Académique Documents

Professionnel Documents

Culture Documents

X60349 Controls Philosophy P1

Transféré par

Karthy Ganesan0 évaluation0% ont trouvé ce document utile (0 vote)

18 vues9 pagesclean room

Copyright

© © All Rights Reserved

Formats disponibles

DOC, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentclean room

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOC, PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

18 vues9 pagesX60349 Controls Philosophy P1

Transféré par

Karthy Ganesanclean room

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOC, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 9

HVAC Systems Control Philosophy

Project: GMP Cell Therapy Facility

Customer: Tadmur Trading, oha, !atar

"#$ %&T'()CT%(&

The new GMP Cell Therapy Laboratory is to be constructed at first floor level in the

hospital. The laboratory comprises of Cleanrooms 1 & 2 which are !GMP Grade "

environments served by #$!%& Cleanroom ' which is an !GMP Grade " environment

served separately by #$!%#& the Processin( )oom and support rooms which are

!GMP Grade C environments served by #$!'.

This controls philosophy document details the control methodolo(y to achieve the

efficient operation of the mechanical services and the specified space conditions

re*uired.

$eatin( is provided by electric heaters either mounted in the #$! or as +one heaters in

the distribution ductwor,.

Coolin( is provided by chilled water ta,en from the chilled water circulation system

connected to an air cooled chiller at roof level.

$umidification is provided by electric self (eneratin( steam in-ection humidifiers in each

air handlin( unit.

"uildin( services are provided in accordance with the followin( documents.

/rawin( no 012'%34M21 $5#C 6chematic #$!'& % & %#

/rawin( no 012'%34M22 $5#C #$! /etails

/rawin( no 012'%34M2' #ir /istribution Layout

*#$ C(&T'(+ ',!)%',M,&TS

2.1 AH)- HVAC System

*#"#" Supply . ,/tract Fan (peration

6ystem to run continuously to maintain specified room pressures.

7ccupied periods. supply and e8tract at 1229 of desi(n duty.

!noccupied periods. supply and e8tract at 1229 of desi(n duty.

ach supply fan motor and e8tract fan motor to be fitted with inverter

drive speed controllers. 6upply fan speed to be controlled by differential

pressure si(nal measured across supply air silencer. The pressure set4

point value will be up to :2 Pa at 1229 but actual value to be measured

durin( commissionin( at the correct flow rates and the value obtained to

be used as set points for supply fan flowrate control. 8tract fan speed

to be controlled by differential pressure si(nal measured across e8tract

air silencer. The pressure set4point value will be up to :2 Pa at 1229 of

flow but actual value to be measured and confirmed durin(

commissionin( at the correct flow rates. the value obtained to be used as

set points for e8tract fan flowrate control.

Pa(e 1 of 3

HVAC Systems Control Philosophy

Project: GMP Cell Therapy Facility

Customer: Tadmur Trading, oha, !atar

#$!' supply fan is fitted with duty and standby motors and inverter

drives. Controls to automatically switch from duty to standby fan in the

event of Low ;low. Low ;low is tri((ered by a measured pressure

across the supply air silencer at <29 of the set4point value for 12

seconds. =n the event of low flow a latched 6upply #ir Low ;low lamp

shall be lit on the control panel and an alarm sent to the "M6 system.

#c,nowled(in( the alarm will re4set the auto chan(e over and e8tin(uish

the 6upply #ir Low ;low lamp.

/uplicate direct drive e8tract fans with inverter drives are fitted to the

(eneral e8tract system to provide run and standby operation. Motorised

dampers are fitted either side of each e8tract fan to allow isolation.

/ampers are to open and close automatically to isolate the fan that is not

runnin(. Controls are to automatically switch from duty to standby fan in

the event of Low ;low. Low ;low is tri((ered by a measured pressure

across the e8tract air silencer at <29 of the set4point value for 12

seconds. =n the event of low flow a latched 8tract #ir Low ;low lamp

shall be lit on the control panel and an alarm sent to the "M6 system.

#c,nowled(in( the alarm will re4set the auto chan(e over and e8tin(uish

the 8tract #ir Low ;low lamp.

*#"#* Heating

6in(le #$! mounted electric heater servin( controlled +one as follows>

?one '41 Process and ancillary rooms.

6pace temp in heatin( mode 2'@C A or 4 1@C room temperature tolerance

durin( occupied period. 1:@C unoccupied period set bac, room

temperature.

Minimum % sta(es each sta(e switched separately by output from +one

heatin(Bcoolin( P=/ control module. =nput to control module from space

avera(in( room temperature detector in individual +one return air

ductwor,.

*#"#- Cooling

6in(le air handlin( unit mounted chilled water coolin( coil.

Chilled water distribution from roof top mounted air cooled li*uid chiller.

Chilled water temperatures 1.<@C flow& 12.2@C return.

6pace temperature in coolin( mode 2'@C A or 4 1@C room temperature

tolerance durin( occupied period. Co room hi(h limit temperature control

durin( unoccupied period. Coolin( coil proportionally controlled by a

modulatin( ' port motorised control valve. 5alve motor to be controlled

by output from +one heatin(Bcoolin( control module.

Chilled water control valve to be selected to operate in mi8in( mode and

provide a minimum of 2.: valve authority.

6upply air temperature 1%@C to 22@C in coolin( mode.

Low limit control of supply duct air temperature at 1'@C.

Pa(e 2 of 3

HVAC Systems Control Philosophy

Project: GMP Cell Therapy Facility

Customer: Tadmur Trading, oha, !atar

2.1.% Humidi0ication

6pace humidity :29)$ A or D :9)$ room humidity tolerance durin(

occupied period. Co room low limit humidity control durin( unoccupied

period.

6in(le sta(e self (eneratin( direct in-ection humidifier to incorporate

proportional control of humidifier output by a si(nal from the humidity

control module. =nput to control module from space avera(in( sensor in

return air ductwor,. $i(h limit control of supply duct air humidity at E:9

)$ only active when humidifier is operatin(. de4humidification mode can

e8ceed E:9.

*#"#1 e2Humidi0ication

6pace humidity :29)$ A or D :9)$ room humidity tolerance durin(

occupied period. Co room hi(h limit humidity control durin( unoccupied

period.

/e4 humidification is controlled by the output from humidity control

module overridin( the coolin( si(nal to the chilled water coolin( coil

control valve. The #$! +one heater will provide re4heatin( as re*uired

to maintain room specified temperatures.

*#"#3 Ventilation

Minimum fresh air re*uired to suit occupancy of 1: persons at 12 lBs

each (ivin( a total of 1E2 lBs or 2.1E2 m'Bs. Ma8imum supply air (reater

than e8tract air volume by 2.2E m'Bs to maintain room pressure. flowrate

above this amount will re*uire additional sealin( of the buildin( fabric&

doors and services penetrations.

*#"#4 'oom Pressure Control

# room pressure of min A2:Pa is maintained in the Process )oom under

all flow conditions when doors are closed. )oom pressure is lost when

doors are opened. # full set of room pressures are shown on drawin( no

012'%34M21. )oom pressure is set up durin( commissionin( by

providin( supply and e8tract duct static pressure set points at 1229 flow

conditions.

)oom pressure is set up durin( commissionin( by providin( supply and

e8tract duct static pressure set points at 1229 flow conditions.

2.2 AH)5 . AH) 5A HVAC Systems

*#*#" Supply . ,/tract Fan (peration

6ystems to run continuously to maintain specified room pressures.

7ccupied periods. supply and e8tract at 1229 of desi(n duty.

!noccupied periods. supply and e8tract at 1229 of desi(n duty.

;umi(ation period. supply and e8tract switched off.

Post fumi(ation ventilation. supply and e8tract at :29 of desi(n duty.

Pa(e ' of 3

HVAC Systems Control Philosophy

Project: GMP Cell Therapy Facility

Customer: Tadmur Trading, oha, !atar

ach supply fan motor and e8tract fan motor to be fitted with inverter

drive speed controllers. 6upply fan speed to be controlled by differential

pressure si(nal measured across supply air silencer. The pressure set4

point value will be up to :2 Pa at 1229 of flow and up to 12.: Pa at :29

of flow FPost fumi(ation ventilationG but actual values to be measured

durin( commissionin( at the correct flow rates to be used as set points

for supply fan flowrate control. 8tract fan speed to be controlled by

differential pressure si(nal measured across e8tract air silencer. The

pressure set4point value will be up to :2 Pa at 1229 of flow and up to

12.: Pa at :29 of flow FPost fumi(ation ventilationG but to actual values

be measured durin( commissionin( at the correct flow rates to be used

as set points for e8tract fan flowrate control.

#$! supply fans are to be fitted with duty and standby motors and

inverter drives. Controls to automatically switch from duty to standby fan

in the event of Low ;low. Low ;low is tri((ered by a measured pressure

across the supply air silencer at <29 of the set4point value for 12

seconds. =n the event of low flow a latched 6upply #ir Low ;low lamp

shall be lit on the control panel and an alarm sent to the "M6 system.

#c,nowled(in( the alarm will re4set the auto chan(e over and e8tin(uish

the 6upply #ir Low ;low lamp.

/uplicate direct drive e8tract fans with inverter drives are fitted to the

(eneral e8tract systems to provide run and standby operation. Motorised

dampers are fitted either side of each e8tract fan to allow isolation.

/ampers are to open and close automatically to isolate the fan that is not

runnin(. Controls are to automatically switch from duty to standby fan in

the event of Low ;low. Low ;low is tri((ered by a measured pressure

across the e8tract air silencer at <29 of the set4point value for 12

seconds. =n the event of low flow a latched 8tract #ir Low ;low lamp

shall be lit on the control panel and an alarm sent to the "M6 system.

#c,nowled(in( the alarm will re4set the auto chan(e over and e8tin(uish

the 8tract #ir Low ;low lamp.

*#*#* Heating

lectric heater servin( each +one as follows>

AHU4

?one %41 ;inal Prep )oom

?one %42 Clean )oom 1

?one %4' Clean )oom 2

AHU4A

?one %#42 Clean )oom '

6pace temp in heatin( mode 2'@C A or 4 1@C room temperature tolerance

durin( occupied period. 1:@C unoccupied period set bac, room

temperature.

Pa(e % of 3

HVAC Systems Control Philosophy

Project: GMP Cell Therapy Facility

Customer: Tadmur Trading, oha, !atar

Minimum % sta(es each sta(e switched separately by output from

relevant +one heatin(Bcoolin( P=/ control module. =nput to control

module from space avera(in( room temperature detector in return air

ductwor,.

*#*#- Cooling

6in(le air handlin( unit mounted chilled water coolin( coil.

Chilled water distribution from roof top mounted air cooled li*uid chiller.

Chilled water temperatures 1.<@C flow& 12.2@C return.

6pace temperature in coolin( mode 2'@C A or 4 1@C room temperature

tolerance durin( occupied period. Co room hi(h limit temperature control

durin( unoccupied period. Coolin( coil proportionally controlled by a

modulatin( ' port mi8in( motorised control valve. ;or #$!% valve motor

controlled by output from ma8imum load module receivin( input from

three individual +one heatin(Bcoolin( control modules. Ma8imum load

module receives input from three +one P=/ control modules and uses

ma8imum load to control valve motor. ;or #$!%# valve motor to be

controlled by output from +one heatin(Bcoolin( control module.

Chilled water control valves to be selected to operate in mi8in( mode and

provide a minimum of 2.: valve authority.

6upply air temperature 1%@C to 22@C in coolin( mode.

Low limit control of supply duct air temperature at 1'@C.

2.2.% Humidi0ication

6pace humidity :29)$ A or D :9)$ room humidity tolerance durin(

occupied period. Co room low limit humidity control durin( unoccupied

period.

6in(le sta(e self (eneratin( direct in-ection humidifier in each air

handlin( unit havin( proportional control of humidifier output by a si(nal

from the humidity control module. =nput to control module from space

avera(in( sensor in return air ductwor,. $i(h limit control of supply duct

air humidity at E:9 )$ only active when humidifier is operatin(. de4

humidification mode can e8ceed E:9.

*#*#1 e2Humidi0ication

6pace humidity :29)$ A or D :9)$ room humidity tolerance durin(

occupied period. Co room hi(h limit humidity control durin( unoccupied

period.

/e4 humidification is controlled by the output from humidity control

module overridin( the coolin( si(nal to the chilled water coolin( coil

control valve. The individual +one heaters will provide re4heatin( as

re*uired to maintain room specified temperatures.

*#*#3 Ventilation

Minimum fresh air re*uired to suit occupancy of>

Pa(e : of 3

HVAC Systems Control Philosophy

Project: GMP Cell Therapy Facility

Customer: Tadmur Trading, oha, !atar

#$!% % persons at 12 lBs each (ivin( a total of %E lBs or 2.2%E m'Bs.

#$!%# ' persons at 12 lBs each (ivin( a total of '1 lBs or 2.2'1 m'Bs.

#$!% supply air (reater than e8tract air volume by 2.12 m'Bs.

#$!%# supply air (reater than e8tract air volume by 2.12 m'Bs.

8cess of supply air flowrate over e8tract are to maintain room pressure.

;lowrates above these amounts will re*uire additional sealin( of the

buildin( fabric& doors and services penetrations.

*#*#4 'oom Pressure Control

# room pressure of min A<2Pa is maintained in Clean )oom 1 and 2&

E2Pa in Cleanroom ' and A12Pa in the ;inal Preparation )oom under all

flow conditions when doors are closed. )oom pressure is lost when

doors are opened. # full set of room pressures are shown on drawin( no

012'%34M21. )oom pressure is set up durin( commissionin( by

providin( supply and e8tract duct static pressure set points at various

F1229 and :29G flow conditions.

*#*#6 Fumigation Control

Two fumi(ation control panels are to be provided to control the

fumi(ation process. Control panel to operate (as ti(ht dampers& plant

shutdown& operation of the fumi(ation process and post fumi(ation

ventilation. Panel 1 is dedicated to Cleanroom 1 and Cleanroom 2 which

are to be fumi(ated to(ether. panel 2 is dedicated to Cleanroom'. The

control panel is to be a recessed desi(n and mounted on the wall of the

Process )oom. # red flashin( fumi(ation beacon is to be mounted in the

ceilin( of the ;inal Preparation )oom over each clean room door. ach

door to be fitted with a prominent si(n statin( H/7 C7T CT) I$C

)/ L=G$T =6 ;L#6$=CGJ.

#ppendi8 # details the fumi(ation process and e*uipment re*uirements.

-#$ Condition Monitoring

'.1 'oom Conditions Monitoring and isplays

# visual pro(rammable display panel is to be mounted ad-acent the door of

Cleanroom 1& Cleanroom 2& Cleanroom ' and the Process )oom. ach panel

will indicate room temperature& humidity and pressure. =ndependent sensors

are to be provided to monitor space conditions as detailed below>

)oom temperature measured in each +one return air ductwor,.

)oom humidity measured in each +one return air ductwor,.

)oom pressure measured in each room. ach room pressure to be a

differential pressure measurement measured to an a(reed datum point in the

area ad-acent the GMP facility.

'.2 Filter Condition Monitoring

Pa(e 1 of 3

HVAC Systems Control Philosophy

Project: GMP Cell Therapy Facility

Customer: Tadmur Trading, oha, !atar

ach filter ban, to be fitted with differential pressure sensors to monitor the filter

condition. The pressure readin( obtained is to be used for front end monitorin(

and display in the "M6 system. These values are to be used to indicate

approachin( dirty and dirty filter alarms within the "M6 system as detailed

below>

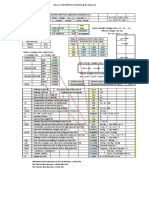

AHU3 Approaching Dirty Dirty Sensor Range

Primary filter ;< 222Pa 222 Pa 2 to :22 Pa

Primary filter ;3 222Pa 222 Pa 2 to :22 Pa

Terminal $P# $1% ':2 Pa %22 Pa 2 to 1222 Pa

AHU4 Approaching Dirty Dirty Sensor Range

Primary filter ;< 222Pa 222 Pa 2 to :22 Pa

Primary filter ;3 222Pa 222 Pa 2 to :22 Pa

$P# $1% ':2 Pa %22 Pa 2 to 1222 Pa

Terminal $P# $1% ':2 Pa %22 Pa 2 to 1222 Pa

AHU4A Approaching Dirty Dirty Sensor Range

Primary filter ;< 222Pa 222 Pa 2 to :22 Pa

Primary filter ;3 222Pa 222 Pa 2 to :22 Pa

$P# $1% ':2 Pa %22 Pa 2 to 1222 Pa

Terminal $P# $1% ':2 Pa %22 Pa 2 to 1222 Pa

=n addition each filter ban, is to be fitted with a /wyer Ma(nehelic pressure

(au(e to provide indication of filter condition at plant room level. The monitored

pressures and (au(e ran(e are as follows.

AHU3 Dirty Magnehelic Gauge Range

Primary filter ;< 222 Pa 2 to :22 Pa

Primary filter ;3 222 Pa 2 to :22 Pa

Terminal $P# $1% %22 Pa 2 to 1222 Pa

AHU4 Dirty Magnehelic Gauge Range

Primary filter ;< 222 Pa 2 to :22 Pa

Primary filter ;3 222 Pa 2 to :22 Pa

$P# $1% %22 Pa 2 to 1222 Pa

Terminal $P# $1% %22 Pa 2 to 1222 Pa

AHU4A Dirty Magnehelic Gauge Range

Primary filter ;< 222 Pa 2 to :22 Pa

Primary filter ;3 222 Pa 2 to :22 Pa

$P# $1% %22 Pa 2 to 1222 Pa

Terminal $P# $1% %22 Pa 2 to 1222 Pa

ach #$! system to be provided with 2 no terminal $P# pressure

sensors and Ma(nehelic (au(es per system.

Pa(e < of 3

HVAC Systems Control Philosophy

Project: GMP Cell Therapy Facility

Customer: Tadmur Trading, oha, !atar

5#$ %SS),

3

th

/ecember 2211 ;irst =ssue P1

1#$ APP,&%7 A

:.1 Fumigation

Cleanrooms 1 and 2 has a dedicated fumi(ation panel and Cleanroom ' has a

dedicated fumi(ation panel. ach panel to include rotary selector switch& alarm

and operation li(hts. # separate red warnin( beacon is to be fitted into the

ceilin( above each cleanroom entrance.

;or Cleanrooms 1 and 2 fumi(ation is to ta,e place at the same time.

Cleanroom ' fumi(ation will ta,e place separately under the control of its own

fumi(ation control panel. Gas ti(ht isolation dampers& as shown on the

schematic& allow the room to be isolated for fumi(ation. The (as ti(ht dampers

are to be controlled by the fumi(ation control panel.

7n operation of the fumi(ation cycle the air handlin( unit is disabled& dampers

closed and fumi(ation soc,ets will be enabled for a pre set time Fad-ustableG.

#n input from the control panel 8normal90umigation: ,ey operated selector

switch enables the fumi(ation cycle.

Ihen the fumi(ation cycle is ener(ised& with 8Fumigation in Progress:

indication on the control panel& the supply and e8tract fans stop& fresh air and

e8haust air dampers move to their open position. The (as4ti(ht isolation

dampers and recirculation damper are driven to the closed position and end

switches illuminate 8ampers Closed: lampsK on the panel and allow the cycle

to proceed when all dampers are closed.

#fter an ad-ustable time period& the fumi(ation soc,ets are enabled for an

ad-ustable time period& with 8Fumigation Soc;ets ,na<led: indication on the

control panel.

7n completion of the (as cycle& fresh& e8haust and (as ti(ht isolation dampers

are driven fully open and recirculation damper closes. Ihen the (as ti(ht

dampers all reach the open position& as proved by their end switches& the

supply and e8tract fans are restarted and the de(as mode runs for an

ad-ustable time period li(htin( a 8egas: lamp on the control panel.

#t the end of this period the 8egas: lamp (oes out and the $5#C system

remains in this mode until the 8normal90umigation: ,ey operated selector

switch is returned to the normal position.

Pa(e E of 3

HVAC Systems Control Philosophy

Project: GMP Cell Therapy Facility

Customer: Tadmur Trading, oha, !atar

# second ,ey operated selector switch is provided on the control panel for

8&ormal9egas o=erride: which provides the ,ey holder with the followin(

additional function.

6hould it be deemed necessary at any time in the cycle to pur(e the

area of the (assin( a(ent& by operation of the switch into the override

position& the system is driven into the de(as mode.

Pa(e 3 of 3

Vous aimerez peut-être aussi

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGD'EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGPas encore d'évaluation

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SD'EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SPas encore d'évaluation

- Experiment 8: Temperature Control: 8.1 Objective of The ExperimentDocument11 pagesExperiment 8: Temperature Control: 8.1 Objective of The ExperimentHemavathy RtPas encore d'évaluation

- Analog Control SystemDocument11 pagesAnalog Control SystemYoginder KumarPas encore d'évaluation

- APHDocument1 pageAPHsai987650Pas encore d'évaluation

- Vav SystemsDocument4 pagesVav SystemsJesus RoldanPas encore d'évaluation

- Micronik ApplicationDocument81 pagesMicronik Applicationman on firePas encore d'évaluation

- BMS Sequence of OperationsDocument18 pagesBMS Sequence of OperationsRa Ar100% (2)

- # Air Conditioning - General:: Note For CPC Manual ModeDocument30 pages# Air Conditioning - General:: Note For CPC Manual Modejontis jasoliyaPas encore d'évaluation

- Capricorn Modul Hidraulic Fisa Tehnica 14.03.2013 NA enDocument7 pagesCapricorn Modul Hidraulic Fisa Tehnica 14.03.2013 NA envalentin proseanchinPas encore d'évaluation

- Process Control Lab ManualDocument19 pagesProcess Control Lab ManualAnkit Singh100% (1)

- Ta 1Document6 pagesTa 1JohnMerrPas encore d'évaluation

- NT3036 - Air Conditioning Lab Report Assessment Brief (HK) 30oct2021Document14 pagesNT3036 - Air Conditioning Lab Report Assessment Brief (HK) 30oct2021ho Po wongPas encore d'évaluation

- Hvac BMS: HVAC Systems Eng. Ahmed MoustafaDocument126 pagesHvac BMS: HVAC Systems Eng. Ahmed MoustafaBahaa bunniPas encore d'évaluation

- 306 Cooling Fan Operation PrincipleDocument7 pages306 Cooling Fan Operation PrincipleGinanjar Purnama100% (1)

- EEL - LIEBERT - Environmental Control SystemDocument15 pagesEEL - LIEBERT - Environmental Control SystemJairo FlechasPas encore d'évaluation

- HvacDocument15 pagesHvacKiran KumarPas encore d'évaluation

- Ak-Cc 460Document30 pagesAk-Cc 460Øyvind SkulstadPas encore d'évaluation

- Control of Temperature, Humidity, Pressure, Flow Rate, Level or PH Process VariablesDocument8 pagesControl of Temperature, Humidity, Pressure, Flow Rate, Level or PH Process VariablessaravananPas encore d'évaluation

- 06 Mem341Document17 pages06 Mem341Muhammad AbdullahPas encore d'évaluation

- Esp ManualDocument12 pagesEsp Manualjaikolangaraparambil100% (3)

- Fundamentals of HVAC Controls: Course ContentDocument28 pagesFundamentals of HVAC Controls: Course ContentMostafa AwadPas encore d'évaluation

- ICME Conference Format Paper Id 103 UpdatedDocument5 pagesICME Conference Format Paper Id 103 Updatedsiva ganesh MallaPas encore d'évaluation

- Temperature Control System... Himanshu RamdeoDocument25 pagesTemperature Control System... Himanshu RamdeoSurya BandhuPas encore d'évaluation

- Process and Instrumentation DiagramsDocument8 pagesProcess and Instrumentation DiagramsMehul DeshpandePas encore d'évaluation

- CS LabReport 8Document10 pagesCS LabReport 8Muhammad AfzaalPas encore d'évaluation

- Section 230993 - Sequence of Operations For Hvac ControlsDocument2 pagesSection 230993 - Sequence of Operations For Hvac ControlsAhmed Abo RashedPas encore d'évaluation

- 18079673Document7 pages18079673Mohammad Hossein SajjadPas encore d'évaluation

- Топливная Система Siemens Sid 201Document105 pagesТопливная Система Siemens Sid 201Vytautas Mackonis67% (3)

- The ALCO Controls EC3-75xDocument8 pagesThe ALCO Controls EC3-75xMaria DazaPas encore d'évaluation

- Sequence of Operation For Constant Air Volume Air Conditioning SystemDocument7 pagesSequence of Operation For Constant Air Volume Air Conditioning SystemDong VanraPas encore d'évaluation

- General: P - A - R - TCDocument18 pagesGeneral: P - A - R - TCMohamed MosaedPas encore d'évaluation

- 22.hvac Controls - InvensysDocument62 pages22.hvac Controls - Invensysmeeng2014Pas encore d'évaluation

- Turbine Gland Steam CondenserDocument4 pagesTurbine Gland Steam CondenserSai Swaroop100% (1)

- Warning Chiller PDFDocument64 pagesWarning Chiller PDFnurcahyo febriPas encore d'évaluation

- Maintaining Uniform Target Temperature - Thermal Processing MagazineDocument7 pagesMaintaining Uniform Target Temperature - Thermal Processing MagazineRichardPas encore d'évaluation

- E1100w enDocument5 pagesE1100w enmihai.aplugariteiPas encore d'évaluation

- Performance and Efficiency Test of A Refrigeration Plant Test ProcedurDocument4 pagesPerformance and Efficiency Test of A Refrigeration Plant Test ProcedurEJ TolentinoPas encore d'évaluation

- HumidificationDocument22 pagesHumidificationmohammed hussienPas encore d'évaluation

- Isystem Hardware: Temperature System: Screen 1Document3 pagesIsystem Hardware: Temperature System: Screen 1Francisco Rodriguez CozarPas encore d'évaluation

- A300-600, Ata 36Document9 pagesA300-600, Ata 36pknight2010Pas encore d'évaluation

- Refrigeration and Air Conditioning Book by Stoecker & JonesDocument1 pageRefrigeration and Air Conditioning Book by Stoecker & JonesRashed KhanPas encore d'évaluation

- ObjectivesDocument7 pagesObjectivesPeeka booPas encore d'évaluation

- XC420 GBDocument4 pagesXC420 GBiuliastarPas encore d'évaluation

- Aircon TroubleshootingDocument11 pagesAircon TroubleshootingpropessorsergioPas encore d'évaluation

- Calibration and Leak-By Test ProceduresDocument2 pagesCalibration and Leak-By Test Proceduresromi_hamdaniPas encore d'évaluation

- MultipleDocument3 pagesMultipleHumaid ShaikhPas encore d'évaluation

- Peugeot 306 Cooling FansDocument7 pagesPeugeot 306 Cooling Fansjez autoPas encore d'évaluation

- EKC312Document12 pagesEKC312bmw72Pas encore d'évaluation

- Trans Air EC3.0 Electronic Climate Control SystemDocument25 pagesTrans Air EC3.0 Electronic Climate Control SystemWilson BuenoPas encore d'évaluation

- Cooling Fan System (1Az-Fe) : On-Vehicle InspectionDocument53 pagesCooling Fan System (1Az-Fe) : On-Vehicle InspectionMusat Catalin-Marian100% (6)

- AFBC-Control Loop Write UpsDocument12 pagesAFBC-Control Loop Write UpsSaurabh BarangePas encore d'évaluation

- Automatic Temperature Control in Furnace Using PLCDocument19 pagesAutomatic Temperature Control in Furnace Using PLCAhammedali Ch0% (1)

- Ahu ManualDocument15 pagesAhu ManualAlan LaundrdayPas encore d'évaluation

- Danfoss EKC 201Document16 pagesDanfoss EKC 201Georgiana DumitruPas encore d'évaluation

- PID Control of Heat Exchanger SystemDocument6 pagesPID Control of Heat Exchanger SystemTuấn Anh Nguyễn100% (1)

- Hvac ExperimentDocument9 pagesHvac ExperimentShadan MuPas encore d'évaluation

- 418000E4422 R0 Write Up On Electro Hydraulic ControllerDocument10 pages418000E4422 R0 Write Up On Electro Hydraulic ControllerkoinsuriPas encore d'évaluation

- Troubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesD'EverandTroubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesÉvaluation : 1 sur 5 étoiles1/5 (2)

- Hot Water Circulation Pump Capacity CalculationDocument2 pagesHot Water Circulation Pump Capacity CalculationKarthy GanesanPas encore d'évaluation

- Ducts Pressure Losses Board: Project: Site: Unit - No.: Building: Airflow (CFM) ESP (Pa)Document12 pagesDucts Pressure Losses Board: Project: Site: Unit - No.: Building: Airflow (CFM) ESP (Pa)Karthy GanesanPas encore d'évaluation

- Pressurization Fan Calculation - PremierDocument6 pagesPressurization Fan Calculation - PremierKarthy GanesanPas encore d'évaluation

- Door LouverDocument6 pagesDoor LouverKarthy GanesanPas encore d'évaluation

- Wild AirDocument1 pageWild AirKarthy GanesanPas encore d'évaluation

- Generator Room LouverDocument1 pageGenerator Room LouverKarthy Ganesan50% (2)

- RainwaterDocument6 pagesRainwaterKarthy GanesanPas encore d'évaluation

- Nak (Villa-1) Duct Under Cut CalculationDocument2 pagesNak (Villa-1) Duct Under Cut CalculationKarthy GanesanPas encore d'évaluation

- Ducts Pressure Losses Board: Carpark Souq Waqif Ahu - A Basement-1Document2 pagesDucts Pressure Losses Board: Carpark Souq Waqif Ahu - A Basement-1Karthy GanesanPas encore d'évaluation

- Tank Capacity, Pump Capacity and Water DemandDocument1 pageTank Capacity, Pump Capacity and Water DemandDesigner ForeverPas encore d'évaluation

- Al Daayen Villa - CHW Comp MOD 16-12-2017 FinalDocument3 pagesAl Daayen Villa - CHW Comp MOD 16-12-2017 FinalKarthy GanesanPas encore d'évaluation

- Souq Waqif CHW Pump Head - Rev-01a As Per Approved DWGDocument1 pageSouq Waqif CHW Pump Head - Rev-01a As Per Approved DWGKarthy GanesanPas encore d'évaluation

- Souq Waqif CHW Pump Head - Rev-01a As Per Approved DWGDocument1 pageSouq Waqif CHW Pump Head - Rev-01a As Per Approved DWGKarthy GanesanPas encore d'évaluation

- Mechanical Design CalculationDocument2 pagesMechanical Design CalculationKarthy GanesanPas encore d'évaluation

- LouversDocument2 pagesLouversKarthy GanesanPas encore d'évaluation

- Louvers (04-05-2017) Rev-6Document2 pagesLouvers (04-05-2017) Rev-6Karthy GanesanPas encore d'évaluation

- VentilationDocument4 pagesVentilationKarthy Ganesan100% (1)

- Mechanical CalculationDocument2 pagesMechanical CalculationKarthy Ganesan100% (1)

- Louver SizingDocument1 pageLouver SizingKarthy GanesanPas encore d'évaluation

- All Mechanical CalculationsDocument1 pageAll Mechanical CalculationsKarthy GanesanPas encore d'évaluation

- Energia PDFDocument1 pageEnergia PDFKarthy GanesanPas encore d'évaluation

- Stair-Pressurization Bin MahmoudDocument1 pageStair-Pressurization Bin MahmoudKarthy GanesanPas encore d'évaluation

- PRD Calculations (1, 4, 6 & 8) Caln - Bin Mahmoud ProjectDocument1 pagePRD Calculations (1, 4, 6 & 8) Caln - Bin Mahmoud ProjectKarthy GanesanPas encore d'évaluation

- Formula Sheet PDFDocument4 pagesFormula Sheet PDFKarthy GanesanPas encore d'évaluation

- Appendix E: Load Values, in Water Supply Fixture Units (Wsfu) Type of Supply Fixture Occupancy Control Cold Hot TotalDocument1 pageAppendix E: Load Values, in Water Supply Fixture Units (Wsfu) Type of Supply Fixture Occupancy Control Cold Hot TotalKarthy GanesanPas encore d'évaluation

- Formula Sheet PDFDocument4 pagesFormula Sheet PDFKarthy GanesanPas encore d'évaluation

- Pipe Sizing Calculations For Water Main Line To UGT-05.07.15Document1 pagePipe Sizing Calculations For Water Main Line To UGT-05.07.15Karthy GanesanPas encore d'évaluation

- Calculation:: Project: Mr. Dafer Villa at PearlDocument1 pageCalculation:: Project: Mr. Dafer Villa at PearlKarthy GanesanPas encore d'évaluation