Académique Documents

Professionnel Documents

Culture Documents

Spe 36630 MS

Transféré par

Jose BarreroDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Spe 36630 MS

Transféré par

Jose BarreroDroits d'auteur :

Formats disponibles

Copyright 1996, Society of Petroleum Engineers, Inc.

This paper was prepared for presentation at the 1996 SPE Annual Technical Conference and

Exhibition held in Denver, Colorado, U.S.A., 69 October 1996.

This paper was selected for presentation by an SPE Program Committee following review of

information contained in an abstract submitted by the author(s). Contents of the paper, as

presented, have not been reviewed by the Society of Petroleum Engineers and are subject to

correction by the author(s). The material, as presented, does not necessarily reflect any

position of the Society of Petroleum Engineers, its officers, or members. Papers presented at

SPE meetings are subject to publication review by Editorial Committees of the Society of

Petroleum Engineers. Permission to copy is restricted to an abstract of not more than 300

words. Illustrations may not be copied. The abstract should contain conspicuous

acknolwedgment of where and by whom the paper was presented. Write Librarian, SPE, P.O.

Box 833836, Richardson, TX 75083-3836, U.S.A., fax 01-972-952-9435.

Abstract

The following paper describes a six month pilot test for the

control of paraffin and asphaltene deposition at the reservoir

level using naturally occurring microorganisms. For the

course of the paper, paraffin will be defined as pentane

soluble hydrocarbon precipitates. Likewise, asphaltene will be

defined as hydrocarbon deposits which are pentane insoluble

and toluene soluble. The microbial project was conducted on

four wells in the Eastern Operating Area of the Prudhoe Bay

oil field. The microorganisms were selected based upon their

ability to metabolize long hydrocarbon chains into lighter

components.

Data collected from the project reflects the impact on total

fluid production and crude oil physical and chemical

properties i.e. API gravity, viscosity, and sulfur content.

Operation and maintenance costs for the microbial

treatments versus alternative methods are shown and proven

to be favorable on certain well types. The advantages of

growing the microbes on site and increasing the variety and

type of microbial functions is presented. The treatment

techniques for effective microbial application along with

candidate selection are discussed.

Introduction

Prudhoe Bay is located on the central north slope of Alaska.

The oil field was discovered in 1968; development began in

1977. Production to date from the Prudhoe Bay field is in

excess of 9 billion barrels. The field depletes the Sadlerochit

reservoir which is characterized by four different zones: Zulu,

Victor, Tango, and Romeo (type log in figure 1). Each zone is

characterized by a different lithology, thickness, porosity,

permeability, etc. The reservoir drainage mechanism is

dependent upon gas cap proximity. Where a gas cap is

present, the field is depleted by a gravity drainage mechanism

supported by gas cap injection. Where there is limited gas cap

support, the field is depleted by water flood (WF) and

enhanced oil recovery (EOR) mechanisms.

The microbial treated wells are located in the southeast

peripheral corner of Prudhoe Bay. All treated wells are

located in the same WF/EOR pattern. Three of the four wells

(A, B, and D) have corner locations in a loosely fitted inverted

five spot pattern. The remaining well, C, occupies the only

developed side well location in the pattern. Well spacing

varies from 80-160 acres.

Reserve depletion in the treated pattern is supported by

alternating injection of water and MI (miscible injectant).

Water injection began in 1984 using sea water as the

displacement medium. In 1994 sea water was replaced with

recycled produced water. MI injection was introduced in

1993 as an enhanced oil recovery mechanism to the existing

water flood. To date, 15 MM bbls of water (80% sea water)

and 1 Bcf of MI have been injected into the treated pattern.

Recovery to date from the treated wells totals 8.5 MMBO.

All the treated wells are completed in the Zulu formation.

Top of structure averages 8975' TVD with an average sand

thickness of 80 feet. Reservoir temperature is approximately

196 F while the reservoir pressure is estimated at 3400 psi.

Table 1 lists reservoir statistics for the treated wells.

Well Porosity (%) Permeability

(md)

Gross Sand

Thickness (ft)

A 19.7 65 96

B 20.4 78 41

C 20.7 122 109

D 19.6 50 71

Table 1: Reservoir characteristics for wells treated in the pilot

program.

Crude oil API gravity prior to treatment averaged 24

degrees, ranging from 21 to 26 degrees. Proceeding northwest

from the treated pattern, oil quality improves. Crude oil API

gravity in neighboring patterns averages 26 degrees. One

component of the improved oil quality is a decrease in the

asphaltene concentration. Asphaltene concentration tends to

increase with proximity to the southeast periphery. Average

SPE 36630

Microbial Pilot Test for the Control of Paraffin and Asphaltenes at Prudhoe Bay

Keith R. Ferguson and Christine T. Lloyd, ARCO Alaska Inc., Dan Spencer and J ames Hoeltgen, Biostar Technologies

2 K. R. FERGUSON, C. T. LLOYD, D. SPENCER, AND J . HOELTGEN SPE 36630

asphaltene concentration in the treated wells was 9.2 wt%

(5.8-15.8 wt%) while adjacent patterns averaged 5.8 wt%

(3.4-11.9 wt%). Coinciding with the increased concentration

of high MW hydrocarbons is an increased crude viscosity.

The effect of crude oil composition has a significant

impact on productivity in the treated region. High crude oil

viscosity has contributed to regionally low gross well fluid

rates of less than ~1000 bbls/day. For two of the treated

wells, B and D, low fluid rates in conjunction with heat losses

through the 2000 ft thick arctic permafrost, contribute to the

deposition of heavier crude constituents as well as gas hydrate

formation. Well production occasionally ceases due to the

formation of a hydrate or paraffin plug. To return wells to

production, the plugs are mechanically and thermally removed

by jetting hot oil with a coil tubing unit. The operations

associated with hydrate/paraffin formation resulted in

unfavorable economics for wells B and D. Various treatments

(conventional hot oil treatments, solvents, surfactants, etc.)

were tested in an effort to increase production and/or reduce

operating costs. The wells showed favorable responses to the

treatments, but the economics did not meet acceptable hurdles.

In addition to production impacts, paraffin/asphaltene

deposition can increase routine well work costs. As a result of

the deposition of high MW hydrocarbons, hot oil treatments

are often required during routine well operations. The

treatment removes the paraffin/asphaltenes preventing

successful execution of the associated down hole well work.

The remaining treated wells, A and C, fell into this category.

As a result of (1) the aforementioned operational and

production impacts and (2) positive responses from an earlier

small microbial pilot

3

, the expanded microbial pilot program

was initiated. Four wells were treated: A, B, C, and D. Well

A has produced since 1981 while the remaining wells were

drilled in the early 1990's. All the treated wells have been

stimulated with fracture treatments. Table 2 lists pre-

treatment production statistics for the treated wells.

Well Cumulative

Oil

Production

(MBO)

Liquid

Rate (blpd)

Water

Cut (%)

Formation

Gas Rate

(Mscfd)

A 7126 1400 70 1000

B 610 800 69 <500

C 559 2450 81 500

D 225 900 69 <500

Table 2: Pre-treatment production statistics for wells in the pilot

program.

Technology

Enhancement of petroleum production through the application

of microbiology began more than fifty years ago. Various

mixtures of yeast, molasses, beer, etc., have been introduced

into oil wells in an attempt to solve production problems

and/or enhance well productivity. Since these early

beginnings, the use of microbes for biodegrading and

enhancing paraffinic oils has been shown to be a viable

technique.

1,2

More recently, supplemental nutrients have been

injected into reservoirs to feed the indigenous microflora.

The additional nutrients are supplied in an attempt to increase

the bacterial activity and thereby accelerate the natural crude

oil biodegradation process.

Injection techniques for well inoculation vary among

annular batch treatments, continuous annular and tubing

injection, and various forms of full bore squeeze procedures.

The type of recent biological products also varies. Freeze

dried products, enzymes, microbial blends, and microbial

concentrates have been tried in domestic and remote locations

throughout the world.

Environmental factors affecting bacterial application

include temperature (down hole and surface), acidity, existing

chemical treatments, and toxic formation materials. Pressure

has not been seen as a detrimental factor to date with some

known pressures to be in excess of 12,000 psig. Acceptable

pH can vary from 4.0 to 9.0, although actual short term pH

values up to 11.5 have been documented without damage to

the culture. Down hole temperatures from 65 degrees F to

270 degrees F are acceptable.

The bacteria colonize at the oil-water interface and move

through the reservoir in the connate water. Therefore an

important prerequisite for successful microbial application is a

preexisting water source.

Bacteria effective against asphaltenes are a new and very

promising development in the enhanced recovery of

asphaltene based crudes. Recent successful results in the

microacrophilic degradation of asphaltenic tars in Southern

California oil fields has spurred interest in reservoir level

application to improve crude characteristics and well

productivity.

Microbial History at Prudhoe Bay

Initial experience with bacterial products at Prudhoe Bay was

obtained from a small scale pilot program in 1992.

3

Two

producing wells with a lengthy history of paraffin deposition

were targeted for microbial treatment in an effort to reduce

operating costs by eliminating or decreasing the frequency of

hot oil treatments. The targeted wells typically required coil

tubing hot oil treatments every 4 to 6 weeks at a cost of

approximately $7,000/month/well. The primary objectives of

the early microbial tests were to verify the effectiveness of

microbial treatments and target a 50% reduction in the costs of

hot oil treatments.

Results of the initial pilot appear to confirm microbial

treatments can have a positive effect on well productivity.

Compositional changes in the crude included an increase in

the API gravity, reduced pour point, and reduced viscosity.

Treatments in the initial pilot resulted in incremental rate

increases of 150 and 300 bopd for the two treated wells. The

ability to discern the effect of the bacteria on the produced

crude was complicated by changes in producing

SPE 36630 MICROBIAL PILOT TEST FOR THE CONTROL OF PARAFFIN AND ASPHALTENES AT PRUDHOE BAY 3

characteristics. Increasing GOR (gas to oil ratio) from gas cap

encroachment posed the potential for stripping off the lower

molecular weight components and altering the crude

composition thereby masking the bacterial compositional

changes. The preliminary results from the early trials offered

encouragement to proceed with a larger microbial test on

additional wells. Operational costs of the initial test indicated

potential cost savings of $1,900 a month per well.

3

Microbial Application

Prudhoe Bay due to its remoteness and environmental

extremes offers a unique challenge for biotechnology.

Bacteria are primarily composed of water and are

subsequently susceptible to freezing in the arctic environment.

In addition to freezing, water mass creates bulk and weight

which increases shipping and handling costs. In the interest of

cost reduction, the bacteria for the pilot project were cultured

in on-site portable fermenters.

In order to design an appropriate treatment program, each

well history was reviewed and produced fluids were analyzed.

Table 3 typifies the produced fluids.

Constituent Measurement

pH 6.2

Bicarbonate, mg/L 2132

Chlorides, mg/L 13,000

Sulfate, mg/L 915

Calcium, mg/L 320

Magnesium, mg/L 238

Silicon, mg/L 25.8

Potassium, mg/L 127

Sodium, mg/L 8720

Iron, mg/L 3.4

Oil Viscosity, SUS 180 F 44

Sulfur in crude, Wt. % 0.93

Asphaltenes, Wt. % 8.58

Paraffin, Wt. % 8.7

Formation Temperature, F 180

Table 3: Produced fluid example from a treated well.

Twelve species of commercially available, naturally

occurring, non-pathogenic, motile, facultative anaerobes were

selected for their ability to (1) degrade asphaltenes and

paraffins and (2) produce and release surfactants and fatty

acids. The selected bacteria have a prior history of surviving

and thriving under similar reservoir conditions (pressure,

temperature, and salinity).

The exact metabolic mechanisms for paraffin and

asphaltene degradation is not entirely understood. However,

the process likely relates to the presence of sulfur, nitrogen,

iron, and/or other metallic cations present in the reservoir.

The metallic cations may serve as electron acceptors under

anaerobic conditions. In addition, the biochemical reactions

likely occur by multiple pathways. Due to the aforementioned

reasons, the biodegradation process cannot be explicitly

described.

Although the exact pathway is unknown, bacterially

produced surfactants and fatty acids are known to be an

important component in the biodegradation of high molecular

weight hydrocarbons. The surfactants and fatty acids assist

paraffin and asphaltene degrading bacteria by increasing the

bacterias ability to invade and establish themselves within the

reservoir ecosystem. Co-metabolism functions are also a

possibility.

Bacteria for the Prudhoe Bay pilot were grown in three

separate batches dependent upon their primary function: (1)

paraffin degradation, (2) asphaltene degradation, and (3)

surfactant/fatty acid production. The microorganisms were

cultured in on-site portable fermenters to insure a highly

active biological product with minimal shipping and handling

complications. Fermentation times for population levels of 1

x 10

8

cells per milliliter were dependent on the specific culture

and were reached in 48 to 72 hours.

For the expanded pilot program, microbial applications

were initiated by either a full bore or CTU (coil tubing unit)

squeeze treatment of the microorganisms followed by a crude

or potassium chloride solution over flush volume sufficient to

displace the bacteria 8 to 10 feet beyond the well bore. Initial

treatment volumes were determined after considering such

variables as the type and amount of paraffin and asphaltenes

present in the produced crude, the type of completion and

amount of sand perforated, and the anticipated flow rates.

After inoculation, the wells were allowed to soak for 48 to 72

hours prior to returning to production. The initial treatments

were augmented weekly with additional microbial treatments

averaging 15 gallon/week. Previous experience from the

initial pilot indicated a minimum 10 gallons per week

augmentation treatment was required to sustain benefits. The

augmentation treatments were performed by adding the

bacterial product to the surface gas-lift supply. Table 4 gives

the initial treatment volumes and supplemental weekly

volumes performed on each well.

4 K. R. FERGUSON, C. T. LLOYD, D. SPENCER, AND J . HOELTGEN SPE 36630

Well Initial

Treatment

Microbial

Volume

(gallons)

Shut-In

Period

(hours)

Weekly

Treatment

Volume

(gallons)

A Full Bore 220 48 15

B Full Bore 290 72 15

C Full Bore 330 72 15

D CTU 275 72 15

Table 4: Microbial treatment program statistics by well.

Pilot Objectives

The primary objectives of the microbial treatment program

were:

(1) Positively establish the viability of microorganisms as an

effective measure for the control of paraffin and

asphaltenes.

(2) Determine the feasibility of producing and applying

biological treatments in an arctic environment.

(3) Improve or stabilize production rates for severe

paraffin/asphaltene producers.

(4) Quantify the costs and benefits of microbial applications

at Prudhoe Bay.

To determine the effectiveness of the microbial treatments,

baseline data was obtained for crude oil physical and

compositional characteristics. This information along with

production performance data and operating costs would be

compared on a pre and post microbial treatment basis.

Compositional and physical data included:

(1) Oil API Gravity (API)

(2) Asphaltene Concentration (weight %)

(3) Paraffin Concentration (weight %)

(4) Viscosity (cSt at 180 F).

(5) Sulfur Concentration (weight %)

Results

Four wells were treated as part of the six month pilot. The first

well, B, was treated on 3/9/95. Wells A, D, and C followed

on 3/20/95, 3/30/95, and 7/18/95 respectively. Six months

after the initial treatment of well B, the pilot program was

reviewed. Wells A, B, and D did not show sufficient benefits

at the time of the pilot review to warrant continued treatments.

Since well C exhibited some production benefits, the

remaining supply of microbial product was exhausted on the

producer. The final microbial augmentation treatment for well

C was pumped on 12/27/95. The impacts of discontinued

treatments was also monitored.

Of the four wells treated, two have sufficient test separator

data to evaluate production impacts: A and C. Well test data

collected from the remaining two wells, B and D, is

inconclusive due to complications with hydrate and paraffin

formation. Wells B and D inability to maintain stable

production rates also prohibited gathering meaningful pre and

post-treatment fluid samples.

Figures 2-5 are plots of test separator results for wells A

and C. The liquid rate of well C is noticeably impacted by the

onset of microbial treatments. Prior to the microbial

treatments, well C liquid rate averaged 2450 blpd. After

treatment initiation, well C liquid rate increased to

approximately 2890 blpd for an incremental 440 blpd or 18%

increase. The increased liquid rate translates to an

incremental 84 bopd at 81% WC. Unlike well C, no obvious

production impacts were noted on well A.

In addition to well test information, crude oil physical and

compositional property changes were measured. To insure oil

samples adequately represented overall well characteristics,

separate one gallon samples were taken over the course of two

days and combined. Figures 6-10 represent the crude oil

physical and compositional changes before, during, and after

the microbial pilot. When available, the graphs include

American Society for Testing and Materials (ASTM) testing

reproducibility errors. In summary, the combined physical

and compositional trends are consistent with the crude oil

bioremediation process. As treatments were initiated, crude

oil quality improved: (1) oil API gravity increased, (2) crude

viscosity decreased, (3) combined asphaltene and paraffin

concentration decreased, and (4) sulfur concentration

decreased. The response is not unexpected. The increased

paraffin concentration either (1) contains cleaved asphaltene

constituents which now register as paraffin under lab analysis

or (2) represents a decrease in the amount of paraffin

deposition in the well bore. Overall, the combined

concentration of the paraffin and asphaltenes decreased with

treatment. To assist in verifying the effects of the microbes on

the crude oil properties, weekly microbial treatments were

discontinued after the trial period in order to monitor crude

property changes. Crude oil properties were observed

returning to pre-treatment values shortly after discontinuing

the weekly augmentation treatments. Microbial counts

indicated viable bacteria were still present in the produced

crude for 3 months following suspension of the treatments, but

in decreasing concentrations.

Total microbial costs for a six month program are included

in Table 5. Table 6 includes individual project economic

indicators for well C.

SPE 36630 MICROBIAL PILOT TEST FOR THE CONTROL OF PARAFFIN AND ASPHALTENES AT PRUDHOE BAY 5

Well 6 Month Project

Implementation

Costs ($)

A $49,025

B $38,540

C $30,578

D $57,958

Table 5: Total microbial treatment costs including associated well

work. Well D treatment includes cost of a CTU.

Incremental Oil

Average Incremental Oil Rate: 84 bopd

Project Cumulative Incremental

Oil (180 Days):

15,120 bbls

Project Individual Well

Cost/Cumulative Incremental Oil:

$2.02/bbl

Table 6: Individual well project economic indicators for microbial

treatment of well C.

For a treatment cost comparison, Table 7 lists conventional

hot oil treatment (HOT) statistics compared to the microbial

results. The HOT results are based on a limited search of

wells in the adjacent patterns to the microbial pilot. Due to

the wide range of HOT results, a conclusive cost comparison

is inappropriate. The comparison of results for wells which

showed favorable responses to their respective treatments is

shown to negate the effects of treated wells which were

unsuitable candidates.

HOT Microbes

Treated Wells: 8 4

Wells With Production Impacts: 3 1

Treatment Cost per Well: $2,166-

$5,388

($3,129

Average)

$30,578-

$57,958

($42,777

Average)

Statistics on Wells with Favorable Responses:

Average Liquid Production

Increase:

+38% +18%

Impact Duration: 9-40 Days

(22 Day

Average)

180 Days

Individual Well Cost/

Incremental Oil:

$0.83/bbl-

$23.95/bbl

($4.01/bbl

Average)

$2.02/bbl

Table 7: Cost comparison of HOT versus microbial treatment.

HOT statistics based on a limited search of wells adjacent to

microbial pilot wells.

Conclusions

The following conclusions were determined from the results

of the Prudhoe Bay expanded microbial pilot:

1. Application of microbial products can result in

significant compositional changes in produced crude

when applied at the reservoir level, including

increased API gravity, reduced viscosity, reduced

sulfur concentration, and reduction in the combined

paraffin and asphaltene concentration.

2. Changes in crude oil characteristics due to microbial

action can result in improved production rates and

lower operating costs as compared to other

conventional methods of paraffin and asphaltene

control.

3. Microbial products are most suitable for wells with

moderate to severe paraffin/asphaltene problems

which are capable of sustained production rates prior

to treatment. Wells with extreme paraffin/asphaltene

problems which are incapable of sustained flow rates

prior to treatment may not be suitable as microbial

candidates.

4. Microbial treatment applications can be successfully

cultured and applied in an arctic environment.

5. There were no significant benefits to performing the

initial microbial squeezes with coil tubing as

compared to simply bull heading the treatments.

6. Effects of microbial treatment, when applied

successfully, should be evident within 30 days of

initiating the treatments.

Acknowledgments

The Authors wish to thank the management of ARCO Alaska,

Inc. and the co-owners of the Prudhoe Bay Unit for

permission to publish this paper. Special thanks to W. H.

Smalstig for the initial microbial work at Prudhoe Bay, the

personal support of ARCOs Prudhoe Bay Wells Group in

the project implementation, and Dowell-Schlumberger for

furnishing equipment and site support for the microbial

culturing unit. This Paper reflects the views of the Authors,

and does not necessarily reflect the views of any owner

company in the Prudhoe Bay Unit.

References

1. Brown, F. G., Microbes-The Practical and Environmental Safe

Solution to Production Problems, Enhanced Production and

Enhanced Recovery, SPE Paper 23955 (Mar. 1992)

2. Streeb, L. P., Brown F. G., MEOR-Altman/Bluebell Field

Project, SPE Paper 24334 (May,1992)

6 K. R. FERGUSON, C. T. LLOYD, D. SPENCER, AND J . HOELTGEN SPE 36630

3. Smalstig, W. H., Microbial Pilot Project Results, AAI Internal

Correspondence, (Dec. 30, 1993)

SI Metric Conversion Factors

API 141.5/(131.5+API) =g/m

3

bbl 1.589 873 E01 =m

3

cp

1.0

*

E03 =Pas

Feet 3.048

*

E01 =m

F (F-32)5/9 =C

gal 3.785 412

E03 =m

3

md 9.869 233 E04 =m

2

psi 6.894 757 E+00 =kPa

Conversion Factor is exact

Prudhoe Bay

Type Log

GR SPHI Zones

Zulu

Victor

Tango

Upper Romeo

50-300

300-3000+

300-700

300-700

200-400

25-200

Lower Romeo 1

Lower Romeo 2

Permeability (md)

Figure 1: Prudhoe Bay type log.

Well Date Oil ,

API

Asphaltene

(wt%)

Paraffin

(wt%)

Pour

Point, F

@ 180

F,

(cSt)

Pre/Post

Microbial

Treatment

A 07/21/87 23.7 8.7 Before

A 09/03/87 5.8 Before

A 03/28/91 23. Before

A 09/01/91 21.1 Before

A 07/23/9425.07 7.7 Before

B 9/8/90 23.4 Before

B 8/10/93 2.5 20.2 Before

B 10/28/93 8.8 Before

B 4/17/95 29.7 After

C 6/15/95 25.6 8.58 8.7 -25 5.5 Before

C 8/3/95 26.8 5 10.8 -3 4.7 After

D 09/30/94 26.3 15.8 Before

D 1/9/95 11.9 0.87 17.6 327.9 Before

D 5/14/95 20.6 17.57 3.72 24.8 After

Table 8: Historical compositional and physical crude oil data for

treated wells in microbial pilot.

Well A Production Test Data

0

500

1000

1500

2000

2500

3000

1

/

1

/

9

5

2

/

2

0

/

9

5

4

/

1

1

/

9

5

5

/

3

1

/

9

5

7

/

2

0

/

9

5

9

/

8

/

9

5

1

0

/

2

8

/

9

5

1

2

/

1

7

/

9

5

2

/

5

/

9

6

3

/

2

6

/

9

6

Test Date

L

i

q

u

i

d

R

a

t

e

(

b

l

p

d

)

Before Treatment During Treatment After Treatment

Figure 2: Well test liquid rate data from 1/1/95, for well A.

SPE 36630 MICROBIAL PILOT TEST FOR THE CONTROL OF PARAFFIN AND ASPHALTENES AT PRUDHOE BAY 7

Well A Production Test Data

0

500

1000

1500

2000

2500

3000

3500

4000

4500

1

/

1

/

9

5

2

/

2

0

/

9

5

4

/

1

1

/

9

5

5

/

3

1

/

9

5

7

/

2

0

/

9

5

9

/

8

/

9

5

1

0

/

2

8

/

9

5

1

2

/

1

7

/

9

5

2

/

5

/

9

6

3

/

2

6

/

9

6

Test Date

F

o

r

m

a

t

i

o

n

G

O

R

(

s

c

f

/

b

b

l

)

Before Treatment During Treatment After Treatment

Figure 3: Produced formation gas to oil ratio (GOR) test separator

data for well A.

Well C Production Test Data

0

500

1000

1500

2000

2500

3000

3500

1

/

1

/

9

5

2

/

2

0

/

9

5

4

/

1

1

/

9

5

5

/

3

1

/

9

5

7

/

2

0

/

9

5

9

/

8

/

9

5

1

0

/

2

8

/

9

5

1

2

/

1

7

/

9

5

2

/

5

/

9

6

3

/

2

6

/

9

6

5

/

1

5

/

9

6

Test Date

L

i

q

u

i

d

R

a

t

e

(

b

l

p

d

)

Before Treatment During Treatment

After Treatment Expon. (Before Treatment)

Expon. (During Treatment)

Figure 4: Test separator liquid rate data from 1/1/95, for well C.

Pre and post-treatment exponential declines included.

Well C Production Test Data

0

1000

2000

3000

4000

5000

6000

7000

1

/

1

/

9

5

2

/

2

0

/

9

5

4

/

1

1

/

9

5

5

/

3

1

/

9

5

7

/

2

0

/

9

5

9

/

8

/

9

5

1

0

/

2

8

/

9

5

1

2

/

1

7

/

9

5

2

/

5

/

9

6

3

/

2

6

/

9

6

5

/

1

5

/

9

6

Test Date

F

o

r

m

a

t

i

o

n

G

O

R

(

s

c

f

/

b

b

l

)

Before Treatment During Treament After Treatment

Figure 5: Produced formation gas to oil ratio (GOR) test separator

data for well C.

0.0

5.0

10.0

15.0

20.0

25.0

1/1/95 4/11/95 7/20/95 10/28/95

Sample Dat e

P

r

o

d

u

c

e

d

G

a

s

C

1

/

C

3

R

a

t

i

o

Well A Well C

Onset of

Microbial

Treatments

Figure 6: Produced gas compositional analysis results for wells A

and C. Methane to pentane ratio (C1/C3) is an indicator of the

relative amount of returned miscible injectant (MI). Baseline

reservoir C1/C3 is approximately 21. A decrease in the C1/C3

value is an indicator of an increase in the amount of returned MI.

8 K. R. FERGUSON, C. T. LLOYD, D. SPENCER, AND J . HOELTGEN SPE 36630

25.6

26.8

25.7

24.6

22.5

23

23.5

24

24.5

25

25.5

26

26.5

27

27.5

6/15/95

(Before

Pilot)

8/3/95

(During

Pilot)

2/13/96

(After

Pilot)

3/2/96

(After

Pilot)

Sample Date

C

r

u

d

e

O

i

l

A

P

I

G

r

a

v

i

t

y

(

d

e

g

r

e

e

s

)

Figure 7: Well C crude oil API gravity measurements by ASTM D-

287. Graph includes a 0.5 degree error bar according to ASTM

testing standards.

5.5

4.7

5.2

6.3

4

4.5

5

5.5

6

6.5

7

6/15/95

(Before

Pilot)

8/3/95

(During

Pilot)

2/13/96

(After

Pilot)

3/2/96

(After

Pilot)

Sample Date

C

r

u

d

e

O

i

l

V

i

s

c

o

s

i

t

y

(

c

S

t

a

t

1

8

0

d

e

g

r

e

e

s

F

)

Figure 8: Well C crude oil viscosity measurements by ASTM

method D-445. Graph includes 5% error established by ASTM

testing procedures.

5

7.22 7.13

10.8

1.26

3.8

17.28

15.8

8.48

10.93

8.58

8.7

0

2

4

6

8

10

12

14

16

18

6/15/95

(Before

Pilot)

8/3/95

(During

Pilot)

2/13/96

(After

Pilot)

3/2/96

(After

Pilot)

Sample Date

C

r

u

d

e

O

i

l

C

o

n

s

t

i

t

u

e

n

t

C

o

n

c

e

n

t

r

a

t

i

o

n

s

(

w

e

i

g

h

t

%

)

Asphaltene Wax Asphaltene +Wax

Figure 9: Asphaltene (ASTM D-3279) and paraffin (UOP-4664)

concentration measurements for Well C.

0.93

0.81

0.89

0.91

0.74

0.76

0.78

0.8

0.82

0.84

0.86

0.88

0.9

0.92

0.94

6/15/95

(Before

Pilot)

8/3/95

(During

Pilot)

2/13/96

(After

Pilot)

3/2/96

(After

Pilot)

Sample Date

C

r

u

d

e

O

i

l

S

u

l

f

u

r

C

o

n

c

e

n

t

r

a

t

i

o

n

(

w

e

i

g

h

t

%

)

Figure 10: Sulfur concentration measurements for Well C by

ASTM D-4294.

Vous aimerez peut-être aussi

- Versa Matic 3 Pulg Clamped - ManualDocument19 pagesVersa Matic 3 Pulg Clamped - ManualJose BarreroPas encore d'évaluation

- Motor Lincoln 286 TSCDocument5 pagesMotor Lincoln 286 TSCJose BarreroPas encore d'évaluation

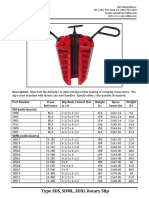

- Type SDS SDML SDXL Rotary Slip Cut SheetDocument2 pagesType SDS SDML SDXL Rotary Slip Cut SheetJose Barrero100% (1)

- Motor Trifasico Baldor 50 HPDocument1 pageMotor Trifasico Baldor 50 HPJose BarreroPas encore d'évaluation

- Caterpillar C15 Engine SpecsDocument5 pagesCaterpillar C15 Engine Specsjinxy5779100% (4)

- Hydril GK Annular Blowout Preventers: 18-3/4"-10,000 Psi Ram BOP Automatic Multiple Position Lock (MPL) IllustratedDocument4 pagesHydril GK Annular Blowout Preventers: 18-3/4"-10,000 Psi Ram BOP Automatic Multiple Position Lock (MPL) IllustratedJose BarreroPas encore d'évaluation

- Bomba de Lodos BH 800 PDFDocument36 pagesBomba de Lodos BH 800 PDFJose Barrero0% (1)

- Lincoln New Code 9935Document22 pagesLincoln New Code 9935Jose Barrero100% (1)

- Agitador - ManualDocument25 pagesAgitador - ManualJose Barrero100% (2)

- BVM Manual Type "C" Tong 35,000 Ft/lbs TORQUEDocument2 pagesBVM Manual Type "C" Tong 35,000 Ft/lbs TORQUEJose Barrero100% (2)

- Unlock-The Petrophysics of Problematic ReservoirsDocument9 pagesUnlock-The Petrophysics of Problematic ReservoirsJose BarreroPas encore d'évaluation

- Especificacion de Normas de InspeccionDocument32 pagesEspecificacion de Normas de InspeccionJose BarreroPas encore d'évaluation

- SPE 88453 Simulation Analysis of Microbial Well Treatment of Bokor Field, MalaysiaDocument1 pageSPE 88453 Simulation Analysis of Microbial Well Treatment of Bokor Field, MalaysiaJose BarreroPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- D&D 5e Conditions Player ReferenceDocument1 pageD&D 5e Conditions Player ReferenceFrank Wilcox, Jr (fewilcox)Pas encore d'évaluation

- Miqro Vaporizer Owners ManualDocument36 pagesMiqro Vaporizer Owners ManualJuan Pablo AragonPas encore d'évaluation

- Atlas Copco ZT55 Instruction ManualDocument90 pagesAtlas Copco ZT55 Instruction ManualRafael Martin Anaya Figueroa100% (4)

- NHPC ReportDocument53 pagesNHPC ReportVishal SinghPas encore d'évaluation

- Iso 21969 2009 en PDFDocument8 pagesIso 21969 2009 en PDFAnonymous P7J7V4Pas encore d'évaluation

- Oyo Busines ModelDocument1 pageOyo Busines ModelVikash KumarPas encore d'évaluation

- Rit Fol Pegelmessung en WebDocument4 pagesRit Fol Pegelmessung en WebPrimo BluesPas encore d'évaluation

- Advanced Power ElectronicsDocument4 pagesAdvanced Power ElectronicsLinkan PriyadarsiniPas encore d'évaluation

- Notice: Agency Information Collection Activities Proposals, Submissions, and ApprovalsDocument2 pagesNotice: Agency Information Collection Activities Proposals, Submissions, and ApprovalsJustia.comPas encore d'évaluation

- Background of UNITAR International UniversityDocument3 pagesBackground of UNITAR International UniversityAin NadiaPas encore d'évaluation

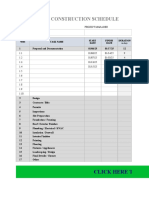

- Residential Construction Schedule: Click Here To Create in SmartsheetDocument14 pagesResidential Construction Schedule: Click Here To Create in SmartsheetVinayak VaghePas encore d'évaluation

- Workshop Manual Automatic Transmission 30 40leDocument2 pagesWorkshop Manual Automatic Transmission 30 40leDony TedyantoPas encore d'évaluation

- Pete443 Chapter3 PDFDocument38 pagesPete443 Chapter3 PDFQaiser HafeezPas encore d'évaluation

- Team Building & Team WorkDocument39 pagesTeam Building & Team WorkAmrita DasPas encore d'évaluation

- Aggregate Planning and Master Scheduling: Mcgraw-Hill/IrwinDocument15 pagesAggregate Planning and Master Scheduling: Mcgraw-Hill/IrwinKushal BhatiaPas encore d'évaluation

- Yousif Yassin PDFDocument124 pagesYousif Yassin PDFJAVIYAROSPas encore d'évaluation

- 1St Flr. Reflected Ceiling Plan 2Nd Flr. Reflected Ceiling PlanDocument1 page1St Flr. Reflected Ceiling Plan 2Nd Flr. Reflected Ceiling PlanMac KYPas encore d'évaluation

- PanasonicBatteries NI-MH HandbookDocument25 pagesPanasonicBatteries NI-MH HandbooktlusinPas encore d'évaluation

- Authorization For Entering Manual ConditionsDocument15 pagesAuthorization For Entering Manual ConditionsSushil Sarkar100% (2)

- Manual Operacion Compresores de AireDocument204 pagesManual Operacion Compresores de AireHugo RodriguezPas encore d'évaluation

- Chapter Application PortfolioDocument51 pagesChapter Application PortfolioShahla AsPas encore d'évaluation

- Azuma 2015 Metrologia 52 360Document17 pagesAzuma 2015 Metrologia 52 360Rudolf KiraljPas encore d'évaluation

- BANDITO-PULSE Engl PDFDocument9 pagesBANDITO-PULSE Engl PDFMario Ariel VesconiPas encore d'évaluation

- Process Safety BeaconDocument1 pageProcess Safety BeaconRaul tejadaPas encore d'évaluation

- Rahul BhartiDocument3 pagesRahul BhartirahuldearestPas encore d'évaluation

- X-Payments:API: Cart - Id CART - D&request REQUESTDocument3 pagesX-Payments:API: Cart - Id CART - D&request REQUESTChristianAntonioPas encore d'évaluation

- Top 20 Web Services Interview Questions and Answers: Tell Me About Yourself?Document28 pagesTop 20 Web Services Interview Questions and Answers: Tell Me About Yourself?sonu kumarPas encore d'évaluation

- 24 - Counting of Bottles - Solution - ENGDocument3 pages24 - Counting of Bottles - Solution - ENGhaftu gideyPas encore d'évaluation

- 21CS8133 Labassignment1Document7 pages21CS8133 Labassignment1Sai PraneethPas encore d'évaluation

- Reverse LogisticsDocument18 pagesReverse Logisticsiazeem2401630Pas encore d'évaluation