Académique Documents

Professionnel Documents

Culture Documents

Evaluate Color Difference

Transféré par

Mansour SolimanCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Evaluate Color Difference

Transféré par

Mansour SolimanDroits d'auteur :

Formats disponibles

PRESTO : Efficiency, Economy, and delta E converge in a new

measurement solution

FAG will launch the new Spectrodensitometer PRESTO at DRUPA2012. The PRESTO offers

unprecedented ease of use in a pressside ink and color control system. The high cost and

complexity of laboratory spectrophotometers make them a poor choice for color control on the

production floor. Their bewildering array of functions and settings requires more training than

many shops can afford and most operators can tolerate. Without a suitable alternative, eyeball

control takes over with unpredictable results. The PRESTO offers all the necessary measurement

functions in a quick, costeffective, and easytouse instrument.

PRESTO is a nonpolarizing Spectrodensitometer with Status E filter set. Because plastic film

substrates have a natural polarizing effect, the use of a polarization filter would be counter

productive. The PRESTO measures Density, Dot Gain, Dot Area, Balance, and finally Delta E 2000.

(Figure 1.)

One of the most important quality parameters in flexo printing is ink transfer. Obtaining optimal ink

transfer is a prerequisite to achieving the desired color strength in the print. Ink viscosity, anilox

volume, plate material and substrate also affect ink transfer, as does press speed and

environmental conditions. Because of the excellent correlation of optical density to the human

visual response, densitometers have been successfully used for many years with excellent results in

press control of the ink transfer. Both process and spot colors lend themselves to density control,

and the PRESTO automatically selects and displays the correct color channel for the operator.

Impression and rolling conditions have to be optimized to avoid doubling and slur effects and to

avoid excessive or premature plate wear. Impression hexagons are widely used to subjectively

evaluate the impression settings on a press. An alternative visual control can be done using the

DFTA AKE 1.0 control element described in DFTA Leitfaden fr die Flexodruckvorstufe v1.0. More

precise control is easily implemented by using a target consisting of vertical lines (machine

direction) and horizontal lines (cross direction) to optimize the pressure between anilox and plate,

as well as between plate and substrate. The pressure between plate and substrate has a higher

impact on horizontal lines than it has on vertical lines. Therefore the dot area measured in the

horizontal line patch is typically higher than the dot area measured in the vertical line patch. The

optimal pressure is achieved when the two dot area values match. Once the platetosubstrate

pressure is optimized, the aniloxtoplate pressure can be reduced as long as the minimum dot

patch is still printed. The PRESTO can be used to measure the dot area quickly and easily during

press setup and to detect small changes of the rolling conditions during the run of the press (see

figure 2: line elements).

The smaller the printed minimum dot, the closer the flexo printing quality is to competing print

methods. During setup and characterization of the printing process the FLEXPRO from PERET is of

great help, as it delivers high resolution images of the print. Dot size and geometry can be

measured while dot void and mottling can be evaluated. During normal production, the PRESTO

E can be used to check if the minimum is still printed correctly or if there are printing problems

(see figure 2: minimum dot)

Special (spot) colors are widely used in FLEXO and packaging. The color is prepared in the ink

department using color formulation systems and Spectrophotometers. Ideally, once the ink is at

the press, no further ink mixing (toning) should take place. Nevertheless it is sometimes necessary

to make adjustments. These changes should be measured in terms of delta E. The PRESTO E

device can be used for a quick check of the accuracy of the color match in terms of Delta E2000.

FAG offer a wide range of control instruments for Flexo and Packaging. The new PRESTO E makes

the portfolio even more complete and costeffective.

Dipl.Ing. Lukas Pescoller

www.fag.ch

Vous aimerez peut-être aussi

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Mean Time Between FailureDocument10 pagesMean Time Between FailureMansour Soliman0% (1)

- Glossary of Graphic Communications TermsDocument10 pagesGlossary of Graphic Communications TermsMansour SolimanPas encore d'évaluation

- Flexo Printing GlosseryDocument58 pagesFlexo Printing GlosseryMansour Soliman100% (1)

- Printing Industries Colour SystemsDocument14 pagesPrinting Industries Colour SystemsMansour SolimanPas encore d'évaluation

- Printing Industries - DensityDocument13 pagesPrinting Industries - DensityMansour SolimanPas encore d'évaluation

- Dot Spread-Dot GainDocument3 pagesDot Spread-Dot GainMansour SolimanPas encore d'évaluation

- General PrepreesDocument1 pageGeneral PrepreesMansour SolimanPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- M4L1Drafting Structural Framing PlanDocument61 pagesM4L1Drafting Structural Framing PlanHappy SunshinePas encore d'évaluation

- 10.musicos y Bandas de Jazz Fusion.Document2 pages10.musicos y Bandas de Jazz Fusion.michaelPas encore d'évaluation

- A Ryght Profytable Treatyse Compendiously Drawen Out of Many and Dyvers Wrytynges of Holy Men by Betson, ThomasDocument23 pagesA Ryght Profytable Treatyse Compendiously Drawen Out of Many and Dyvers Wrytynges of Holy Men by Betson, ThomasGutenberg.orgPas encore d'évaluation

- ConclusionDocument8 pagesConclusionPablo PiquerasPas encore d'évaluation

- Christmas Tree Emotions: Interactive BookDocument10 pagesChristmas Tree Emotions: Interactive BookAnnaPas encore d'évaluation

- In Love With The Whirlwind PDFDocument256 pagesIn Love With The Whirlwind PDFAlexander GuerreroPas encore d'évaluation

- The Meso American CivilizationDocument40 pagesThe Meso American Civilizationsami karemPas encore d'évaluation

- Daniella Ignacio First DraftDocument7 pagesDaniella Ignacio First DraftDaniella IgnacioPas encore d'évaluation

- ARTH303 DelhiSultanate FINAL PDFDocument6 pagesARTH303 DelhiSultanate FINAL PDFusernaga84Pas encore d'évaluation

- MBC Pale OneDocument1 pageMBC Pale OnestevePas encore d'évaluation

- Living-in-Christ - Billy Graham PDFDocument27 pagesLiving-in-Christ - Billy Graham PDFPrecious Udoada75% (8)

- EAPP Critique PaperDocument2 pagesEAPP Critique PaperIvy Dianne PascualPas encore d'évaluation

- A Thankful Heart 1 - A Key To Overflowing Joy!Document6 pagesA Thankful Heart 1 - A Key To Overflowing Joy!kzeckPas encore d'évaluation

- #34: The Adam Carolla Show (August 2006) : Date Start End Title Oswaldo's Movie Review-Miami ViceDocument2 pages#34: The Adam Carolla Show (August 2006) : Date Start End Title Oswaldo's Movie Review-Miami VicethisyearcollectionPas encore d'évaluation

- FINALDocument63 pagesFINALKhushbu DinkarPas encore d'évaluation

- The Old Man and The Little Cat Reading ComprehensionDocument2 pagesThe Old Man and The Little Cat Reading ComprehensionbettyPas encore d'évaluation

- Asme section-IIDocument25 pagesAsme section-IIAmit Singh100% (10)

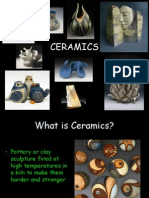

- CeramicsDocument27 pagesCeramicsAthiyo Martin100% (4)

- Pricecatalogue 130207 MiddleDocument93 pagesPricecatalogue 130207 MiddleDacian BalosinPas encore d'évaluation

- Character and Songs Requested With Links Provided: Mark La Vie BohemeDocument2 pagesCharacter and Songs Requested With Links Provided: Mark La Vie BohemejohnisaPas encore d'évaluation

- End-Of-Year Test 1 A: GrammarDocument4 pagesEnd-Of-Year Test 1 A: GrammarjPas encore d'évaluation

- A Teaching Pioneer: Star TrailsDocument2 pagesA Teaching Pioneer: Star TrailsDavor BatesPas encore d'évaluation

- The Girl in The Converse Shoes PDFDocument2 pagesThe Girl in The Converse Shoes PDFRitu SharmaPas encore d'évaluation

- Unit 3 4 Studio Art Exploration ProposalDocument8 pagesUnit 3 4 Studio Art Exploration Proposalapi-340277232Pas encore d'évaluation

- Thematic Study of Fear in The Text 'Things Fall Apart'Document4 pagesThematic Study of Fear in The Text 'Things Fall Apart'Sankalp Pratap TrivediPas encore d'évaluation

- Prayer That Pleases God PDFDocument2 pagesPrayer That Pleases God PDFJeth KlausePas encore d'évaluation

- Great Drawings and Illustrations From Punch 1841-1901Document166 pagesGreat Drawings and Illustrations From Punch 1841-1901torosross6062100% (3)

- Lotus PanacheDocument1 pageLotus PanacheAvdhesh Kumar SharmaPas encore d'évaluation

- Weekly Test No.1 Q1 Module1Document2 pagesWeekly Test No.1 Q1 Module1Jessalyn RadaPas encore d'évaluation