Académique Documents

Professionnel Documents

Culture Documents

Specific Gravity Determination: 3.1 Purpose

Transféré par

Yellaturi Siva Kishore Reddy0 évaluation0% ont trouvé ce document utile (0 vote)

32 vues10 pagesThe specific gravity of a soil is used in the phase relationship of air, water, and solids in a given volume of the soil. The Liquid Limit (LL) is arbitrarily defined as the water content, in percent, at which a pat of soil in a standard cup and cut by a groove of standard dimensions will flow together at the base of the groove for a distance of 13 mm (1 / 2 in.) when subjected to 25 shocks from the cup being dropped 10 mm in

Description originale:

Titre original

Chapter-4

Copyright

© © All Rights Reserved

Formats disponibles

DOCX, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentThe specific gravity of a soil is used in the phase relationship of air, water, and solids in a given volume of the soil. The Liquid Limit (LL) is arbitrarily defined as the water content, in percent, at which a pat of soil in a standard cup and cut by a groove of standard dimensions will flow together at the base of the groove for a distance of 13 mm (1 / 2 in.) when subjected to 25 shocks from the cup being dropped 10 mm in

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOCX, PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

32 vues10 pagesSpecific Gravity Determination: 3.1 Purpose

Transféré par

Yellaturi Siva Kishore ReddyThe specific gravity of a soil is used in the phase relationship of air, water, and solids in a given volume of the soil. The Liquid Limit (LL) is arbitrarily defined as the water content, in percent, at which a pat of soil in a standard cup and cut by a groove of standard dimensions will flow together at the base of the groove for a distance of 13 mm (1 / 2 in.) when subjected to 25 shocks from the cup being dropped 10 mm in

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOCX, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 10

Assessment of Soil Stabilization Using Fly Ash and Rice Husk Ash

DEPARTMENT OF CIVIL ENGINEERING Page 26 SVIST,KADAPA(YSR)

3. SPECIFIC GRAVITY DETERMINATION

3.1 Purpose:

This lab is performed to determine the specific gravity of soil by using a

pycnometer. Specific gravity is the ratio of the mass of unit volume of soil at a stated

temperature to the mass of the same volume of gas-free distilled water at a stated

temperature. Standard Reference:

ASTM D 854-00 Standard Test for Specific Gravity of Soil Solids by Water

Pycnometer.

3.1.1 Significance:

The specific gravity of a soil is used in the phase relationship of air, water, and

solids in a given volume of the soil.

3.1.2 Equipment:

Pycnometer, Balance, Vacuum pump, Funnel, Spoon. Engineering Properties of

Soils Based on Laboratory Testing

Assessment of Soil Stabilization Using Fly Ash and Rice Husk Ash

DEPARTMENT OF CIVIL ENGINEERING Page 27 SVIST,KADAPA(YSR)

3.1.4 Test Procedure:

(1) Determine and record the weight of the empty clean and dry

pycnometer, W

(2) Place 10g of a dry soil sample (passed through the sieve No. 10) in the pycnometer.

Determine and record the weight of the pycnometer containing the dry soil, W

(3) Add distilled water to fill about half to three-fourth of the pycnometer. Soak the

sample for 10 minutes.

(4) Apply a partial vacuum to the contents for 10 minutes, to remove the entrapped air.

3.2 ATTERBERG LIMITS

3.2.1Purpose:

This lab is performed to determine the plastic and liquid limits of a fine-grained

soil. The liquid limit (LL) is arbitrarily defined as the water content, in percent, at which

a pat of soil in a standard cup and cut by a groove of standard dimensions will flow

together at the base of the groove for a distance of 13 mm (1/2 in.) when subjected to 25

shocks from the cup being dropped 10 mm in a standard liquid limit apparatus operated at

a rate of two shocks per second. The plastic limit (PL) is the water content, in percent, at

which a soil can no longer be deformed by rolling into 3.2 mm (1/8 in.) diameter threads

without crumbling.

Standard Reference:

ASTM D 4318 - Standard Test Method for Liquid Limit, Plastic Limit, and

Plasticity Index of Soils

Assessment of Soil Stabilization Using Fly Ash and Rice Husk Ash

DEPARTMENT OF CIVIL ENGINEERING Page 28 SVIST,KADAPA(YSR)

3.2.2 Significance:

The Swedish soil scientist Albert Atterberg originally defined seven limits of

consistency to classify fine-grained soils, but in current engineering practice only two of

the limits, the liquid and plastic limits, are commonly used. (A third limit, called the

shrinkage limit, is used occasionally.) The Atterberg limits are based on the moisture

content of the soil. The plastic limit is the moisture content that defines where the soil

changes from a semi-solid to a plastic (flexible) state. The liquid limit is the moisture

content that defines where the soil changes from a plastic to a viscous fluid state. The

shrinkage limit is the moisture content that defines where the soil volume will not reduce

further if the moisture content is reduced. A wide variety of soil engineering properties

have been correlated to the liquid and plastic limits, and these Atterberg limits are also

used to classify a fine-grained soil according to the Unified Soil Classification system or

AASHTO system.

3.2.3 Equipment:

Liquid limit device, Porcelain (evaporating) dish, Flat grooving tool with gage,

Eight moisture cans, Balance, Glass plate, Spatula, Wash bottle filled with distilled water,

Drying oven set at 105C.

Assessment of Soil Stabilization Using Fly Ash and Rice Husk Ash

DEPARTMENT OF CIVIL ENGINEERING Page 29 SVIST,KADAPA(YSR)

Assessment of Soil Stabilization Using Fly Ash and Rice Husk Ash

DEPARTMENT OF CIVIL ENGINEERING Page 30 SVIST,KADAPA(YSR)

Assessment of Soil Stabilization Using Fly Ash and Rice Husk Ash

DEPARTMENT OF CIVIL ENGINEERING Page 31 SVIST,KADAPA(YSR)

3.4.4 Test Procedure:

Liquid Limit:

(1) Take roughly 3/4 of the soil and place it into the porcelain dish. Assume

that the soil was previously passed though a No. 40 sieve, air-dried, and then pulverized.

Thoroughly mix the soil with a small amount of distilled water until it appears as a

smooth uniform paste. Cover the dish with cellophane to prevent moisture from escaping.

(2) Weigh four of the empty moisture cans with their lids, and record the

respective weights and can numbers on the data sheet.

(3) Adjust the liquid limit apparatus by checking the height of drop of the cup.

The point on the cup that comes in contact with the base should rise to a height of 10

Assessment of Soil Stabilization Using Fly Ash and Rice Husk Ash

DEPARTMENT OF CIVIL ENGINEERING Page 32 SVIST,KADAPA(YSR)

mm. The block on the end of the grooving tool is 10 mm high and should be used as a

gage. Practice using the cup and determine the correct rate to rotate the crank so that the

cup drops approximately two times per second.

(4) Place a portion of the previously mixed soil into the cup of the liquid limit

apparatus at the point where the cup rests on the base. Squeeze the soil down to eliminate

air pockets and spread it into the cup to a depth of about 10 mm at its deepest point. The

soil pat should form an approximately horizontal surface (See Photo B).

(5) Use the grooving tool carefully cut a clean straight groove down the center

of the cup. The tool should remain perpendicular to the surface of the cup as groove is

being made. Use extreme care to prevent sliding the soil relative to the surface of the cup

(See Photo C).

(6) Make sure that the base of the apparatus below the cup and the underside

of the cup is clean of soil. Turn the crank of the apparatus at a rate of approximately two

drops per second and count the number of drops, N, it takes to make the two halves of the

soil pat come into contact at the bottom of the groove along a distance of 13 mm (1/2 in.)

(See Photo D). If the number of drops exceeds 50, then go directly to step eight and do

not record the number of drops, otherwise, record the number of drops on the data sheet.

(7) Take a sample, using the spatula, from edge to edge of the soil pat. The

sample should include the soil on both sides of where the groove came into contact. Place

the soil into a moisture can cover it. Immediately weigh the moisture can containing the

soil, record its mass, remove the lid, and place the can into the oven. Leave the moisture

can in the oven for at least 16 hours. Place the soil remaining in the cup into the porcelain

dish. Clean and dry the cup on the apparatus and the grooving tool.

Assessment of Soil Stabilization Using Fly Ash and Rice Husk Ash

DEPARTMENT OF CIVIL ENGINEERING Page 33 SVIST,KADAPA(YSR)

(8) Remix the entire soil specimen in the porcelain dish. Add a small amount

of distilled water to increase the water content so that the number of drops required to

close the groove decrease.

(9) Repeat steps six, seven, and eight for at least two additional trials

producing successively lower numbers of drops to close the groove. One of the trials

shall be for a closure requiring 25 to 35 drops, one for closure between 20 and 30 drops,

and one trial for a closure requiring 15 to 25 drops. Determine the water content from

each trial by using the same method used in the first laboratory. Remember to use the

same balance for all weighing.

Plastic Limit:

(1) Weigh the remaining empty moisture cans with their lids, and record the

respective weights and can numbers on the data sheet.

(2) Take the remaining 1/4 of the original soil sample and add distilled water until the

soil is at a consistency where it can be rolled without sticking to the hands.

(3) Form the soil into an ellipsoidal mass (See Photo F). Roll the mass between the

palm or the fingers and the glass plate (See Photo G). Use sufficient pressure to

roll the mass into a thread of uniform diameter by using about 90 strokes per

minute. (A stroke is one complete motion of the hand forward and back to the

starting position.) The thread shall be deformed so that its diameter reaches 3.2

mm (1/8 in.), taking no more than two minutes.

(4) When the diameter of the thread reaches the correct diameter, break the thread

into several pieces. Knead and reform the pieces into ellipsoidal masses and re-

roll them. Continue this alternate rolling, gathering together, kneading and re-

Assessment of Soil Stabilization Using Fly Ash and Rice Husk Ash

DEPARTMENT OF CIVIL ENGINEERING Page 34 SVIST,KADAPA(YSR)

rolling until the thread crumbles under the pressure required for rolling and can no

longer be rolled into a 3.2 mm diameter thread (See Photo H).

(5) Gather the portions of the crumbled thread together and place the soil into a

moisture can, then cover it. If the can does not contain at least 6 grams of soil, add

soil to the can from the next trial (See Step 6). Immediately weigh the moisture

can containing the soil, record its mass, remove the lid, and place the can into the

oven. Leave the moisture can in the oven for at least 16 hours.

(6) Repeat steps three, four, and five at least two more times. Determine the water

content from each trial by using the same method used in the first laboratory.

Remember to use the same balance for all weighing.

Liquid Limit:

(1) Calculate the water content of each of the liquid limit moisture cans after they

have been in the oven for at least 16 hours.

(2) Plot the number of drops, N, (on the log scale) versus the water content (w). Draw

the best-fit straight line through the plotted points and determine the liquid limit

(LL) as the water content at 25 drops.

Plastic Limit:

(1) Calculate the water content of each of the plastic limit moisture cans after they

have been in the oven for at least 16 hours.

(2) Compute the average of the water contents to determine the plastic limit, PL.

Check to see if the difference between the water contents is greater than the

acceptable range of two results (2.6 %).

Assessment of Soil Stabilization Using Fly Ash and Rice Husk Ash

DEPARTMENT OF CIVIL ENGINEERING Page 35 SVIST,KADAPA(YSR)

(3) Calculate the plasticity index, PI=LL-PL. Report the liquid limit, plastic limit,

and plasticity index to the nearest whole number, omitting the percent

designation.

Vous aimerez peut-être aussi

- The Chemistry of Soils - Including Information on Acidity, Nitrification, Lime Requirements and Many Other Aspects of Soil ChemistryD'EverandThe Chemistry of Soils - Including Information on Acidity, Nitrification, Lime Requirements and Many Other Aspects of Soil ChemistryÉvaluation : 4 sur 5 étoiles4/5 (1)

- Scientific American Supplement, No. 446, July 19, 1884D'EverandScientific American Supplement, No. 446, July 19, 1884Pas encore d'évaluation

- Purpose: Experiment No. Atterberg Limit TestDocument4 pagesPurpose: Experiment No. Atterberg Limit TestOpu DebnathPas encore d'évaluation

- Lab2 SUGDANDocument15 pagesLab2 SUGDANKi KiethPas encore d'évaluation

- CARLDocument10 pagesCARLMohamed MoralesPas encore d'évaluation

- Experiment 7-Atterberg LimitsDocument14 pagesExperiment 7-Atterberg LimitsJack RasalPas encore d'évaluation

- Experiment 4 Atterberg Limits DeterminationDocument6 pagesExperiment 4 Atterberg Limits DeterminationZakirul Aslam ChowdhuryPas encore d'évaluation

- Experiment Atterberg Limits: PurposeDocument8 pagesExperiment Atterberg Limits: PurposefoidsPas encore d'évaluation

- Atterberg Limits: Aim: To Determine The Shrinkage, Plastic and Liquid Limits of A Fine Grained Soil. TheoryDocument13 pagesAtterberg Limits: Aim: To Determine The Shrinkage, Plastic and Liquid Limits of A Fine Grained Soil. TheorysouravPas encore d'évaluation

- Atterberg Limits TestDocument9 pagesAtterberg Limits Testzainjoiya100% (1)

- AtterbergeDocument5 pagesAtterbergebiruk melesePas encore d'évaluation

- LL & PLDocument6 pagesLL & PLSougata DasPas encore d'évaluation

- Liquid Limit and Plastic LimitDocument6 pagesLiquid Limit and Plastic LimitSHIVANSH BAGHELPas encore d'évaluation

- Geotech Lab ReportDocument23 pagesGeotech Lab ReportNtsika SokasiPas encore d'évaluation

- Soil Mechanics - Lab - 2015-2016م. رنا محمد PDFDocument75 pagesSoil Mechanics - Lab - 2015-2016م. رنا محمد PDFAhmed SuhailPas encore d'évaluation

- Liquid Limit and Plastic LimitDocument18 pagesLiquid Limit and Plastic Limitmathirenga88Pas encore d'évaluation

- 84 039 Liquid Limit ASTM D423 66Document6 pages84 039 Liquid Limit ASTM D423 66Haftari HarmiPas encore d'évaluation

- Job #4: Determination of Atterberg Limits: SignificanceDocument6 pagesJob #4: Determination of Atterberg Limits: Significancesimply greenPas encore d'évaluation

- Soil Classification Test: Determination of Liquid Limit and Plastic LimitDocument11 pagesSoil Classification Test: Determination of Liquid Limit and Plastic LimitEver SimPas encore d'évaluation

- Laboratory Testing Manual: Soil Mechanic S TestingDocument40 pagesLaboratory Testing Manual: Soil Mechanic S TestingMatthew PagulayanPas encore d'évaluation

- Chapter-3 Methodology of TestingDocument25 pagesChapter-3 Methodology of TestingGampa Vamshi KrishnaPas encore d'évaluation

- Atterberg Limits PDFDocument10 pagesAtterberg Limits PDFcamillelelePas encore d'évaluation

- Determination of Liquid Limit and Plastic LimitDocument12 pagesDetermination of Liquid Limit and Plastic LimitEver Sim100% (2)

- Total Modified FilesDocument87 pagesTotal Modified FilesHala SaadPas encore d'évaluation

- Atterberg Limit ExperimentDocument6 pagesAtterberg Limit ExperimentsaravananveranPas encore d'évaluation

- Test and ProceduresDocument12 pagesTest and ProceduresSven RayPas encore d'évaluation

- Ce 210 L Expt 03 Consistency LimitsDocument6 pagesCe 210 L Expt 03 Consistency LimitsheidibguerraPas encore d'évaluation

- Soil Mechanics - Compaction TestDocument12 pagesSoil Mechanics - Compaction TestSaif SulemanPas encore d'évaluation

- Catarungan - Lab Report 5Document3 pagesCatarungan - Lab Report 5kyle catarunganPas encore d'évaluation

- Atterberg Limit TestDocument6 pagesAtterberg Limit Testameenazhar2020Pas encore d'évaluation

- Laboratory Test No.8Document6 pagesLaboratory Test No.8ENAD, Angeline Isabelle C.Pas encore d'évaluation

- 1) List of Unit in GTEDocument9 pages1) List of Unit in GTES GOPas encore d'évaluation

- Project On Soil TestingDocument33 pagesProject On Soil TestingVinayPawar67% (3)

- Atterberg Limit AstmDocument22 pagesAtterberg Limit Astmsitti.aPas encore d'évaluation

- Lab2 IntroductionDocument5 pagesLab2 IntroductionEngr Ghulam MustafaPas encore d'évaluation

- Atterberg Limits TestDocument11 pagesAtterberg Limits TestUTKARSH MEENA 16110171Pas encore d'évaluation

- Lab Sheet - Atterberg LimitsDocument6 pagesLab Sheet - Atterberg LimitsLuqman YusofPas encore d'évaluation

- Operation Manual Liquid Limit DeviceDocument4 pagesOperation Manual Liquid Limit DeviceOkello StevenPas encore d'évaluation

- Extracted 10CVL67 Geotechnical-Engineering LAB PDFDocument7 pagesExtracted 10CVL67 Geotechnical-Engineering LAB PDFPaul TilichPas encore d'évaluation

- New Microsoft Word DocumentDocument2 pagesNew Microsoft Word DocumentaltheajanelawagonPas encore d'évaluation

- Lab Report Sample FormatDocument8 pagesLab Report Sample FormatAlexis RoguelPas encore d'évaluation

- Atter Berg LimitsDocument3 pagesAtter Berg Limitssunleon31Pas encore d'évaluation

- LL3 OdtDocument15 pagesLL3 OdtFatin NajwaPas encore d'évaluation

- Soil Presentation K.a.shah 25-11-2015Document39 pagesSoil Presentation K.a.shah 25-11-2015krunalshah1987Pas encore d'évaluation

- 6.0 Test Procedure - Liquid LimitDocument2 pages6.0 Test Procedure - Liquid LimitsowmyaPas encore d'évaluation

- Plastic LimitDocument7 pagesPlastic LimitRajat KotwalPas encore d'évaluation

- Standard Proctor Compaction Test ObjectiveDocument3 pagesStandard Proctor Compaction Test ObjectiveDhirendraPas encore d'évaluation

- Lab Plastic LimitDocument17 pagesLab Plastic LimitnurulselangorPas encore d'évaluation

- تقرير تحديد الكثافة والحدل للتربةDocument16 pagesتقرير تحديد الكثافة والحدل للتربةEng.AhmedShamkhiPas encore d'évaluation

- Atterberg Limit TestDocument11 pagesAtterberg Limit TestisharanaveenPas encore d'évaluation

- CE 162 LAB #4 ATTERBERG LIMITS: Liquid Limit, Plastic Limit, and Plasticity Index of SoilsDocument12 pagesCE 162 LAB #4 ATTERBERG LIMITS: Liquid Limit, Plastic Limit, and Plasticity Index of SoilsAngel Umali Gacutan86% (14)

- Moisture Content-Unit Weight Relationship (Compaction Test: Soil Mechanics Laboratory Tests Experiment No. 7Document6 pagesMoisture Content-Unit Weight Relationship (Compaction Test: Soil Mechanics Laboratory Tests Experiment No. 7Mohamad DuhokiPas encore d'évaluation

- Compaction Test PDFDocument6 pagesCompaction Test PDFACTION plusPas encore d'évaluation

- Atterberg LimitDocument8 pagesAtterberg LimitSalem AlbarkiPas encore d'évaluation

- Atterberg Limit Lab 1Document6 pagesAtterberg Limit Lab 1Akeel Marcel DixonPas encore d'évaluation

- Experiment No. 3: University of The East - Caloocan College of Engineering Civil Engineering DepartmentDocument6 pagesExperiment No. 3: University of The East - Caloocan College of Engineering Civil Engineering DepartmentJHONRUSSEL ANTONIOPas encore d'évaluation

- Alibin, Marie Fe P.-bscE 4A-Geotech-Laboratory 3Document7 pagesAlibin, Marie Fe P.-bscE 4A-Geotech-Laboratory 3Marie Fe alibinPas encore d'évaluation

- Draining for Profit, and Draining for HealthD'EverandDraining for Profit, and Draining for HealthPas encore d'évaluation

- Project Report On Job Satisfaction by KishoreDocument83 pagesProject Report On Job Satisfaction by KishoreYellaturi Siva Kishore ReddyPas encore d'évaluation

- Certificate of CompletionDocument1 pageCertificate of CompletionYellaturi Siva Kishore ReddyPas encore d'évaluation

- 133271994-Web-Technologies & E-CommersDocument93 pages133271994-Web-Technologies & E-CommersYellaturi Siva Kishore ReddyPas encore d'évaluation

- Certificate: Dula Lakshumma Memorial College of Engineering For WomenDocument2 pagesCertificate: Dula Lakshumma Memorial College of Engineering For WomenYellaturi Siva Kishore ReddyPas encore d'évaluation

- Xerox Legal Xerox Scanning Print Lamination A4 Color Xerox Text Color Xerox Image Spiral Binding Minimum Internet Charge InternetDocument1 pageXerox Legal Xerox Scanning Print Lamination A4 Color Xerox Text Color Xerox Image Spiral Binding Minimum Internet Charge InternetYellaturi Siva Kishore ReddyPas encore d'évaluation

- Abstract:: Embedded System in Embedded SystemDocument7 pagesAbstract:: Embedded System in Embedded SystemYellaturi Siva Kishore ReddyPas encore d'évaluation

- Certificate: Dula Lakshumma Memorial College of Engineering For WomenDocument2 pagesCertificate: Dula Lakshumma Memorial College of Engineering For WomenYellaturi Siva Kishore ReddyPas encore d'évaluation

- RC Cool PDFDocument15 pagesRC Cool PDFYellaturi Siva Kishore ReddyPas encore d'évaluation

- Bachelor of Technology: Under Water Wireless CommunicationDocument7 pagesBachelor of Technology: Under Water Wireless CommunicationYellaturi Siva Kishore ReddyPas encore d'évaluation

- Communication System Without FibersDocument16 pagesCommunication System Without FibersYellaturi Siva Kishore ReddyPas encore d'évaluation

- Automotive Embedded Systems PDFDocument46 pagesAutomotive Embedded Systems PDFYellaturi Siva Kishore ReddyPas encore d'évaluation

- Virtual Memory: A) Processes A) Oldest Page Is ChosenDocument6 pagesVirtual Memory: A) Processes A) Oldest Page Is ChosenYellaturi Siva Kishore ReddyPas encore d'évaluation

- 3D Display: WithoutDocument18 pages3D Display: WithoutYellaturi Siva Kishore ReddyPas encore d'évaluation

- PORUMAMILLADocument16 pagesPORUMAMILLAYellaturi Siva Kishore ReddyPas encore d'évaluation

- VONTIMITTADocument8 pagesVONTIMITTAYellaturi Siva Kishore ReddyPas encore d'évaluation

- Kadapa Kishore Reddy S.noDocument8 pagesKadapa Kishore Reddy S.noYellaturi Siva Kishore ReddyPas encore d'évaluation

- Vemula Mandal: Rank Result NameDocument3 pagesVemula Mandal: Rank Result NameYellaturi Siva Kishore ReddyPas encore d'évaluation

- PLV DataDocument15 pagesPLV DataYellaturi Siva Kishore ReddyPas encore d'évaluation

- SIDHOUTDocument8 pagesSIDHOUTYellaturi Siva Kishore ReddyPas encore d'évaluation

- MYDUKURDocument12 pagesMYDUKURYellaturi Siva Kishore ReddyPas encore d'évaluation

- Eamcet Data 2015Document107 pagesEamcet Data 2015Yellaturi Siva Kishore ReddyPas encore d'évaluation

- Experimental Study On Reproductive Effect of Phalagritha in Normal and D.E.S (Diethylstilbestrol) Treated Female Albino RatsDocument14 pagesExperimental Study On Reproductive Effect of Phalagritha in Normal and D.E.S (Diethylstilbestrol) Treated Female Albino RatsYellaturi Siva Kishore ReddyPas encore d'évaluation

- Trained Applicator : M.Sreenivasu Level - IiDocument1 pageTrained Applicator : M.Sreenivasu Level - IiYellaturi Siva Kishore ReddyPas encore d'évaluation

- Roff Quot Applicator Malli-KadapaDocument5 pagesRoff Quot Applicator Malli-KadapaYellaturi Siva Kishore ReddyPas encore d'évaluation

- KDE11SSDocument2 pagesKDE11SSluisgomezpasion1Pas encore d'évaluation

- CURRICULUM PharmasubDocument10 pagesCURRICULUM PharmasubZE Mart DanmarkPas encore d'évaluation

- PDFDocument27 pagesPDFER Saurabh KatariyaPas encore d'évaluation

- Federalist Papers 10 51 ExcerptsDocument2 pagesFederalist Papers 10 51 Excerptsapi-292351355Pas encore d'évaluation

- CHARACTER FORMATION 1 PrelimDocument15 pagesCHARACTER FORMATION 1 PrelimAiza Minalabag100% (1)

- 2201 IntGCSE (9-1) Subject Grade Boundaries V1Document4 pages2201 IntGCSE (9-1) Subject Grade Boundaries V1Fariha RahmanPas encore d'évaluation

- Nantai Catalog NewDocument30 pagesNantai Catalog Newspalomos100% (1)

- John DrydenDocument3 pagesJohn DrydenDunas SvetlanaPas encore d'évaluation

- Universitas Tidar: Fakultas Keguruan Dan Ilmu PendidikanDocument7 pagesUniversitas Tidar: Fakultas Keguruan Dan Ilmu PendidikanTheresia Calcutaa WilPas encore d'évaluation

- Module 6 Metal Properties and Destructive TestingDocument46 pagesModule 6 Metal Properties and Destructive TestingMiki Jaksic100% (6)

- CG Photo Editing2Document3 pagesCG Photo Editing2Mylene55% (11)

- NHD Process PaperDocument2 pagesNHD Process Paperapi-203024952100% (1)

- The Effect of Co-Op Approach in Improving Visual Motor Integration Skills in Children With Learning DisabilityDocument7 pagesThe Effect of Co-Op Approach in Improving Visual Motor Integration Skills in Children With Learning DisabilityIJAR JOURNALPas encore d'évaluation

- Engleza Referat-Pantilimonescu IonutDocument13 pagesEngleza Referat-Pantilimonescu IonutAilenei RazvanPas encore d'évaluation

- Yetta Company ProfileDocument6 pagesYetta Company ProfileAfizi GhazaliPas encore d'évaluation

- Wealth and Poverty in The Book of Proverbs PDFDocument133 pagesWealth and Poverty in The Book of Proverbs PDFMaahes Cultural Library100% (1)

- UNIT 5-8 PrintingDocument17 pagesUNIT 5-8 PrintingNOODPas encore d'évaluation

- Hockney-Falco Thesis: 1 Setup of The 2001 PublicationDocument6 pagesHockney-Falco Thesis: 1 Setup of The 2001 PublicationKurayami ReijiPas encore d'évaluation

- XII CS Material Chap7 2012 13Document21 pagesXII CS Material Chap7 2012 13Ashis PradhanPas encore d'évaluation

- Session 1Document18 pagesSession 1Akash GuptaPas encore d'évaluation

- Crypto Wall Crypto Snipershot OB Strategy - Day Trade SwingDocument29 pagesCrypto Wall Crypto Snipershot OB Strategy - Day Trade SwingArete JinseiPas encore d'évaluation

- Mecha World Compendium Playbooks BWDocument12 pagesMecha World Compendium Playbooks BWRobson Alves MacielPas encore d'évaluation

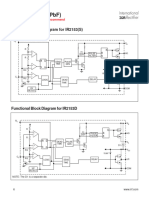

- IR2153 Parte6Document1 pageIR2153 Parte6FRANK NIELE DE OLIVEIRAPas encore d'évaluation

- USER MANUAL ABRITES Commander For Nissan PDFDocument20 pagesUSER MANUAL ABRITES Commander For Nissan PDFBosi GashiPas encore d'évaluation

- Quality Control of Rigid Pavements 1Document58 pagesQuality Control of Rigid Pavements 1pranjpatil100% (1)

- 19 Dark PPT TemplateDocument15 pages19 Dark PPT TemplateKurt W. DelleraPas encore d'évaluation

- Sale Counter List JuneDocument9 pagesSale Counter List Junep6a4nduPas encore d'évaluation

- DCS800ServiceManual RevADocument96 pagesDCS800ServiceManual RevAElinplastPas encore d'évaluation

- CISF Manual Final OriginalDocument17 pagesCISF Manual Final OriginalVaishnavi JayakumarPas encore d'évaluation

- I. Learning Objectives / Learning Outcomes: Esson LANDocument3 pagesI. Learning Objectives / Learning Outcomes: Esson LANWilliams M. Gamarra ArateaPas encore d'évaluation