Académique Documents

Professionnel Documents

Culture Documents

Load Test Inspection Form

Transféré par

Iziyon Harrison Osaloboh0 évaluation0% ont trouvé ce document utile (0 vote)

750 vues3 pagesBRIDGE, WALL, GANTRY CRANE LOAD TEST REPORT MANUFACTURE: ____________________ SN. __________________ BLDG. # ______ EQUIPMENT # _______________ CAPACITY: _______ crane ITEM DEFECT, OK, SR, NA: ________ _ 1 Load Hook and Blocks _________ 18 Controllers ________ 2 Wire Rope and End Connections _

Description originale:

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentBRIDGE, WALL, GANTRY CRANE LOAD TEST REPORT MANUFACTURE: ____________________ SN. __________________ BLDG. # ______ EQUIPMENT # _______________ CAPACITY: _______ crane ITEM DEFECT, OK, SR, NA: ________ _ 1 Load Hook and Blocks _________ 18 Controllers ________ 2 Wire Rope and End Connections _

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

750 vues3 pagesLoad Test Inspection Form

Transféré par

Iziyon Harrison OsalobohBRIDGE, WALL, GANTRY CRANE LOAD TEST REPORT MANUFACTURE: ____________________ SN. __________________ BLDG. # ______ EQUIPMENT # _______________ CAPACITY: _______ crane ITEM DEFECT, OK, SR, NA: ________ _ 1 Load Hook and Blocks _________ 18 Controllers ________ 2 Wire Rope and End Connections _

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 3

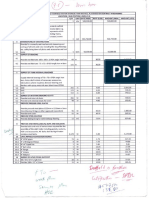

BRIDGE, WALL, GANTRY CRANE LOAD TEST REPORT

MANUFACTURE: ____________________ SN. __________________

BLDG. # ______ EQUIPMENT # ________________ CAPACITY: _______

LOAD TEST INSPECTION REPORT:

The following checklist identifies the items to be inspected before the load test. Any unusual conditions

observed during the inspection should be noted in the Remarks section.

NOTE: 1. Qualified inspector must verify all steps before load test.

CRANE ITEM DEFECT, OK, SR, NA:

________ _ 1 Load Hook & Blocks _________ 18 Controllers

_________ 2 Wire Rope and End Connections _________ 19 Relays and Coils

_________ 3 Handrails, Walkways, and Ladders _________ 20 Conductors and Collectors

_________ 4 Bridge and Trucks _________ 21 Panel Wiring

_________ 5 Bridge Wheels and Bearings _________ 22 Resistors

_________ 6 Trolley and Rails _________ 23 Bypass Switches

_________ 7 Trolley Wheels and Bearings _________ 24 Limit Switches

_________ 8 Crane Alignment _________ 25 Contactor (Electrical)

_________ 9 Runway Rail & Clamps _________ 26 Motors

_________ 10 Bumpers/End Stops _________ 27 Gauges

_________ 11 Brake System _________ 28 Lighting System

_________ 12 Drive Shafts, Gears, Couplings & Bearings _________ 29 Heater and Switches

_________ 13 Pawls, Ratchets, Spuds, & Windlocks _________ 30 Operators Cab

_________ 14 Sheaves _________ 31 Safety

_________ 15 Warning Devices _________ 32 Chain and Sprockets

_________ 16 Capacity Signs _________ 33 Structural

_________ 17 Main Disconnect _________ 34 Wire Rope Drum and

Machinery Foundation

REMARKS (unusual conditions noises, structural cracks, misalignment, etc).

6.1/12911e021.pdf 1 (12/2007)

BRIDGE CRANE AND FOLLOW-UP CHECKS

NOTES: 1. Qualified inspector must verify all steps below.

2. Load test must be performed on all new, repaired, or modified cranes before initial use.

3. Load test crane at 125% of rated capacity. In no case shall the load test exceed 125% of rated

capacity. Test weights must be accurate to 5%, +0% of stipulated values.

INITIAL

_______ 1. Set crane up for load test; qualified inspector verifies inspection is complete prior to load test.

_______ 2. The trip setting of hoist-limit devices must be determined by tests, with an empty hook traveling

at increasing speeds up to the maximum speed. The actuating mechanism of the limit device

must be located so that it will trip the device under all conditions and in sufficient time to

prevent contact of the hook or load block with any part of the trolley or crane.

_______ 3. Rig test weight to hoist hook using appropriate slings.

_______ 4. Hoist the test load a sufficient distance to ensure that the load is supported by the crane and

held by the hoist brakes.

________ 5. Transport the test load by means of the trolley for the full length of the bridge. Ensure during

operation that the trolley runs true on the bridge. Check trolley motor, brake, and gear case for

overheating.

_______ 6. Transport the test load by means of the bridge for the full length of the runway, first in one

direction with the trolley as close to the extreme right-hand end of the crane as practical, and

then in the other direction with the trolley as close to the extreme left-hand end of the crane as

practical. Ensure that the bridge runs true on the runway rails and that no undue girder

deflection occurs. Check for bridge motor, brake, and gear-case overheating.

______ 7. Move the test load back into the original position and lower the test load, stopping by the

brakes. Hold the load for 10 minutes or the time required to check all primary load-bearing

parts while under load for slippage, damage, or permanent deformation.

______ 8. Slowly lower the test load to the floor.

______ 9. At the completion of the load test, visually inspect the following load-bearing parts for signs of

wear, deformation, and deterioration:

DEFECTIVE/OK/SRNA

______ a. Bridge track _______ e. Gears

_______ b. Bridge wheels _______ f. Magnetic brakes

_______ c. Trolley track _______ g. Blocks

_______ d. Trolley wheels

VISUALLY INSPECT ROPE

_______ a. Rope diameter: (Previous) _______ (Present) _______

_______ b. Wear

_______ c. Kinks

_______ d. Broken wires

_______ e. Other signs of deterioration.

6.1/12911e021.pdf 2 (12/2007)

VISUALLY INSPECT ROPE DRUM

_______ a. Wear

_______ b. Deformation

_______ c. Deterioration.

INITIAL

______ 10. Qualified inspector must perform nondestructive tests on hook by visual examination,

liquid penetrant examination or magnetic-particle examination. Acceptance: No cracks,

linear indications, laps, or seams.

Hooks with any distortion causing an increase in the throat opening of 5% not to exceed of

original throat opening, hooks with any visible bend or twist from the original plane of the hook,

and hooks having any wear exceeding 10% of original must be replaced.

Lubricate hook bearing and latch pin, as applicable.

Establish three marks, A, B, and C, with center punch. For ease in measuring, set distances on an even

number of inches.

BEFORE LOAD TEST

North #1

Length AB _______ in.

Length BC _______ in.

AFTER LOAD TEST

Length AB _______ in.

Length BC _______ in.

Check for:

1. Wear and deformation

2. Cracks and twisting

3. Signs of opening between Point A and Point B

Qualified Inspector: _________________________________________

Operated By: _______________________________________________

Actual Load Test lbs. ________________ Percent of Rated Capacity: ________

Load Test Insp. Date: ___________________ BNL Inspection Tag # ____________

Remarks:

6.1/12911e021.pdf 3 (12/2007)

Vous aimerez peut-être aussi

- Work Method Rehabilitation of Water Storage Tank-Shell R.A PDFDocument4 pagesWork Method Rehabilitation of Water Storage Tank-Shell R.A PDFIziyon Harrison OsalobohPas encore d'évaluation

- Work Method Rehabilitation of Water Storage Tank-Shell R.A PDFDocument4 pagesWork Method Rehabilitation of Water Storage Tank-Shell R.A PDFIziyon Harrison OsalobohPas encore d'évaluation

- F4a 2020 LEEA Assessments - Information For Members Students Nov 2019Document4 pagesF4a 2020 LEEA Assessments - Information For Members Students Nov 2019VishnuPas encore d'évaluation

- Hoist Load Test ReportDocument2 pagesHoist Load Test ReportSoedarjoto S100% (1)

- Ponta Da Madeira - Port RestrictionsDocument5 pagesPonta Da Madeira - Port RestrictionsbicliomaPas encore d'évaluation

- Load Test Procedure For Coflex Hanger......Document2 pagesLoad Test Procedure For Coflex Hanger......dada2880Pas encore d'évaluation

- Overhead Crane Inspection ProcedureDocument2 pagesOverhead Crane Inspection ProcedureEphraim John Tangelon AquinoPas encore d'évaluation

- Mobile Crane Test Procedure.Document4 pagesMobile Crane Test Procedure.Deepak GehlotPas encore d'évaluation

- Boom Crane: Maintenance and Certification, NAVFAC P-307, All Lattice Boom CranesDocument14 pagesBoom Crane: Maintenance and Certification, NAVFAC P-307, All Lattice Boom CranesMat Uyin100% (1)

- Pull Out Test On LIft Anchour - 2Document3 pagesPull Out Test On LIft Anchour - 2jbmune6683Pas encore d'évaluation

- RFQ Crane (MHE - DEMAG)Document6 pagesRFQ Crane (MHE - DEMAG)Agung Pandega PutraPas encore d'évaluation

- Inspection Checklist Overhead CraneDocument2 pagesInspection Checklist Overhead CraneEzzaddeen albraikiPas encore d'évaluation

- Replace Wire RopeDocument7 pagesReplace Wire RopeBistok MarbunPas encore d'évaluation

- Bridon Offshore ExplorationDocument44 pagesBridon Offshore ExplorationAthox QhurienPas encore d'évaluation

- DOE Std.1090 07 Forklift TrucksDocument35 pagesDOE Std.1090 07 Forklift TrucksjoseritoPas encore d'évaluation

- Crawler Crane ChecklistDocument2 pagesCrawler Crane ChecklistAnuraj100% (1)

- Wps PQRDocument6 pagesWps PQRneelson_099Pas encore d'évaluation

- Especificacion de Normas de InspeccionDocument32 pagesEspecificacion de Normas de InspeccionJose BarreroPas encore d'évaluation

- RM 1ehsapprovedcosforliftingequippressvessels250914Document9 pagesRM 1ehsapprovedcosforliftingequippressvessels250914wholenumberPas encore d'évaluation

- Fcaw Wps-001a PDFDocument3 pagesFcaw Wps-001a PDFirfan bari100% (1)

- BT Lifter HPT Brochure 0614Document12 pagesBT Lifter HPT Brochure 0614Ram ReddyPas encore d'évaluation

- BS 7072.1989 Inspection and Repair of Offshore ContainerDocument17 pagesBS 7072.1989 Inspection and Repair of Offshore ContainerAriq FauzanPas encore d'évaluation

- Defect / Non Compliance ReportDocument12 pagesDefect / Non Compliance ReportMichael OkwuwaPas encore d'évaluation

- Loading Test ProcedureDocument3 pagesLoading Test Procedurealec63636Pas encore d'évaluation

- Blasting & Painting Inspection Report Format For Bottom Plate 01Document7 pagesBlasting & Painting Inspection Report Format For Bottom Plate 01ABEC Trombay sitePas encore d'évaluation

- Witness Joint ChecklistDocument1 pageWitness Joint ChecklistAustin J AlfredPas encore d'évaluation

- NullDocument15 pagesNullMichael OkwuwaPas encore d'évaluation

- Sabs GuideDocument3 pagesSabs Guidealextentwenty0% (1)

- Lars Diver Launch Recovery Systems Datasheet PDocument4 pagesLars Diver Launch Recovery Systems Datasheet Padrian luthfiPas encore d'évaluation

- 2009 Crane Start Up Inspection FormDocument3 pages2009 Crane Start Up Inspection Formsaeed ghafooriPas encore d'évaluation

- Monorail Hoist SystemDocument17 pagesMonorail Hoist SystemypatelsPas encore d'évaluation

- Testing ProcedureDocument6 pagesTesting Procedure810806100% (1)

- RS1 Standard 8-11-09 PDFDocument40 pagesRS1 Standard 8-11-09 PDFMuresan VirgilPas encore d'évaluation

- Edaran PedestalCraneDocument2 pagesEdaran PedestalCranegeorgekc77100% (1)

- Crane Load Test ProcedureDocument3 pagesCrane Load Test ProcedureBadeng LawotPas encore d'évaluation

- Gantry Crane Rail Inspection Form NAVFACDocument6 pagesGantry Crane Rail Inspection Form NAVFACTracy JohnsonPas encore d'évaluation

- Inspection: AIR Winch Ingersoll RandDocument19 pagesInspection: AIR Winch Ingersoll RandAbdou BoucheritPas encore d'évaluation

- CranesDocument36 pagesCranesgaziahmad100% (2)

- 385-06-021 Air Winch Load TestDocument1 page385-06-021 Air Winch Load TestnisarPas encore d'évaluation

- Anchor Chain Preparation For MeasuringDocument2 pagesAnchor Chain Preparation For MeasuringVaibhav DesaiPas encore d'évaluation

- Crane Hoist and Rigging SafetyDocument36 pagesCrane Hoist and Rigging SafetySalim Mohd RazPas encore d'évaluation

- Stress Analysis of Mast Structure For Water-Well Drilling MachineDocument8 pagesStress Analysis of Mast Structure For Water-Well Drilling MachineBruno Santos100% (1)

- Muhammad Ayub Bin Khalid: Personal DataDocument5 pagesMuhammad Ayub Bin Khalid: Personal DataAnwarul Shafiq AwalludinPas encore d'évaluation

- BS 3701 1964Document12 pagesBS 3701 1964Mohamed FaroukPas encore d'évaluation

- EIAC Requirements TrainingDocument52 pagesEIAC Requirements TrainingFarrukh AhmedPas encore d'évaluation

- Crane Loading ProcedureDocument6 pagesCrane Loading ProcedureBala MPas encore d'évaluation

- Guide Line For Inspection of Overhead Crane StructureDocument43 pagesGuide Line For Inspection of Overhead Crane StructurePranoy Barua100% (1)

- Carton Policies and ProceduresDocument4 pagesCarton Policies and ProceduresJohnPas encore d'évaluation

- Valve Weight PDFDocument10 pagesValve Weight PDFPrabha KaranPas encore d'évaluation

- Ultrasonic Report FormatDocument1 pageUltrasonic Report FormatAditya PratapPas encore d'évaluation

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument3 pagesAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportMohamed Yasir100% (1)

- X 904 ManualDocument19 pagesX 904 Manualuser123Pas encore d'évaluation

- Aws N-1 WPS-PQR FormDocument2 pagesAws N-1 WPS-PQR FormEdwin MariacaPas encore d'évaluation

- Is 6203 1971Document8 pagesIs 6203 1971Ahmed HossamPas encore d'évaluation

- Lifting Device Used in ConstructionDocument18 pagesLifting Device Used in ConstructionAr Deyvanai Kannan100% (1)

- Basket Design Details As Per DNV StandardDocument4 pagesBasket Design Details As Per DNV StandardmirraoPas encore d'évaluation

- Certificate of Visual Examination: International LimitedDocument33 pagesCertificate of Visual Examination: International LimitedMichael OkwuwaPas encore d'évaluation

- SIFAPP 1: Working at Height: Chapter 1: Access & EgressDocument122 pagesSIFAPP 1: Working at Height: Chapter 1: Access & EgressAnonymous 9VohZYTMPas encore d'évaluation

- Mobile Crane Load TestDocument4 pagesMobile Crane Load TestMeritorious KhanPas encore d'évaluation

- Lifting Bars and Spreaders Load Test Report: 6.0/12911e051.pdf 1 (07/2007)Document1 pageLifting Bars and Spreaders Load Test Report: 6.0/12911e051.pdf 1 (07/2007)bhichaiPas encore d'évaluation

- Mobile CranesDocument7 pagesMobile CranesEr Faiyaz Ahmed100% (1)

- Steel Erection Crane InspectionDocument3 pagesSteel Erection Crane InspectionSyaiful BahriPas encore d'évaluation

- Crane and Hoist Safety ProgramDocument1 pageCrane and Hoist Safety ProgramAARON QA QCPas encore d'évaluation

- Business AdvertDocument1 pageBusiness AdvertIziyon Harrison OsalobohPas encore d'évaluation

- Business Company Profile Template Doc Doc 765Document5 pagesBusiness Company Profile Template Doc Doc 765Ibnu Ali100% (3)

- Vendor Inspection Checklist PDFDocument1 pageVendor Inspection Checklist PDFIziyon Harrison OsalobohPas encore d'évaluation

- Business Company Profile Template Doc Doc 765Document5 pagesBusiness Company Profile Template Doc Doc 765Ibnu Ali100% (3)

- Business AdvertDocument1 pageBusiness AdvertIziyon Harrison OsalobohPas encore d'évaluation

- Microsoft Project - WORK PLAN For SHELL R.a-UpdateDocument2 pagesMicrosoft Project - WORK PLAN For SHELL R.a-UpdateIziyon Harrison OsalobohPas encore d'évaluation

- Work Schedule For TUNU Water Storage Tank RepairDocument1 pageWork Schedule For TUNU Water Storage Tank RepairIziyon Harrison OsalobohPas encore d'évaluation

- Agreed Scope For The Last Coordination Meeting PDFDocument3 pagesAgreed Scope For The Last Coordination Meeting PDFIziyon Harrison OsalobohPas encore d'évaluation

- Equipment and Tool ListDocument1 pageEquipment and Tool ListIziyon Harrison OsalobohPas encore d'évaluation

- Site Inspection Report-Ra Water Tank VisitDocument6 pagesSite Inspection Report-Ra Water Tank VisitIziyon Harrison OsalobohPas encore d'évaluation

- Agreed Scope For The Last Coordination Meeting PDFDocument3 pagesAgreed Scope For The Last Coordination Meeting PDFIziyon Harrison OsalobohPas encore d'évaluation

- Jha For Storage TanksDocument4 pagesJha For Storage TanksIziyon Harrison Osaloboh50% (2)

- CVtemplateDocument1 pageCVtemplateabdoh08Pas encore d'évaluation

- MBA 801 Production and Operations ManagementDocument308 pagesMBA 801 Production and Operations ManagementZaid Chelsea0% (1)

- Balancing Pump ImpellersDocument4 pagesBalancing Pump ImpellersIziyon Harrison OsalobohPas encore d'évaluation

- Lifting Checklist - 28 Nov 2013 (Final)Document1 pageLifting Checklist - 28 Nov 2013 (Final)Beste Ardıç ArslanPas encore d'évaluation

- CXT Uno Tech Specs A4 en Konecranes 2017Document2 pagesCXT Uno Tech Specs A4 en Konecranes 2017Aydin BighamPas encore d'évaluation

- Sandeep K. Pawar: A4-502, Mangeshi Sahara, Madhavkunj, Chikanghar, Kalyan (W) - 421301Document3 pagesSandeep K. Pawar: A4-502, Mangeshi Sahara, Madhavkunj, Chikanghar, Kalyan (W) - 421301Sandeep PawarPas encore d'évaluation

- Job Safety Analysis For Pump Installation in Ts3 Area: Hcu & Lobs Revamp ProjectDocument5 pagesJob Safety Analysis For Pump Installation in Ts3 Area: Hcu & Lobs Revamp ProjectShilpiengg SafetyPas encore d'évaluation

- LTM 1070 - 1Document655 pagesLTM 1070 - 1Cristyan GabrielPas encore d'évaluation

- Bypass User Manual 20200617Document13 pagesBypass User Manual 20200617SEC SolarPas encore d'évaluation

- Mos - Substructure WorkDocument5 pagesMos - Substructure WorkHSL CHANPas encore d'évaluation

- Thermax Engineering Construction Co. LTD: Crane Inspection ChecklistDocument2 pagesThermax Engineering Construction Co. LTD: Crane Inspection ChecklistSrinivasa Rao VenkumahanthiPas encore d'évaluation

- Under Running Single GirderDocument8 pagesUnder Running Single GirderJorge GtzPas encore d'évaluation

- Jsa For KahsDocument3 pagesJsa For Kahsfrancis_e_tan100% (2)

- Osha 29 CFR 1926.1400Document13 pagesOsha 29 CFR 1926.1400Aly MurrietaPas encore d'évaluation

- Design Piers & WharvesDocument167 pagesDesign Piers & WharvesPARALELO10100% (1)

- Wms Skid LiftingDocument2 pagesWms Skid LiftingAdil AzPas encore d'évaluation

- Lifting PermitDocument1 pageLifting PermitManesh MPas encore d'évaluation

- SP-2275 Lifting & RiggingDocument9 pagesSP-2275 Lifting & RiggingZakariyaPas encore d'évaluation

- BSG - tp01 - SW - 07004 - Rev 00 Swms For Bored PileDocument10 pagesBSG - tp01 - SW - 07004 - Rev 00 Swms For Bored Pilekhairul barsriPas encore d'évaluation

- A Simulation Tool For Combined Rail/road Transport in Intermodal TerminalsDocument15 pagesA Simulation Tool For Combined Rail/road Transport in Intermodal TerminalsSofiene GuedriPas encore d'évaluation

- Tadano - Faun - Atf 80-4 - Full - Vip PDFDocument882 pagesTadano - Faun - Atf 80-4 - Full - Vip PDFMamdouh Almalki100% (2)

- Komatsu Wheeled Excavators Pw140 7 Shop ManualDocument20 pagesKomatsu Wheeled Excavators Pw140 7 Shop ManualBarbara100% (45)

- Manitowoc 222exbDocument36 pagesManitowoc 222exbrenatoxtrPas encore d'évaluation

- Presentation For Assembly and Launching of 71.01M OWG SPANDocument48 pagesPresentation For Assembly and Launching of 71.01M OWG SPANAnonymous sfkedkymPas encore d'évaluation

- 2018618EN - 2 - DC07 - EN - Transport Specification - Transport Tooling - NR77 - 5...Document41 pages2018618EN - 2 - DC07 - EN - Transport Specification - Transport Tooling - NR77 - 5...ozgurbozkurt111Pas encore d'évaluation

- Wa200-5 MTDocument782 pagesWa200-5 MTEscobar Medellin Juan PabloPas encore d'évaluation

- GH Sinopec Ms SC Pkg17 r0Document75 pagesGH Sinopec Ms SC Pkg17 r0AmeerHamzaWarraichPas encore d'évaluation

- PreviewDocument254 pagesPreviewIgor OkPas encore d'évaluation

- 2018-11-01 Truck Model World PDFDocument52 pages2018-11-01 Truck Model World PDFمنصرين محمد100% (2)

- Crane Operations and Safety: Section 12Document8 pagesCrane Operations and Safety: Section 12Khalid ZaeemPas encore d'évaluation

- Initial (Annual) Risk Assessment 최초 (정기) 위험성평가 R0Document14 pagesInitial (Annual) Risk Assessment 최초 (정기) 위험성평가 R0HMN YDVPas encore d'évaluation

- CraneBeam v1 1Document44 pagesCraneBeam v1 1harry_1981Pas encore d'évaluation