Académique Documents

Professionnel Documents

Culture Documents

Ve Edc

Transféré par

Moaed KanbarDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Ve Edc

Transféré par

Moaed KanbarDroits d'auteur :

Formats disponibles

VP-37

The VP37 family of EDC pumps are port controlled systems similar to the

conventional mechanical distributor pumps. The high pressure is generated

by the pumping action of the plunger as the cam plate rides over rollers,

producing a rotating-reciprocating motion. The end of delivery is controlled

by the relative position of the control sleeve with respect to the outlet port in

the plunger.

The system incorporates an Eddy current positioner for controlling the

injected fuel quantity and a solenoid valve for controlling the injection begin.

The application specific maps for start quantity, idle, full load, accelerator

pedal characteristic, smoke limitation, etc. are programmed into the

ECU.Todays small, high speed diesel engine demands a lightweight and

compact fuel-injection installation. The VE distributor pump fulfils these

stipulations by combining fuel-supply pump, high pressure pump, electronic

governor and timing device in a small compact unit.

El ec t r oni c Cont r ol Uni t (ECU)

The ECU for the EDC (Electronic Diesel Control) uses a microcontroller and

a program and a data storage utilizing Flash technology. Its major

assignments are control of the high-pressure generation, and of start-of-

injection and duration of injection. In addition, the ECU is responsible for a

range of other functions such as glow control (GZS) and system monitoring.

By means of CAN (Controller Area Network), it is a simple matter to network

the ECU with other systems in the vehicle. For instance with the electronic

transmission-shift control, the Antilock braking system (ABS) or the air-

conditioning system

Sensor s:

: In combination with the cam sensor signal the speed sensor signal

re of the

endently

Speed sensor

delivers the absolute angular crankshaft position to the combustion TDC of the first cylinder.

The speed sensor works on the principle of variable reluctance.

Phase sensor : The Hall Effect camshaft sensor identifies the position of the camshaft

in combustion engines. Together with the speed sensor signal the camshaft sensor signal

supplies the absolute angular position of the crankshaft referred to top dead center (TDC) of

the first fired engine cylinder.

Ac c el er at or pedal modul e: is used to measure the accelerator pedal angle. It

features a sensor integrated into the accelerator pedal which recognizes the driver's command

and forwards a corresponding signal to the control unit.

Water temperature sensor: The temperature sensor measures the temperature of the engine,

e.g., in the coolant water circuit.

Fuel t emper at ur e sensor : The temperature sensor measures the

temperature of the fuel, e.g., in the fuel filter.

Boost pressure sensor: The Boost- pressure sensor is used to measures the pressu

aspirated or charged air in the intake-manifold with pressure controlled injection systems.

Hot -f i l m ai r mass met er : The hot-film air mass meter serves for the

measurement of the air mass sucked by the engine of diesel injection systems indep

of the atmospheric pressure and temperature.

Rai l pr essur e sensor : The high pressure sensor serves for the measurement of

the fuel pressure in the fuel pressure accumulator (High pressure rail) by diesel engines with

Common rail-injection systems.

Vous aimerez peut-être aussi

- الأزمنة في الإنكليزيDocument23 pagesالأزمنة في الإنكليزيMoaed KanbarPas encore d'évaluation

- اسئلة تمهيدي انكليزي من 2014 -2020Document114 pagesاسئلة تمهيدي انكليزي من 2014 -2020Moaed KanbarPas encore d'évaluation

- PB AT A4CF1 EngDocument19 pagesPB AT A4CF1 EngMoaed KanbarPas encore d'évaluation

- PB Air Conditioning EngDocument18 pagesPB Air Conditioning EngMoaed KanbarPas encore d'évaluation

- Manual 6488 OTCDocument6 pagesManual 6488 OTCjr100100100% (1)

- PB AT A4CF1 EngDocument19 pagesPB AT A4CF1 EngMoaed KanbarPas encore d'évaluation

- PB Engine Gamma EngDocument14 pagesPB Engine Gamma EngMoaed Kanbar100% (3)

- Denoxtronic PDFDocument29 pagesDenoxtronic PDFanshel100% (2)

- Manual Transmission: (M5/6Cfx-1)Document10 pagesManual Transmission: (M5/6Cfx-1)Moaed Kanbar100% (1)

- PB SRS EngDocument18 pagesPB SRS EngMoaed KanbarPas encore d'évaluation

- In-Vehicle Repair: Timing Drive Components - Hydraulic Chain Tensioner, RHDocument1 pageIn-Vehicle Repair: Timing Drive Components - Hydraulic Chain Tensioner, RHMoaed Kanbar100% (1)

- صمام التمددDocument5 pagesصمام التمددnazar750Pas encore d'évaluation

- PB MDPS EngDocument9 pagesPB MDPS EngMoaed KanbarPas encore d'évaluation

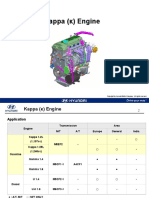

- PB Engine Kappa EngDocument15 pagesPB Engine Kappa EngMoaed Kanbar50% (2)

- PB Engine U-II EngDocument12 pagesPB Engine U-II EngMoaed Kanbar100% (1)

- Acl Pistonproducts Pp99Document275 pagesAcl Pistonproducts Pp99Moaed Kanbar100% (1)

- Mitsubishi Galant 4g63 Engine Repair ManualDocument29 pagesMitsubishi Galant 4g63 Engine Repair ManualMoaed Kanbar100% (1)

- 28-01008 2254-2262 PDFDocument9 pages28-01008 2254-2262 PDFMoaed KanbarPas encore d'évaluation

- Piston Ring Assembly Tips 4strk - Ringinstall2!24!05Document2 pagesPiston Ring Assembly Tips 4strk - Ringinstall2!24!05michaelmangaaPas encore d'évaluation

- SSP 275 Phaeton Air Suspension 3 PDFDocument21 pagesSSP 275 Phaeton Air Suspension 3 PDFMoaed Kanbar0% (1)

- Cross Section F8M F8Q Engine Repair (Motor Diesel F8M F8Q Dacia Papuc Solenza 1307)Document107 pagesCross Section F8M F8Q Engine Repair (Motor Diesel F8M F8Q Dacia Papuc Solenza 1307)bogdanxp2000100% (4)

- VVT-i (Variable Valve Timing-Intelligent) System: GeneralDocument5 pagesVVT-i (Variable Valve Timing-Intelligent) System: GeneralsadiksnmPas encore d'évaluation

- 28-01008 2254-2262 PDFDocument9 pages28-01008 2254-2262 PDFMoaed KanbarPas encore d'évaluation

- 05Document7 pages05Moaed KanbarPas encore d'évaluation

- Variable Valve TimingDocument3 pagesVariable Valve TimingAjay AgarwalPas encore d'évaluation

- Clean and Cool PDFDocument4 pagesClean and Cool PDFMoaed KanbarPas encore d'évaluation

- Continuous Variable Valve Timing (CVVT), FunctionDocument2 pagesContinuous Variable Valve Timing (CVVT), FunctionMoaed KanbarPas encore d'évaluation

- Fuel InjectionDocument37 pagesFuel InjectionBence M ZoltanPas encore d'évaluation

- Variable Valve TimingDocument19 pagesVariable Valve TimingShrigopal PrajapatPas encore d'évaluation

- Eng 2013031916240410Document6 pagesEng 2013031916240410Moaed KanbarPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5782)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Sine and Cosine Functions WorksheetDocument6 pagesSine and Cosine Functions WorksheetManya MPas encore d'évaluation

- ASTM D 3044 - 94 (Reapproved 2000) Shear Modulus of Wood-Based Structural PanelsDocument3 pagesASTM D 3044 - 94 (Reapproved 2000) Shear Modulus of Wood-Based Structural Panelsalin2005Pas encore d'évaluation

- This Study Resource Was: Ran - Shorrer@hks - Harvard.edu Eneida - Rosado@hks - Harvard.eduDocument5 pagesThis Study Resource Was: Ran - Shorrer@hks - Harvard.edu Eneida - Rosado@hks - Harvard.eduTOM ZACHARIASPas encore d'évaluation

- TLEN 5830-AWL Lecture-05Document31 pagesTLEN 5830-AWL Lecture-05Prasanna KoratlaPas encore d'évaluation

- MSCP HND Computing Lo1Document29 pagesMSCP HND Computing Lo1yuulooPas encore d'évaluation

- Giving OpinionsDocument3 pagesGiving OpinionsAndreea BudeanuPas encore d'évaluation

- G17 Comprehensive Detailed Area Plan On Rs Mauza MapDocument1 pageG17 Comprehensive Detailed Area Plan On Rs Mauza MapMd Omor Faruk100% (1)

- Klem Et Al 2022 - Part 5 Rigor in Qualitative ResearchDocument3 pagesKlem Et Al 2022 - Part 5 Rigor in Qualitative ResearchNora ElaPas encore d'évaluation

- Reading Skills Practice: Your Digital Footprint - ExercisesDocument2 pagesReading Skills Practice: Your Digital Footprint - ExercisesagnaldopedroPas encore d'évaluation

- Iron and Steel ReviewDocument2 pagesIron and Steel ReviewSajal SinghPas encore d'évaluation

- Genima 380-385 Parts CatalogueDocument57 pagesGenima 380-385 Parts Cataloguecupid75Pas encore d'évaluation

- WCO - Data Model PDFDocument25 pagesWCO - Data Model PDFCarlos Pires EstrelaPas encore d'évaluation

- Arun GangwarDocument7 pagesArun GangwarArun GangwarPas encore d'évaluation

- Electric Power Distribution - Wikipedia, The Free EncyclopediaDocument3 pagesElectric Power Distribution - Wikipedia, The Free EncyclopediasacuarsPas encore d'évaluation

- Operation: ManualDocument43 pagesOperation: Manualsolmolina20100% (1)

- DbtdihwnaDocument6 pagesDbtdihwnaapi-2522304Pas encore d'évaluation

- Materi TOEFL ListeningDocument29 pagesMateri TOEFL Listeningputra fajarPas encore d'évaluation

- Making A StandDocument22 pagesMaking A StandQueens Nallic Cillan100% (2)

- Ds Esprimo c910 LDocument9 pagesDs Esprimo c910 Lconmar5mPas encore d'évaluation

- INDUSTRIAL VISIT TO ESCORTS TRACTOR ASSEMBLYDocument5 pagesINDUSTRIAL VISIT TO ESCORTS TRACTOR ASSEMBLYShane Khan50% (2)

- Irene Muliawan: Tarumanagara University - Bachelor of Accountancy - Aug 2016 - Jan 2020Document1 pageIrene Muliawan: Tarumanagara University - Bachelor of Accountancy - Aug 2016 - Jan 2020naboyaPas encore d'évaluation

- Genbio 2 Module 1 Genetic Engineering ProcessDocument26 pagesGenbio 2 Module 1 Genetic Engineering Processeaishlil07Pas encore d'évaluation

- Installing A Konica Minolta C220, C280, C360, C452, C652Document3 pagesInstalling A Konica Minolta C220, C280, C360, C452, C652nazerrulPas encore d'évaluation

- SUZ BusaDocument165 pagesSUZ BusaPraveen kumar RPas encore d'évaluation

- Bashar - Abundance IIIDocument3 pagesBashar - Abundance IIIDraco XulPas encore d'évaluation

- 4340 Fracture Toughness PDFDocument22 pages4340 Fracture Toughness PDFGrafton Montgomery0% (1)

- Barangay Clearance2014Document68 pagesBarangay Clearance2014Barangay PangilPas encore d'évaluation

- Subject Link 8 - TGDocument73 pagesSubject Link 8 - TGPi PiPas encore d'évaluation

- PBS 1.1 Quiz Review (Sickels) 23Document158 pagesPBS 1.1 Quiz Review (Sickels) 23tyson.bergsrudPas encore d'évaluation

- Joe Armstrong (Programmer)Document3 pagesJoe Armstrong (Programmer)Robert BonisoloPas encore d'évaluation