Académique Documents

Professionnel Documents

Culture Documents

Pattern Making

Transféré par

poonam_ranee3934Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Pattern Making

Transféré par

poonam_ranee3934Droits d'auteur :

Formats disponibles

Agenda

Body Measurements

Sizing System

Pattern Construction Techniques

Production Patterns

Patternmaking

Population

Size chart formation

Somatometric data analysis

Taking body measurements

Pattern construction procedure:

PATTERN PATTERNMAKING MAKING

Virtual display

The Block Patternbasic pattern

that is used as a basic for all adaptations.

The Working Patternis used for

marking out the basic style lines and design

feature.

The final Pattern (Master)is pattern

from which the garment will be cut. It must be

clearly market with all the information required

for making up the garment.

SIZE 8 10 12 14 16 18 20

Bust (cm) 80.0 84.0 88.0 92.0 96.0 100.0 104.0

Waist (cm) 62.0 66.0 70.0 74.0 78.0 82.0 86.0

Hips (cm) 86.0 90.0 94.0 98.0 102.0 106.0 104.0

0

50

100

150

200

250

300

350

400

450

500

550

600

650

700

750

800

-34 -29 -24 -19 -14 -9 -4 1 6 11 16 21 26 31 36

dif f er ence (bust and hip)

F

r

e

q

u

e

n

c

y

Straight Straight- -lined lined

(linear) (linear)

Curves Curves

( (non non- -linear linear) )

Others Others

Heights Widths

Lengths

Widths

Girths

Front Profile

Diagram of the Body Measurements

measuring tool-

measuring tape

Bust prominence width

measuring tool-

anthropometre

Stature

Head width

Under arm length

Shoulder width

Bust girth

Crutch depth

(Body rise)

Taking body measurements manually

Measurements required for bodice and sleeve

Across back (back width) (bw) 15

Nape to waist (back

length)

(nw) 14

Bust prominence width (bwp) 13

Across front (front width) (fw) 12

Front length to waist (wfl) 11

Shoulder length (shl) 10

Sleeve length (sl) 9

Front length to bust (bfl) 8

Wrist girth (wrg) 7

Upper arm girth (uag) 6

Elbow girth (eg) 5

Neck girth (ng) 4

Waist girth (wg) 3

Bust girth (bg) 2

Body height (h) 1

Measurements required for skirt and trousers

Waist girth (wg)

3

Crutch depth

(Body rise)

(cd)

26

Inside leg length (lli)

25

Outside leg length (llo)

24

Ankle length

(waist to ankle)

(al)

23

Knee length

(waist to knee)

(kl)

22

Ankle girth (ag)

21

Calf girth (cg)

20

Knee girth (kg) 19

Thigh girth (tg)

18

Upper hip girth (uhg)

17

Hip girth (hg)

16

Height (h) 1

Measurements

The parallel plains with the basic plain

are horizontal plains

and perpendicular to the vertical plains.

Significant horizontal (transversal) plains,

which are situated in important points

on the human body surface, are e.g.

v

n

sh

b

w

h

c

t

k

a

Basic plain

Vertical plains

1 - centre back plain,

2 - side neck plain,

3 - back armhole plain,

4 - side plain,

5 - front armhole plain,

6 - chest plain,

7 - centre front plain,

8 - inside leg plain.

Horizontal plains

v - vertex plain,

n - neck plain,

sh -shoulder plain,

b - bust plain,

w - waist plain,

h - hip plain,

c - crutch plain

t - thigh plain,

k - knee plain,

a - ankle plain.

1 2

3

4

4

5

6

7

Back body

Front body

Apparel patternmaking construction net

The horizontal and vertical contour lines of the cross sections

project into the frontal plane. The flattened human body surface

gives to us systems of respectively perpendicular lines so called

construction net.

The net is the base for the apparel pattern construction.

v

n

sh

b

w

h

c

k

a

v

n

b

w

c

k

a

sh

b

e

wr

Industrial Sizing System

A sizing system A sizing system is a table of numbers which presents the value of each

of the body dimensions used to classify the bodies encountered in the population

for each size group in the system. Sizing system is the parameter complex specified

with the help of essential body dimensions:

Height, Bust girth, Waist girth for men, Hip girth for women

Size intervals are usually

classified according

to height and drop value.

For women, drop value

is defined as the difference

between the hip

circumference and the bust

circumference.

For men, drop value is

defined as the difference

between the chest and the

waist measurement.

SIZE 8 10 12 14 16 18 20

Bust (cm) 80.0 84.0 88.0 92.0 96.0 100.0 104.0

Waist (cm) 62.0 66.0 70.0 74.0 78.0 82.0 86.0

Hips (cm) 86.0 90.0 94.0 98.0 102.0 106.0 104.0

104

96

158

women

100

men

80

170

Ready-to-wear garment pattern is produced touse body =constructional dimensions,

that are setting in connection with the proposed sizing assortment

Constructional abscissa

A

B

B

A

C

K

B

O

D

I

C

E

F

R

O

N

T

B

O

D

I

C

E

Body block pattern construction

e.g. Basic formula for front width:

AB = 0.24 * wg + 2,5

Constructional abscissa

(regression equation)

AB

i

= k

i

* D

i

+ q

i

+ e

i

AB

i

constructional abscissa

k

i

regression coefficient

D

i

body dimension

q

i

absolute term

e

i

easy allowances

Pattern construction techniques

Pattern represents the two-dimensional

component parts of a garment.

They are used as a guide for cutting

the fabric, which sewn together form

a three dimensional garment.

The creation of these patterns is

the technique of pattern construction.

Garment shaping by suppression Garment shaping by suppression

Suppression is the reduction of surplus

fabric to obtain a closer fit using darts,

seams, pleats or gathers.

C

C

C

D D

A

A

A

D

E

E

E

E

B B

G

bk fr

G

C

B

D

C A

B E

C

F

SUPRASIONS AREAS

A =front shoulder dart E =side seam

B =front waist dart F =elbow dart

C =back shoulder dart G =wrist dart

D =back waist dart

The construction points are named according to their place on the body

surface and according to the number of construction steps and they are

marked by letters and numbers e.g.

-N1-

horizontal

line n

vertical

line 1

-N2-

horizontal

line n

vertical

line 2

-N21-

horizontal

line n

vertical

line 2

-N21- step 1th

N1

N2

N21

1

2

n

Production patterns

Seams, hems and facings are required to complete a garment pattern

for production.

Shell pattern

Lining pattern

Interlining pattern

Shell

Lining Interlining B

a

c

k

-

I

n

t

e

r

l

i

n

i

n

g

B

a

c

k

-

L

i

n

i

n

g

B

a

c

k

-

S

h

e

l

l

Seam allowances

The seam allowance is the distance from the

stitching line to the perimeter of a cut garment

part. The amount of seam allowance can vary

greatly according to:

(1) The position of the seam and how much stress

it has from body movement, e.g. an armhole and

sleeve head (minimum allowance 1 cm).

(2) The curvature of the seam influences the seam

width, e.g. the curved seam of a panelled bodice

requires a narrower seam where convex and concave

curves have to be joined together (maximum of 1cm).

(3) Enclosed seams require a narrow seam allowance,

e.g. the faced neck and armhole (maximum of 0.7 cm).

(4) The type of machinery required for stitching

the seam influences the seam allowance width

e.g. a flat felled seam

(1)

Flat Felled Seam

(2)

(3)

(2)

stitching line

seam allowance

(5) The type of fabric often

determines the width of the seam

allowance and how it is neatened e.g.:

- loosely woven fabric

- sheer fabric

- thick fabric

- stretch fabric

(6) A wide seam allowance

is required for inserting a zip fastener,

e.g. skirt placket (1.5 to 3.5cm).

Wide seam allowances, known

as inlays, are also required where

a garment is specifically constructed

for altering and letting out (1.5 to 3.5

cm).

Seam for loosely

woven fabric

Seams for sheer fabric

Seam for thick fabric Seam for stretch fabric

Wide seam allowances

Hem allowance

The shape of the hemline influences the width of the hem allowance.

A straight hem lies flat when folded back so the hem can be quite wide.

Curved hems do not lie flat when folded back and therefore the hem

width has to be reduced.

The corners at each end of the hem also have to be considered

so that the turned up hem mirrors the intersecting seam.

Straight hem

Straight hem with

mirrored corners

Circular hem

References

MUSILOVA,B. KOMARKOVA,P. GLOMBIKOVA,V.Basic pattern block construction.

Liberec:TUL 2003, ISBN 80-7083-687-3

LINDSAY CARTER,J ,E.HONEYMAN HEATH,B. Somatotyping: Development and

Applications . Cambridge UniversityPress1999, ISBN 0521351170

Aldrich, W. Metric Pattern Catting. Manchester: Blackwell Publishing2003,

ISBN-1-4051-0278-0.

Winks,J ,M.Clothing Sizes:International Standardization. Thetextile institut Manchester

1997,ISBN 1870812727

FAN,J .YU,W.HUNTER,L.Clothing appearance and fit:Science and

technology.Woodhead Publishing Ltd,Cambridge2004,ISBN1855737450

EBERLE,H. Clothing technology. Europa Lehrmittel Verlag2008,

ISBN-13: 978- 3808562246

Vous aimerez peut-être aussi

- Constructing The Basic Trouser Block OriginalDocument15 pagesConstructing The Basic Trouser Block Originalneel12321100% (3)

- Drafting Mens Shirt Collar - How to Shape Collar Stand & CurvesDocument8 pagesDrafting Mens Shirt Collar - How to Shape Collar Stand & Curvespi11sbury100% (1)

- Drafting The Easy Fitting Overgarment Block OriginalDocument15 pagesDrafting The Easy Fitting Overgarment Block OriginalAaisha Jagot100% (1)

- Measurement For SalwarDocument15 pagesMeasurement For Salwarsanjee2100% (1)

- Teach Yourself Stitch Craft and Dressmaking Volume IV: Pattern Drafting for Men and Practice Drafts - Trying your hand at drafting shirtsD'EverandTeach Yourself Stitch Craft and Dressmaking Volume IV: Pattern Drafting for Men and Practice Drafts - Trying your hand at drafting shirtsPas encore d'évaluation

- Teach Yourself Stitch Craft and Dressmaking Volume V: Introduction to Sleeves and Collars - Drafting Patterns for Stitching Sleeves and CollarsD'EverandTeach Yourself Stitch Craft and Dressmaking Volume V: Introduction to Sleeves and Collars - Drafting Patterns for Stitching Sleeves and CollarsPas encore d'évaluation

- Pattern Making for Dressmaking and NeedleworkD'EverandPattern Making for Dressmaking and NeedleworkÉvaluation : 4 sur 5 étoiles4/5 (2)

- Simplified Systems of Sewing Styling - Lesson Two, Pattern AlterationD'EverandSimplified Systems of Sewing Styling - Lesson Two, Pattern AlterationPas encore d'évaluation

- Gentlemen's Garment Cutting and Tailoring - The Dressmaker's GuideD'EverandGentlemen's Garment Cutting and Tailoring - The Dressmaker's GuideÉvaluation : 2 sur 5 étoiles2/5 (1)

- Sleeves: A Directory of Design Details and TechniquesD'EverandSleeves: A Directory of Design Details and TechniquesÉvaluation : 5 sur 5 étoiles5/5 (5)

- Dress Making - Drafting and Pattern MakingD'EverandDress Making - Drafting and Pattern MakingÉvaluation : 4.5 sur 5 étoiles4.5/5 (8)

- How to Draft a Pattern: The Essential Guide to Custom DesignD'EverandHow to Draft a Pattern: The Essential Guide to Custom DesignPas encore d'évaluation

- Bare Essentials: Bras - Third EditionD'EverandBare Essentials: Bras - Third EditionÉvaluation : 4.5 sur 5 étoiles4.5/5 (7)

- Gentlemen's Garment Cutting: Trousers, Vests, Coats, Overgarments, Corpulent Figures, and VariationsD'EverandGentlemen's Garment Cutting: Trousers, Vests, Coats, Overgarments, Corpulent Figures, and VariationsPas encore d'évaluation

- Pattern Making InstructionsDocument16 pagesPattern Making InstructionsVania Yulita100% (3)

- Pattern MakingDocument3 pagesPattern MakingMark Pingkian100% (2)

- Pattern FashionDocument7 pagesPattern FashionMehedi Hasan100% (1)

- Garment Cutting 1Document6 944 pagesGarment Cutting 1xtyomonigho50% (2)

- Analysing Shirts & BlousesDocument14 pagesAnalysing Shirts & BlousesNoèlia Cristina Alves Fonseca67% (3)

- Making A Collar With A StandDocument2 pagesMaking A Collar With A StandCalliePas encore d'évaluation

- Basic Bodice DraftingDocument1 pageBasic Bodice DraftingarunkadvePas encore d'évaluation

- Body MapTop DressDocument2 pagesBody MapTop DressPat Ro100% (2)

- Measure Bodice and Pants PatternsDocument16 pagesMeasure Bodice and Pants PatternsMary PaulatPas encore d'évaluation

- Cen TR e Back: 10cm X 10cm Print Accuracy Check SquareDocument1 pageCen TR e Back: 10cm X 10cm Print Accuracy Check SquareAna DragoiPas encore d'évaluation

- A Basic Pattern For You, Jane Speece, 1977Document9 pagesA Basic Pattern For You, Jane Speece, 1977Dan Andrei StefanPas encore d'évaluation

- Constructing The Basic Bodice Block - OriginalDocument20 pagesConstructing The Basic Bodice Block - Originalpawan T100% (4)

- Scienceofgrading 00 SimoDocument80 pagesScienceofgrading 00 SimoDelina HangallPas encore d'évaluation

- Drafting A Princess Line Dress Pattern From The Basic Bodice Block OriginalDocument12 pagesDrafting A Princess Line Dress Pattern From The Basic Bodice Block OriginalNikoletta KourtakiPas encore d'évaluation

- Armhole Princess Styleline PatternDocument11 pagesArmhole Princess Styleline Patternwhilmeragudelo100% (1)

- Pattern: Pre-Requites For PatternDocument3 pagesPattern: Pre-Requites For Patternzaya sarwarPas encore d'évaluation

- Paper patterns guide for clothing and craft projectsDocument28 pagesPaper patterns guide for clothing and craft projectsMayaPas encore d'évaluation

- Gored Skirt Pattern DraftingDocument3 pagesGored Skirt Pattern DraftingJeff50% (2)

- Pattern Grading)Document2 pagesPattern Grading)zoomerfins2267% (3)

- Adding Fullness in DartDocument4 pagesAdding Fullness in Dartrohinihoney100% (1)

- Drafting Patterns For WomenDocument13 pagesDrafting Patterns For Womenzzz2299100% (2)

- Understanding Body Shapes Through PatternmakingDocument17 pagesUnderstanding Body Shapes Through PatternmakingmahimabhatPas encore d'évaluation

- Ladies' Blazer: Small Parts PreparationDocument4 pagesLadies' Blazer: Small Parts PreparationMichael AlabadoPas encore d'évaluation

- Add Draping To A Common Pattern OriginalDocument4 pagesAdd Draping To A Common Pattern OriginalcarmenluciamodaPas encore d'évaluation

- DrapingDocument39 pagesDrapingB Parikh100% (2)

- Making Sense of Pattern Grading - Threads PDFDocument3 pagesMaking Sense of Pattern Grading - Threads PDFtritidief67% (3)

- Pattern for a fitted men's shirtDocument10 pagesPattern for a fitted men's shirtsalyPas encore d'évaluation

- Dart Manipulation Techniques For Flat PatternsDocument30 pagesDart Manipulation Techniques For Flat PatternsZa-c Pelangi SenjaPas encore d'évaluation

- Garment Construction - Amina CreationsDocument74 pagesGarment Construction - Amina Creationspoonam_ranee3934100% (2)

- Garment Textbook FinalDocument122 pagesGarment Textbook Finaljaglansunil100% (8)

- Baby FrockDocument1 pageBaby FrockSushma KaushikPas encore d'évaluation

- College PortfolioDocument54 pagesCollege PortfolioYashashree GaonkarPas encore d'évaluation

- Draft Men's Pants PatternsDocument6 pagesDraft Men's Pants PatternsTanmay JagetiaPas encore d'évaluation

- Fabric - Form and Flat Pattern Cutting - Designing PatternsDocument21 pagesFabric - Form and Flat Pattern Cutting - Designing Patternsadnan100% (4)

- HTM Womenswear Current-UpdatedDocument10 pagesHTM Womenswear Current-UpdatedSujon SarkarPas encore d'évaluation

- Draping Techniques and PrinciplesDocument18 pagesDraping Techniques and PrinciplesGunjan Maan100% (1)

- GradingDocument19 pagesGradingsarprajkatre143Pas encore d'évaluation

- Images Measurements Underbust Corset Measurement FormDocument3 pagesImages Measurements Underbust Corset Measurement FormelygudPas encore d'évaluation

- Lesson 5 Clothing ConstructionDocument11 pagesLesson 5 Clothing ConstructionEmerson John RosetePas encore d'évaluation

- Drafting Patterns For CHILDREN PANTSDocument8 pagesDrafting Patterns For CHILDREN PANTSJavier LeonPas encore d'évaluation

- Knitwear Design: Presented By: Priyambada SemalDocument20 pagesKnitwear Design: Presented By: Priyambada Semalpriyambada semalPas encore d'évaluation

- Shirt Collar With A StandDocument2 pagesShirt Collar With A StandCallie100% (1)

- Types of SleevesDocument43 pagesTypes of SleevesZiva BabaPas encore d'évaluation

- Baby Clothes Jabla Drafting and Sewing GuideDocument7 pagesBaby Clothes Jabla Drafting and Sewing Guideshilpashree100% (2)

- Drafting a Basic Sleeve BlockDocument16 pagesDrafting a Basic Sleeve BlockFlorenciaPas encore d'évaluation

- The Secret of SuccessDocument72 pagesThe Secret of SuccessStudioCentroVeneto s.a.s.Pas encore d'évaluation

- Crime Against WomenDocument38 pagesCrime Against WomenAaditya BhattPas encore d'évaluation

- Construction Tolerances PDFDocument11 pagesConstruction Tolerances PDFmohamed4879Pas encore d'évaluation

- Epson Stylus Pro 7890 9890 Professional Photographic Product BrochureDocument8 pagesEpson Stylus Pro 7890 9890 Professional Photographic Product BrochureLucho F.Pas encore d'évaluation

- TravelDocument28 pagesTravelAnnamma Shammy100% (2)

- RelaxationDocument13 pagesRelaxationGigel PuscoiuPas encore d'évaluation

- Hyundia Brio CarDocument8 pagesHyundia Brio Carpoonam_ranee3934Pas encore d'évaluation

- Golds Gym INdiaDocument12 pagesGolds Gym INdiapoonam_ranee3934Pas encore d'évaluation

- JAM 2014 BrochureDocument30 pagesJAM 2014 BrochureRahul MehtaPas encore d'évaluation

- Indo Global SummitDocument26 pagesIndo Global Summitpoonam_ranee3934Pas encore d'évaluation

- Phaser PrinterDocument4 pagesPhaser Printerpoonam_ranee3934Pas encore d'évaluation

- ConflictDocument6 pagesConflictapi-306437258Pas encore d'évaluation

- Survey - Women-Cosmetics IndiaDocument17 pagesSurvey - Women-Cosmetics Indiapoonam_ranee3934100% (1)

- Problems Relating To NRI Marriages: Dos and DontsDocument6 pagesProblems Relating To NRI Marriages: Dos and Dontspoonam_ranee3934Pas encore d'évaluation

- Calm in The Storm 40Document40 pagesCalm in The Storm 40poonam_ranee3934Pas encore d'évaluation

- Concrete Construction: Estimate The Cost ofDocument12 pagesConcrete Construction: Estimate The Cost ofYay B. GicoPas encore d'évaluation

- Calm in The Storm 40Document40 pagesCalm in The Storm 40poonam_ranee3934Pas encore d'évaluation

- India - Cosmetics Imports & Regulatory AspectsDocument6 pagesIndia - Cosmetics Imports & Regulatory AspectsSuruchi ChopraPas encore d'évaluation

- Survey - Women-Cosmetics IndiaDocument17 pagesSurvey - Women-Cosmetics Indiapoonam_ranee3934100% (1)

- Quality Control Manual Papua New GuineaDocument59 pagesQuality Control Manual Papua New Guineapoonam_ranee3934Pas encore d'évaluation

- Hacking Indian LawsDocument16 pagesHacking Indian LawsPRATICK RANJAN GAYENPas encore d'évaluation

- Construction Tolerances PDFDocument11 pagesConstruction Tolerances PDFmohamed4879Pas encore d'évaluation

- Cyber Crimes PDFDocument7 pagesCyber Crimes PDFSellappan RathinamPas encore d'évaluation

- India - Cosmetics Imports & Regulatory AspectsDocument6 pagesIndia - Cosmetics Imports & Regulatory AspectsSuruchi ChopraPas encore d'évaluation

- MBA For Working ExecutivesDocument7 pagesMBA For Working Executivespoonam_ranee3934Pas encore d'évaluation

- Civil SpecificationsDocument65 pagesCivil SpecificationsmrkssastryPas encore d'évaluation

- Stone IndiaDocument20 pagesStone Indiapoonam_ranee3934Pas encore d'évaluation

- Wood Mosaic Price List NewDocument8 pagesWood Mosaic Price List Newpoonam_ranee3934Pas encore d'évaluation

- Civil Engineers GuideDocument46 pagesCivil Engineers GuideSrinivasan Reddy88% (17)

- NGP Section 04Document4 pagesNGP Section 04poonam_ranee3934Pas encore d'évaluation

- BOW Dressmaking JHS 9 10Document2 pagesBOW Dressmaking JHS 9 10Scarlette Beauty EnriquezPas encore d'évaluation

- Questionnaire OTOP ADocument16 pagesQuestionnaire OTOP AChristel Marasigan MagnoPas encore d'évaluation

- PW KootenayLake Nov8Document55 pagesPW KootenayLake Nov8Pennywise PublishingPas encore d'évaluation

- MarketingDocument31 pagesMarketingpergiwati dewiPas encore d'évaluation

- Food Vocabulary Beginners PDFDocument3 pagesFood Vocabulary Beginners PDFTanja Jovcevska100% (1)

- September 2015 Mechanical Engineer Board ExamDocument2 pagesSeptember 2015 Mechanical Engineer Board ExamAngela Julia100% (1)

- Project Outline and Questionnaire-Mother DairyDocument4 pagesProject Outline and Questionnaire-Mother DairyRuchita Ranjan100% (2)

- Levi's Brand AuditDocument21 pagesLevi's Brand Auditjamie71% (7)

- 07-14-11 - Moneysaver - Lewis-Clark EditionDocument20 pages07-14-11 - Moneysaver - Lewis-Clark EditionDavid ArndtPas encore d'évaluation

- SCM Amazon ProfilingDocument14 pagesSCM Amazon Profilinggaurav2616146Pas encore d'évaluation

- Amazon FBA 137 Hot Product Opportunities Freedom FormulaDocument148 pagesAmazon FBA 137 Hot Product Opportunities Freedom FormulaАлександр НовиковPas encore d'évaluation

- Competitive Analysis of Bhatbhateni Super Market - Case StudyDocument5 pagesCompetitive Analysis of Bhatbhateni Super Market - Case Studysuman chaudharyPas encore d'évaluation

- Lay Planning TypesDocument1 pageLay Planning TypesGaurav Shakya100% (1)

- Callaway Golf Company Case Study AnalysisDocument3 pagesCallaway Golf Company Case Study AnalysisHualu ZhaoPas encore d'évaluation

- Click125i 32K60F100 1 PDFDocument108 pagesClick125i 32K60F100 1 PDFJosé Luis Carreño BautistaPas encore d'évaluation

- FMCG Industry and Amul's SuccessDocument52 pagesFMCG Industry and Amul's SuccessRohma TasePas encore d'évaluation

- Bhat Bhateni GroupDocument23 pagesBhat Bhateni Groupprakash_ghimire755183% (6)

- Workbook ResueltoDocument2 pagesWorkbook ResueltoRmr Xelionayx0% (1)

- Victoria's Secret Summer 2021 E-Catalogue MalaysiaDocument24 pagesVictoria's Secret Summer 2021 E-Catalogue MalaysiaWafaa PalomaPas encore d'évaluation

- Mauritius Tourism Satellite Account IntroductionDocument20 pagesMauritius Tourism Satellite Account IntroductionMario Ima NhiPas encore d'évaluation

- Spirality of Single Jersey Knitted FabricDocument13 pagesSpirality of Single Jersey Knitted FabricKazi Saiful IslamPas encore d'évaluation

- Usage of Shampoo Products & Analysis of Consumer Perception Towards Various Shampoo BrandsDocument42 pagesUsage of Shampoo Products & Analysis of Consumer Perception Towards Various Shampoo Brandsanndyrulz2381% (16)

- Effectivness of Promotional Schemes in Reliance MartDocument22 pagesEffectivness of Promotional Schemes in Reliance MartSavan BhattPas encore d'évaluation

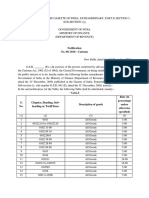

- Customs Tariff Notifications No.66/2016 Dated 31st December, 2016Document26 pagesCustoms Tariff Notifications No.66/2016 Dated 31st December, 2016stephin k jPas encore d'évaluation

- Safety ContractDocument1 pageSafety Contractapi-361126391Pas encore d'évaluation

- Apple Watch Sales Rise 16% in IndiaDocument3 pagesApple Watch Sales Rise 16% in IndiaNayeem RajaPas encore d'évaluation

- SEO-Optimized Title for Space Management DocumentDocument14 pagesSEO-Optimized Title for Space Management DocumentHari KrishnaPas encore d'évaluation

- 18th International Shoes Leather Exhibition Ho Chin Minh City Vietnam July 13 15 2016Document44 pages18th International Shoes Leather Exhibition Ho Chin Minh City Vietnam July 13 15 2016Kathirasan Ramalingam100% (1)

- Provide Valet Services 300812Document156 pagesProvide Valet Services 300812Angee Pot100% (2)

- 26.pdffor All Subjects Notes VisitDocument7 pages26.pdffor All Subjects Notes VisitR.S.H100% (2)