 1foot Methodjakjak67% (3)

- Teto Api620Document3 pagesTeto Api620viniciuskurtPas encore d'évaluation

- Storage Tank DesignDocument21 pagesStorage Tank Designravi456compPas encore d'évaluation

- Supported Cone Roof (CS) Add.4Document21 pagesSupported Cone Roof (CS) Add.4skhurramq100% (2)

- API 650 Storage Tank TCA PreparationDocument86 pagesAPI 650 Storage Tank TCA PreparationBimal DeyPas encore d'évaluation

- API 650 Water Storage Tank - Xls 36Document71 pagesAPI 650 Water Storage Tank - Xls 36rudi 01Pas encore d'évaluation

- STORAGE TANK DESIGN CALCULATION API 620 WIND AND SEISMIC FORCESDocument74 pagesSTORAGE TANK DESIGN CALCULATION API 620 WIND AND SEISMIC FORCESThinh ViproPas encore d'évaluation

- Report Rectangular Tank - REV 0 - 28.11.12Document26 pagesReport Rectangular Tank - REV 0 - 28.11.12JijinJohn100% (1)

- Shell Design and Thickness CalculationsDocument6 pagesShell Design and Thickness CalculationsPrasanna kumar subudhiPas encore d'évaluation

- API 650 Storage Tank Load Computations With Ring Wall Foundation Design (8.7-m Diameter X 9.0-m Height)Document25 pagesAPI 650 Storage Tank Load Computations With Ring Wall Foundation Design (8.7-m Diameter X 9.0-m Height)AVBP100% (3)

- Rectangular TankDocument38 pagesRectangular TankSam LowPas encore d'évaluation

- 20100419043934!el Chaguite Tank DesignDocument37 pages20100419043934!el Chaguite Tank DesignSana UllahPas encore d'évaluation

- Storage Tank CALC Api 650Document10 pagesStorage Tank CALC Api 650kuselanml100% (3)

- Molasses Tank Design Sheet CalculationsDocument9 pagesMolasses Tank Design Sheet CalculationsGautam Paul100% (2)

- RECTANGULAR TANK DESIGN CALCULATION SHEETDocument37 pagesRECTANGULAR TANK DESIGN CALCULATION SHEETSyaiful Iwasranto100% (1)

- Api 620 - 2002Document12 pagesApi 620 - 2002ductaiutc100% (1)

- API 620 CalculationDocument114 pagesAPI 620 Calculationvikram100% (4)

- Tank DesignDocument108 pagesTank DesignFRBM2Pas encore d'évaluation

- 100cub API 650 STEEL SiloDocument19 pages100cub API 650 STEEL SiloUDayPas encore d'évaluation

- Tank 620 US 0002 API 620 Calculation ReportDocument39 pagesTank 620 US 0002 API 620 Calculation ReportPhượng NguyễnPas encore d'évaluation

- Storage Tank Design Calculations - Seismic Design & Overturning Moment - by Abdel Halim GalalaDocument10 pagesStorage Tank Design Calculations - Seismic Design & Overturning Moment - by Abdel Halim Galalamarkfgt57% (7)

- Design of 900 Cum Water Tank DomeDocument33 pagesDesign of 900 Cum Water Tank Domeanirban das100% (2)

- Chimney Calculation SheetDocument12 pagesChimney Calculation SheetVinoth Rajendra40% (5)

- Design Data and Calculations for Rectangular Storage TankDocument31 pagesDesign Data and Calculations for Rectangular Storage Tanknamasral100% (9)

- Calculation API 650Document78 pagesCalculation API 650jamil93% (14)

- Hfo Service Tank - ht003 Data Sheet r1 PDFDocument4 pagesHfo Service Tank - ht003 Data Sheet r1 PDFsocomenin2013Pas encore d'évaluation

- 26 Pressure VesselDocument21 pages26 Pressure VesseljnmanivannanmechPas encore d'évaluation

- API 650 Storage Tank Design CalculationDocument14 pagesAPI 650 Storage Tank Design CalculationMohammed EljammalPas encore d'évaluation

- Self-Supported Cone Roof: Design of Steel Storage Tanks As Per Api-650 (Diameter 3M)Document29 pagesSelf-Supported Cone Roof: Design of Steel Storage Tanks As Per Api-650 (Diameter 3M)amokhta0% (1)

- API 650 Tank Design 1Document5 pagesAPI 650 Tank Design 1Jose Ortiz100% (1)

- Design Calculation TankDocument28 pagesDesign Calculation Tankibiceng100% (4)

- API 650 Tank Design 1Document5 pagesAPI 650 Tank Design 1Nguyễn Thành Trung100% (1)

- Design Tanks Menurut API 650Document80 pagesDesign Tanks Menurut API 650irbar.darmansyah.alwiPas encore d'évaluation

- Tank DesignDocument152 pagesTank Designnkmishra99100% (1)

- CalDocument19 pagesCalpandiangv100% (1)

- Total Middle East New Bitumen Terminal in TlbuDocument25 pagesTotal Middle East New Bitumen Terminal in TlbuAnupam Jana100% (2)

- Tank design calculations sheet analysisDocument5 pagesTank design calculations sheet analysisapminshull88% (8)

- Tank Design As Per IS803 and API650Document36 pagesTank Design As Per IS803 and API650Mani Vannan100% (3)

- Ldo Storage Tank Calculation 170Document12 pagesLdo Storage Tank Calculation 170Alvin SmithPas encore d'évaluation

- 26 Pressure Vessel.Document21 pages26 Pressure Vessel.mishtinil93% (14)

- Storage Tanks CalculationsDocument21 pagesStorage Tanks Calculationsjimallen21288% (26)

- Orica Tank Design Calculation AWWADocument8 pagesOrica Tank Design Calculation AWWAmohanuma100% (2)

- Ldo Storage Tank CalculationDocument7 pagesLdo Storage Tank CalculationchetanmalePas encore d'évaluation

- Abut DesignDocument32 pagesAbut DesignSubir Kunda100% (2)

- API-650 Design Procedure ExampleDocument21 pagesAPI-650 Design Procedure Examplegdwvcd92% (13)

- API 650 Design TanksDocument39 pagesAPI 650 Design TanksAhmedAli25% (4)

- Rectangular tank calculation projectDocument15 pagesRectangular tank calculation projectaku9450% (2)

- API 650 Storage Tank Design CalculationsDocument5 pagesAPI 650 Storage Tank Design CalculationsFabian Nuñez Diaz100% (1)

- Southern Marine Engineering Desk Reference: Second Edition Volume ID'EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IPas encore d'évaluation

- Wasa Guidelinesfordesignofwaterandwastewatersystems 150630122700 Lva1 App6892Document45 pagesWasa Guidelinesfordesignofwaterandwastewatersystems 150630122700 Lva1 App6892ace1205Pas encore d'évaluation

- WASA Design Guidelines (BOETT) 2003Document43 pagesWASA Design Guidelines (BOETT) 2003companyltd394100% (1)

- Leachate TreatmentDocument14 pagesLeachate Treatmentace1205Pas encore d'évaluation

- Design of Reinforced Concrete Water TanksDocument71 pagesDesign of Reinforced Concrete Water Tanksace1205100% (3)

- ChristmasDocument4 pagesChristmasace1205Pas encore d'évaluation

- Base Pad Width (Perp. To Sail)Document1 pageBase Pad Width (Perp. To Sail)ace1205Pas encore d'évaluation

- Research ProposalDocument1 pageResearch Proposalace1205Pas encore d'évaluation

- Noe9058096081 ch29Document10 pagesNoe9058096081 ch29ace1205Pas encore d'évaluation

- Water Resources Chapter SummaryDocument30 pagesWater Resources Chapter Summaryace1205Pas encore d'évaluation

- Hydraulic Structures II-1Document51 pagesHydraulic Structures II-1ace1205100% (2)

- Tank CalculatorDocument19 pagesTank Calculatorace1205Pas encore d'évaluation

- Concrete Ring Wall FoundationDocument16 pagesConcrete Ring Wall Foundationrao159951Pas encore d'évaluation

- Elements of Soil Mechanics, 8th Edition Exercises 7.2 & 7.5Document19 pagesElements of Soil Mechanics, 8th Edition Exercises 7.2 & 7.5ace1205Pas encore d'évaluation

- Welcome To E-Z-Slab 2001Document18 pagesWelcome To E-Z-Slab 2001api-19878202Pas encore d'évaluation

- Base Pad Width (Perp. To Sail)Document1 pageBase Pad Width (Perp. To Sail)ace1205Pas encore d'évaluation

- Design of SlabDocument9 pagesDesign of Slabace1205Pas encore d'évaluation

- Rectangular Tank CalculationDocument28 pagesRectangular Tank CalculationHiếu Nguyên78% (32)

- Design of One-Way SlabDocument3 pagesDesign of One-Way Slabace1205Pas encore d'évaluation

- Tank Spreadsheet V 6 ADocument88 pagesTank Spreadsheet V 6 Aace1205100% (1)

- Api 650 2007Document449 pagesApi 650 2007ace1205100% (1)

- 28Document13 pages28ace1205Pas encore d'évaluation

- API Tank DesignDocument189 pagesAPI Tank DesignDD3NZ91% (11)

- CE 428 - Screens EqualizationDocument2 pagesCE 428 - Screens Equalizationace1205Pas encore d'évaluation

- 650 Rev.02 ITP With Plan at Site (API 650 Tanks) PDFDocument41 pages650 Rev.02 ITP With Plan at Site (API 650 Tanks) PDFMohamed Abd El DayemPas encore d'évaluation

- Colloid Coagulation: How Water Treatment Removes Colloidal ParticlesDocument103 pagesColloid Coagulation: How Water Treatment Removes Colloidal ParticlesAkulSenapatiPas encore d'évaluation

- API 620 Tank CalculationsDocument11 pagesAPI 620 Tank CalculationsPrashant Malve64% (11)

- Tank Calc - Api650Document90 pagesTank Calc - Api650kamleshyadavmoney100% (3)

- Watertank GS PDFDocument24 pagesWatertank GS PDFManoj RautPas encore d'évaluation

- Stresses Due To Fluid Pressure in Thin CylindersDocument25 pagesStresses Due To Fluid Pressure in Thin Cylindersace1205Pas encore d'évaluation

- Ankit Mukati 16523004 Pre Engineered BuildingDocument33 pagesAnkit Mukati 16523004 Pre Engineered BuildingAnkit PatidarPas encore d'évaluation

- Clayton RajaDocument7 pagesClayton RajaSrinivasm SriniPas encore d'évaluation

- A Publication of The James F. Lincoln Arc Welding FoundationDocument24 pagesA Publication of The James F. Lincoln Arc Welding FoundationamokhtaPas encore d'évaluation

- Dynamic Analysis of The Stress and Strain State of The Spur Gear PairDocument6 pagesDynamic Analysis of The Stress and Strain State of The Spur Gear PairMabelus BurgerPas encore d'évaluation

- JKSSB JE & JKPSC AE Sample Updated Previous Year QuestionsDocument134 pagesJKSSB JE & JKPSC AE Sample Updated Previous Year Questionsklllerr RaeesPas encore d'évaluation

- Anatech Concrete Material ModelingDocument12 pagesAnatech Concrete Material ModelingcurvedbrainPas encore d'évaluation

- CAEPIPE Code Compliance ManualDocument460 pagesCAEPIPE Code Compliance ManualmionomePas encore d'évaluation

- (EN) Rsni-T-03-2005Document166 pages(EN) Rsni-T-03-2005Anindio PrabuPas encore d'évaluation

- Design of Systematic Support System For Development and Depillaring in Underground Coal MinesDocument70 pagesDesign of Systematic Support System For Development and Depillaring in Underground Coal MinesSushantPas encore d'évaluation

- Design Steel Reinforced Elastomeric Bridge BearingsDocument27 pagesDesign Steel Reinforced Elastomeric Bridge BearingsRupchanda BarmanPas encore d'évaluation

- Stress Analyses Around Holes in Composite Laminates Using Boundary Element MethodDocument10 pagesStress Analyses Around Holes in Composite Laminates Using Boundary Element MethodpdhurveyPas encore d'évaluation

- Is 800:2007Document150 pagesIs 800:2007crajtry100% (2)

- Type Test CablesDocument9 pagesType Test CablesvkartikeyPas encore d'évaluation

- Civil Engineering Assignment ProblemsDocument3 pagesCivil Engineering Assignment ProblemschritPas encore d'évaluation

- Crane Lifting Lug DesignDocument3 pagesCrane Lifting Lug DesignsajadbePas encore d'évaluation

- Service Life Prediction of Rubber Compound by Accelerated Ageing and Mechanical PropertiesDocument15 pagesService Life Prediction of Rubber Compound by Accelerated Ageing and Mechanical PropertiesIAEME Publication100% (1)

- 7 Design of Deep Flexural MemberDocument56 pages7 Design of Deep Flexural MemberSarah SpearsPas encore d'évaluation

- Design to BS 5950 Part 1: Limit State Design of Tubular StructuresDocument55 pagesDesign to BS 5950 Part 1: Limit State Design of Tubular StructuresTingluhelen90% (10)

- Determinate and Indeterminate Structures - FilesDocument8 pagesDeterminate and Indeterminate Structures - FilesSuvajit BisaiPas encore d'évaluation

- Cimentaciones en Rocas Anisotropicas Serrano y OlallaDocument11 pagesCimentaciones en Rocas Anisotropicas Serrano y OlallaHoover AzcaratePas encore d'évaluation

- (TGD05) - Guide P414 - Steel Concrete PDFDocument50 pages(TGD05) - Guide P414 - Steel Concrete PDFshanicePas encore d'évaluation

- ECSS E ST 32 10C - Rev.1 (6march2009) PDFDocument24 pagesECSS E ST 32 10C - Rev.1 (6march2009) PDFTomaspockPas encore d'évaluation

- Is 8147Document170 pagesIs 8147Asha JatalPas encore d'évaluation

- 2014 Rina Rules EnglishDocument4 pages2014 Rina Rules EnglishBHARANIPas encore d'évaluation

- ISOLATED FOOTING DESIGNDocument12 pagesISOLATED FOOTING DESIGNSaketRusiaPas encore d'évaluation

- 1-Direct Stresses, Tension and CompressionDocument14 pages1-Direct Stresses, Tension and CompressionsarmadPas encore d'évaluation

- Gete 201100024Document11 pagesGete 201100024superwxrPas encore d'évaluation

- Theory of Flow Fracture NadaiDocument611 pagesTheory of Flow Fracture Nadaimarc53042100% (1)

- ABAQUS Training PDFDocument114 pagesABAQUS Training PDFManuelDarioFranciscoPas encore d'évaluation

- Development of Analytical Methods For Fuselage DesignDocument13 pagesDevelopment of Analytical Methods For Fuselage DesignSaidu Bala MadaksPas encore d'évaluation