Académique Documents

Professionnel Documents

Culture Documents

Is 1897 2008

Transféré par

Santosh KumarTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Is 1897 2008

Transféré par

Santosh KumarDroits d'auteur :

Formats disponibles

Disclosure to Promote the Right To Information

Whereas the Parliament of India has set out to provide a practical regime of right to

information for citizens to secure access to information under the control of public authorities,

in order to promote transparency and accountability in the working of every public authority,

and whereas the attached publication of the Bureau of Indian Standards is of particular interest

to the public, particularly disadvantaged communities and those engaged in the pursuit of

education and knowledge, the attached public safety standard is made available to promote the

timely dissemination of this information in an accurate manner to the public.

!"#$%&# '(%)

!"# $ %& #' (")* &" +#,-.

Satyanarayan Gangaram Pitroda

Invent a New India Using Knowledge

/0)"1 &2 324 #' 5 *)6

Jawaharlal Nehru

Step Out From the Old to the New

7"#1 &" 8+9&"), 7:1 &" 8+9&")

Mazdoor Kisan Shakti Sangathan

The Right to Information, The Right to Live

!"# %& ;<" =7"#" > 72 &(: ?0)"@" #AB 7" <&*" A*

Bhart+hariN,ti-atakam

Knowledge is such a treasure which cannot be stolen

IS 1897 (2008): Copper strip for electrical purposes [MTD

8: Copper and Copper Alloys]

IS 1897 : 2008

~ ~ c f i ~ ~ e t ~ ~

(rfJfi'<! y;r#erur)

Indian Standard

COPPER STRIP FOR ELECTRICAL PURPOSES -

SPECIFICATION

( Third Revision)

ics 77.150.30

BIS 2008

BUREAU OF INDIAN STANDARDS

MANAK BHAVAN, 9 BAHADUR SHAH ZAFAR MARG

NEW DELHI 110002

November 2008 Price Group 3

Copper and Copper Alloys Sectional Committee. MTD 8

FOREWORD

This Indian Standard (Third Revision) was adopted by the Bureau of Indian Standards, after the draft finalized

by the Copper and Copper Alloys Sectional Committee had been approved by the Metallurgical Engineering

Division Council.

This standard was first published in 1962and was subsequently revised in 1971 and T983. In this revision, the

following modifications have been made:

a) Definition of strip has been modified to 6 mm thick (see 3.1),

b) Reference of cathode copper have been deleted (see 6) ,

c) Edgewise bending test have been made optional (see 8.3),

d) Mechanical properties Table I have been modified (see 8.1),

e) Temperature correction factor in electrical resistivity has been added as a Note (see Table 3),

t) Alternate method for electrical conductivity test included (see 9.1.1), and

g) Straightness value 00 mm per 1 000 mm length has been added (see 11.3).

Copper strips are used for electrical connections and windings, for transformers and related electrical machinery.

Bright annealed copper strips are used for non-insulated connections. Halfhard copper strips are required to

be used when the finished products, such as bus-bars and connections elements in heavy switchgear

constructions call for a certain amount of stiffness and rigidity and at the same time are subject to some

degree of cold work.

The composition of the Committee responsible for the formulation of this standard is given in Annex A.

For the purpose ofdeciding whether a particular requirement of this standard is complied with the final value,

observed or calculated, expressing the result of a test or analysis, shall be rounded off in accordance with

IS 2 : 1960 ' Rules for rounding off numerical values (revised)' . The number of significant places retained in

the rounded off value should be the same as that of the specified value in this standard.

IS 1897 : 2008

Indian Standard

COPPER STRIP FOR ELECTRICAL PURPOSES -

SPECIFICATION

( Third Revision)

440 : 1964

613:2000

1501:2002

1387: 1993

Title

Methods of test for resistance of

me tallic electrical resistance

material

IS No.

3635: 1966

The material shall be supplied in one ofthe following

conditions, as specified by the purchase:

3 TERMINOLOGY

For the purpose of this standard, the definition given

in IS 3288 (Parts 1 and 3) and the following shall

apply.

3.1 Strip - Flat product over 0.15 mm thick and

upto and including 6 mm thick, of any width and

generally not cut to length; usually in coil, but may

be flat or folded.

5 CONDITION OF SUPPLY

4 SUPPLY OF MATERIAL

The general requirements relating to the supply of

material shall conform to IS 1387.

7 FREEDOM FROM DEFECTS

a) 0 - Annealed (Soft),

b) HB- Half-hard, and

c) HD-Hard.

6 CHEMICAL COMPOSITION

The materials when analysed as per IS 440 or any

other established instrumental (spectrometer)/

chemical method shall conform to the requirements

ofGrade Cu-ETP or Cu-FRHC as per IS 191. Incase

of dispute, the procedure given in IS 440 shall be the

referee method. However, when the method is not

given in IS 440 the referee method shall beas agreed

to between the purchaser and the manufacturer.

The material shall be clean, bright, smooth and free

from harmful defects. Strips not supplied in coils

shall be reasonably flat and free from twists.

8 MECHANICAL PROPERTIES

8. I The material when tested in accordance with

IS 1608 and IS 150 I shall have the mechanical

properties as given in Table 1.

IS No.

191 : 2007

The following standards contain provisions which

through reference in this text , constitute provisions

of this standard. At the time of publication, the

editions indicated were valid. All standards ~

subject to revision and parties to agreements based

on this standard are encouraged to investigate the

possibility of applying the most recent editions of

the standards indicated below:

I SCOPE

This standard specifies the requirements of copper

strip for electrical purposes with drawn or rolled

edges (either round or square) in the annealed , half-

hard and hard condition.

2 REFERENCES

tut

Copper (fourth revision)

Methods of chemical analysis of

copper

Copper rods and bars for electrical

purposes - Specification (third

revision)

General requirements for the supply

ofmetallurgical materials

(second revision)

Method for Vickers hardness test

for metallic materials (third

revision)

Method for bend test (second

revision)

Metallic materials - Tensile testing

at ambient temperature (third

revision)

Dimensions and tolerances for

wrought copper and copper alloys

sheet, strip and foil (for general

engineering purposes) (second

revision)

3288 Glossary oftenns relating to copper

and copper alloys :

(Part 1): 1986 Materials (third revision)

(Part 3): 1986 Wrought forms

1599: 1985

1608:2005

3052: 1986

IS 1897: 2008

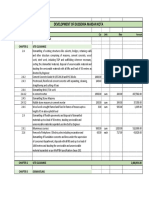

Table 1 Mechanical Properties of Strip

(Clause 8. I)

SI Temper Tbitknus Tensile Elongation Percent on Hardnus

No. mm Strength MPa 5.65 .rs. or 50 mm Gauge HV

.A

Length, Min

tQver

"I

Up 10and Min Max

Including

(I) (2) (3) (4) (5) (6) (7) (8)

i) 0 0.15 1.8 205 250 30 60, Max

1.8 6.0 205 250 35 60, Max

ii) HB 0.15 1.8 245 10 75-90

1.8 6.0 245 IS 75-90

iii) HD 0.15 6.0 290 90, Min

NOTES

I The material which has undergone further process of insulation and covering, the hardness values in annealed condition shall

increase to an extent to 10 percent maximum of the values specified in the Table.

2 I MPa = 0.102 kgflmm'.

8.2 Bend Test

The material is to be tested for bend test in accor-

dance with IS 1599 . The test piece shall not fracture

or crack on the convex surface of the bend portion,

when bent once through the angle and bend radius

as specified in Table 2.

8.3 Edgewise Bending

8.3.1 When agreed to between the purchaser and

the manufacturer, annealed strip with more than

12mmwidth, tested at full width, shall be capable of

being bent on edge through 180

0

around a former of

radius equal to halfofthe width of the strip without

cracking.

8.3.2 For annealed strip of width up to 12 mm the

radius of bend shall be as agreed to between the

purchaser and the supplier.

NOTE- For annealed strip below and upto I mm thick,

the edgewise bending test shall not be applicable.

9 ELECTRICAL RESISTIVITY TEST

9.1 The standard value at 20"C for the electrical

resistivity of annealed high conductivity copper shall

be taken as 0.017 24 ohm mmvm. The electrical

resistivity of the strip shall be measured in

accordance with IS 3635. The electrical resistivity

values are given in Table 3.

9.1.1 The method of measurement employing eddy

current probe shall be applied for electrical

conductivity test subject to mutual agreement

between the purchaser and the supplier.

10 TEST FOR CONTROLLED PROOF

RESISTANCE (OPTIONAL)

10.1 This test is to be conducted only when it is

asked by the purchaser.

10.2 For the purpose ofthe electrical resistance per

unit length in material supplied to a controlled range

O. I percent proof stress the material shall be deemed

to be in the hard or half-hard condition. The values

Condition

Table 2 Bend Test

(Clause 8.2)

Transnrse Bead Test Longitudinal Bend Telt

A

A

r

.....,

r "'\

Angle

Radius Angle Radius

Up to and 0 180" Close 180" Close

Including HB 180" Close 180" Close

6mm HD 90' Close 90' Close

2

IS 1897 : 2008

Table3 Electrical Resistivityand Conductivity

(Clause 9. I)

SI

No.

(I)

i)

ii)

Condition

(2)

o

HB and HD

Resistivity

Obm mm'/m at 20C

Max

(3)

0.01737

0.01777

Conduetlvity (lACS)

Pereeat

Min

(4)

99.25

. 97.00

NOTES

I Conductivity percent is expressed as percentage of the standard value for standard annealed copper of 100 percent conduct ivity

as laid down by lACS.

2 When tested at temperature other than specified above, the temperature correction factor as given in Annex B of IS 613 shall

be applied.

of 0.1 percent proof stress of three different

controlled range of proof stress up to 6 mm thick

strip are given in Table 4.

II DlMENSIONSANDTOLERANCES

11.1 The strip shall be supplied in dimensions

specified in IS 3052 subject to the tolerance specified

in the same standard.

11.2 The strip shall have comers or edges either

radiused or square. In the former case, the radius of

curvature shall be in accordance with Table 5, unless

otherwise stated.

11.3 Straightness

The tolerances on straightness and/or edgewise

curvature shall not vary from a straight line by more

than 3 mm in any I 000 mm length.

12 SAMPLING AND CRITERIA FOR

CONFORMITV

12.1 Unless otherwise agreed to between the

purchaser and the manufacturer, the following

SI

No.

DalgDatioD

Table 4 Controlled ProofStress Copper Strip

(Clause 10.2)

TbitkDCSS

_------.A..------_

mm

0.1 Perceat

Proof Stress

MPa

(I)

i)

i i)

iii)

(2)

CPRI

CPR2

CPRJ

(3)

0.80

0.80

1.20

0.80

(4)

6.0

1.20

6.0

6.0

(5)

140-200

170-230

170-220

220-260

Table 5 Radius on Edges or Corner of Strip

(Clause 11.2)

All dimensions in millimetrcs .

(2)

SI

No.

(I)

Tbitkacss of Strip

_ ~ .....----

:\

Up to and

Including

(3)

Nominal Radins

oaEdges

(4) (5)

i)

ii)

iii)

iv)

v)

1.0

1.6

2.25

J.SS

1.0

1.6

2.25

J .55

Semicircular

0.6

0.8

1.0

1.2S

3

0.06

r+0.15

1.- 0.10

0.15

0.20

0.25

IS 1897 : 2008

sampling procedure and criteria for conformity shall

apply.

12.2 Lot

In a consignment the copper strips of the same width

and thickness, and of the same temper shall be

grouped together to form a lot not exceeding

2 000 kg. One or more lots may be formed from the

material submitted for inspection depending on the

weight. Each lot shall be separately sampled for

acceptance purposes.

12.3 Visual and Dimensional Requirements

The material shall be individually examined for

freedom from defects and dimensional tolerance. At

least one sample or coil from each bundle shall be

selected for dimensional inspection. No failure shall

occur if the lot is to be accepted under this clause.

12.4 Chemical Composition and Mechanical

Properties Requirements

From each lot, one sample at the rate of 2 000 kg or

part thereof for chemical test and one sample at the

rate of 500 kg or part thereof shall be tested for

mechanical properties requirements of this standard.

The sample shall be cut-off cold and shall receive no

further treatment (except that they may be machined

to the shape of the test piece) before being tested.

The lot shall be accepted under this clause if the

samples tested meet all the chemical composition and

mechanical properties requirements of the

specification.

12.5 Electrical Resistivity Test

For this test at least one sample for each bundle or

from 500 kgor single coil weight, whichever is higher

shall be taken from different boxes or crates or

bundles as the case may beand shall beindividually

subjected to electrical resistivity test. The samples

shall meet the requirements ifthe lot is to beaccepted

under this clause.

13 RETFSf

13.1 If a test result of chemical analysis fails to

satisfy the requirements for any element, two more

4

tests for that element, shall be done on the

sample in order to confirm that the analysis ha

done properly. If both the test results satis

relevant requirements, the lot shall be conside

conforming to the specification, otherwise no

13.2 Should anyone of the test pieces first se

fail to pass the mechanical tests, two further sa

from the same batch shall be selected for tl

one of which shall be from the strip from whi

original test sample was taken, unless that str

been withdrawn by the supplier.

13.2.1 Should the test pieces from both

additional samples pass, the batch represenl

the test sample shall be deemed to comply wi

standard. Should the test pieces from either oj

additional sample fail, the batch represented

test sample shall be deemed not to comply wi

standard.

14 PACKING

The strip shall be packed in bundles, boxes, ca

crates so as to ensure safe transportation l

material.

15 MARKING

15.1 Each package shall be marked with the

and temper ofthe material, name ofthe manufat

the mass, size, lot number, date of manufactui

any other information required by the purcha

15.2 BIS Certification Marking

The material may also be marked with the Sta

Mark.

15.2.1 The use of the Standard Mark is gov

by the provisions of the Bureau ofIndian Stan

Act, 1986 and the Rules and Regulations

thereunder. The details ofthe conditions under

the licence for the use of the Standard Mark m

granted to manufacturers or producers m:

obtained from the Bureau of Indian Standards

IS 1897 : 2008

ANNEXA

(Foreword)

COMMITIEE COMPOsmON

Copper and CopperAlloysSectional Committee,MTD8

Organization

Indian Copper Development Centre, Kolkata

Agarwal Metal Works Pvt Ltd, Rewari

A1cobcx Metals Ltd, Jodhpur

Bhabha Atomic Research Centre, Mumbai

Bharat Electronics Ltd, BangalorclGhaziabad

Bharat Heavy Electricals Ltd, Bhopal

Birla Copper Ltd, Bharuch

Crompton Greaves Ltd, Mumbai

Chandra Protcco Ltd, Silvasa

DGS&D (Quality Assurance Wing), KolkatalNcw Delhi

Finolcx Cable Ltd, Bangalore

Gem Sanitary Appliances P Ltd, Delhi

Hindustan Copper Ltd, Kolkata

Indoswc Engineers Pvt Ltd, Pune

International Copper Promotion Council (India), Mumbai

Larsen &; Toubro Ltd, Murnbai

Ministry of Defence (DGQA), Katni

Ministry of Defence (OFB), Kolkata

Ministry of Defence (DMRL), Hydcrabad

Ministry of Railways (ROSO), Lucknow

Rupam Conductors (P) Ltd, Mwnbai

Machine Tool Prototype Factory, Ambcmath

Rapsari En.linccring Industries Ltd, BangaIOI'C

Saru Copper Alloy Semis Pvt Ltd, Meerut

5

Representativets)

DRD. DE SARKAR (Chairman)

SHRI D. K. JAIN

SHRI O. P. lUNA (Alternate)

SHRI G. C. KANuNGO

SHRI S. D. PUROHIT (Alternate)

SHRI V. K. TANGRI

SHRI S. K. GUPTA (Alternate)

SHRI SRIDHAR S. NADIGER

SHRI ANuJ SINOH (Alternate)

REPRESENI'ATIVE

DR P. R. lANDGE

SHJU B. M. SHAAMA (Alternate)

SHRI T. 1'. GoVINDAN

SHRI A. CHAKRAVO!mf'\'

DRS. K. Roy (Alternate)

SHRI B. DAS GUPTA

SHRI S. K. PANDEY (Alternate)

REPRESENI'ATIVE

SHRI B. K. SINGHAL

SHRI V. K. CHOWDHARY (Alternate)

SHRI A. K. SARKAR

SHRJ J. BHATTACHARJEE (Alternate)

SHRJ U. K. JAnA

SHRJ S. K. JAlN (Alternate)

SHRJ AnT AoVANI

SHRI MILINO RAJE (Alternate)

REPRESENI'ATIVE

QAO, QAE (MET)

SHRJ P. K. SAJWWANI (Alternate)

SHRJ R. K.VARSHNEY

SHRJ P. S. BANDHOPADHYAY (Alternate)

DRS. NAGAlUUNA

SHRJ A. K. MANDAI.

SHRJ S. K. DAS (Alternate)

SHRJ HASMUKH R. MEHTA

SHRI S. R. RAlYAGOII. (Alternate)

DRA. S. BALOIIl

DRP. SRJJtAM

SHRJ K. U. B. PIlAVEEN (Alternate)

SHIU D. P. JAIN

SHRJ SANJEEV JAIN (Alternate)

IS 1897 : 2008

Organization

Sterlite Industries India Ud, Silvasa

The Indian Smehing &: Refining Co, Mumbai

Vanaz Engineers Pvt ltd, Pune

BIS Directorate General

Member tary

SHRI DEEPAX JAIN

Scientist ' E' (MTD), BIS

6

Representativets)

Ms MEENAXStD SABHAR,WAL .

SHRI SURESH SIDWALKAR (Alternate)

SHIll D. BH-":rrACHARVYA

Siilu M. P. SAHLIYf (Alternate I)

SHRI V. D. KE!.USKAR (Alternate Jl)

REPttEsENTATIVE

DR(SIIIUMA1l) SNEll BHAllA, Scientist ' F' &:Head(MTD)

(Representing Director General (Ex-officio)1

Bureau of Indian Standards

BIS is a statutory institution established under the Bureau ofIndian Standards Act, 1986 to promote harmonious

development of the activities of standardization, marking and quality certification of goods and attending to

connected matters in the country.

Copyright

BIS has the copyright ofall its publications. No part ofthese publications may be reproduced inany formwithout

the prior permission in writing of BIS. This does not preclude the free use, in course ofimplementing the standard,

of necessary details, such as symbols and sizes, type or grade designations. Enquiries relating to copyright be

addressed to the Director (Publications), BIS.

Review oflndian Standards

Amendments are issued to standards as the need arises on the basis of comments. Standards are also reviewed

periodically; a standard along with amendments is reaffirmed when such review indicates that no changes are

needed; if the review indicates that changes are needed, it is taken up for revision. Users of Indian Standards

should ascertain that they are in possession of the latest amendments or edition by referring to the latest issue of

'BIS Catalogue' and 'Standards: Monthly Additions'.

This Indian Standard has been developed from Doc: No. MTD 8 (4598).

Amendments Issued Since Publication

Amendment No. Date of Issue

BUREAUOFINDIANSTANDARDS

Text Affected

Headquarters:

Manak Bhavan, 9 Bahadur Shah Zafar Marg, New Delhi 110002

Telephones:2323 0131,23233375,23239402 Website: www.bis.org.in

Regional Offices:

Central: Manak Bhavan, 9 Bahadur Shah Zafar Marg

NEWDELHI 110002

Eastern: 1/14, C.LT. Scheme VII M, Y.LP. Road, Kankurgachi

KOLKATA700054

Northern: SC0335-336, Sector 34-A, CHANDIGARH160022

Southern: C.I.T.Campus,IVCrossRoad,CHENNAI6oo1l3

Western: Manakalaya, E9 MIDC, Marol, Andheri (East)

MUMBAI400093

Telegrams: Manaksanstha

(Common to all offices)

Telephones

{

23237617

23233841

{

23378499,23378561

23378626,23379120

{

2603843

2609285

{

2254 1216,22541442

22542519,22542315

{

28329295,28327858

28327891,28327892

Branches: AHMEDABAD. BANGALORE. BHOPAL. BHUBANESHWAR. COIMBATORE. FARIDABAD.

GHAZIABAD. GUWAHATL HYDERABAD. JAIPUR. KANPUR. LUCKNOW. NAGPUR.

PARWANOO. PATNA. PUNE. RAJ KOT. THIRUVANATHAPURAM. VISAKHAPATNAM.

Printed by the Manager. Govt. of India Press, Faridabad

Vous aimerez peut-être aussi

- Estimate With NIT2020-21Document23 pagesEstimate With NIT2020-21BL AHIRWARPas encore d'évaluation

- Ronak India PVT LTD New 1Document34 pagesRonak India PVT LTD New 1Ronak FirePas encore d'évaluation

- Finolex Cable Price List Updated 30th October 2020Document20 pagesFinolex Cable Price List Updated 30th October 2020Sahili SalvePas encore d'évaluation

- Company Profile KE - 2020Document35 pagesCompany Profile KE - 2020fuadymfPas encore d'évaluation

- 2B P6 MVCC - RDSS - PGVCL - Infra SBD - Part 2 - TS - Version-2 - 28062022Document202 pages2B P6 MVCC - RDSS - PGVCL - Infra SBD - Part 2 - TS - Version-2 - 28062022Mrugesh Samsung.m31sPas encore d'évaluation

- Raychem RPG UL Listed Lug Range PDFDocument20 pagesRaychem RPG UL Listed Lug Range PDFDarwinPowChonLong100% (1)

- Effective Length About X Axis & y Axis p20Document40 pagesEffective Length About X Axis & y Axis p20cu1988Pas encore d'évaluation

- Haryana Vidyut Prasaran Nigam Limited: SPECIFICATION No. HGD/S-67/DGMS-171 (APRIL-2017)Document37 pagesHaryana Vidyut Prasaran Nigam Limited: SPECIFICATION No. HGD/S-67/DGMS-171 (APRIL-2017)samkarmakar2002Pas encore d'évaluation

- VMT ERT 03 REPORT 220 KV LUCKNOWDocument27 pagesVMT ERT 03 REPORT 220 KV LUCKNOWAnoop DikshitPas encore d'évaluation

- SANS 182-2 Conductors For Overhead Electrical Transmission Lines. AACDocument16 pagesSANS 182-2 Conductors For Overhead Electrical Transmission Lines. AACLaxmishankar Katiyar100% (1)

- Is 7098 2 2011Document17 pagesIs 7098 2 2011prajaptijagdishPas encore d'évaluation

- FRP Rods For Brittle Fracture ResistantDocument9 pagesFRP Rods For Brittle Fracture Resistantdmsoares1989Pas encore d'évaluation

- Copper Grade ListDocument2 pagesCopper Grade ListAnand KumaranPas encore d'évaluation

- TR Civil Build (Rev.0 2018)Document24 pagesTR Civil Build (Rev.0 2018)selva.uae8207Pas encore d'évaluation

- Guarantee Technical ParametersDocument3 pagesGuarantee Technical ParametersDramebaaz SandeepPas encore d'évaluation

- Development of Dussehra Maidan Kota: Part A - Civil WorksDocument91 pagesDevelopment of Dussehra Maidan Kota: Part A - Civil WorksShruti KabraPas encore d'évaluation

- Iec 61869 - 87 2009Document16 pagesIec 61869 - 87 2009Anonymous UbwGTAcKlsPas encore d'évaluation

- Phosphor Bronze E28093 Copper Alloy UNS C51000Document3 pagesPhosphor Bronze E28093 Copper Alloy UNS C51000Rafael CastroPas encore d'évaluation

- QAP CI Flsnged PipesDocument11 pagesQAP CI Flsnged PipesNaveen NagisettiPas encore d'évaluation

- AWWCE Unit Rates For Pipe Work - LegaDocument24 pagesAWWCE Unit Rates For Pipe Work - LegaMiko Abi0% (1)

- Cable Tray Selection GuideDocument18 pagesCable Tray Selection Guidestuart3962Pas encore d'évaluation

- WSA 109 - 2011 Flange Gaskets Working SheetDocument1 pageWSA 109 - 2011 Flange Gaskets Working SheetAbit BronjaPas encore d'évaluation

- Kiosk Earthing CircularDocument1 pageKiosk Earthing CircularsunilgvoraPas encore d'évaluation

- Iron Castings With Spheroidal or Nodular Graphite-SpecificationDocument13 pagesIron Castings With Spheroidal or Nodular Graphite-SpecificationAbinashBeheraPas encore d'évaluation

- Temporary Power Supply Arrangement Work BOQDocument1 pageTemporary Power Supply Arrangement Work BOQDeepa Junnarkar DegwekarPas encore d'évaluation

- As 60034.22-2010 Rotating Electrical Machines AC Generators For Reciprocating Internal Combustion (RIC) EnginDocument8 pagesAs 60034.22-2010 Rotating Electrical Machines AC Generators For Reciprocating Internal Combustion (RIC) EnginSAI Global - APAC100% (1)

- Annexure 6.2 (Part 1of5) PDFDocument227 pagesAnnexure 6.2 (Part 1of5) PDFAyman SaberPas encore d'évaluation

- StainlessSteel Fasteners Manufacturer in IndiaDocument2 pagesStainlessSteel Fasteners Manufacturer in Indiaviha steelPas encore d'évaluation

- Disclosure To Promote The Right To InformationDocument13 pagesDisclosure To Promote The Right To InformationSCRIBDPas encore d'évaluation

- Early Works Package - Specification B (Section 317210) - Tunnel Primary Support - Ground ReinforcementDocument3 pagesEarly Works Package - Specification B (Section 317210) - Tunnel Primary Support - Ground ReinforcementZain AbidiPas encore d'évaluation

- S TR Lightning (Rev.0 2009)Document8 pagesS TR Lightning (Rev.0 2009)Abhinav SinhaPas encore d'évaluation

- Vitreous China Plumbing Fixtures 75SMSS2Document25 pagesVitreous China Plumbing Fixtures 75SMSS2Pageduesca RouelPas encore d'évaluation

- Indian Standard: Specification For Steel ScaffoldingsDocument27 pagesIndian Standard: Specification For Steel Scaffoldingshari6krishnanPas encore d'évaluation

- Amendment No. 6 June 2021 To Is 1239 (Part 1) : 2004 Steel Tubes, Tubulars and Other Wrought Steel Fittings - SpecificationDocument3 pagesAmendment No. 6 June 2021 To Is 1239 (Part 1) : 2004 Steel Tubes, Tubulars and Other Wrought Steel Fittings - Specificationbeshnu garanaikPas encore d'évaluation

- Aerial Bundled Conductor Solutions: Product CatalogDocument44 pagesAerial Bundled Conductor Solutions: Product CatalogNimish TaterhPas encore d'évaluation

- 132kV Composite InsulatorDocument1 page132kV Composite InsulatorAneelPas encore d'évaluation

- DG BusductDocument16 pagesDG BusductanandpurushothamanPas encore d'évaluation

- ConduitsDocument10 pagesConduitsSiddiqui Abdul KhaliqPas encore d'évaluation

- Types of Materials for Marine and Offshore CablesDocument55 pagesTypes of Materials for Marine and Offshore Cablesandy175Pas encore d'évaluation

- Specification For 33 KV PTDocument7 pagesSpecification For 33 KV PTPapun Scribd100% (1)

- 2062Document17 pages2062hswed91100% (1)

- Cescom - Schedule of Rates PDFDocument178 pagesCescom - Schedule of Rates PDFPunith S MurthyPas encore d'évaluation

- Spacers and Spacer DampersDocument14 pagesSpacers and Spacer Dampersahmadove1Pas encore d'évaluation

- High Conductive High Galvanized Round Steel WireDocument2 pagesHigh Conductive High Galvanized Round Steel WirequycoctuPas encore d'évaluation

- 110 - Technical REC - 112Document199 pages110 - Technical REC - 112umamaheshwarraoPas encore d'évaluation

- MQP - Fiber Optic CableDocument6 pagesMQP - Fiber Optic CableSiva KumarPas encore d'évaluation

- IS 2486 Part-2 (1989)Document28 pagesIS 2486 Part-2 (1989)tanto_deep_15Pas encore d'évaluation

- Acsr Conductor: Engineering DepartmentDocument8 pagesAcsr Conductor: Engineering DepartmentpvenkyPas encore d'évaluation

- Aluminum Clad Steel Wire: IEC 61232-1993 ASTM B415 ASTM B502Document4 pagesAluminum Clad Steel Wire: IEC 61232-1993 ASTM B415 ASTM B502ipraoPas encore d'évaluation

- ASTMB286Document5 pagesASTMB286kamlesh vaishnavPas encore d'évaluation

- Crompton LED Price List Nov 2019Document72 pagesCrompton LED Price List Nov 2019Ravish RamPas encore d'évaluation

- Railway Applications - Fixed Installations - Electric Traction Overhead Contact LinesDocument12 pagesRailway Applications - Fixed Installations - Electric Traction Overhead Contact LinesandreadelsolePas encore d'évaluation

- General Brochure eDocument6 pagesGeneral Brochure eShafeek GhreebPas encore d'évaluation

- IS-7098 PT - 1.Document17 pagesIS-7098 PT - 1.Rishi PalPas encore d'évaluation

- Is - 01897 - 2008Document9 pagesIs - 01897 - 2008Sangita GhaisasPas encore d'évaluation

- I S 613 - 2000Document11 pagesI S 613 - 2000Hariprasad gantyalaPas encore d'évaluation

- Is 12776 2002 PDFDocument12 pagesIs 12776 2002 PDFVenkataLakshmiKorrapatiPas encore d'évaluation

- Is 5082 1998Document11 pagesIs 5082 1998dipenkhandhediyaPas encore d'évaluation

- Analysis of Uncertainity in Atomic AbsorptionDocument7 pagesAnalysis of Uncertainity in Atomic AbsorptionMohammad YoussefiPas encore d'évaluation

- Humidity MIL-STD-810E 507.3 PDFDocument17 pagesHumidity MIL-STD-810E 507.3 PDFSantosh KumarPas encore d'évaluation

- Uncertainty Estimation For SDAR-OES Internal Standard MethodDocument7 pagesUncertainty Estimation For SDAR-OES Internal Standard MethodSantosh KumarPas encore d'évaluation

- Is 10810 16 1986Document5 pagesIs 10810 16 1986Santosh KumarPas encore d'évaluation

- Vocabulary Worksheet 7Document1 pageVocabulary Worksheet 7Santosh KumarPas encore d'évaluation

- Comparative Test of Top Packaged Water BrandsDocument10 pagesComparative Test of Top Packaged Water BrandsSantosh KumarPas encore d'évaluation

- Disclosure To Promote The Right To InformationDocument9 pagesDisclosure To Promote The Right To InformationSantosh KumarPas encore d'évaluation

- Disclosure To Promote The Right To Information: IS 1433 (1990) : Beam Scales (PGD 26: Weights and Measures)Document15 pagesDisclosure To Promote The Right To Information: IS 1433 (1990) : Beam Scales (PGD 26: Weights and Measures)Santosh KumarPas encore d'évaluation

- IA 03addition of Vectors (15 22)Document5 pagesIA 03addition of Vectors (15 22)Santosh KumarPas encore d'évaluation

- IA-05Vector Product of Two Vectors (28-30)Document1 pageIA-05Vector Product of Two Vectors (28-30)Santosh KumarPas encore d'évaluation

- TMT Hand Book: Storage & HandlingDocument11 pagesTMT Hand Book: Storage & HandlingHiren Desai100% (1)

- Owners Manual JBL OnBeat Air EnglishDocument15 pagesOwners Manual JBL OnBeat Air EnglishSantosh KumarPas encore d'évaluation

- INTERNET STANDARDSDocument18 pagesINTERNET STANDARDSDawn HaneyPas encore d'évaluation

- Determination of Metal Quality of Aluminium and Its AlloysDocument130 pagesDetermination of Metal Quality of Aluminium and Its AlloysGh AbadiPas encore d'évaluation

- Amh43 209-152Document4 pagesAmh43 209-152Santosh KumarPas encore d'évaluation

- Is 10810 4 1984Document7 pagesIs 10810 4 1984Santosh KumarPas encore d'évaluation

- INTERNET STANDARDSDocument18 pagesINTERNET STANDARDSDawn HaneyPas encore d'évaluation

- INTERNET STANDARDSDocument18 pagesINTERNET STANDARDSDawn HaneyPas encore d'évaluation

- Disclosure To Promote The Right To InformationDocument16 pagesDisclosure To Promote The Right To InformationSantosh KumarPas encore d'évaluation

- Is 101 8 6 1993Document8 pagesIs 101 8 6 1993Santosh KumarPas encore d'évaluation

- Disclosure To Promote The Right To InformationDocument7 pagesDisclosure To Promote The Right To InformationSantosh KumarPas encore d'évaluation

- Disclosure To Promote The Right To InformationDocument8 pagesDisclosure To Promote The Right To InformationSantosh KumarPas encore d'évaluation

- 10Document94 pages10Santosh KumarPas encore d'évaluation

- Is 2266 2002Document24 pagesIs 2266 2002Santosh KumarPas encore d'évaluation

- IS 10810-5 (1984): Methods of test for cables, Part 5: Conductor resistance test ETD 9: Power CablesDocument6 pagesIS 10810-5 (1984): Methods of test for cables, Part 5: Conductor resistance test ETD 9: Power CablesSantosh Kumar0% (1)

- Is 1363 Black Hexagon Bolts, Nuts, Lock Nuts and Hexagon ScrewsDocument16 pagesIs 1363 Black Hexagon Bolts, Nuts, Lock Nuts and Hexagon ScrewsprashantlingayatPas encore d'évaluation

- Is.204.1.1991 Tower BoltsDocument17 pagesIs.204.1.1991 Tower BoltsSantosh KumarPas encore d'évaluation

- INTERNET STANDARDSDocument18 pagesINTERNET STANDARDSDawn HaneyPas encore d'évaluation

- INTERNET STANDARDSDocument18 pagesINTERNET STANDARDSDawn HaneyPas encore d'évaluation

- Leaching Kinetics of Low-Grade Copper Ore Containing Calcium-Magnesium Carbonate in Ammonia-Ammonium Sulfate Solution With PersulfateDocument9 pagesLeaching Kinetics of Low-Grade Copper Ore Containing Calcium-Magnesium Carbonate in Ammonia-Ammonium Sulfate Solution With PersulfateSeba DonosoPas encore d'évaluation

- 216Document16 pages216Mehdi NasiroleslamiPas encore d'évaluation

- As 2738-2000 Copper and Copper Alloys - Compositions and Designations of Refinery Products Wrought Products IDocument7 pagesAs 2738-2000 Copper and Copper Alloys - Compositions and Designations of Refinery Products Wrought Products ISAI Global - APACPas encore d'évaluation

- Set A Multiple Choice Questions Metals and Non-MetalsDocument7 pagesSet A Multiple Choice Questions Metals and Non-MetalsskandhaPas encore d'évaluation

- BS 7884-1997 Specification For Copper and Copper-Cadmium Stranded Conductors For Overhead Electric Traction and Power Transmission SystemsDocument16 pagesBS 7884-1997 Specification For Copper and Copper-Cadmium Stranded Conductors For Overhead Electric Traction and Power Transmission SystemsThanh DangPas encore d'évaluation

- Vecom 0503 RustremoverDocument1 pageVecom 0503 RustremoverSPYROPas encore d'évaluation

- Hydraulic Services Design Guide 1st Edition April 2014optDocument204 pagesHydraulic Services Design Guide 1st Edition April 2014optHopePas encore d'évaluation

- Copper GlycerolDocument7 pagesCopper Glycerolerem90Pas encore d'évaluation

- Babbitt Metal: A Key Bearing MaterialDocument11 pagesBabbitt Metal: A Key Bearing MaterialMeghali BorlePas encore d'évaluation

- Archives of Animal NutritionDocument16 pagesArchives of Animal NutritiondedyPas encore d'évaluation

- Key Technical Researches On A Waste-Heat Boiler Associated With Non-Ferrous Metal Smelting FurnaceDocument6 pagesKey Technical Researches On A Waste-Heat Boiler Associated With Non-Ferrous Metal Smelting FurnacevinayakbunPas encore d'évaluation

- D. Specs For Field & Shop PaintingDocument10 pagesD. Specs For Field & Shop PaintingrajeshPas encore d'évaluation

- Novacast: High Tensile Brass Htb1Document1 pageNovacast: High Tensile Brass Htb1Siddharth PatilPas encore d'évaluation

- Lesson Plan in Conductors and InsulatorsDocument5 pagesLesson Plan in Conductors and InsulatorsKeith yacoPas encore d'évaluation

- Comparative Study of Organic Solvents For Extraction of Copper From Ammoniacal Carbonate Solution Hu2010Document6 pagesComparative Study of Organic Solvents For Extraction of Copper From Ammoniacal Carbonate Solution Hu2010mtanaydinPas encore d'évaluation

- Silver Coated Copper and Copper Alloy Stranded Conductors For Electronic Space ApplicationDocument8 pagesSilver Coated Copper and Copper Alloy Stranded Conductors For Electronic Space ApplicationSofia YuliPas encore d'évaluation

- IS 207 - 1964 Specification For Gate and Shutter Hooks and EyesDocument13 pagesIS 207 - 1964 Specification For Gate and Shutter Hooks and EyesAryansh Rocky RanaPas encore d'évaluation

- Mixtures and PartnershipDocument2 pagesMixtures and Partnershipvijendra maurya0% (1)

- 2019 Bookmatter MetallographyInArchaeologyAndADocument29 pages2019 Bookmatter MetallographyInArchaeologyAndAMornePas encore d'évaluation

- 266 - Sulphuric AcidDocument20 pages266 - Sulphuric AcidKaushik SenguptaPas encore d'évaluation

- Name: - Course: - Date: - Group NoDocument12 pagesName: - Course: - Date: - Group NoGenSan PnpPas encore d'évaluation

- Copper Alloy Guide EnglishDocument2 pagesCopper Alloy Guide Englishdesc82Pas encore d'évaluation

- SD8B 4 Part2Document109 pagesSD8B 4 Part2Sathish KumarPas encore d'évaluation

- Product: ISO 9001:2008 Certified CompanyDocument5 pagesProduct: ISO 9001:2008 Certified CompanySharad KokatePas encore d'évaluation

- Properties and Uses of Zinc MetalDocument9 pagesProperties and Uses of Zinc Metalshahin azPas encore d'évaluation

- Experiment 7: Determination of AshDocument7 pagesExperiment 7: Determination of AshhasifahPas encore d'évaluation

- 100 Every Day Science Solved MCQs NotesDocument25 pages100 Every Day Science Solved MCQs NotesizharPas encore d'évaluation

- Lepro Herbal Borewell Water Quality StandardsDocument5 pagesLepro Herbal Borewell Water Quality StandardssushantPas encore d'évaluation

- Astm A636Document2 pagesAstm A636tsliaPas encore d'évaluation