Académique Documents

Professionnel Documents

Culture Documents

200 4

Transféré par

AhsanJaleelTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

200 4

Transféré par

AhsanJaleelDroits d'auteur :

Formats disponibles

Heat Transfer Products

Taco PF Series Plate and Frame Heat Exchangers are ASME designed and constructed.

Computerized product selection helps you choose the heat exchanger that's just right for

your application. Their compact size and ease of servicing, coupled with Taco dependability,

make the PF Series the perfect choice.

PF Series: Plate & Frame Heat Exchangers

Taco Catalog #200-4

Supersedes: 01/23/09

Effective Date: 09/24/10

Printed in USA

Furnish a TACO plate and frame

heat exchanger to meet the

operating conditions as indicated

in the attached schedule.

The exchanger shall be designed,

constructed and tested in accor-

dance with Section VIII, Division

I of the ASME Pressure Vessel

Code, and shall be code stamped.

Pressure vessels provided for

installation in Canada shall be

marked with the appropriate

CRN number.

Preference will be given to single

pass designs with all system con-

nections to be located on the

face of the fixed cover plate.

The plate and frame heat

exchangers fixed and movable

covers shall be designed to

provide sufficient uniform thick-

ness to withstand all loading.

Stiffeners and welded reinforce-

ments shall not be permitted.

Any plate within the exchangers

plate pack shall be replaceable

without the need to remove

other plates.

A roller bearing shall be provided

on the movable cover for all units

with port sizes 3" or larger. The

frame assembly shall be of bolted

construction. Welding to the

pressure retaining components is

not permitted. The frame assembly

design shall allow the addition

of a minimum of 10% additional

plates.

Each plate shall be pressed from

a homogenous metal sheet in

one step. Each plate channel

shall be designed to allow full

design pressure on one side with

no pressure on the adjacent

plate channel. Contact between

adjacent plates is required to

optimize structural integrity and

elimination of vibration.

Gaskets shall be designed to indi-

cate leakage across the sealing

gaskets prior to the intermixing

of fluids.

The suspension and guidance

method in the design of the

plates, frame, carrying and

guide bars shall mechanically

align the plates during tightening.

Gasket surfaces shall be used for

sealing not for plate alignment.

The carrying and guide bar sur-

faces in contact with the plate

pack shall be stainless

steel. All other carbon steel sur-

faces except the bolts shall be

epoxy painted.

An aluminum or optional 304

stainless steel OSHA shroud

could be provided.

A comprehensive operations and

maintenance manual and ASME

nameplate shall be attached on

the face of the fixed cover.

Connections less than or equal

to 2-inch shall be NPT type.

Connections larger than 2-inch

shall be of studded port design.

Each studded port shall be lined

with a fluid compatible material

to prevent process fluid from

coming in contact with the

painted cover.

The exchanger shall be hydro-

staticly tested in accordance with

the requirements of the ASME

Code Section VIII Div 1, para.

UG-99.

A computer generated submittal

and specification sheet indicating

the criteria used in each units

selection shall be submitted for

approval.

Applications

Economizer free cooling; ground source heat pumps; ground water cooling;

water source heat pump freeze protection isolation; campus (district)

heating and cooling; industrial processes; and pressure zone isolation.

TACO PF Series: Plate and Frame Heat Exchanger Specification

1. Frame Plate

(Fixed Plate)

2. Pressure Plate

(Movable Plate)

3. Support Column

4. Upper Carry Bar

5. Lower Guide Bar

6. Pressure Plate Roller

7. Tightening Bolt

8. Fixing Screws

9. Rubber or Metal Liners

10. Heat Transfer Plates

11. Gaskets

A

A

B

B

C

C

D

D

E E

L

L

Glue-Free Gaskets

Glue-free gaskets offer fast and

easy gasket replacement on site.

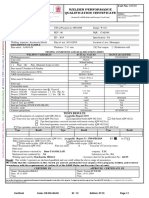

Unit Type A B C D E L

Maximum #

of Plates

Port

Size

Maximum

Flow

(GPM)

Maximum

Surface Area

(Sq. Ft.)

PF05 18.2 6.3 13.3 3.4 3.4 23.7 150 1" --- 54 65

PF09 31.5 6.3 26.6 3.4 3.4 23.7 150 1" --- 54 129

PF10 29.8 12.3 19.4 5.0 6.0 59.0 250 2" --- 220 269

PF16 37.7 12.3 27.3 5.0 6.0 59.0 250 2" --- 220 430

PF22 45.6 12.3 35.2 5.0 6.0 59.0 250 2" --- 220 565

PF19 43.3 17.6 25.6 8.0 8.4 118.0 350 3" --- 484 716

PF205 46.2 18.5 28.3 8.9 8.6 98.5 450 3" 4" 858 1017

PF31 53.2 18.5 35.2 8.9 8.7 118.0 600 3" 4" 858 1937

PF40 62.8 18.5 44.9 8.9 8.5 118.0 600 3" 4" 858 2581

PF50 72.5 18.5 54.6 8.9 8.6 118.0 600 3" 4" 858 3229

PF71 91.3 18.5 74.1 8.9 8.6 118.0 600 3" 4" 858 4521

PF41/42 59.6 24.6 37.1 11.4 10.3 157.5 700 6" --- 1897 3011

PF60/62 73.8 24.6 51.4 11.4 10.2 157.5 700 6" --- 1897 4521

PF80/82 88.2 24.6 65.8 11.4 10.2 157.5 700 6" --- 1897 6027

PF112 108.2 24.6 84.9 11.4 11.0 157.5 700 6" --- 1897 9042

PF70 69.6 30.3 44.5 15.6 12.4 157.5 750 8" --- 3210 5651

PF100 83.8 30.4 58.7 15.6 12.4 157.5 750 8" --- 3210 8073

PF130 98.2 30.3 72.9 15.6 12.7 157.5 750 8" --- 3210 10495

PF120 92.0 45.6 58.7 18.9 14.5 168.5 700 12" --- 7163 9042

PF160 106.7 45.6 73.9 18.9 14.5 168.5 700 12" --- 7163 12055

PF190 121.8 45.6 89.3 18.9 14.5 168.5 700 12" --- 7163 14316

* Plate Pack tightening dimension varies with number of plates.

This value is provided within selection program output

Frame Designs & Operating Pressures: 150 PSI & 300 PSI

Materials: 304SS & 316SS

Standard & High Temperature Gaskets: Nitrile & EPDM

These dimensions may be subject to change

Clip-on Snap-on

PF Series: Plate & Frame Heat Exchanger

Specification Sheet

Taco Inc., 1160 Cranston Street. Cranston, RI 02920 / (401) 942-8000 / Fax (401) 942-2360

Taco (Canada) Ltd., 8450 Lawson Road, Unit #3, Milton, Ontario L9T 0J8 / (905) 564-9422 / Fax (905) 564-9436

www.taco-hvac.com

For sizing assistance please fax to your local

Taco representative or Taco Engineering

directly at (508) 674-5932.

Bold areas should be completed to provide design calculations.

. o N b o J r u o Y r e m o t s u C . 1

. o N e c n e r e f e R r u o Y s s e r d d A . 2

Our Inquiry No.

e t a D n o i t a c o L t n a l P . 3

. o N m e t I t i n U f o e c i v r e S . 4

n I d e t c e n n o C d q R . h c x E f o . o N e p y T . 5

6. Total Surface ft.

2

Surface/Exch. ft.

2

e d i S d l o C e d i S t o H e c n a m r o f r e P d e e t n a r a u G

7. Fluid Circulated

8. Total Fluid Entering

9. Vapor

10. Liquid

11. Steam

12. Non-Condensables

13. Fluid Vaporized or Condensed

*

14. Steam Condensed

15. Physical Property Data Temp. F

16. Specific Heat BTU/lb. F

17. Specific Gravity

18. Thermal Conductivity BTU/lb. ft.F

19. p C y t i s o c s i V

20. Latent Heat Vapors BTU/lb.

21. Non-Newtonian k/n

22. Molecular Weight

23. Temperature In F

24. Temperature Out F

25. Operating Pressure Psig

26. Max.Allow. Pressure Drop Psig

27. Thermal Margin %

F : D T M L . r H / U T B : d e g n a h c x E t a e H . 8 2

*

For two-phase duties, also provide either condensing curve or vapor pressure data.

Construction

g i s P : e r u s s e r P t s e T g i s P e r u s s e r P n g i s e D . 9 2

: l a i r e t a M n o i t c e n n o C F e r u t a r e p m e T n g i s e D . 0 3

- A S : l e e t S n o b r a C l a i r e t a M s r e v o C : s t e k s a G - l a i r e t a M . 1 3

: l a i r e t a M t l o B g n i n e t h g i T : s e t a l P - l a i r e t a M . 2 3

: l a i r e t a M r a B e d i u G : l a i r e t a M r a B g n i y r r a C . 3 3

Remarks:

/ / / /

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Peugeot 408 Press Info EnglishDocument19 pagesPeugeot 408 Press Info Englishanthonykylim100% (1)

- C Rollway PDFDocument16 pagesC Rollway PDFoxonoerPas encore d'évaluation

- Cpi Gtr50 Service ManualDocument43 pagesCpi Gtr50 Service ManualKlara PataiPas encore d'évaluation

- Stability-Calculation For PipelineDocument2 pagesStability-Calculation For PipelineGeorge100% (1)

- SSC 350 Ship Vibration Design GuideDocument343 pagesSSC 350 Ship Vibration Design GuideKelvin Xu100% (1)

- Rotary Valve Functions BookletDocument17 pagesRotary Valve Functions Bookletamahmoud3Pas encore d'évaluation

- United States Patent (10) Patent No.: US 6,293,107 B1: Kitagawa Et Al. (45) Date of Patent: Sep. 25, 2001Document19 pagesUnited States Patent (10) Patent No.: US 6,293,107 B1: Kitagawa Et Al. (45) Date of Patent: Sep. 25, 2001Burak PalaPas encore d'évaluation

- Rolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 73-20-01Document6 pagesRolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 73-20-01anony81030% (1)

- Steam InjectorDocument5 pagesSteam InjectorJannel TobongbanuaPas encore d'évaluation

- Manual-Auto Grease System 自动打黄油操作手册Document10 pagesManual-Auto Grease System 自动打黄油操作手册Khowchae KunapatPas encore d'évaluation

- Composite Materials (Collection of Previous Final Exam) 110863Document8 pagesComposite Materials (Collection of Previous Final Exam) 110863habba3Pas encore d'évaluation

- MGT Turbec t100 CCDocument28 pagesMGT Turbec t100 CCDk DamoPas encore d'évaluation

- Atif Baig (22467), Lal Chand (21591) Abdul Hannan (21618 Alveena (21651)Document1 pageAtif Baig (22467), Lal Chand (21591) Abdul Hannan (21618 Alveena (21651)Lal ChandPas encore d'évaluation

- J54-100 Parte1Document45 pagesJ54-100 Parte1angel gabriel perez valdezPas encore d'évaluation

- Illustrated Parts Catalogue: Oi IsDocument40 pagesIllustrated Parts Catalogue: Oi IsDarren-Edward O'NeillPas encore d'évaluation

- Comparative Cost Analysis - MechanicalDocument1 pageComparative Cost Analysis - MechanicalRayley Daven SusiPas encore d'évaluation

- CWCH4IN Instal Manual WebDocument39 pagesCWCH4IN Instal Manual WebEnrique ScibiliaPas encore d'évaluation

- BE Specs VG1000 M9000 TableDocument3 pagesBE Specs VG1000 M9000 TableKumar sssssPas encore d'évaluation

- Assignment Synchronous Generator and Induction MotorDocument20 pagesAssignment Synchronous Generator and Induction MotorSyahril Abdullah100% (1)

- TK2203 - 2nd AssignmentDocument2 pagesTK2203 - 2nd Assignmentharris fikrenPas encore d'évaluation

- Chapter 2 - Lubrication (Added)Document32 pagesChapter 2 - Lubrication (Added)Najip TalibinPas encore d'évaluation

- Agf' R Pack: With S IserDocument4 pagesAgf' R Pack: With S IseralbertoPas encore d'évaluation

- Physics 1st Year Full BookDocument3 pagesPhysics 1st Year Full BookMukhtar AhmedPas encore d'évaluation

- 183-19 Wpqc-W162-6''-Asme XiDocument1 page183-19 Wpqc-W162-6''-Asme Xibouchoucha jebaliPas encore d'évaluation

- Thermodynamics ProjectDocument4 pagesThermodynamics Projectapi-352243139Pas encore d'évaluation

- Mechanics of Fluids 5th Edition Potter Wiggert Ramadan Test BankDocument12 pagesMechanics of Fluids 5th Edition Potter Wiggert Ramadan Test Banklynn100% (15)

- Presentation 1Document44 pagesPresentation 1Adugna GosaPas encore d'évaluation

- 01 Hazim Awbi (University of Reading) Basic Concepts For Natural Ventilation of Buildings PDFDocument38 pages01 Hazim Awbi (University of Reading) Basic Concepts For Natural Ventilation of Buildings PDFSamiYousifPas encore d'évaluation

- Introduction and TheoryDocument2 pagesIntroduction and TheoryAhmad NajibPas encore d'évaluation

- Questions & Answers On Synchronous Machine StabilityDocument20 pagesQuestions & Answers On Synchronous Machine Stabilitykibrom atsbha50% (2)