Académique Documents

Professionnel Documents

Culture Documents

White Paper 5 4

Transféré par

api-236263046Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

White Paper 5 4

Transféré par

api-236263046Droits d'auteur :

Formats disponibles

Eliturbo : Whitepaper

EXECUTIVE SUMMARY:

Heat rises and humidity falls. In buildings with a ceiling height of 14 feet or more, warmer air

accumulates up towards the ceiling where it is of no use, while humidity accumulates at floor-level

which causes damage to the building, equipment, and creates an unhealthy environment for occupants.

In order to maintain a desirable temperature at the lower level, a significant waste of energy occurs as

the heat unit battles to keep up with the thermostat (at human level) signaling that its cold! Not only is

heat stratification costing the planet, it is hurting businesses and organizations who operate in large

open spaces huge amounts of money that can be reduced. A similar phenomenon is true for humidity

as building managers often resort to heat to resolve humidity problems.

The Eliturbo Air-Mixer prevents heat and humidity stratification via its patented convergent divergent,

heli-centrifugal air mixing motion. As opposed to classic blade fans or turbine type fans which simply

push air in a column, the Eliturbo pulls air in from above and below, mixes it and expels air radially. The

result is constant air mixing of both the coldest and the warmest air temperatures in the room,

equalizing the temperature and air pressure throughout a large space saving on heting and cooling

costs, and all without any annoying or damaging downdrafts. Eliturbos draw air away from the corners

and the constant air-mixing action prevents cold air settling and subsequent pockets of humidity and

cold.

The Eliturbo Air-Mixer is designed for buildings with ceilings from 14 to 60 feet in height and each unit

can cover up to 100,000 cubic feet by mixing the air five times in an hour.

Eliturbos have been installed and proven effective with a multitude of applications in over 100,000

structures in Europe, and are now available in the US.

PROBLEM: STRATIFICATION OF WARM AIR & HEAT LOSS IN HIGHER CEILINGED BUILDINGS

Warm air delivered via a typical heat source (forced air, radiators, baseboard, fireplace, etc.) in a low

ceilinged space, such as a room, tends to develop minimal differences in temperature between the

ceiling and floor (called heat or thermal stratification). This is not the case in spaces with higher ceilings,

where thermal stratification becomes quite pronounced, and the taller the inside of a building the

greater the difference in temperature between floor and ceiling.

Hot air rises due to the difference of density between hot and cold air,

accumulating just below the ceiling precisely where heating is seldom

needed. In building with ceilings of only 14 foot height can have

temperature differences of 5-10 degrees Fahrenheit between ceiling

and floor, while in higher ceilinged buildings the difference can be up

to 25/40 F.

Human physiology is such that we prefer warmer temperatures near our feet, and can tolerate cooler

temperatures near head level; therefore, for comfort purposes we want to avoid thermal stratification

and in business terms productivity is directly linked to comfort.

Energy consumption for heating is determined by three essential factors:

1. the type and efficiency of the heating unit (gas vs. electric, forced air vs. radiant, etc.);

2. the level of conductive heat loss through the building envelope (walls, glass, floor, roof); and

3. the amount of infiltration and exfiltration of outdoor air into the structure.

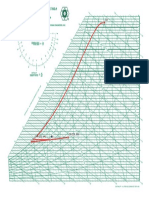

Clearly, the second and third elements are greatly affected by the exterior temperature which creates a

higher level heat loss at colder temperatures. The amount of heated air accumulating near the ceiling is

also tied to the variations of seasonal temperatures. As the chart below shows, heat difference between

ceiling and floor ranges from none in the warm seasons, to 39 F difference at an average winter low

temperature of 23 F .. The result is that the stratification of heat is worse during the cold weather.

As interior temperatures are generally measured 5 feet from the floor and regulated by a wall-mounted

thermostats they reflect only the temperature at that point, not the temperature at floor or ceiling level.

The air temperature increases as elevation increases because warm air is lighter and rises. This increase

is regularly calculated at 1-2 F per foot.

0

5

10

15

20

25

30

35

50 60 70 80 90 100

H

e

i

g

h

t

A

b

o

v

e

F

l

o

o

r

,

f

e

e

t

Space Temperature, F

Effect of Outdoor Temperature on

Stratification

T

o

=

T

o

= Outdoor Temp.

C = Temperature

difference due to

stratification

Heat

Delivery

Height

Ceiling

Height C = 9F

C = 22F

C = 39F

Thermostat Height

Considering the value C as the difference between internal and external temperature (Delta T) , the

increase of heat loss from the roof and walls at great temperature differences compared to the loss

without thermal stratification is shown in the graph below.

Similar to the heat loss from walls and roofs, the heat

loss from air-exchange and infiltration is also

negatively impacted by thermal stratification. As the

temperature at the roof level increases due to

stratification, the amount of heat loss increases up to

2.8% for each degree difference in Fahrenheit between

the floor and ceiling. For example if the out-door

temperature is 32 F then the resultant heat loss in a

structure with stratified heat is 70% greater than the

same structure with an even thermal pattern. (C=86-61=25 F at ceiling level -> Heat loss = 2.8 * 25 = 70%)

0

20

40

60

80

100

0 0.4 0.8 1.2 1.6 2

P

e

r

c

e

n

t

I

n

c

r

e

a

s

e

i

n

H

e

a

t

L

o

s

s

C

o

m

p

a

r

e

d

t

o

t

h

a

t

d

u

e

t

o

S

t

r

a

t

i

f

i

c

a

t

i

o

n

UA RATIO = UA Roof / UA Walls

Effects of Stratification on Heat Loss via Walls of

Industrial Buildings based on "C"

HEAT LOSS IS A SAMPLE BUILDING WITH & WITHOUT STRATIFICATION

Example #1: Industrial Factory or Warehouse Older (pre-1980) Construction

For the purposes of our first example, we will use a moderate sized steel-framed structure with saw-

tooth roof and clerestory windows. It is an older building, as are many throughout the US, and does not

conform to the latest standards for energy efficient construction. The heating required is calculated using

23F average nighttime winter outdoor temperature as is usual for design purposes.

If the air in this structure were to be fully mixed resulting in zero difference in internal temperature

between the ceiling, the walls and the floor then the heat loss calculated in BTU/Hr would be 2,523,371

as shown in the table below .

Aspect

U

BTU/hr ft2 F

Area,ft2

U*Area

BTU/hr F

T, F

Q Heat Loss,

BTU/hr

Walls 0.335 22,389 7,497 37.8 283,370

Floors 0.106 32,292 3,414 37.8 129,065

Roof (total) 0.557 43,056 23,977 37.8 906,325

Glass 1.022 8,611 8,802 37.8 332,702

Roof Panels 0.441 34,444 15,175 37.8 573,624

1,318,761

Ventilation 2x 0.062 258,334 31,868 37.8 1,204,610

Total Heat Lost 2,523,371

Projected Heat Loss with No Stratification

Floor Dimensions 330 x 100 feet

Perimeter 860 feet

Floor Area 33,000 sq. feet

Average Ceiling Height 26'3" feet

Max. Ceiling Height 32'10" feet

Volume 866,250 cubic feet

Infiltration Air Changes 2 per hour

Min. Outdoor Temp. 23 F

Average Seasonal Temp. 41 F

Floor Temp. 61 F

Temp. at Ceiling 100 F

Heating Unit Capacity 2,450,000 BTU/hr

719 kW

This theoretical calculation is based on there being zero temperature stratification in the building with

the air totally mixed. However, in most cases there would be significant thermal stratification leading to

ceiling temperatures that can

reach as much as 39F higher

than the floor temperature on a

cold winter night even in this

relatively low building. The

same concept holds true for the

average temperatures of the walls and for the temperature of air-exchange; all of which can have a

significant impact on heat loss.

Most the heated air sits trapped near ceiling where the difference in temperature from the ceiling to the

outside can reach 67 F. or more as shown above. As expected, much of the heat lost by conduction is

through the roof, especially through the glass window panels. The result is a significantly larger heat

loss.

In the case below example, where we have used a lower than maximum heat differential from floor to

ceiling (only 28F), the heat loss with thermal stratification is 143% of the loss estimated with the air

fully destratified, or over an additional 1,000,000 BTU/Hr (3,596,051 Vs. 2,523,371).

Example #2: Industrial Factory or Warehouse Newer Construction (post-1980)

In a second example we will use the same type of building, a moderate sized steel-framed structure with

saw-tooth roof and clerestory windows, however in this case it will be constructed to comply with the

1980 Seattle Energy Code. It is built using non-pressurized loose construction and has a U factor of 0.046

for the roof and 0.109 for the walls. Here again, the heat required is calculated using the prescribed 23F

nighttime winter outdoor design temperature for Seattle and the differences of internal vs. external

temperature due to stratification are the same as above.

The results using fully modern construction change dramatically in terms of heat loss reducing it by

2/3

rd

s in the case of both stratified air and mixed air cases; however the benefits of destratification

continue to be significant with heat loss reduced by fully mixing the air and thereby eliminating

stratification remain significant as shown in the following table.

Aspect

U*Area

BTU/hr F T, F

Q Heat Loss,

BTU/hr

Walls 7,497 46.8 350,840

Floor 3,414 37.8 129,065

Total Roof 23,977 55.8 1,337,911

Glass 8,802 55.8 491,132

Coverings 15,175 55.8 846,779

1,817,816 38% Qs

Infiltration 31,868 55.8 1,778,236 48% Qv

Total Heat Loss 3,596,051 43% QT

Calculated Heat Loss with Stratification

Outside Air T = 23F

Floor Temp. T = 61F

Ceiling Temp. T = 61 + 39 = 100F

Roof T = 100 - 23 = 67F

Walls, average T = [(100 + 61)/2] - 23 = 57.5F

Infiltration Air T = 61 - 23 = 38 F (outside air heated to floor temp.)

In this case with the outdoor temperature of 23F, the building with destratified air will save the same

43% of the heat input to maintain the floor level temperature than the building with fully stratified air.

In many buildings, the effect of stratification is much worse. Although this is the case in deep winter,

heat loss percent improvements will be similar at higher ambient temperatures. This evaluation also

points out the need to control ventilation as much as possible, as much of the gains possible by mixing

are lost by infiltration of cold outside air.

HOT AIR HEATING UNITS

Heating via hot-air heating units works in two phases:

1. the heating of ambient room air by conductive or radiant heat exchange using electric heater

coils or gas burners, and then

2. the distribution of the hot air in the space using fans with or without ducts.

The ambient air is drawn from the lower area generally at a height of 5 to 8 feet, and it is occasionally

mixed with exterior air. The heating unit increases the temperature of the air normally between 45 and

90F; most frequently about 55-60F. This corresponds to a volume of air equal to 3,530 cf/hr, or 59 cfm

per kW of thermal power.

The greatest challenge in heating large rectangular spaces is how to obtain a uniform, evenly distributed

temperature both vertically and horizontally so that the vertical space and four corners are equally

heated. Warm air stagnating in the upper portion of the building is heat wasted; which means energy

wasted and money wasted. Meanwhile, the lower portion of the space suffers a less-than-optimal

temperature and is subject to humidity in cold zones. Condensation forms on cold surfaces which not

only can lead to corrosion and reduced longevity for equipment, but can also lead to dangerous mold

growth creating health hazards. An owner or building manager will often adjust the thermostat to a

higher setting to achieve comfort at floor level, making the problem worse by sending more heat to the

ceiling.

Additionally, heating units are often placed in less-than-optimal positions dictated by access, work-flow

or machinery locations, exacerbating the temperature imbalance

THE DISTRUBTION OF HOT AIR

To resolve these problems, a constant mixing of the air in a space is desired. Ceiling fans are designed

to merely push warm air downward, but causes pockets of warm and cold, as well as drafts which stir up

accumulated dust. Space heaters usually direct heated air flow in only one direction, angled towards

the floor resulting in only a limited area being heated, and do nothing to circulate the air or reduce

stratification.

Ideally, the goal is to recycle the volume of air in the

space 5 times per hour. One solution is to install

heating units that have a CFH heating capacity of 5

times the volume of space, but in order to achieve

this level of air movement it would require

significantly more heating capacity than would be

needed if the air were destratified. Considering the

purchase price and the running costs of additional industrial heating units to create the needed air flow,

it is well above the cost of installing an appropriate number of Eliturbo Air-Mixers to destratify the air as

we heat.

Additionally, condensation on the walls and the resulting corrosive impact on machinery would be

eliminated, along with improvements in comfort and temperature uniformity for workers. The heating

units can cycle as needed without the burden of maintaining even air distribution, as that function is

now assured by the Eliturbo units. Applying the Eliturbos thermal and humidity destratification

capabilities to HVAC installations at the design phase will lower the initial investment needed as well as

save energy costs over time.

ELITURBO = AIR-MIXING, not pushing

The Eliturbo Air-Mixer recycles air continuously throughout a space, preventing the stratification of

temperature and buildup of humidity.

Traditional blade ceiling fans or turbine type fans attempt to destratify the air in a space by pushing

warm air from the ceiling downward to the floor, creating a turbulent, narrow column of air resulting in

uncomfortable drafts and the stirring up of dust. Whats more, as fans work only in vertical columns,

they often do not cover the entire space needed. Further, once strong fans have emptied the ceiling

area of heat, they need to be turned off awaiting a new build up so that they can then be turned on

again to forcefully push the heat down. From all of this, one can easily conclude that these types of fans

are a very incomplete solution to thermal stratification and humidity accumulation problems.

Sample Industrial Building

Surface Area 33,000 sq. ft.

Ceiling Height 26.25 feet

Internal Volume 866,250 cu. feet

Required Heat 2,453,500 BTU/hr

719 kW

Eliturbo on the other hand, leverages a set of uniquely designed, heli-centrifugal curved blades that

create a fluid-aerodynamic, convergence-divergence action, mixing the air continuously without

producing unnecessary turbulence and downdrafts. The result is no accumulation of hot air at the

ceiling, no costly stopping and starting of heating systems and no dust stirred up. Eliturbo works

constantly creating, in effect, its own low-velocity micro-climate.

(please note that according to AMCA, the national standard for fan testing, Eliturbos CFM & Air-flow

should not be compared to fan or turbine destratifiers CFM or Air-flow measurements as they have one

directional thrust of air; Eliturbo on the other hand, expels air 360 and therefore cannot be measured

or evaluated in the same way.)

VERTICAL MIXING

The Eliturbo Air-Mixer is a complete solution to heat stratification

and humidity build-up. The way it works, is both quite complicated

and quite simple. Referring to the drawing below:

Cooler air is drawn from below up into the unit, while at the same

time, warmer air is drawn into the unit from above. Air is drawn

away from the corners and these streams are mixed within

Eliturbo unit and expelled radially in all directions (360) through

sloped deflectors creating convergence divergence.

The air is expelled radially, creating a circular movement. Air

slowly travels downward along the walls to the floor and back up

to the units, all with minimal perception of air movement and

without warmer and cooler zones; hence, vertical mixing and

prevention of heat stratification.

Continuous mixing of air throughout the space provides even distribution of heat, humidity and

pressure, with minimal controls and maintenance.

Horizontal Mixing

The Eliturbo Air-Mixer takes the coldest and the warmest air in the space and re-distributes the mixed

air radially, dispersing it 360 as it exits the unit. In doing so it balances the temperature throughout a

space horizontally at the same time as it destratifies the heat vertically. The Eliturbo insures the

temperature is evenly distributed thereby making heating systems more efficient.

The illustrations below show how installed Eliturbos work to distribute air/heat evenly throughout a

space.

The Eliturbo air-mixers are manufactured with clock-wise or anti-clockwise rotation and are best

installed in a checker-board fashion with each Eliturbo rotating in an alternate direction to the adjacent

units.

Air expelled from an Eliturbo unit rotating clock-wise encounters air expelled from an adjacent unit

rotating counter-clockwise and is similar to meshing gears. Less fan energy is lost due to unnecessary

turbulence.

Heating systems push air into a space

creating pockets of hot and cold

Heating Elements pushing air into a space

With Eliturbos deployed the heat is

balanced throughout the building

THE ADVANTAGES of the ELITURBO Air-Mixer

Clearly, eliminating thermal stratification provides huge advantages in energy savings, comfort and

health vs. a stratified environment. Furthermore, the Eliturbos continuous air-mixing is superior to any

classic fan type point, air-pushing solutions that unavoidably leave pockets of hot & cold.

Destratified air results in dramatically lower ceiling temperatures, lower heat loss through roof and walls

and lower energy costs. Typically the savings amount to 20 to 30% on heating bills. A heating unit may

be the right size for the volume of a space, but without an efficient method to distribute the heat to the

lower levels of the space, two things will happen:

1. the space will have inconsistent temperatures, and/or

2. the heating unit will work overtime, continually providing heated air at work level, which will

quickly rise to the ceiling.

RECAP OF ELITURBO Air-Mixers:

In Winter

Reduction of thermal stratification between floor and ceiling resulting in uniform temperature

within different vertical zones of a structure.

Considerable improvement in comfort in the work space with the heat designed for occupants

comfort, remaining at the human level (floor to 6-7 feet).

Reduction in heat loss through roof and wall areas.

Better use of the heat generated by heating unit and/or heat produced by machinery.

Reduced needed capacity, running time and therefore energy costs of heating units.

Less wear and tear on heating unit (less frequently turned on and off).

Minimal air turbulence at floor level and very little stirring of dust improving worker comfort

and extending machinery life.

Reduction in heating differences throughout a space.

Reduced air stagnation in isolated areas of the space (corners, behind equipment, etc.)

Reduces risk of condensation forming on machinery, walls, windows, etc.

Overall energy savings and increased worker comfort.

In Summer

Greater exchange/recycle of air through ventilation.

Greater efficiency of natural ventilation.

Reduced concentration of odors/fumes.

Reduced areas with stagnant, high humidity in isolated areas of the space (corners, behind

equipment, etc.) resulting in increased life and decreased maintenance for machinery.

Reduces risk of condensation forming on machinery, walls, windows, etc.

Greater efficiency of air conditioning units.

ECONOMIC ADVANTAGES of the ELITURBO Air-Mixer

Installing Eliturbos in existing structures can reduce energy consumption costs immediately leading to

the capital investment being paid back within the first year. Therefore, all subsequent years energy cost

savings would go straight to the bottom line as the maintenance costs of Eliturbo are basically zero.

To show an example of how this works using real costs, using the same sample building from above, the

heating need for this structure is approximately 2,400,000 BTU/hr. or 57,600,000 BTU per day.

The most cost effective power/heating source, readily

available in the US today is natural gas and the US Energy

Information Administration predicts average 2015

**Industrial gas prices to be $5.45 per 1,000 cubic feet

(McF). The full report is available at

http://www.eia.gov/forecasts/steo/report/natgas.cfm.

By reducing heating loss by just 25% through reduced

stratification, the cost of installing 12 Eliturbos in this

sample industrial building will be recovered within 1

years.

* calculations based on technical specs from a major manufacturer of

commonly used industrial heating units and the application of modern

code U-Factors. Older buildings with higher U-Factors, will find the

payback period for installing Eliturbos even shorter.

**$5.45 projected industrial rate & $9.58 commercial

Savings associated with installing Eliturbo Air-Mixers with existing and new HVAC systems come from:

1) Reducing the number of times heat unit starts up by keeping the desired temperature down at human

level through destratifcation; and

2) Reducing the size and quantity of heating units needed as thermal destratification closes the gaps

between theoretical heat loss calculations and actual heat loss.

Summary

Thermal loss through buildings is a major culprit in wasted energy resources and of great cost to

organizations. Reducing thermal stratification can provide significant savings on energy costs and can

noticeably improve the comfort and health; but only if implemented correctly. Competing

destratification devices unavoidably create warm and cool zones and pocket of hot air escaping to the

ceiling. Partial coverage will ultimately deliver partial results.

The Eliturbo Air-Mixers revolutionary method of continuously mixing air delivers balanced temperatures

both vertically and horizontally and reduces the effects of humidity; instead of simply pushing air,

Eliturbo mixes the air.

Copyright 2014: Import IT LLC . All rights reserved.

Sample Industrial Building

Surface Area 33,000 sq. ft.

Ceiling Height 26.25 feet

Internal Volume 866,250 cu. feet

Required Heat 2,453,500 BTU/hr

719 kW

Vous aimerez peut-être aussi

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- CH 10 and 11 Acid-Base QuestionsDocument8 pagesCH 10 and 11 Acid-Base QuestionsNap DoPas encore d'évaluation

- Ashrae ChartDocument1 pageAshrae Chartalone160162lPas encore d'évaluation

- Psychrometric ProcessesDocument14 pagesPsychrometric ProcessesKabin BoraPas encore d'évaluation

- Law of ThermodynamicsDocument2 pagesLaw of ThermodynamicsRajesh PandaPas encore d'évaluation

- Titration CurveDocument4 pagesTitration CurveElaine CortesPas encore d'évaluation

- HVAC Mid Exam ReviewDocument72 pagesHVAC Mid Exam Reviewvoch007Pas encore d'évaluation

- Assignment # 4 (Chapter 5) Due 3:00 PM of February 07, 2008 1Document2 pagesAssignment # 4 (Chapter 5) Due 3:00 PM of February 07, 2008 1Adam SchellPas encore d'évaluation

- Practical Convection Heat TransferDocument11 pagesPractical Convection Heat TransfertskPas encore d'évaluation

- Daily Test Temperature, Heat and ExpDocument4 pagesDaily Test Temperature, Heat and ExpbenyPas encore d'évaluation

- Psychrometrics: Dry-Bulb Temperature (DBT)Document4 pagesPsychrometrics: Dry-Bulb Temperature (DBT)Shania LoveresPas encore d'évaluation

- Heat and TemperatureDocument1 pageHeat and TemperatureSinta NovaliaPas encore d'évaluation

- Calculating The Heat Transfer Between Wax and Water.: Lab ReportDocument4 pagesCalculating The Heat Transfer Between Wax and Water.: Lab Reportapi-406055813Pas encore d'évaluation

- Problem Set 2Document2 pagesProblem Set 2Julcris JimenezPas encore d'évaluation

- Chemical Equilibrium (E)Document32 pagesChemical Equilibrium (E)Gadde Gopala KrishnaPas encore d'évaluation

- Chapter 19: TEMPERATURE, HEAT, and The First Law of ThermodynamicsDocument18 pagesChapter 19: TEMPERATURE, HEAT, and The First Law of ThermodynamicsWahyu RiyandiPas encore d'évaluation

- Unit V PDFDocument27 pagesUnit V PDFSafeer MPas encore d'évaluation

- PS-4-Spring - 2015Document2 pagesPS-4-Spring - 2015agu josephPas encore d'évaluation

- Ali 5Document7 pagesAli 5Losi GrahamPas encore d'évaluation

- Drying Lab ReportDocument26 pagesDrying Lab ReportAriel Joseph Stern100% (2)

- Exothermic ReactionsDocument25 pagesExothermic ReactionsazilaPas encore d'évaluation

- Complete PPT On Chemical EquilibriaDocument52 pagesComplete PPT On Chemical EquilibriaSaikiran Chamakuri71% (7)

- Lecture 3 Convective Mass TransferDocument33 pagesLecture 3 Convective Mass Transferافكر اشتري كورياPas encore d'évaluation

- Me2121 2Document12 pagesMe2121 2Wei QuanPas encore d'évaluation

- The Effects of Longitudinal Heat Conduction in Compact Plate-Fin and Tube-Fin Heat Exchangers Using A Finite Element MethodDocument17 pagesThe Effects of Longitudinal Heat Conduction in Compact Plate-Fin and Tube-Fin Heat Exchangers Using A Finite Element MethodchrissbansPas encore d'évaluation

- Heat Transfer SummaryDocument16 pagesHeat Transfer SummaryNuzhat SafdarPas encore d'évaluation

- Chem 1332Document4 pagesChem 1332geoffreyrascherPas encore d'évaluation

- Combined Convection and Radiation Report - OdtDocument9 pagesCombined Convection and Radiation Report - OdtPasindu MalithPas encore d'évaluation

- A2 18 QuesDocument12 pagesA2 18 QuesNguyen Linh TrangPas encore d'évaluation

- Tut 2Document2 pagesTut 2GUNJAN MUDGALPas encore d'évaluation

- Chemsheets A2 1079 KP Basics ANSDocument2 pagesChemsheets A2 1079 KP Basics ANSAashis Singh KHATTARPas encore d'évaluation