Académique Documents

Professionnel Documents

Culture Documents

Lss S

Transféré par

maherkamelTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Lss S

Transféré par

maherkamelDroits d'auteur :

Formats disponibles

THE

LSS PRIMER

SOLUTIONS TEXT

2007 by Bill Wortman - All rights reserved

SECTION II

LEAN SIX SIGMA GOALS - SAMPLE QUESTIONS

LSSS 2007 QUALITY COUNCIL OF INDIANA 1

2.1. Lean and six sigma share in common all of the following issues, EXCEPT:

a. They both focus on continuous improvement

b. They both require top management commitment

c. They both focus on customer satisfaction

d. They both require long learning curves

Solution: Note that a negative response is requested. Lean and six sigma are not opposite or mutually

exclusive. Answers a and c are reasons why lean and six sigma so naturally became a powerful hybrid

approach for continuous improvement. Both approaches, separately or combined, require management

commitment. Many of the lean tools have short learning curves.

Answer d is the correct, incorrect, choice.

Reference: LSS Primer, Section II - 2/3.

2.2. The most important element in lean six sigma deployment would be considered:

a. Training

b. Organizational structure

c. Management support

d. Reward and recognition

Solution: All of the answer choices are key lean six sigma elements. However, the question states the "most

important element." Management support is the most important element listed. Training, structure, and

rewards can all be provided and/or adjusted if management support is present.

Answer c is correct.

Reference: LSS Primer, Section II - 39 (and logic).

_____________________________________________________________________________

2.3. Which of the following concepts is mostly associated with Taiichi Ohno?

a. SPC

b. TOC

c. CTQ

d. TPS

Solution: Taiichi Ohno is the main contributor to the Toyota Production System (TPS).

Answer d is correct.

Reference: LSS Primer, Section II - 17/18.

SECTION II

LEAN SIX SIGMA GOALS - SAMPLE QUESTIONS

LSSS 2007 QUALITY COUNCIL OF INDIANA 2

2.4. Which of the following is the LEAST acceptable reason for the deployment of lean six sigma projects?

a. A focus on cost savings

b. A focus on customer satisfaction

c. A focus on internal problems

d. A focus on design improvements

Solution: It should be recognized that different organizations may have different priorities at different times.

Harry states that answers a, b, and c are all valid. There are other ways to manage design improvements.

Answer d is the correct, incorrect, choice.

References: LSS Primer, Section II - 2/6 (and logic). Harry, M. & Schrodeder, R. (2000). Six Sigma. New

York: Currency, Doubleday.

2.5. Lean six sigma project benefits could include all of the following, EXCEPT:

a. Increased profits

b. Improved process capability

c. Increased defects

d. Reduced warranty claims

Solution: Note that a negative response is requested. Some project benefits are easily expressed in dollar

amounts, for example: increased sales, increased profits, reduced defects, reduced scrap, lowered warranty

claims, improved process capability, increased up-time, reduced spare parts inventories, fewer customer

cancellations or returned product. Other project benefits are worthwhile, but harder to equate to dollars:

improved employee morale, increased skill levels through training, lower employee turnover, increased

customer satisfaction, more aesthetically appealing product, organization's reputation enhanced, pride from

a job well done, friendships, or political power. Of the four items listed, increased defects would not be

considered a project benefit.

Answer c is the correct, incorrect, choice.

Reference: LSS Primer, Section II - 2/6.

2.6. Kaplan and Norton have outlined a business planning process that gives consideration to factors other

than strictly financial ones. It provides a greater perspective for stakeholder interests. This approach

is referred to as:

a. Balanced scorecard

b. Strategic planning

c. Five forces of competitive strategy

d. Quality function deployment

Solution: The balanced scorecard focuses the planning process on: financial, internal business process,

learning and growth, and customer perspectives. The answer, five forces of competitive strategy, is related

to Michael Porter's work. Quality function deployment is sometimes referred to as the House of Quality.

Answer a is correct.

References: LSS Primer, Section II - 45. Kaplan, R.S., & Norton, D.P. (1996, January-February). "Using the

Balanced Scorecard as a Strategic Management System." Harvard Business Review.

SECTION II

LEAN SIX SIGMA GOALS - SAMPLE QUESTIONS

LSSS 2007 QUALITY COUNCIL OF INDIANA 3

2.7. Increasing performance in a lean six sigma corporation from 3 sigma to 4 sigma would reduce defects

per million by a factor of:

a. 2

b. 8

c. 10

d. 16

Solution: Since six sigma is referenced in the question, the assumption is that a 1.5 sigma must be included.

Using the shift, the 4 sigma defect rate is 6,210 ppm and the 3 sigma defect rate is 66,810 ppm or a ratio of

1:10.76.

Answer c is correct.

Reference: LSS Primer, Section II - 8.

2.8. In a nutshell, lean six sigma is considered:

a. A business improvement approach

b. A focus on critical customer items

c. An elimination of mistakes and defects

d. A concentrated focus on business outputs

Solution: All answers have some validity. The best choice is answer a. Answer choices b, c, and d are

considered subsets of answer choice a.

Answer a is correct.

Reference: LSS Primer, Section II - 2/11 (and logic).

2.9. What guru is MOST widely associated with DOE?

a. Shingo

b. Juran

c. Ishikawa

d. Taguchi

Solution: Certainly design of experiments is (was) not outside of the grasp of any of the four listed luminaries.

However, Taguchi presented a cookbook approach for Japanese (and later American) engineers to use in the

application of DOE.

Answer d is correct.

Reference: LSS Primer, Section II - 36/37.

SECTION II

LEAN SIX SIGMA GOALS - SAMPLE QUESTIONS

LSSS 2007 QUALITY COUNCIL OF INDIANA 4

2.10. The term "metrics" most frequently refers to:

a. A unit of measurement

b. The metric system

c. The science of weights and measurements

d. An evaluation method

Solution: This is a definition question. Answers a and b refer to a traditional form of measurement such as

the metric system and are incorrect. Answer c is the definition for metrology. The modern definition of

"metrics" is a form of measurement or evaluation (answer d).

Answer d is correct.

Reference: LSS Primer, Section II - 42.

2.11. If one chose to look at any business enterprise on a main level basis, which of the following categories

would NOT have either KPIV (key process input variables) or KPOV (key process output variables)?

a. Process

b. Operations

c. Business

d. Technological

Solution: Note that a negative response is requested. Although the variables themselves may differ, process,

operations and business levels have key input and output variables. A technological level is not separately

identified. It is integrated into the major three categories.

Answer d is the correct, incorrect, choice.

Reference: LSS Primer, Section II - 46/47.

2.12. What luminary is generally recognized as being the creator of the control chart?

a. Deming

b. Shewhart

c. Harry

d. Ishikawa

Solution: The honor belongs to Dr. Walter Shewhart. In fact, some quality professionals still refer to them as

Shewhart control charts.

Answer b is correct

Reference: LSS Primer, Section II - 34.

SECTION II

LEAN SIX SIGMA GOALS - SAMPLE QUESTIONS

LSSS 2007 QUALITY COUNCIL OF INDIANA 5

2.13. The defect levels, as reported by Motorola in their six sigma program, are higher than one might expect

from use of a standard normal table or traditional capability calculations. Why is this true?

a. Motorola found their processes followed the exponential distribution

b. Motorola allowed for failure on one-tail only

c. Motorola allowed for a 1.5 sigma shift in the mean

d. Motorola found that six sigma efforts increased process variation

Solution: Motorola allowed for a potential process shift or drift of 1.5 standard deviations in order to safely

report defect levels or process improvements.

Answer c is correct.

References: LSS Primer, Section II - 7/8.

2.14. A lean enterprise approach encompasses which of the following departments?

a. Manufacturing only

b. All company departments plus suppliers

c. Manufacturing, quality, and the supply chain

d. Manufacturing and quality departments

Solution: Lean enterprise encompasses the entire production system, beginning with the customer. Both

production and service departments are included. Lean enterprise also includes suppliers.

Answer b is correct.

Reference: LSS Primer, Section II - 11.

2.15. From an upper management perspective, what has been the principal motivating factor in embracing

lean six sigma?

a. Bottom line results

b. Market share growth

c. Defect reductions

d. Customer focus

Solution: Philip Crosby once stated that upper management is interested in money, making money, and not

losing money. He said there must be something else, but he never got that far in conversations with them.

Answers b, c, and d could be considered subsets of answer a.

Answer a is correct.

Reference: LSS Primer, Section II - 10/11 (and logic).

SECTION II

LEAN SIX SIGMA GOALS - SAMPLE QUESTIONS

LSSS 2007 QUALITY COUNCIL OF INDIANA 6

2.16. Strategic goals will be subdivided into:

a. Major benchmarks

b. Loss functions

c. Numerous tactical goals

d. Appropriate metrics

Solution: The strategic goals must be moved down to the lower levels of the organization via some technique.

Major benchmarks (answer a) and loss functions, a Taguchi term, (answer b) are filler answers. Metrics

(answer d) or measurements may be applied. However, none of these choices are subdividing or deployment

techniques. The strategic goals must be subdivided into numerous tactical goals (answer c).

Answer c is correct.

Reference: LSS Primer, Section II - 44 (and logic).

2.17. Of the key elements of an organizational plan, which of the following would be most likely to contain

numbers and dates?

a. Vision statements

b. Tactical objectives

c. Guiding principles

d. Mission statements

Solution: Some goals and all tactical objectives contain elements that are quantifiable and measurable.

Answer b is correct.

Reference: LSS Primer, Section II - 44 (and logic).

2.18. Who was the first CEO to understand the need to control variation instead of the process average as

a way to significantly improve quality?

a. Jack Welch

b. Robert Galvin

c. Henry Ford

d. Bill Smith

Solution: Robert Galvin was Motorolas CEO when Bill Smith being first developed the concept of +/- 6 sigma

quality levels. Many CEOs would have rejected the concept as being too technical. There was a lot of merit

in Galvins decision to give the 6 sigma concept a try.

Answer b is correct.

Reference: LSS Primer, Section II 37.

SECTION II

LEAN SIX SIGMA GOALS - SAMPLE QUESTIONS

LSSS 2007 QUALITY COUNCIL OF INDIANA 7

2.19. Which of the following would be considered a strategic quality goal?

a. Commitment to the customer

b. Reducing the scrap rate in the finishing department by 1%

c. Improved performance inspection checks on work in progress

d. Training 6 green belts in statistical techniques this quarter

Solution: Given the four answers to choose from, the idea is to distinguish between the options in some

manner. There is one broad scope (strategic) goal and three detailed (tactical) department goals listed. The

strategic goal is answer a. The other three answers are more tactical in nature. Strategic quality goals are

set by top management, while the tactical quality goals are established at the lower organizational levels.

Answer a is correct.

Reference: LSS Primer, Section II - 42/44 (and logic).

2.20. The concept most closely associated with lean production is:

a. Better quality

b. Faster production

c. Flexible production

d. Elimination of waste

Solution: All answer choices have merit. A good lean implementation will result in better quality, and faster

and more flexible production. However, the central concept in lean production is the elimination of waste.

Answer d is correct.

Reference: LSS Primer, Section II - 11.

2.21. Why is lean six sigma called TQM on steroids?

a. Because of the extensive training element required

b. Because of the inclusion of statistical and lean tools

c. Because of the heavy impact of top management support

d. Because of the impact of cost savings on the bottom line

Solution: The steroid quote comes from the inclusion of statistical items such as DOE, DFSS, statistical

analysis, etc. and certain lean manufacturing tools.

Answer b is correct.

Reference: LSS Primer, Section II - 9/11 (and logic).

SECTION II

LEAN SIX SIGMA GOALS - SAMPLE QUESTIONS

LSSS 2007 QUALITY COUNCIL OF INDIANA 8

2.22. Strategic goals must be subdivided. Thus, they are:

a. Delegated

b. Distributed

c. Accountable

d. Deployed

Solution: The key question word is "subdivided." Delegated means to be assigned goals (answer a).

Distributed means to be given goals (answer b). Accountable means to be responsible for the goals (answer

c). Deployed means to have the goals spread out into attainable portions. Answer d is the best choice.

Answer d is correct.

Reference: LSS Primer, Section II - 44 (and logic).

2.23. Many tools can be used in either lean or six sigma projects. A problem solving approach that unifies

project follow-up is:

a. SIPOC

b. DOE

c. DMAIC

d. TPM

Solution: Some experts argue the grandfather of problem solving approaches PDCA (plan, do, check, act) is

the default choice for lean projects. DMAIC (define, measure, analyze, improve, control) could be seen as

an improved version of PDCA and it has been the favorite of the six sigma crowd for many years. Notice that

PDCA is not an answer option and SIPOC, DOE, and TPM are specific techniques for specific purposes.

DMAIC has become the preferred problem solving approach for lean six sigma projects.

Answer c is correct.

Reference: LSS Primer, Section II - 6.

2.24. Which of the following quality gurus is most closely associated with the term total quality

management?

a. Crosby

b. Feigenbaum

c. Deming

d. Juran

Solution: In the USA, Feigenbaum is generally given credit for the term total quality control (including total

quality management). None of the other answer choices were against the concept.

Answer b is correct.

Reference: LSS Primer, Section II - 22 and 28/29.

SECTION II

LEAN SIX SIGMA GOALS - SAMPLE QUESTIONS

LSSS 2007 QUALITY COUNCIL OF INDIANA 9

2.25. The difference between strategic goals and the strategic business plan is that:

a. Strategic goals are often a lower tier than the strategic business plan

b. They are determined by top management only

c. They may offer conflicting priorities

d. They are based on priorities given by all levels of the company

Solution: The key word in this question is "difference." Answers b, and d are common to both strategic quality

goals and the strategic business plan. Answer c is incorrect. The strategic business plan forms the higher

level, with strategic quality goals being a part of it. Answer a is correct.

Answer a is correct.

Reference: LSS Primer, Section II - 44 and 46/47 (and logic).

2.26 What would occur if the quality goals were not a part of the strategic plan?

a. There would be no strategic goals

b. There would not be as much emphasis on quality

c. The total quality effort would not suffer

d. The quality department would still maintain the quality goals

Solution: Strategic goals could exist without a quality element. Therefore, answer a is not correct. Answer b,

lack of emphasis, can occur. The total quality effort would possibly suffer if it was not part of the strategic plan.

The quality effort needs commitment from top management. Therefore, answer c is not a correct statement.

Quality department goals (answer d) would not be strategic in nature. The best choice is answer b.

Answer b is correct.

Reference: LSS Primer, Section II - 42/44 (and logic).

2.27. Which American figure is seen as the earliest advocate of waste reduction?

a. Henry Ford

b. Frederick W. Taylor

c. W. Edwards Deming

d. James Womack

Solution: Henry Fords dramatic gains in his Highland Park and River Rouge plants could be seen as the

earliest examples of waste reduction.

Answer a is correct.

Reference: LSS Primer, Section II - 14.

SECTION II

LEAN SIX SIGMA GOALS - SAMPLE QUESTIONS

LSSS 2007 QUALITY COUNCIL OF INDIANA 10

2.28. A company has just started a lean six sigma initiative. Which set of tools would be better suited for

initial projects?

a. Lean tools because they provide stability and repeatability for future projects

b. Six sigma tools because they provide a larger number of available options

c. Lean tools because they provide a more reliable and accurate picture of the root cause

d. Six sigma tools because they provide more measurement data

Solution: Lean tools often precede six sigma approaches. A lot can be gained from the application of simple

and powerful lean techniques. Data collected from this effort will guide further improvements.

Answer a is correct.

Reference: LSS Primer, Section II - 3.

2.29. Which of the following quality luminaries would be most clearly identified as a proponent of

improvement and breakthrough projects?

a. Ishikawa

b. Deming

c. Juran

d. Crosby

Solution: Juran's Trilogy consists of three processes: quality planning, quality control, and quality

improvement. The quality improvement phase would certainly be considered a project approach to

improvement.

Answer c is correct.

Reference: LSS Primer, Section II - 33 (and logic).

2.30. Strategic plan implementation at the functional level requires:

a. Functional level metrics

b. A company quality policy with everyone understanding it

c. Functional short and long-term strategic goals

d. A customer focus

Solution: Strategic plans require long and short-term goals. Therefore, strategic plan implementation at the

functional level would contain short and long term goals.

Answer c is correct.

Reference: LSS Primer, Section II - 44 (and logic).

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- LUMAScape List SearchableDocument11 pagesLUMAScape List SearchableDianne RobbPas encore d'évaluation

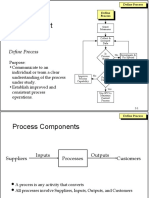

- Define Process in 40 CharactersDocument18 pagesDefine Process in 40 Charactersmaherkamel100% (1)

- Quality ControlDocument3 pagesQuality ControlmagePas encore d'évaluation

- General ManagerDocument14 pagesGeneral Managerdamianuskrowin100% (1)

- Final ExamDocument59 pagesFinal ExamME ValleserPas encore d'évaluation

- Chapter 7Document15 pagesChapter 7YnaPas encore d'évaluation

- Quality Assurance and Quality ControlDocument17 pagesQuality Assurance and Quality Controltraslie0% (1)

- AP 300Q Quizzer On Audit of Liabilities ResaDocument13 pagesAP 300Q Quizzer On Audit of Liabilities Resaryan rosalesPas encore d'évaluation

- COA Circular 78-77 Rules and Regulations To Implement The Instructions On Overtime-PaymentDocument6 pagesCOA Circular 78-77 Rules and Regulations To Implement The Instructions On Overtime-PaymentRobehgene Atud-JavinarPas encore d'évaluation

- Robotic Process Automation: Bachelor of TechnologyDocument9 pagesRobotic Process Automation: Bachelor of TechnologyShivam Juneja0% (1)

- Strategic Planning SyllabusDocument3 pagesStrategic Planning Syllabusnikub58Pas encore d'évaluation

- 8 QualityDocument26 pages8 QualitymaherkamelPas encore d'évaluation

- Introduction To Six SigmaDocument30 pagesIntroduction To Six SigmaadysubagyaPas encore d'évaluation

- Inspection, Quality Control, and Assurance SHEET (1) : 6-If The Mean Value of The Measured Stress Was 15 KG/MMDocument1 pageInspection, Quality Control, and Assurance SHEET (1) : 6-If The Mean Value of The Measured Stress Was 15 KG/MMmaherkamelPas encore d'évaluation

- Beyond Taguchi's Concept of The Quality Loss Function: Atul Dev, Pankaj JhaDocument5 pagesBeyond Taguchi's Concept of The Quality Loss Function: Atul Dev, Pankaj JhamaherkamelPas encore d'évaluation

- PQ Unit-IiDocument6 pagesPQ Unit-IimaherkamelPas encore d'évaluation

- The Quality Improvement Model: Is Process Capable?Document19 pagesThe Quality Improvement Model: Is Process Capable?maherkamelPas encore d'évaluation

- Chapter 9Document9 pagesChapter 9Rasha Abduldaiem ElmalikPas encore d'évaluation

- GE2022 TQM Notes 2 PDFDocument15 pagesGE2022 TQM Notes 2 PDFBalakumar MurugesanPas encore d'évaluation

- Acceptance SamplingDocument19 pagesAcceptance Samplingpm3dPas encore d'évaluation

- Attributes Data: Binomial and Poisson DataDocument31 pagesAttributes Data: Binomial and Poisson DatamaherkamelPas encore d'évaluation

- Gage R&RDocument24 pagesGage R&ROMAR CECEÑASPas encore d'évaluation

- ISO History (Brief) and Basic FactsDocument9 pagesISO History (Brief) and Basic FactsmaherkamelPas encore d'évaluation

- Acceptance SamplingDocument19 pagesAcceptance Samplingpm3dPas encore d'évaluation

- Basic Chart ConceptsDocument13 pagesBasic Chart ConceptsmaherkamelPas encore d'évaluation

- Mechanics 2Document14 pagesMechanics 2maherkamelPas encore d'évaluation

- Pareto and QualityDocument1 pagePareto and QualitymaherkamelPas encore d'évaluation

- Forming 2 PDFDocument43 pagesForming 2 PDFNeoXana01Pas encore d'évaluation

- Chapter 9Document9 pagesChapter 9Rasha Abduldaiem ElmalikPas encore d'évaluation

- Basics 1Document7 pagesBasics 1maherkamelPas encore d'évaluation

- ME 423 Machine DesignDocument2 pagesME 423 Machine DesignmaherkamelPas encore d'évaluation

- ChatterDocument9 pagesChattermaherkamelPas encore d'évaluation

- Course 649Document2 pagesCourse 649jambu99Pas encore d'évaluation

- HW3 ADocument2 pagesHW3 Ajambu99Pas encore d'évaluation

- HW 1Document2 pagesHW 1maherkamelPas encore d'évaluation

- HW1 2Document2 pagesHW1 2maherkamelPas encore d'évaluation

- Me338 10Document2 pagesMe338 10maherkamelPas encore d'évaluation

- QM in Library PDFDocument25 pagesQM in Library PDFgaurav sharmaPas encore d'évaluation

- Quality Lecture NotesDocument23 pagesQuality Lecture NotesmaherkamelPas encore d'évaluation

- 2023 07 q1-2024 Investor PresentationDocument73 pages2023 07 q1-2024 Investor PresentationtsasidharPas encore d'évaluation

- Public Enterprise CharacteristicsDocument8 pagesPublic Enterprise Characteristicsraiac047Pas encore d'évaluation

- College of Accountancy Final Examination Acctg 207A InstructionsDocument5 pagesCollege of Accountancy Final Examination Acctg 207A InstructionsCarmela TolinganPas encore d'évaluation

- Characteristics of Successful Employer Brands PDFDocument17 pagesCharacteristics of Successful Employer Brands PDFengmostafa_2007Pas encore d'évaluation

- Chapter 3Document3 pagesChapter 3Mariya BhavesPas encore d'évaluation

- The Future of Retail in Asia-Pacific: How To Thrive at High SpeedDocument12 pagesThe Future of Retail in Asia-Pacific: How To Thrive at High SpeedPhạm Thanh HuyềnPas encore d'évaluation

- July 2021Document14 pagesJuly 2021RkkvanjPas encore d'évaluation

- Simulacro Ititl 2Document18 pagesSimulacro Ititl 2Yoshieki Daniel Tanamachic ChavezPas encore d'évaluation

- Tech & Ops Trends in Wealth Management 2021: Key Developments Explained by Top Industry ExpertsDocument33 pagesTech & Ops Trends in Wealth Management 2021: Key Developments Explained by Top Industry Expertsvk2012Pas encore d'évaluation

- Aspects of StaffingDocument18 pagesAspects of StaffingKASHISH JAINPas encore d'évaluation

- Teaching Innovation Currency in DisciplineDocument5 pagesTeaching Innovation Currency in Disciplineapi-393438096Pas encore d'évaluation

- Relationship Between Financial Management Skills and Job Satisfaction Amon The Teachers of Bagumbayan National High School - Group1 - ABM - Chapter1Document12 pagesRelationship Between Financial Management Skills and Job Satisfaction Amon The Teachers of Bagumbayan National High School - Group1 - ABM - Chapter1Wenzil CastillonPas encore d'évaluation

- JD Windham JR - ResumeDocument2 pagesJD Windham JR - ResumeJ.D. Windham, JrPas encore d'évaluation

- Product Release Oracle Banking Treasury Management Release 14.6.0.0.0 File NameDocument64 pagesProduct Release Oracle Banking Treasury Management Release 14.6.0.0.0 File NamenajusmaniPas encore d'évaluation

- HDB Financial Services FY2019 Update PDFDocument8 pagesHDB Financial Services FY2019 Update PDFCharu BhattPas encore d'évaluation

- Organizational Culture and EnvironmentDocument5 pagesOrganizational Culture and EnvironmentJanette CortezPas encore d'évaluation

- Ek AkuntansiDocument74 pagesEk AkuntansiEsa SulyPas encore d'évaluation

- FINANCIAL STATEMENT ANALYSIS OF Nokia Inc LTDDocument4 pagesFINANCIAL STATEMENT ANALYSIS OF Nokia Inc LTDROHIT SETHI100% (2)

- ENM 301 Speaking Examination - SVDocument1 pageENM 301 Speaking Examination - SVBích NgânPas encore d'évaluation

- Prob Set - 1Document2 pagesProb Set - 1Amal MobarakiPas encore d'évaluation

- Unit 29 Managing and Running A Small Business: Student Name: Student IDDocument15 pagesUnit 29 Managing and Running A Small Business: Student Name: Student IDFahmina AhmedPas encore d'évaluation