Académique Documents

Professionnel Documents

Culture Documents

اجابات الاسئلة

Transféré par

صابرفراج0 évaluation0% ont trouvé ce document utile (0 vote)

10 vues5 pagesBrinell hardness test is widely used for testing metals and nonmetals of low to mediumhardness. In the Rockwell hardness test, a cone-shaped indenter or small-diameter ball is pressed into the specimen. This additional penetration distance d is converted into a Rockwell hardness reading.

Description originale:

Copyright

© © All Rights Reserved

Formats disponibles

DOCX, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentBrinell hardness test is widely used for testing metals and nonmetals of low to mediumhardness. In the Rockwell hardness test, a cone-shaped indenter or small-diameter ball is pressed into the specimen. This additional penetration distance d is converted into a Rockwell hardness reading.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOCX, PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

10 vues5 pagesاجابات الاسئلة

Transféré par

صابرفراجBrinell hardness test is widely used for testing metals and nonmetals of low to mediumhardness. In the Rockwell hardness test, a cone-shaped indenter or small-diameter ball is pressed into the specimen. This additional penetration distance d is converted into a Rockwell hardness reading.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOCX, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 5

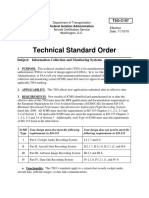

Brinell Hardness Test The Brinell hardness test is widely used for testing metals and

nonmetals of low to mediumhardness. It is named after the Swedish engineerwho developed

it around 1900. In the test, a hardened steel (or cemented carbide) ball of 10-mmdiameter is

pressed into the surface of a specimen using a load of 500, 1500, or 3000 kg. The load is then

divided into the indentation area to obtain the BrinellHardnessNumber (BHN). In equation

form

where HB = Brinell Hardness Number (BHN); F =indentation load, kg; Db =diameter

of the ball, mm; and Di = diameter of the indentation on the surface, mm.

These dimensions are indicated in Figure 3.14(a). The resultingBHNhas units of kg/

mm2, but the units are usually omitted in expressing the number. For harder materials

(above 500 BHN), the cemented carbide ball is used because the steel ball experiences

elastic deformation that compromises the accuracy of the reading. Also, higher loads (1500

and 3000 kg) are typically used for harder materials. Because of differences in results under

different loads, it is considered good practice to indicate the load used in the test when

reporting HB readings.

Rockwell Hardness Test This is another widely used test, named after the metallurgist

who developed it in the early 1920s. It is convenient to use, and several enhancements

over the years have made the test adaptable to a variety of materials.

In the Rockwell Hardness Test, a cone-shaped indenter or small-diameter ball, with

Diameter= 1.6 or 3.2 mm (1/16 or 1/8 in) is pressed into the specimen using a minor load of

10 kg, thus seating the indenter in the material.Then, a major load of 150 kg (or other value) is

applied, causing the indenter to penetrate into the specimen a certain distance beyond its

initial position. This additional penetration distance d is converted into a Rockwell hardness

reading by the testing machine. The sequence is depicted in Figure 3.14(b). Differences in

load and indenter geometry provide various Rockwell scales for differentmaterials.Themost

common scales are indicated in Table 3.5.

Vickers Hardness Test This test, also developed in the early 1920s, uses a pyramidshaped

indentermade of diamond. It is based on the principle that impressionsmade by this

indenter are geometrically similar regardless of load. Accordingly, loads of various size are

applied, depending on the hardness of the material to be measured. The Vickers Hardness

(HV) is then determined from the formula

where F applied load, kg, andD=the diagonal of the impression made by the indenter,

mm, as indicated in Figure 3.14(c).

The Vickers test can be used for all metals and has one of the widest scales among

hardness test

Another difference in melting occurs with noncrystalline materials (glasses). In these

materials, there is a gradual transition fromsolid to liquid states. The solid material gradually

softens as temperature increases, finally becoming liquid at the melting point. During

softening, the material has a consistency of increasing plasticity (increasingly like a fluid)

as it gets closer to the melting point.

Surface Roughness and Surface Finish Surface roughness is a measurable characteristic

based on the roughness deviations as defined in the preceding. Surface finish is a more

subjective term denoting smoothness and general quality of a surface. In popular usage,

surface finish is often used as a synonym for surface roughness.

The most commonly used measure of surface texture is surface roughness. With

respect to Figure 5.15, surface roughness can be defined as the average of the vertical

deviations from the nominal surface over a specified surface length.An arithmetic average

(AA) is generally used, based on the absolute values of the deviations, and this roughness

value is referred to by the name average roughness. In equation form

where Ra = arithmetic mean value of roughness, m (in); y = the vertical deviation from

nominal surface (converted to absolute value),m(in); andLm=the specified distance over

which the surface deviations are measured.

As defined earlier, Steel is an alloy of iron that contains carbon ranging by weight between

0.02% and 2.11% (most steels range between 0.05% and 1.1%C). It often includes other

alloying ingredients, such as manganese, chromium, nickel, and/or molybdenum (see

Table 6.2); but it is the carbon content that turns iron into steel. Hundreds of compositions

of steel are available commercially. For purposes of organization here, the vast majority of

commerciallyimportant steels canbe groupedintothe following categories: (1) plain carbon

steels, (2) low alloy steels, (3) stainless steels, (4) tool steels, and (5) specialty steels.

The precious metals, also called the noble metals because they are chemically inactive,

include silver, gold, and platinum. They are attractive metals, available in limited supply,

and have been used throughout civilized history for coinage and to underwrite paper

The noblemetals (copper, silver, and gold) in column IB

have similar properties. Generally there are correlations in propertiesamongelements within

a given column, whereas differences exist among elements in different columns.

A polymer is a compound consisting of long-chain

molecules, each molecule made up of repeating units connected

together. There may be thousands, even millions of

units in a single polymer molecule. The word is derived from

the Greekwords poly,meaningmany, and meros (reduced to

mer), meaning part.Most polymers are based on carbon and

are therefore considered organic chemicals

Degree of Polymerization and Molecular Weight A macromolecule produced by

polymerization consists of n repeatingmers. Sincemolecules in a given batch of polymerized

material vary in length, n for the batch is an average; its statistical distribution is normal. The

mean value of n is called the degree of polymerization (DP) for the batch. The degree of

polymerization affects the properties of the polymer: higher DP increases mechanical

strength but also increases viscosity in the fluid state, which makes processingmore difficult.

Copolymers Polyethylene is a homopolymer; so are polypropylene, polystyrene, and

many othercommon plastics; theirmolecules consist of repeatingmers that are all the same

type. Copolymers are polymers whose molecules are made of repeating units of two

different types. An example is the copolymer synthesized from ethylene and propylene to

produce a copolymer with elastomeric properties. The ethylene-propylene copolymer

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Pell (2017) - Trends in Real-Time Traffic SimulationDocument8 pagesPell (2017) - Trends in Real-Time Traffic SimulationJorge OchoaPas encore d'évaluation

- DU Series MCCB CatalogueDocument8 pagesDU Series MCCB Cataloguerobinknit2009Pas encore d'évaluation

- Micronet TMRDocument316 pagesMicronet TMRHaithem BrebishPas encore d'évaluation

- Gothic ArchitectureDocument6 pagesGothic ArchitectureleePas encore d'évaluation

- Basler Electric TCCDocument7 pagesBasler Electric TCCGalih Trisna NugrahaPas encore d'évaluation

- Present Perfect Tense ExerciseDocument13 pagesPresent Perfect Tense Exercise39. Nguyễn Đăng QuangPas encore d'évaluation

- 2 Year Spares List For InstrumentationDocument2 pages2 Year Spares List For Instrumentationgudapati9Pas encore d'évaluation

- Heisenberg, "Über Den Anschaulichen Inhalt Der Quantentheoretischen Kinematik Und Mechanik"Document16 pagesHeisenberg, "Über Den Anschaulichen Inhalt Der Quantentheoretischen Kinematik Und Mechanik"Benjamin Crowell0% (1)

- Robbie Hemingway - Text God VIP EbookDocument56 pagesRobbie Hemingway - Text God VIP EbookKylee0% (1)

- SCC5-4000F Single ShaftDocument15 pagesSCC5-4000F Single ShaftudelmarkPas encore d'évaluation

- T Rex PumpDocument4 pagesT Rex PumpWong DaPas encore d'évaluation

- O Repensar Da Fonoaudiologia Na Epistemologia CienDocument5 pagesO Repensar Da Fonoaudiologia Na Epistemologia CienClaudilla L.Pas encore d'évaluation

- Islcollective Present SimpleDocument2 pagesIslcollective Present Simplecrisan mirunaPas encore d'évaluation

- APRStt Implementation Notes PDFDocument36 pagesAPRStt Implementation Notes PDFCT2IWWPas encore d'évaluation

- Forex 1 PDFDocument3 pagesForex 1 PDFChandreshPas encore d'évaluation

- Tso C197Document6 pagesTso C197rdpereirPas encore d'évaluation

- Wits Appraisalnof Jaw Disharmony by JOHNSONDocument20 pagesWits Appraisalnof Jaw Disharmony by JOHNSONDrKamran MominPas encore d'évaluation

- Letter of Acceptfor TDocument3 pagesLetter of Acceptfor TCCSPas encore d'évaluation

- 120 Câu Tìm Từ Đồng Nghĩa-Trái Nghĩa-Dap AnDocument9 pages120 Câu Tìm Từ Đồng Nghĩa-Trái Nghĩa-Dap AnAlex TranPas encore d'évaluation

- Plant Vs Filter by Diana WalstadDocument6 pagesPlant Vs Filter by Diana WalstadaachuPas encore d'évaluation

- Unit: 1: Newton's Laws of Motion & Principle of Transmissibility of ForceDocument5 pagesUnit: 1: Newton's Laws of Motion & Principle of Transmissibility of ForceKunal SinghPas encore d'évaluation

- A Project Report On "A Comparative Study Between Hero Honda Splendor+ and Its Competitors To Increase The Market Share in MUDHOL RegionDocument70 pagesA Project Report On "A Comparative Study Between Hero Honda Splendor+ and Its Competitors To Increase The Market Share in MUDHOL RegionBabasab Patil (Karrisatte)Pas encore d'évaluation

- Computer in Community Pharmacy by Adnan Sarwar ChaudharyDocument10 pagesComputer in Community Pharmacy by Adnan Sarwar ChaudharyDr-Adnan Sarwar Chaudhary100% (1)

- Abacus 1 PDFDocument13 pagesAbacus 1 PDFAli ChababPas encore d'évaluation

- Asme b16.3 (1998) Malleable Iron Threaded FittingsDocument30 pagesAsme b16.3 (1998) Malleable Iron Threaded FittingsMarcos RosenbergPas encore d'évaluation

- PDFDocument3 pagesPDFvaliPas encore d'évaluation

- Choosing An Effective Visual ToolDocument9 pagesChoosing An Effective Visual ToolAdil Bin KhalidPas encore d'évaluation

- Lightolier Lytecaster Downlights Catalog 1984Document68 pagesLightolier Lytecaster Downlights Catalog 1984Alan MastersPas encore d'évaluation

- AREMA Shoring GuidelinesDocument25 pagesAREMA Shoring GuidelinesKCHESTER367% (3)

- Travelstart Ticket (ZA10477979) PDFDocument2 pagesTravelstart Ticket (ZA10477979) PDFMatthew PretoriusPas encore d'évaluation