Académique Documents

Professionnel Documents

Culture Documents

Fundiciones Chilenas 2005

Transféré par

Karen Carmona Michea0 évaluation0% ont trouvé ce document utile (0 vote)

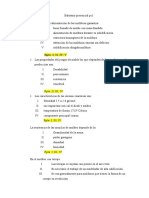

83 vues27 pagesEl documento proporciona información sobre 7 fundiciones de cobre en Chile, incluidas sus capacidades de producción, tecnologías utilizadas y estándares de emisión. Las 7 fundiciones son Chuquicamata, Altonorte, Paipote, Potrerillos, Chagres, Ventanas y Caletones. En conjunto, estas fundiciones tienen una capacidad anual de producción de cobre de 1,830,000 toneladas métricas.

Description originale:

f

Titre original

Fundiciones_Chilenas_2005

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentEl documento proporciona información sobre 7 fundiciones de cobre en Chile, incluidas sus capacidades de producción, tecnologías utilizadas y estándares de emisión. Las 7 fundiciones son Chuquicamata, Altonorte, Paipote, Potrerillos, Chagres, Ventanas y Caletones. En conjunto, estas fundiciones tienen una capacidad anual de producción de cobre de 1,830,000 toneladas métricas.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

83 vues27 pagesFundiciones Chilenas 2005

Transféré par

Karen Carmona MicheaEl documento proporciona información sobre 7 fundiciones de cobre en Chile, incluidas sus capacidades de producción, tecnologías utilizadas y estándares de emisión. Las 7 fundiciones son Chuquicamata, Altonorte, Paipote, Potrerillos, Chagres, Ventanas y Caletones. En conjunto, estas fundiciones tienen una capacidad anual de producción de cobre de 1,830,000 toneladas métricas.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 27

ANGL AMERICAN CHILE

MINERA SUR ANDES Ltda. MINERA SUR ANDES Ltda.

An

An

Update

Update

on

on

Chilean

Chilean

Copper

Copper

Smelters

Smelters

Chilean Smelters

Chuquicamata Smelter: Codelco Norte Division

Altonorte Smelter: Noranda

Paipote HVL Smelter: (ENAMI) Paipote

Potrerillos Smelter: El Salvador Division

Ventanas Smelter: Ventanas Division CODELCO

(Ex ENAMI)

Chagres Smelter: Minera Sur Andes Ltda.

MSA, AngloAmerican Group

Caletones Smelter: El Teniente Division CODELCO

COPPER PRODUCTION CAPACITY

IN CHILEAN SMELTERS

COMPANY SMELTER ANUAL COPPER

PRODUCTION

MTPY COPPER

Codelco Chuquicamata 580,000

Noranda Altonorte 290,000

ENAMI Paipote 100,000

Codelco Potrerillos 200,000

MSA Chagres 185,000

Codelco Ventanas 110,000

Codelco Caletones 365,000

TOTAL 1,830,000

CONCENTRATE QUALITY

FEED ANALYSIS

Codelco Noranda ENAMI Codelco MSA Codelco Codelco

CONCENTRATE Chuquicamata Altonorte Paipote Potrerillos Chagres Ventanas Caletones

tspa

1,650,000 800.000 330,000 680,000 610,000 420,000 1,600,000

%Cu

33.0 36.6 28-30 30.8 31 30.7 30.8

% Fe

20 15.0 28-30 23.0 22.4 25.3 26.5

% S

32.9 28.2 32-35 31.2 31 32.4 31.8

% As

0.83 - 0.06 0.31 0,08 - 0.19

% SiO2

6.2 - 1.8-2.5 7.7 6.58 6.9 5.5

% Sb

- - - 0.04 0.005 - 0.23

% Pb

0.18 - - 0.01 0.007 - 0.045

% Zn

1.28 - - 0.22 0.03 - 0.22

% Bi

0.08 - - 0.01 - - -

% Mo

0.19 - - 0.17 0.09 - 0.15

% Ni

0.01 - - 0.01 - - 0.004

Au g/t

0.5 - - 1.5 - - -

Ag g/t

110 - - 75 - - -

% H20 Wet Con

- 8.42 7.5-9.0 8.0 10 8.6 8.5

% H20 Dry Con

0.2 - - 0.2 - - 0.2

Mesh Size

80%

< 150 Mesh

- 80%

< 270

Mesh

80%

< 80 Mesh

76%

< 325 Mesh

70%

< 200Mesh

70%

< 325 Mesh

SMELTER / DIVISION FINAL PRODUCT

COMPANY SMELTER

SMELTER

PRODUCT

TYPE

ANODE

ANALYSIS

%Cu

DIVISION

FINAL

PRODUCT

Codelco Chuquicamata Anodes 99.60

99.65

99.57

99.47

99.75

99.61

99.70

< 99.92

Noranda Altonorte Anodes

Cathode

Anodes

Anodes

Cathode

Anodes

Cathode

ENAMI Paipote Anodes

Codelco Potrerillos Anodes

MSA Chagres Anodes

Codelco Ventanas Anodes

Codelco Caletones Anodes &

Fire Refined

Copper Ingots

Anodes &

Fire Refined

Copper Ingots

SMELTER WORK FORCE

COMPANY SMELTER Number of

Employees

Codelco Chuquicamata 800

Noranda Altonorte 520

ENAMI Paipote 500

Codelco Potrerillos 400

MSA Chagres 300 operations

200 maint. & servs.

Codelco Ventanas 230 operations

230 maintenance

Codelco Caletones 730

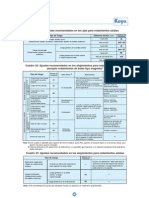

SMELTER EMISSION REGULATIONS

COMPANY SMELTER SO

2

(ug/Nm

3

)

Arsenic

Tpa As

Codelco Chuquicamata 1,000 (1h); 250 (1d); 80 (1y) 400-800*

Noranda Altonorte 1,000 (1h); 250 (1d); 80 (1y) 126

ENAMI Paipote 1,000 (1h); 250 (1d); 80 (1y) 34

Codelco Potrerillos 1,000 (1h); 250 (1d); 80 (1y) 150-800*

MSA Chagres 1,000 (1h); 250 (1d); 80 (1y) 95

Codelco Ventanas 1,000 (1h); 250 (1d); 80 (1y) 120

Codelco Caletones 700 (1h); 250 (1d); 60-80 (1y) 375

* Higher Limit Applies in case with no Human Settlements 8 kmfromEmission Source

SMELTER PERMISSIBLE AIR CONCENTRATION

LIMITS IN WORKPLACE

Maximum Concentration

Weakly Average

Maximum Concentration

Fifteen Min. Air Sample

ppm mg/m

3

ppm mg/m

3

Sulfur Dioxide 1.6 4

Arsenic - 0.0008 - -

Dust (total) - 8 - -

2.4

5 13

Dust (breathable fraction,

PM-5)

- - -

SULPHURIC ACID

ACID PRODUCTION

Product

Grade

Plant

Type

Codelco Caletones

TC+PS

2

162,000/

258,000

1,500/

2,350

510,000/

110,000

98.5/

98.5

Single

Absorption

TOTAL 12

1,400,000/

1,600,000

12,630/

13,760

3,900,000/

4,300,000

COMPANY SMELTER Source

Gas

Number

Acid

Plants

Volume

Nm

3

/h

MTPD MTPY H2SO4

%

Codelco Chuquicamata

SF+TC+PS

3

465,000 4,590 1,560,000 98.5

Single

Absorption

Noranda Altonorte

Continuous

Reactor +

PS

2

260,000/

300,000

2,400 816,000 97-98

Double

Absorption

ENAMI Paipote

PS+TC

2

50.000/

80.000

300/580 102,000/

197,000

98.5/

98.5

Sybetra/

Monsanto

Codelco Potrerillos

TC+PS

1

200,000 1,100 374,000 98

Single

Absorption

MSA Chagres

SF+PS

1

150,000 1,690 551,000 98

Lurgi Fenco

Double Abs.

Codelco Ventanas

TC+PS

1

115,000 1,050 354,000 97.8

Hugo

Petersen

SMELTER TECHNOLOGY

CODELCO NORANDA ENAMI CODELCO MSA CODELCO CODELCO

Chuquicamata Altonorte Paipote Potrerillos Chagres Ventanas Caletones

SMELTING Flash Smelting

+

Teniente

Converter

Continuous

Reactor

Teniente

Converter

Teniente

Converter

Flash

Furnace

Teniente

Converter

2 Teniente

Converter

CONVERTING 4 Peirce Smith 3 Peirce

Smith

1 Peirce

Smith

3 Peirce

Smith

4 Peirce

Smith

3 Peirce

Smith

3 Peirce

Smith

SLAG

CLEANING

Electric

Furnace +

Cylindrical

(Slag

Flotation)

Electric

Furnace

3 TSC

Furnaces

Cylindrical Electric

Furnace

4 Fuel fired

Furnace

FIRE

REFINING

6 Anode

Furnace + 2

Scrap Furnace

3 Tilting

Furnaces

1 Anode

Furnace

2 Anode

Furnaces

2 Anode

Furnace

1 Rotary

Anode

Furnace

+ 2 Furnace

Reverb

3 Rotary

Anode

Furnace

+ 3 FR

Furnaces

CASTING

WHEEL TYPE

3 Outokumpu

Casting

Wheels

2

Outokumpu

Casting

Wheels

Outokumpu

Casting

Wheel

Twin Demag

Casting

Wheel

1 Outokumpu

Casting

Wheel

Walker

Casting

Wheel

2 Outokumpu

Casting

Wheels

TENIENTE CONVERTER TECHNOLOGY

Enriched Air

White

Metal

Slag

Tapping

Gas Mouth

Wet

Concentrate

Coal + Silica

Dry

Concentrate

Feed

Air + Oxygen

Tuyeres

Dry

Concentrate

DRY CONCENTRATE

INJECTION TO CT

Concentrate

Bin

COMPRESOR

Air

Drier

Air

0,2% Moisture

CODELCO TENIENTE TECHNOLOGY

The Teniente Converter

Smelts concentrates and performs the initial Conversion slag-blow

Yields 75% Cu white metal

The Teniente Slag Cleaning Furnace

Treats Teniente slags - usually of 5 to 7% Cu

Yields matte and final discard slag

Complementary devices improving operations

Tuyere blocks for expediting tuyere hot-repairs

Teniente Converters operating since the 70s

At present there are 7 units in operation in Chilean Smelters

Total smelting capacity of 4.8 MM tpy concentrates

yielding 1.7 MM tpy copper

TC Dry Concentrate Injection

Bone-dry Concentrate Injection through tuyeres

dense/ultra-dense phase pneumatic transport

(80 to 140 kg material conveyed per kg transport air)

Preceded by an efficient Dryer (rotary, fluid bed or steam), to

produce bone-dry concentrate at 0.2% moisture

Ultra Dense-phase injection has permitted up to 100% capacity

increase of Teniente Reactor

Teniente Converter Production Capacity in Chile

CONCENTRATE SMELTER CAPACITY

DAILY

DESIGN NOMINAL

YEARLY

COMPANY SMELTER CT

TOTAL

DIMENSIONS

L x D

(m)

TPD TPD TPH TPY

CODELCO Caletones 2 22 x 5 2,600 2,300 98 1,600,000

CODELCO Chuquicamata 1 22 x 5 2,500 2,200 100 748,000

CODELCO Potrerillos 1 22 x 5 2,200 2,000 90 680,000

CODELCO Ventanas 1 14 x 5 - 1,400 60 450,000

ENAMI Paipote FHVL 1 14.9 x 3.8 - 1,050 65 357,000

NORANDA Alto Norte 1 26.4 x 5.3 - 2,800 120 950,000

Total 7 11,750 533 4,785,000

TENIENTE SLAG CLEANING FURNACE

Slag

Feed

Burner

SCF Gas

Tuyeres Diesel

Burner

Air

Fuel Oil + Air

Injection

Slag

White Metal

TENIENTE SLAG CLEANING TECHNOLOGY

The Teniente Slag Cleaning Furnace

Magnetite reduction using fuel reductant, plus auxiliary burner,

followed by matte settling period

Treats molten slag from CT or Flash Furnace; converter slag can

also be added, with limitations (high Fe

3

O

4

needs strong reduction)

Yields matte and final discard slag

Final slag usually 0.8 to 1.0 %Cu

Different feed and product discharge configuration

Batch or Semi-continuous process (continuous under development)

Based on Oil or Coal injection through tuyeres to a Rotary Furnace

Operating since the 80s, first at Caletones Smelter

At present there are 9 units in operation in Chilean Smelters

Slag cleaning capacity 600 to 1,000 tpd slag per furnace

FLASH SMELTING FURNACE

CONCENTRATE

BURNER

Off Gas

Air + Oxygen

Distribution Air

Natural Gas

Matte to PS

REACTION

SHAFT

UP TAKE

SETTLER

Slag

To SCF

Dry Concentrate

Slag

Matte

RADIATIVE CHAMBER GAS COOLING TECHNOLOGY

Dust Collection

Chambers

Water

Cooled

Screen

Peirce

Smith

Converter

Hood

Gas to

Electrostatic

Precipitator

and

Acid Plant

Radiant Cooling Tubes

Radiative Cooling of Metallurgical Gas

Pairs of exposed bare metal ducts - approx 1.2 m diameter x 17 m

Heat is definitively removed from the gas train.

In some cases with smaller and multiple tube bundles for P-S

Converters, with final forced air convection double tube section.

On occasions combined with final evaporative cooling (spray) for

temperature adjustment.

Successful installations at : Successful installations at :

Chuquicamata, Caletones, Potrerillos, Paipote, Chuquicamata, Caletones, Potrerillos, Paipote, La La Caridad Caridad Smelter in Smelter in

Mexico, and presently at MSA Chagres Smelter. Mexico, and presently at MSA Chagres Smelter.

ALTONORTE SMELTER

ALTONORTE SMELTER

Wet Concentrate

Coal + Si l i ca

NORANDA / TENIENTE REACTOR

Whi te Metal

Sl ag Fl otati on

Process

NR Sl ag

Water

Water

Water

Anodes to Sal es

ACID PLANT

ACID PLANT

Enriched Air

PEIRCE-SMITH

CONVERTERS

Bl i ster Copper

ANODE FURNACES

CASTING

WHEELS

PSC Gas

to

Aci d Pl ant

NR Gas

PSC Gas

OXYGEN PLANT

ELECTROSTATIC

PRECIPITATOR

CHUQUICAMATA SMELTER AND REFINERY

CHUQUICAMATA SMELTER AND REFINERY

ELECTRIC FURNACE

White

Metal

TSC Slag

CASTING WHEELS

FLASH SMELTING FURNACE

Concentrate

+

Silica

SFGas to Boiler

SF Slag

Enri ched Ai r

TENIENTE CONVERTER

Wet Concentrate

Coal + Silica

Gas to Acid Plant

White Metal

CT Slag

Enriched Air

Dry Concentrate

Injection

Slag Flotation

Process

White Metal

ELECTROLITIC REFINERY

Commercial

Catodes

To pre-processing and

Sales

Anode Slime

Anodes

Anodes

Anodes

ANODE

FURNACES

ELECTROSTATIC

PRECIPITATOR

Slag to Granulation

ELECTROSTATIC

PRECIPITATORS

ACID PLANT

Gas

to Stack

RADIATIVE

CHAMBERS

RADIATIVE

CHAMBERS

Oi l

OXYGEN PLANT

POTRERILLOS SMELTER AND REFINERY

POTRERILLOS SMELTER AND REFINERY

TENIENTE CONVERTER

Wet Concentrate

Coal + Si l i ca CT Gas

to Aci d Pl ant

Whi te

Metal

Bl i ster Copper

CT Sl ag

CASTING WHEEL

Dry Concentrate

Inj ecti on

Whi te

Metal

PSC Gas

to

Aci d Pl ant

ANODE FURNACES

Anodes

Anodes

ACID PLANT

ELECTROSTATIC

PRECIPITATORS

OXYGEN PLANT

Enri ched Ai r

ELECTROSTATIC

PRECIPITATORS

MIXING CHAMBER

ONE PASS

RADIATIVE CHAMBER

ONE PASS

RADIATIVE

CHAMBERS

Sl ag

PEIRCE-SMITH

CONVERTERS

ELECTROLITIC REFINERY

Commerci al

Cathodes

Anode Sl i me

PAIPOTE SMELTER (HVL)

PAIPOTE SMELTER (HVL)

PEIRCE SMITH

CONVERTER

TENIENTE CONVERTER

ELECTRIC FURNACE

Wet Concentrate

Coal + Si l i ca

CT Gas

to Aci d Pl ant

Whi te

Metal

Bl i ster Copper

CT Sl ag

CASTING WHEEL

EF Waste Sl ag

Dry Concentrate

Inj ecti on

Whi te

Metal

EF Gas

to

Aci d Pl ant

ANODE FURNACE

Anodes

Anodes

ACID PLANT 2

ACID PLANT 1

EF Gas

to ESP

ELECTROSTATIC

PRECIPITATOR

OXYGEN PLANT

Enri ched Ai r

Scrubber

ELECTROSTATIC

PRECIPITATOR

Commerci al

Anodes

CT Gas

VENTANAS SMELTER AND REFINERY

VENTANAS SMELTER AND REFINERY

TENIENTE CONVERTER

PEIRCE-SMITH

CONVERTERS

ELECTRIC FURNACE

ACID PLANT

ROTARY

ANODE FURNACE

ELECTROLITIC REFINERY

Wet Concentrate

Coal + Si l i ca

Gas to

Aci d Pl ant

Whi te Metal

Bl i ster Copper

REVERBERATORY

REFINING

FURNACES

CT Sl ag

Whi te Metal

CASTING WHEELS

EF Sl ag

Commerci al

Cathodes

PRECIOUS

METALS PLANT

Anode Sl i me

Anodes

Anodes

Enriched Air

Dry Concentrate

Inj ecti on

OXYGEN PLANT

Enri ched Ai r

Au

Ag

Se

TC Gas

ELECTROSTATIC

PRECIPITATOR

CHAGRES SMELTER

CHAGRES SMELTER

PEIRCE-SMITH

CONVERTERS

FLASH SMELTER

Concentrate

+

Si l i ca

Bl i ster Copper

SF Sl ag

CASTING WHEEL

Whi te

Metal

PSC Gas

to

Aci d Pl ant

ANODE FURNACES

Anodes

Anodes

ACID PLANT

OXYGEN PLANT

Enri ched Ai r

ELECTROSTATIC

PRECIPITATOR

Commerci al

Anodes

SLAG CLEANING FURNACES

Sl ag

Gas

to Stack

MIXING

CHAMBER

SF Gas to Boiler

PS Gas

Whi te

Metal

CALETONES SMELTER

CALETONES SMELTER

TENIENTE CONVERTER 1

Wet Concentrate

Coal + Si l i ca

Dry Concentrate

Inj ecti on

Dry Concentrate

Inj ecti on

Wet Concentrate

Coal + Si l i ca

Whi te Metal

Whi te Metal

TENIENTE CONVERTER 2

CT 2 Sl ag

CT 1 Sl ag

Anodes

Commerci al

Anodes

Commerci al

Fi re Refi ned

Copper

Bl i ster Copper

Bl i ster Copper

ANODE FURNACES

ANODE FURNACES

SPRAY

WATER

SPRAY

WATER

Single Absorption

ACID PLANT No. 2

Single Absorption

ACID PLANT No. 1

EVAPORATIVE CHAMBER

EVAPORATIVE CHAMBER

Sl ag

SLAG FURNACES

SLAG FURNACES

PEIRCE SMITH

CONVERTER

Enriched Air

OXYGEN PLANT

Enri ched Ai r

Enri ched Ai r

PS Gas

PS Gas to Aci d Pl ant

ANGLO AMERICAN CHILE

MINERA SUR ANDES Ltda. MINERA SUR ANDES Ltda.

An

An

Update

Update

on

on

Chilean

Chilean

Copper

Copper

Smelters

Smelters

END

END

Vous aimerez peut-être aussi

- NGO50Document2 pagesNGO50Bruno E Ines GuedezPas encore d'évaluation

- UF0903 - Caracterización de equipos y elementos en instalaciones de climatizaciónD'EverandUF0903 - Caracterización de equipos y elementos en instalaciones de climatizaciónPas encore d'évaluation

- UF0902 - Caracterización de instalaciones de climatizaciónD'EverandUF0902 - Caracterización de instalaciones de climatizaciónÉvaluation : 5 sur 5 étoiles5/5 (1)

- Libro de HidrometalurgiaDocument169 pagesLibro de Hidrometalurgiadiko100% (1)

- Tipos de Circuitos SABC DSAG SAGDocument50 pagesTipos de Circuitos SABC DSAG SAGFrancisBaxter100% (1)

- El Arte de Manejo de EscoriasDocument8 pagesEl Arte de Manejo de EscoriasSalvador Tovar FranciscoPas encore d'évaluation

- Plantas CriogénicasDocument55 pagesPlantas CriogénicasEnyerberht Castañeda Brito50% (2)

- Alfran Energia ReducidoDocument9 pagesAlfran Energia ReducidoFran Marin100% (1)

- Iusa CalentadoresDocument6 pagesIusa CalentadoresDeusexmachina Nexus VIPas encore d'évaluation

- Guia Lubricacion AmbraDocument16 pagesGuia Lubricacion AmbraEduardo Ariel BernalPas encore d'évaluation

- Planta de Desorcion A Presion (40pag)Document40 pagesPlanta de Desorcion A Presion (40pag)luisantonio260% (5)

- Horno Flash Convert Id or TenienteDocument29 pagesHorno Flash Convert Id or TenienteFreddy Alonso Carvajal Carvajal100% (2)

- Portafolio Del Segundo ParcialDocument40 pagesPortafolio Del Segundo ParcialJ C Gabino FlorenciaPas encore d'évaluation

- Cotizacion Pelco #20180917-900 Conversion - Parrilla Viajera-Camara de Combustion Caldera de 200 BHPDocument9 pagesCotizacion Pelco #20180917-900 Conversion - Parrilla Viajera-Camara de Combustion Caldera de 200 BHPWilliam Muñoz100% (1)

- Golden - Euro 200-850 Rev 1 (Manual Operación Caldera)Document62 pagesGolden - Euro 200-850 Rev 1 (Manual Operación Caldera)Jeremias Rojas ParraPas encore d'évaluation

- Proceso de Electrobtención Plantas MinerasDocument118 pagesProceso de Electrobtención Plantas MinerasDaniel Cisternas Cortes100% (1)

- Caldera A GasDocument24 pagesCaldera A GasJose Manuel Castro100% (1)

- Control de Emisiones Contaminantes VehicularesDocument15 pagesControl de Emisiones Contaminantes VehicularesValentina MedinaPas encore d'évaluation

- Presentacion de Js Ecology SacDocument15 pagesPresentacion de Js Ecology SacEnrique Justino SilvaPas encore d'évaluation

- Mantos BlancosDocument29 pagesMantos BlancosMiguel Vásquez100% (2)

- Instalaciones 1 - Gas - 2012 - Araujo (17-09)Document30 pagesInstalaciones 1 - Gas - 2012 - Araujo (17-09)graphyco1Pas encore d'évaluation

- Operacion y Mantenimiento de Centrales Termoelectricas (Ing. Ruben Rojas Ramirez)Document26 pagesOperacion y Mantenimiento de Centrales Termoelectricas (Ing. Ruben Rojas Ramirez)Alexander RamosPas encore d'évaluation

- Manual MagnaDocument11 pagesManual MagnamanuelvidaluchilePas encore d'évaluation

- Proceso Del MetanolDocument22 pagesProceso Del Metanoljulio_higi100% (4)

- Calentador Ciclonik. Mod. CL 8000 y Ficha TecnicaDocument5 pagesCalentador Ciclonik. Mod. CL 8000 y Ficha TecnicaAJM Controles y Q0% (1)

- Auditoria Alto HornoDocument74 pagesAuditoria Alto HornoCarlos YauriPas encore d'évaluation

- Visita Técnica La Refinería PetroperúDocument15 pagesVisita Técnica La Refinería PetroperúRaphael FernandoPas encore d'évaluation

- 0509-18 - Presupuesto Caldera m125 FGDocument20 pages0509-18 - Presupuesto Caldera m125 FGmatias mancillaPas encore d'évaluation

- Datasheet RL 1250Document10 pagesDatasheet RL 1250Danilo Jose Saavedra MayerPas encore d'évaluation

- Ajustes Recomendados KoyoDocument54 pagesAjustes Recomendados KoyoMiguel Carlin Jimenez100% (1)

- Bongiornni Caldera T90Document18 pagesBongiornni Caldera T90Juan Carlos Peña CordónPas encore d'évaluation

- Calentador de Aceite TermicoDocument4 pagesCalentador de Aceite TermicoWilliam Gómez SuárezPas encore d'évaluation

- Calderas en Hierro Fundido para Gas Ó Gasóleo "SIME": RondóDocument35 pagesCalderas en Hierro Fundido para Gas Ó Gasóleo "SIME": Rondóalquinta1983Pas encore d'évaluation

- Tema 5 REV. FlexicokingDocument33 pagesTema 5 REV. FlexicokingMayker GonzalezPas encore d'évaluation

- Ferroli 1838Document40 pagesFerroli 1838viorelduca0% (2)

- Enfriadores HYDAC PDFDocument7 pagesEnfriadores HYDAC PDFAurelio Cano LópezPas encore d'évaluation

- Caldera HCDocument2 pagesCaldera HCMatias MancillaPas encore d'évaluation

- Stray GassingDocument35 pagesStray Gassinghectorlqh90Pas encore d'évaluation

- 21 Proyecto Planta de Acido Sulfurico Mejillones PDFDocument42 pages21 Proyecto Planta de Acido Sulfurico Mejillones PDFIsrael Saavedra0% (1)

- jm20100930 Southern PDFDocument69 pagesjm20100930 Southern PDFEdwin Roger Hernandez MejiaPas encore d'évaluation

- Const. Catalogo Calentadores IUSADocument12 pagesConst. Catalogo Calentadores IUSAUriel MartinezPas encore d'évaluation

- Ajuste RecomendadoDocument54 pagesAjuste RecomendadoHusa GomezPas encore d'évaluation

- Fallas en Los RodamientosDocument54 pagesFallas en Los RodamientosRomina Pia Ortiz V100% (1)

- Ficha Tecnica Caldera Pirotubular 150 BHP y Calidad Del AguaDocument7 pagesFicha Tecnica Caldera Pirotubular 150 BHP y Calidad Del AguaAW Company SGIPas encore d'évaluation

- Memoria de Calculos BomberosDocument4 pagesMemoria de Calculos BomberosMauro Quisbert HuariPas encore d'évaluation

- Fundicion CaletonesDocument25 pagesFundicion CaletonesCarla AguileraPas encore d'évaluation

- BronceDocument74 pagesBronceEliana MejiaPas encore d'évaluation

- Practica 4 Horizontal (Bueno)Document4 pagesPractica 4 Horizontal (Bueno)MV VannaPas encore d'évaluation

- Diagrama y BalancesDocument25 pagesDiagrama y BalancesGabriel CGPas encore d'évaluation

- Soluciones para La Industria de Proceso PDFDocument200 pagesSoluciones para La Industria de Proceso PDFjosePas encore d'évaluation

- CalderasDocument91 pagesCalderasDiego Edison Torres Penagos100% (1)

- 01 - Chemetics - Introduction - 2012 - SpanishDocument84 pages01 - Chemetics - Introduction - 2012 - SpanishWeb LogueandoPas encore d'évaluation

- Visión General Del Proceso de FabricaciónDocument40 pagesVisión General Del Proceso de FabricaciónMili VivianiPas encore d'évaluation

- Manual de Capacidades de AsmarDocument45 pagesManual de Capacidades de AsmarDaniel Roman100% (1)

- Catálogo Relé Buchholz COMEMDocument18 pagesCatálogo Relé Buchholz COMEMAlezsander RguezArPas encore d'évaluation

- Ingeniería de procesos siderúrgicos: La experiencia de AHMSAD'EverandIngeniería de procesos siderúrgicos: La experiencia de AHMSAPas encore d'évaluation

- Puesta en marcha y regulación de instalaciones de climatización y ventilación-extracción. IMAR0208D'EverandPuesta en marcha y regulación de instalaciones de climatización y ventilación-extracción. IMAR0208Pas encore d'évaluation

- Preparar y acondicionar los equipos principales e instalaciones auxiliares de la planta química. QUIE0108D'EverandPreparar y acondicionar los equipos principales e instalaciones auxiliares de la planta química. QUIE0108Évaluation : 5 sur 5 étoiles5/5 (1)

- El Mejor Libro de Preparación Para Tu Examen De Licencia De Operador De CalderaD'EverandEl Mejor Libro de Preparación Para Tu Examen De Licencia De Operador De CalderaPas encore d'évaluation

- Guía práctica de dimensionado de tuberías: Agua, gas, calefacción y energía solarD'EverandGuía práctica de dimensionado de tuberías: Agua, gas, calefacción y energía solarÉvaluation : 3.5 sur 5 étoiles3.5/5 (4)

- Transmisión de calor en motores alternativos: aplicación al aprovechamiento energético de los gasesD'EverandTransmisión de calor en motores alternativos: aplicación al aprovechamiento energético de los gasesPas encore d'évaluation

- Proceso de Tostacion - Antecedentes GeneralesDocument29 pagesProceso de Tostacion - Antecedentes GeneralesKaren Carmona Michea100% (1)

- Proceso AceroDocument52 pagesProceso AceroKaren Carmona MicheaPas encore d'évaluation

- LixiviacionDocument115 pagesLixiviacionKaren Carmona MicheaPas encore d'évaluation

- Diseno de EspesadoresDocument14 pagesDiseno de EspesadoresKaren Carmona MicheaPas encore d'évaluation

- Avances Vol 19 (1) 2022 - 6856Document15 pagesAvances Vol 19 (1) 2022 - 6856Antony Zavala MPas encore d'évaluation

- Estudio de La Oxidacion de Telurito de Sodio en Medio AlcalinoDocument4 pagesEstudio de La Oxidacion de Telurito de Sodio en Medio AlcalinoRicardo SolisPas encore d'évaluation

- Trabajo Final - Culminado 01.05.22Document29 pagesTrabajo Final - Culminado 01.05.22Jesus Chupayo ChuquillanquiPas encore d'évaluation

- Proceso Del CobreDocument35 pagesProceso Del CobreWalterJ.AlvaradoLuceroPas encore d'évaluation

- YANACOCHA RefinacionDocument49 pagesYANACOCHA RefinacionJuan Carlos Ramos CentenoPas encore d'évaluation

- Equipos de FundiciónDocument9 pagesEquipos de FundicióntlacatianPas encore d'évaluation

- Altos Hornos, Hirro FundidoDocument12 pagesAltos Hornos, Hirro FundidoWilliam Miguel Pérez AlarcónPas encore d'évaluation

- L.7.Influecias Impurezas de La Caserita en La Pirom Del Estaño PDFDocument14 pagesL.7.Influecias Impurezas de La Caserita en La Pirom Del Estaño PDFEduardo Mendoza VidalPas encore d'évaluation

- Seminario de Análisis de Oro Por Vía SecaDocument17 pagesSeminario de Análisis de Oro Por Vía SecaVICTOR RONALD LAZARO TACOPas encore d'évaluation

- PC1 - PresencialDocument5 pagesPC1 - PresencialHoyuelosbonitos NamPas encore d'évaluation

- 0 Covertidor Teniente IloDocument13 pages0 Covertidor Teniente IloSaritha ParionaPas encore d'évaluation

- D.S. #001 2022 Produce PDFDocument12 pagesD.S. #001 2022 Produce PDFJimena Valentina Inga RojasPas encore d'évaluation

- Proyecto Ingeniería Ambiental: Control de Contaminación de Aire en Indutria Del Cemento PDFDocument21 pagesProyecto Ingeniería Ambiental: Control de Contaminación de Aire en Indutria Del Cemento PDFSimón MedinaPas encore d'évaluation

- Calculo Carga CubiloteDocument110 pagesCalculo Carga Cubilotejose.figueroa@foseco.comPas encore d'évaluation

- PreguntasDocument5 pagesPreguntasClaudia VargasPas encore d'évaluation

- Escoria de Aluminio AnularDocument5 pagesEscoria de Aluminio AnularAsdrubal Antonio Gonzalez DiazPas encore d'évaluation

- Fusion de ConcentradosDocument28 pagesFusion de ConcentradosCristian Segura BidermannPas encore d'évaluation

- La Reducción Carbotérmica de Óxidos Metálicos Utilizando CoqueDocument24 pagesLa Reducción Carbotérmica de Óxidos Metálicos Utilizando CoqueKevin Y. Cornelio Prado0% (1)

- Procesos Metalúrgicos I Expo Nu Se !!Document13 pagesProcesos Metalúrgicos I Expo Nu Se !!Jesus CamposPas encore d'évaluation

- RepsaDocument30 pagesRepsaJhoel ChaucaPas encore d'évaluation

- Ecomateriales Desde La Ciencia y La Tecnologia DiapositivasDocument6 pagesEcomateriales Desde La Ciencia y La Tecnologia DiapositivasErick Padilla AntaurcoPas encore d'évaluation

- Alto Horno: Tecnicatura Mantenimiento Electromecánico Elementos de Máquinas Industriales I E.T.A.S Prof.: W.BarcelóDocument25 pagesAlto Horno: Tecnicatura Mantenimiento Electromecánico Elementos de Máquinas Industriales I E.T.A.S Prof.: W.BarcelóLos compas fan UwU Siempre con los compas ;PPas encore d'évaluation

- Practica Obtencion de Una Pieza Por Medio de Moldeo ManualDocument10 pagesPractica Obtencion de Una Pieza Por Medio de Moldeo ManualRichardCamachoPas encore d'évaluation

- Siderurgia HuachipatoDocument35 pagesSiderurgia HuachipatoJose Garcia RamirezPas encore d'évaluation

- Horno Eléctrico de ArcoDocument19 pagesHorno Eléctrico de ArcoDaniel CarlosPas encore d'évaluation

- Identificacion de Los MaterialesDocument7 pagesIdentificacion de Los Materialesjofleapeppers752539Pas encore d'évaluation

- DESULFURACIÓN EN CUCHARA2 AgrgadoDocument12 pagesDESULFURACIÓN EN CUCHARA2 AgrgadoAnge SpinozaPas encore d'évaluation

- Intro EnsayoDocument5 pagesIntro EnsayoGabriela VelezPas encore d'évaluation

- METALURGÍADocument5 pagesMETALURGÍAJorge David Mendoza CanolesPas encore d'évaluation