Académique Documents

Professionnel Documents

Culture Documents

SDM Datasheet 04 UK PDF

Transféré par

hepcomotionDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

SDM Datasheet 04 UK PDF

Transféré par

hepcomotionDroits d'auteur :

Formats disponibles

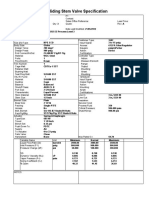

HepcoMotion

SDM - Screw Driven Module

G L4

Min

L1 - Beam Length

E2 L2

Stroke Length

G

Min

L3

M

B

K

A

J

V

4 HxI

N1

N2

Y A-A

X2 X1

X

4

X3

R

2

P

R1

O A

F

C

2

C1 C1

E1

D

4 TxU

S

A

Q

W

The HepcoMotion

SDM range has been based on the popular SBD range of belt driven linear actuators but incorporates a

ballscrew into the design. This allows for improved stiffness and precision.

Units are supplied in increments of 60mm (SDM20-80) and 80mm (SDM30-100) up to 2800mm in one piece. Longer units

are available on request. The nominal stroke length is calculated with the carriage up against the internal buffers. In practice a

clearance should be provided to allow for overrun.

SDM units with a high lead ballscrew drive and cleanroom versions will be available shortly. Please contact Hepco for more

details.

The main dimensions of the standard length SDM unit are shown below.

Note

1. Diameters Q and W relate to a recess 2mm deep

(All dimensions in mm)

SDM Unit Pitch A B C1 C2 D E1 E2 F G HxI J K

L1

(min)

L2

Nominal

stroke

SDM 20-80 16x5/10/16 54 52 51.5 58 140 185 218 23 12 M5x12 103.5 85 530 L1-294

SDM 30-100

20x5

69 60 65 76 180 235 268 24.5 12 M5x12 123.5 105

530 L1-322

20x20 540 L1-332

SDM Unit Pitch

L3

(min)

L4

(min)

M N1 N2 O P Q

*1

H7

R1 R2 S TxU V W

*1

X1 X2 X3 X4 Y

SDM 20-80 16x5/10/16 31 45 80 91.5 52 25 10 44.5 20 3 17 M6x9.5 30 - 20 40 10 40 80

SDM 30-100

20x5

28

26.5

100 112 62.5 30 15 50 25 5 17 M8x9.5 45 43 30 40 10 50 100

20x20 36.5

SDM - Screw Driven Module - Long Carriage

2

G L4

Min

L1 - Beam Length

E2 L2

Stroke Length Min

L3 G

M

B

4 HxI

A

K

J

V

N1

N2

A-A

X2

Y

X1

X4

X3

R1

R2

P

O

S

A

A F

C2

C1 C1

C3

E1

D1 D1

D2

8 TxU

Q

W

SDM units are available with a long carriage option. This version has two LBG bearing blocks in the carriage and has much

improved load capacity. The main dimensions of the standard long carriage SDM units are shown below. For further information

please contact Hepcos technical department.

(All dimensions in mm)

Note:

1. Diameters Q and W relate to a recess 2mm deep.

SDM Unit Pitch A B C1 C2 C3 D1 D2 E1 E2 F G HxI J K

L1

(min)

L2

Nominal

Stroke

SDM 20-80 16x5/10/16 54 52 51.5 58 196 26 235 275 308 23 12 M5x12 103.5 85 540 L1-362

SDM 30-100

20x5

69 60 65 76 260 46 295 340 373 24.5 12 M5x12 123.5 105

530 L1-414

20x20 540 L1-424

SDM Unit Pitch

L3

(min)

L4

(min)

M N1 N2 O P Q

*1

H7

R1 R2 S TxU V W

*1

X1 X2 X3 X4 Y

SDM 20-80 16x5/10/16 10 45 80 91.5 52 25 10 44.5 20 3 17 M6x9.5 30 - 20 40 10 40 80

SDM 30-100

20x5

20

21

100 112 62.5 30 15 50 25 5 17 M8x9.5 45 43 30 40 10 50 100

20x20 31

SDM Lubrication Information

3

Y4

Y1 Y2

Y5

2 x M20 Lubrication Plugs

Y4

Y1

Y3

Y2

Y5

3 x M20 Lubrication Plugs

Re- lubrication of the ball guide carriage blocks and the ballscrew is via the access points in the side of the beam, and closed off

with a threaded plug. The lubrication interval depends on length of stroke, speed and duty, but should be no longer than 500km

linear travel.

The positions of the lubrication holes for both standard and long carriage arrangements are detailed below.

Standard

Long carriage

Lubricant must be applied to all lubrication points on the SDM unit. Use lithium soap based grease NLGI consistency No 2 or

similar. For further details please contact Hepcos technical department.

SDM Unit Ballscrew Pitch Y1 Y2 Y3 Y4 Y5

SDM20-80

Standard

16x05

150

172

- 36 36 16x10 179.5

16x16 175

Long Carriage

16x5/10

150

264.5

186.5 36 36

16x16 266.5

SDM30-100

Standard

20x5

150

213.5

- 43.5 50

20x20 221

Long Carriage

20x5

150

309

258 43.5 50

20x20 316.5

Calculations & Performance

4

System Life Calculation

The table shows the maximum carriage loading, and the calculation below determines the system life.

To determine system life, rst calculate the load factor LF using the equation below.

Note: fv is the variable load factor which takes account of speed and vibration/impact conditions. A value of 2 is appropriate for

typical SDM applications, but consult Hepcos technical department for specic advice.

The tabulated load gures above for 10000km assume a value for variable load factor fv = 2, which is suitable for most applications. The long

carriage gures are based on LBG ball guide dynamic load capacities combined with a mounting factor of 0.8 (see LBG Catalogue 17).

The life of the system is then calculated using the equation below:

The system life of a SDM unit will be dependant on many factors. These include the life of the LBG linear ball guide, which supports

the moving load applied to the carriage, and the ballscrew which provides the driving force. In many applications the limiting factor

will be the linear ball guide, and this life can be calculated in the section below. In some applications where the SDM is providing

a high driving force, then the life of the ballscrew should also be considered.

LBG Linear Ball Guide life

Ballscrew Life

For more further details on ballscrew life please refer to the BSP catalogue, available at www.HepcoMotion.com/bspdatauk

or contact Hepcos technical department.

The table below shows details of the ballscrew static and dynamic capacities, and the maximum driving force that can be applied

by the SDM unit for a linear travel of 10000km.

SDM Unit

L1 L2 Ms Mv M

L1

L2 Ms Mv M

Nominal @ 10000km Nominal @ 10000km Nominal @ 10000km Nominal @ 10000km Nominal @ 10000km

S

D

M

2

0

-

8

0

Standard

Carriage

21200N 1813N 21200N 1813N 189Nm 16.2Nm 175Nm 14.9Nm 175Nm 14.9Nm

Long

Carriage

33920N 2900N 33920N 2900N 302Nm 25.8Nm 1150Nm 138Nm 1150Nm 138Nm

S

D

M

3

0

-

1

0

0

Standard

Carriage

52100N 4455N 52100N 4455N 639Nm 54Nm 755Nm 64Nm 755Nm 64Nm

Long

Carriage

68800N 5882N 68800N 5882N 848Nm 72.5Nm 2990Nm 360Nm 2990Nm 360Nm

SDM Unit

Ballscrew

Diameter x pitch

Ballscrew Nut Capacity

Maximum driving

force @ 10000 km

Static Coa Dynamic Ca

SDM20-80

16 x 5 17900N 7800N 620N

16 x 10 12490N 7210N 720N

16 x 16 12800N 6500N 760N

SDM30-100

20 x 5 23800N 11300N 900N

20 x 20 21400N 9800N 1230N

0.2

Mv

Mv

M

M

Ms

Ms

2 L

2 L

1 L

1 L

LF

(max) (max) (max) (max) (max)

< + + + + =

3

v

x f L

F

1

x 50

)

km

(

System Life =

(

(

Calculations & Performance

5

Drive Data & Calculations

The linear force which can be generated by a SDM unit is determined by the torque applied ( in Nm), the force coefcient (Cf)

and composite drag (Dc) of the SDM unit.

The above equation gives the linear force developed by a typical system in typical conditions, but there will be some variation. It is

recommended to select motors which have signicantly more than the minimum torque, to ensure performance and reliability.

Where LA is load applied to the carriage

Beam Deection Calculations & Data

The deection of a SDM unit under load follows conventional beam calculations.

For example, the deection of a SDM unit L (mm) long, simply supported at the ends and subject to a central load F (N) is:

Where E is the youngs modulus of aluminium alloy (= 7x10

4

N/mm

2

)

and I is the second moment of area of the SDM beam section (see table).

Example: In the case of a simply supported SDM 20-80 beam 2000mm between supports, and subject to a central Ix-x loading

of 150N, the deection at the centre of the span will be 0.25mm.

The weight of a SDM unit is calculated using the formula in the table below, where L is the beam length in m. This data will allow

the calculation of the mass of the moving parts.

SDM Unit Weights

SDM Force Coefcient Cf

SDM20-80 SDM30-100

Screw pitch /mm 5 10 16 5 20

Force Coefcient Cf 1131 565 353 1131 283

SDM Composite Drag Dc

Standard Carriage Long Carriage

SDM 20-80 40 + 0.01xLA 50+ 0.01xLA

SDM 30-100 55 + 0.01xLA 70 + 0.01xLA

SDM Unit Weights (kg)

Mass of Carriage

(kg)

SDM 20-80

Standard Carriage

Standard 9.75 x L + 2.86 2.00

Cleanroom 9.75 x L + 3.09 2.22

Long Carriage

Standard 9.75 x L + 3.72 2.85

Cleanroom 9.75 x L + 3.95 3.09

SDM 30-100

Standard Carriage

Standard 16.1 x L + 5.41 3.99

Cleanroom 16.1 x L + 5.69 4.27

Long Carriage

Standard 16.1 x L + 7.13 5.71

Cleanroom 16.1 x L + 7.37 5.95

Second moment

of area (mm

4

)

Ix-x Iy-y

SDM 20-80 14.2x10

5

17.0x10

5

SDM 30-100 36.2x10

5

44.0x10

5

Dc Cf x )

N

( e Linear Forc - =

x E x I 48

F x L

) mm ( Deflection

3

=

Calculations & Performance

6

Screw Buckling Load

The maximum axial load on the screw can be limited by buckling of the screw, where systems are long or thrust loads are high.

The curves shown include a safety factor of 100%.

For long systems, where the loading on the screw (which is xed at the drive end and oats axially at the other end) is high, then it

may be possible to arrange the principle load to put the screw in tension.

Screw Critical Speed

For any SDM unit, there is a critical speed of rotation beyond which the screw is susceptible to large amplitude vibration and

deection due to whip. The speed at which this becomes possible depends upon the maximum length of the screw between the

support bearing and the nut, and the length of the screw. It is important that operating speeds are below this critical speed. In all

cases the ballscrew should not operate at speeds in excess of 3000rpm.

The curves shown include a safety factor of 20% on speed.

0.6

0

2

4

6

8

10

12

0.8 1.0 1.2 1.4 1.6 1.8 2.0 2.2 2.4 2.6 2.8 3.0

SDM Beam Length (m)

A

l

l

o

w

a

b

l

e

T

h

r

u

s

t

F

o

r

c

e

(

k

N

)

20 Ballscrew

16 Ballscrew

SDM Beam Length (m)

A

l

l

o

w

a

b

l

e

L

i

n

e

a

r

S

p

e

e

d

(

m

/

s

)

0.6

0

0.2

0.4

0.6

0.8

1

0.8 1.0 1.2 1.4 1.6 1.8 2.0 2.2 2.4 2.6 2.8 3.0

20 x 20

20 x 5

16 x 16

16 x 10

16 x 5

HepcoMotion

, Lower Moor Business Park,

Tiverton Way, Tiverton, Devon, England EX16 6TG

Tel: +44 (0) 1884 257000

Fax: +44 (0) 1884 243500

E-mail: sales@hepcomotion.com

ISO 9001

BUREAUVERITAS

Certifcation

www.HepcoMotion.com

Ancillary Components

Ref: SDM 04 UK

Ordering Details

SDM - Product Range

Size of unit: Choose 20-80 or 30-100

Beam Length. Beam lengths are available in increments of 60mm for SDM 20-80

and increments of 80mm for SDM 30-100.

Long Carriage option with twin LBG bearing blocks: B2

SDM 20-80 L1200 B2

Ballscrew size and pitch: Choose from 16x5, 16x10 or 16x16 for SDM20-

80 and 20x5 or 20x20 for SDM30-100.

1605

Limit Switch Assembly

(Includes switch, brackets and xings)

SBD20-80-V3SWA-M

SBD30-100-V3SWA-M

SBD20-80-V3SWA-I

SBD30-100-V3SWA-I

T-Slot Cover ( Supplied tted in each of the T-slots)

1-242-1016

T-Nuts

1-242-1029 1-242-1030 1-242-1001 1-242-1002

M4

M5 M6 M8

Mechanical Inductive

Motor Connection Kits

(These include the ange tube, coupling components

and all fasteners required.)

Coupling Components

Flange Tube

Hepco will make anges to t any motor type on

request, standard kits are available to t a wide

range of motors and gearboxes. Please contact

Hepcos technical department for further advice

and information.

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- CFD Study Heat PipeDocument8 pagesCFD Study Heat PipeSalman Chowdhury ShawonPas encore d'évaluation

- Biomes of The EarthDocument273 pagesBiomes of The Earthbruiatu100% (1)

- HOW TO DESIGN AMMONIA REFRIGERATION PLANT USING AAR STANDARD 1 2016 by Ramesh ParanjpeyDocument7 pagesHOW TO DESIGN AMMONIA REFRIGERATION PLANT USING AAR STANDARD 1 2016 by Ramesh ParanjpeyMark Anthony CentenoPas encore d'évaluation

- Design of Reinforced Concrete Beams Per ACI 318Document21 pagesDesign of Reinforced Concrete Beams Per ACI 318Aram Chtchyan0% (1)

- As-NZS 1554.1 Testing RequirementsDocument2 pagesAs-NZS 1554.1 Testing RequirementsSyed Mahmud Habibur RahmanPas encore d'évaluation

- 2021 BUILDING UTILITIES 3 - Module 2 Lecture 5 LUMINAIRES (S)Document46 pages2021 BUILDING UTILITIES 3 - Module 2 Lecture 5 LUMINAIRES (S)Sophia Manila SillaPas encore d'évaluation

- Ap-13-Uk (DLS & HB25C) PDFDocument1 pageAp-13-Uk (DLS & HB25C) PDFhepcomotionPas encore d'évaluation

- Hepco GV3 10 UK Low Res PDFDocument74 pagesHepco GV3 10 UK Low Res PDFhepcomotionPas encore d'évaluation

- MCS RapiLok 01 UK PDFDocument2 pagesMCS RapiLok 01 UK PDFhepcomotionPas encore d'évaluation

- MLG 01 Uk (21-05-15) PDFDocument6 pagesMLG 01 Uk (21-05-15) PDFhepcomotionPas encore d'évaluation

- HPS MCSDocument4 pagesHPS MCShepcomotionPas encore d'évaluation

- MLG 01 Uk (21-05-15) PDFDocument6 pagesMLG 01 Uk (21-05-15) PDFhepcomotionPas encore d'évaluation

- BSP 05 UK (Nov-11) PDFDocument20 pagesBSP 05 UK (Nov-11) PDFhepcomotionPas encore d'évaluation

- SBD 04 UK (Apr-10) PDFDocument20 pagesSBD 04 UK (Apr-10) PDFhepcomotionPas encore d'évaluation

- HDS2 - Esr 01 Uk PDFDocument4 pagesHDS2 - Esr 01 Uk PDFhepcomotionPas encore d'évaluation

- HDS2 - Esr 01 Uk PDFDocument4 pagesHDS2 - Esr 01 Uk PDFhepcomotionPas encore d'évaluation

- HDS2 - Esr 01 Uk PDFDocument4 pagesHDS2 - Esr 01 Uk PDFhepcomotionPas encore d'évaluation

- MLG 01 Uk (21-05-15) PDFDocument6 pagesMLG 01 Uk (21-05-15) PDFhepcomotionPas encore d'évaluation

- No.7 GV3 End Stop 01 UK PDFDocument2 pagesNo.7 GV3 End Stop 01 UK PDFhepcomotionPas encore d'évaluation

- No.7 GV3 End Stop 01 UK PDFDocument2 pagesNo.7 GV3 End Stop 01 UK PDFhepcomotionPas encore d'évaluation

- MLG 01 Uk (25-03-15) PDFDocument6 pagesMLG 01 Uk (25-03-15) PDFhepcomotionPas encore d'évaluation

- No.11 Mix & Match 01 UK PDFDocument3 pagesNo.11 Mix & Match 01 UK PDFhepcomotionPas encore d'évaluation

- No.7 GV3 End Stop 01 UK PDFDocument2 pagesNo.7 GV3 End Stop 01 UK PDFhepcomotionPas encore d'évaluation

- No.7 GV3 End Stop 01 UK PDFDocument2 pagesNo.7 GV3 End Stop 01 UK PDFhepcomotionPas encore d'évaluation

- No.7 GV3 End Stop 01 UK PDFDocument2 pagesNo.7 GV3 End Stop 01 UK PDFhepcomotionPas encore d'évaluation

- No.11 Mix & Match 01 UK PDFDocument3 pagesNo.11 Mix & Match 01 UK PDFhepcomotionPas encore d'évaluation

- HDS2 - Esr 01 Uk PDFDocument4 pagesHDS2 - Esr 01 Uk PDFhepcomotionPas encore d'évaluation

- No.11 Mix & Match 01 UK PDFDocument3 pagesNo.11 Mix & Match 01 UK PDFhepcomotionPas encore d'évaluation

- No.11 Mix & Match 01 UK PDFDocument3 pagesNo.11 Mix & Match 01 UK PDFhepcomotionPas encore d'évaluation

- HDS2 - Esr 01 Uk PDFDocument4 pagesHDS2 - Esr 01 Uk PDFhepcomotionPas encore d'évaluation

- HDS2 - Esr 01 Uk PDFDocument4 pagesHDS2 - Esr 01 Uk PDFhepcomotionPas encore d'évaluation

- No.11 Mix & Match 01 UK PDFDocument3 pagesNo.11 Mix & Match 01 UK PDFhepcomotionPas encore d'évaluation

- HDS2 - Esr 01 Uk PDFDocument4 pagesHDS2 - Esr 01 Uk PDFhepcomotionPas encore d'évaluation

- HDS2 - Esr 01 Uk PDFDocument4 pagesHDS2 - Esr 01 Uk PDFhepcomotionPas encore d'évaluation

- No. 9 HDS2 Cap Wiper Options 02 UK PDFDocument2 pagesNo. 9 HDS2 Cap Wiper Options 02 UK PDFhepcomotionPas encore d'évaluation

- No. 4 HDS2 Bearing Blocks 02 UK PDFDocument6 pagesNo. 4 HDS2 Bearing Blocks 02 UK PDFhepcomotionPas encore d'évaluation

- Jee Advanced Check List Set 1Document1 pageJee Advanced Check List Set 1Pulkit BaghelPas encore d'évaluation

- Data Sheet Control Valve FisherDocument9 pagesData Sheet Control Valve FisherFIRMANSYAHPas encore d'évaluation

- Eva EmpDocument18 pagesEva Emphata669Pas encore d'évaluation

- Mil PRF 13830BDocument82 pagesMil PRF 13830Bmmottola12Pas encore d'évaluation

- WPQ Is 2062 Haresh Shah W1Document1 pageWPQ Is 2062 Haresh Shah W1Anand KesarkarPas encore d'évaluation

- Flow Around A CylinderDocument17 pagesFlow Around A CylinderMatheus PauloPas encore d'évaluation

- Aluminium Alloy - Wikipedia, The Free EncyclopediaDocument13 pagesAluminium Alloy - Wikipedia, The Free EncyclopediajishnuPas encore d'évaluation

- Neet Code A Question PaperDocument41 pagesNeet Code A Question PaperRohit Kumar JenaPas encore d'évaluation

- Sgsits ManualDocument91 pagesSgsits ManualJoyita BiswasPas encore d'évaluation

- Lateral Earth PressureDocument34 pagesLateral Earth PressureTimothy Charles YabutPas encore d'évaluation

- Astm A 829 - SAE 4140 / SAE 4142: CR Mo-Alloyed Vacuum Degassed SteelsDocument3 pagesAstm A 829 - SAE 4140 / SAE 4142: CR Mo-Alloyed Vacuum Degassed Steelsssip officePas encore d'évaluation

- Mechanics of Solids (CIE 1051) (Makeup)Document5 pagesMechanics of Solids (CIE 1051) (Makeup)Alok KumarPas encore d'évaluation

- Vertical Turbine PumpsDocument18 pagesVertical Turbine PumpsazkPas encore d'évaluation

- Module 15 - UNIT III - PolymersDocument12 pagesModule 15 - UNIT III - PolymersJhess GaliciaPas encore d'évaluation

- SSC JE Mechanical Study Material Strength of Materials PDFDocument13 pagesSSC JE Mechanical Study Material Strength of Materials PDFSameer ShahPas encore d'évaluation

- Sindie Otg Catalogo EngDocument2 pagesSindie Otg Catalogo EngJorge EpbPas encore d'évaluation

- Organograma ASME IX Art. I PDFDocument4 pagesOrganograma ASME IX Art. I PDFfabiocorreasilvaPas encore d'évaluation

- Intro SolidsDocument25 pagesIntro SolidsCQChoongPas encore d'évaluation

- Structural BehaviourDocument43 pagesStructural BehaviourDr RajeevPas encore d'évaluation

- PROBLEMS For Orifice and WeirsDocument1 pagePROBLEMS For Orifice and WeirsIrene Grace Batalao50% (2)

- Chemical Reaction Engineering (CRE) Is TheDocument24 pagesChemical Reaction Engineering (CRE) Is TheVaibhav GuptaPas encore d'évaluation

- 16.7 Overturningseismic PDFDocument7 pages16.7 Overturningseismic PDFnickPas encore d'évaluation