Académique Documents

Professionnel Documents

Culture Documents

ZJ Vehicle Theft/Security Systems 8Q - 1

Transféré par

Dalton WiseDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

ZJ Vehicle Theft/Security Systems 8Q - 1

Transféré par

Dalton WiseDroits d'auteur :

Formats disponibles

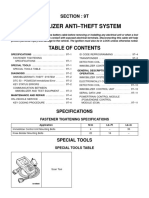

VEHICLE THEFT/SECURITY SYSTEMS

CONTENTS

page page

GENERAL INFORMATION

ARMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

DISARMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

ENABLING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . 1

POWER-UP MODE . . . . . . . . . . . . . . . . . . . . . . . 2

TAMPER ALERT . . . . . . . . . . . . . . . . . . . . . . . . . 2

DESCRIPTION AND OPERATION

AUTO HEADLAMP RELAY . . . . . . . . . . . . . . . . . 3

BODY CONTROL MODULE . . . . . . . . . . . . . . . . . 2

DOOR AJ AR SWITCH . . . . . . . . . . . . . . . . . . . . . 3

DOOR LOCK CYLINDER SWITCH . . . . . . . . . . . . 3

HORN RELAY . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

LIFTGATE AJ AR SWITCH . . . . . . . . . . . . . . . . . . 3

LIFTGATE LOCK CYLINDER SWITCH . . . . . . . . . 3

LIFTGLASS AJ AR SWITCH . . . . . . . . . . . . . . . . . 3

PARK LAMP RELAY . . . . . . . . . . . . . . . . . . . . . . 3

SET LAMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

DIAGNOSIS AND TESTING

RELAYS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

VEHICLE THEFT SECURITY SYSTEM . . . . . . . . . 4

REMOVAL AND INSTALLATION

AUTO HEADLAMP AND PARK LAMP RELAYS . . 8

DOOR AJ AR SWITCH . . . . . . . . . . . . . . . . . . . . . 5

DOOR LOCK CYLINDER SWITCH . . . . . . . . . . . . 5

HORN RELAY . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

LIFTGATE AJ AR SWITCH . . . . . . . . . . . . . . . . . . 6

LIFTGATE LOCK CYLINDER SWITCH . . . . . . . . . 7

LIFTGLASS AJ AR SWITCH . . . . . . . . . . . . . . . . . 7

SET LAMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

GENERAL INFORMATION

INTRODUCTION

The Vehi cl e Theft Securi ty System (VTSS) i s an

avai l abl e factory-i nstal l ed opti on on thi s model . Thi s

system i s desi gned to provi de peri meter protecti on

agai nst unauthori zed use or tamperi ng by moni tori ng

the vehi cl e doors, l i ftgate, and i gni ti on system. I f

unauthori zed use or tamperi ng i s detected, the sys-

tem responds by soundi ng the horn, fl ashi ng the

exteri or l amps, and provi di ng an engi ne no-run fea-

ture. The VTSS can be di sarmed by unl ocki ng the

vehi cl e wi th the key i n ei ther front door l ock cyl i nder

or usi ng the Remote Keyl ess Entry (RKE) transmi t-

ters.

Fol l owi ng are some general descri pti ons of the fea-

tures of the VTSS. Refer to the vehi cl e owners man-

ual for addi ti onal i nformati on on the use and

operati on of thi s system. Refer to 8W-39 - Vehi cl e

Theft Securi ty System i n Group 8W - Wi ri ng Di a-

grams for compl ete ci rcui t descri pti ons and di agrams.

ENABLING

The Vehi cl e Theft Securi ty System (VTSS) features

are provi ded by two el ectroni c modul es i n the vehi cl e;

the Powertrai n Control Modul e (PCM) l ocated i n the

engi ne compartment, and the Body Control Modul e

(BCM) l ocated i n the passenger compartment. Both

of these modul es must have thei r respecti ve VTSS

functi ons el ectroni cal l y enabl ed i n order for the

VTSS to perform as desi gned.

The VTSS engi ne no-run feature i s di sabl ed when

i t i s shi pped from the factory. Thi s i s done by pro-

grammi ng wi thi n the Powertrai n Control Modul e

(PCM). The l ogi c i n the PCM prevents the VTSS

engi ne no-run feature from armi ng unti l the engi ne

start counter wi thi n the PCM sees twenty engi ne

starts. The VTSS no-run feature must be enabl ed

when the vehi cl e i s recei ved from the assembl y pl ant.

The preferred method for enabl i ng the VTSS

engi ne no-run feature i s to el ectroni cal l y advance the

PCM engi ne start counter usi ng a DRB scan tool .

Refer to the Vehi cl e Theft Securi ty System menu

i tem on the DRB scan tool for the procedures. Once

thi s condi ti on has been met, the PCM wi l l al l ow the

engi ne no-run feature to arm. Once the VTSS engi ne

no-run feature has been enabl ed i n the PCM, i t can-

not be di sabl ed. The same VTSS engi ne no-run fea-

ture enabl e l ogi c wi l l appl y anyti me the PCM i s

repl aced wi th a new uni t.

The remai ni ng VTSS features are control l ed by the

BCM. The l ogi c i n the BCM keeps i ts VTSS features

dormant unti l i t i s enabl ed usi ng a DRB scan tool .

The VTSS features of the BCM are enabl ed on vehi -

cl es equi pped wi th the VTSS opti on at the factory,

but a servi ce repl acement BCM must be enabl ed by

the deal er wi th a DRB scan tool anyti me the BCM i s

repl aced wi th a new uni t.

ZJ VEHICLE THEFT/SECURITY SYSTEMS 8Q - 1

ARMING

Passi ve armi ng of the Vehi cl e Theft Securi ty Sys-

tem (VTSS) occurs when the vehi cl e i s exi ted wi th

the key removed from the i gni ti on swi tch, the head-

l amps are turned off, and the doors are l ocked usi ng

the power l ock swi tch. The power l ock swi tch wi l l not

functi on i f the key i s i n the i gni ti on swi tch or the

headl amps are on wi th the dri ver si de front door

open. The VTSS wi l l not arm i f ei ther front door or

the l i ftgate are l ocked usi ng the key i n the l ock cyl -

i nder or usi ng the mechani cal l ock button.

Acti ve armi ng of the VTSS occurs when the

Remote Keyl ess Entry (RKE) transmi tter i s used to

l ock the vehi cl e, even i f the doors and/or the l i ftgate

are open when the RKE transmi tter Lock button i s

depressed. However, the VTSS armi ng wi l l not be

compl ete unti l al l of the doors and the l i ftgate are

cl osed.

Fol l owi ng successful passi ve or acti ve VTSS arm-

i ng, the VTSS set l amp on the top of the i nstrument

panel wi l l fl ash rapi dl y for about fi fteen seconds after

the i l l umi nated entry system ti mes out. Thi s i ndi -

cates that VTSS armi ng i s i n progress. Once the fi f-

teen second armi ng functi on i s successful l y

compl eted, the set l amp wi l l fl ash at a sl ower rate to

i ndi cate that the VTSS i s armed.

DISARMING

Passi ve di sarmi ng of the Vehi cl e Theft Securi ty

System (VTSS) occurs when the vehi cl e i s unl ocked

usi ng the key to unl ock ei ther front door or the l i ft-

gate. Acti ve di sarmi ng of the VTSS occurs when the

vehi cl e i s unl ocked by depressi ng the Unl ock button

of the Remote Keyl ess Entry (RKE) transmi tter.

Once the al arm has been acti vated (horn soundi ng,

exteri or l amps fl ashi ng, and the engi ne no-run fea-

ture), ei ther di sarmi ng method wi l l al so deacti vate

the al arm.

Depressi ng the Pani c button on the RKE transmi t-

ter wi l l al so di sarm the VTSS, but the horn wi l l

sound and the exteri or l amps wi l l fl ash for about

three mi nutes as part of the Pani c feature functi on.

Refer to Group 8P - Power Lock Systems for more

i nformati on on the Pani c feature.

POWER-UP MODE

When the armed Vehi cl e Theft Securi ty System

(VTSS) senses that the battery has been di sconnected

and reconnected, i t enters i ts power-up mode. I n the

power-up mode the al arm system remai ns armed fol -

l owi ng a battery fai l ure or di sconnect. I f the VTSS

was armed pri or to a battery di sconnect or fai l ure,

the system wi l l have to be acti vel y or passi vel y di s-

armed after the battery i s reconnected.

The power-up mode wi l l al so appl y i f the battery

goes dead whi l e the system i s armed, and battery

jump-starti ng i s attempted. The engi ne no-run fea-

ture wi l l prevent the engi ne from starti ng unti l the

al arm system has been acti vel y or passi vel y di s-

armed.

TAMPER ALERT

The Vehi cl e Theft Securi ty System (VTSS) tamper

al ert wi l l sound the horn three ti mes upon di sarm-

i ng, i f the al arm was acti vated and has si nce ti med-

out (about ei ghteen mi nutes). Thi s feature al erts the

vehi cl e operator that the VTSS was acti vated whi l e

the vehi cl e was unattended.

DESCRIPTION AND OPERATION

BODY CONTROL MODULE

A Body Control Modul e (BCM) i s used on thi s

model to control and i ntegrate many of the el ectroni c

functi ons and features i ncl uded on the vehi cl e. The

BCM contai ns a central processi ng uni t and i nter-

faces wi th other modul es i n the vehi cl e on the

Chrysl er Col l i si on Detecti on (CCD) data bus network.

The CCD data bus network al l ows the shari ng of

sensor i nformati on. Thi s hel ps to reduce wi re har-

ness compl exi ty, reduce i nternal control l er hardware,

and reduce component sensor current l oads. At the

same ti me, thi s system provi des i ncreased rel i abi l i ty,

enhanced di agnosti cs, and al l ows the addi ti on of

many new feature capabi l i ti es.

One of the functi ons and features that the BCM

supports and control s, i s the Vehi cl e Theft Securi ty

System (VTSS). I n the VTSS, the BCM recei ves CCD

message i nputs from the Passenger Door Modul e

(PDM), whi ch contai ns the Remote Keyl ess Entry

(RKE) recei ver. I n addi ti on to the i nformati on

recei ved on the CCD data bus, the BCM recei ves

hard-wi red i nputs from the door ajar, door l ock cyl i n-

der, i gni ti on, l i ftgate ajar, l i ftgate l ock cyl i nder, and

l i ftgl ass ajar swi tches. The programmi ng i n the BCM

al l ows i t to process the i nformati on from al l of i ts

i nputs and send control outputs to energi ze or de-en-

ergi ze the auto headl amp rel ay, horn rel ay, park

l amp rel ay, Powertrai n Control Modul e (PCM), and

the securi ty set l amp.

The BCM i s mounted under the dri ver si de out-

board end of the i nstrument panel , behi nd the i nstru-

ment panel support armature and bel ow the

outboard swi tch pod. Refer to Group 8E - I nstrument

Panel Systems for the removal and i nstal l ati on pro-

cedures. For di agnosi s of the BCM or the CCD data

bus, the use of a DRB scan tool and the proper Di ag-

nosti c Procedures manual are recommended. The

BCM can onl y be servi ced by an authori zed el ectroni c

repai r stati on. Refer to the l atest Warranty Pol i ci es

and Procedures manual for a current l i sti ng of autho-

ri zed el ectroni c repai r stati ons.

8Q - 2 VEHICLE THEFT/SECURITY SYSTEMS ZJ

GENERAL INFORMATION (Continued)

DOOR AJAR SWITCH

The door ajar swi tches are mounted to the pi l l ar i n

the rear of each door openi ng. They are pl unger-type

swi tches that are case grounded to the pi l l ar. When

the door i s open the swi tch i s cl osed, and when the

door i s cl osed the swi tch i s open.

The door ajar swi tches cannot be repai red and, i f

faul ty or damaged, they must be repl aced.

DOOR LOCK CYLINDER SWITCH

The door l ock cyl i nder swi tches are mounted to the

back of the key l ock cyl i nder i nsi de each front door.

They are normal l y-open momentary swi tches that

cl ose to ground onl y when the l ock cyl i nder i s rotated

to the unl ock posi ti on.

The door l ock cyl i nder swi tches cannot be repai red

and, i f faul ty or damaged, they must be repl aced.

LIFTGATE AJAR SWITCH

The l i ftgate ajar swi tch i s i ntegral to the l i ftgate

l atch assembl y on the l i ftgate. I t i s a momentary-

type swi tch that i s open when the l i ftgate i s cl osed,

and cl osed when the l i ftgate i s open.

The l i ftgate ajar swi tch cannot be repai red and, i f

faul ty or damaged, the l i ftgate l atch assembl y must

be repl aced.

LIFTGATE LOCK CYLINDER SWITCH

The l i ftgate l ock cyl i nder swi tch i s mounted to the

back of the key l ock cyl i nder i nsi de the l i ftgate. I t i s

a normal l y-open momentary swi tch that cl oses to

ground onl y when the l ock cyl i nder i s rotated to the

unl ock posi ti on.

The l i ftgate l ock cyl i nder swi tch cannot be repai red

and, i f faul ty or damaged, i t must be repl aced.

LIFTGLASS AJAR SWITCH

The l i ftgl ass ajar swi tch i s i ntegral to the l i ftgl ass

l atch assembl y on the l i ftgate. I t i s a momentary-

type swi tch that i s open when the l i ftgl ass i s cl osed,

and cl osed when the l i ftgl ass i s open.

The l i ftgl ass ajar swi tch cannot be repai red and, i f

faul ty or damaged, the l i ftgl ass l atch assembl y must

be repl aced.

AUTO HEADLAMP RELAY

The auto headl amp rel ay i s a I nternati onal Stan-

dards Organi zati on (I SO) mi cro-rel ay. The termi nal

desi gnati ons and functi ons are the same as a conven-

ti onal I SO rel ay. However, the mi cro-rel ay termi nal

ori entati on (or footpri nt) i s di fferent, current capaci ty

i s l ower, and the rel ay case di mensi ons are smal l er

than those of the conventi onal I SO rel ay.

The auto headl amp rel ay i s a el ectromechani cal

devi ce that swi tches battery current to the head-

l amps when the Body Control Modul e (BCM) grounds

the rel ay coi l . See the Di agnosi s and Testi ng secti on

of thi s group for more i nformati on on the operati on of

the auto headl amp rel ay.

The auto headl amp rel ay i s l ocated i n the juncti on

bl ock, on the ri ght cowl si de i nner panel bel ow the

i nstrument panel i n the passenger compartment.

The auto headl amp rel ay cannot be repai red and, i f

faul ty or damaged, i t must be repl aced.

HORN RELAY

The horn rel ay i s a I nternati onal Standards Orga-

ni zati on (I SO) mi cro-rel ay. The termi nal desi gnati ons

and functi ons are the same as a conventi onal I SO

rel ay. However, the mi cro-rel ay termi nal ori entati on

(or footpri nt) i s di fferent, current capaci ty i s l ower,

and the rel ay case di mensi ons are smal l er than those

of the conventi onal I SO rel ay.

The horn rel ay i s a el ectromechani cal devi ce that

swi tches battery current to the horn when the horn

swi tch or the Body Control Modul e (BCM) grounds

the rel ay coi l . See the Di agnosi s and Testi ng secti on

of thi s group for more i nformati on on the operati on of

the horn rel ay.

The horn rel ay i s l ocated i n the Power Di stri buti on

Center (PDC), i n the engi ne compartment. Refer to

the PDC l abel for rel ay i denti fi cati on and l ocati on.

I f a probl em i s encountered wi th a conti nuousl y

soundi ng horn, i t can usual l y be qui ckl y resol ved by

removi ng the horn rel ay from PDC unti l further

di agnosi s i s compl eted.

The horn rel ay cannot be repai red and, i f faul ty or

damaged, i t must be repl aced.

PARK LAMP RELAY

The park l amp rel ay i s a I nternati onal Standards

Organi zati on (I SO) mi cro-rel ay. The termi nal desi g-

nati ons and functi ons are the same as a conventi onal

I SO rel ay. However, the mi cro-rel ay termi nal ori enta-

ti on (or footpri nt) i s di fferent, current capaci ty i s

l ower, and the rel ay case di mensi ons are smal l er

than those of the conventi onal I SO rel ay.

The park l amp rel ay i s a el ectromechani cal devi ce

that swi tches battery current to the park l amps

when the Body Control Modul e (BCM) grounds the

rel ay coi l . See the Di agnosi s and Testi ng secti on of

thi s group for more i nformati on on the operati on of

the park l amp rel ay.

The park l amp rel ay i s l ocated i n the juncti on

bl ock, on the ri ght cowl si de panel bel ow the i nstru-

ment panel i n the passenger compartment. The park

l amp rel ay can be accessed by removi ng the fuse

access panel and the ri ght cowl si de tri m panel .

The park l amp rel ay cannot be repai red and, i f

faul ty or damaged, i t must be repl aced.

ZJ VEHICLE THEFT/SECURITY SYSTEMS 8Q - 3

DESCRIPTION AND OPERATION (Continued)

SET LAMP

The Vehi cl e Theft Securi ty System (VTSS) set l amp

i s a red l i ght-emi tti ng di ode mounted wi th the auto

headl amp ambi ent l i ght sensor on top of the i nstru-

ment panel near the dri ver si de defroster outl et. The

set l amp recei ves fused battery feed at al l ti mes and

i s grounded by the Body Control Modul e (BCM) to

gi ve a vi sual i ndi cati on of the VTSS status.

The set l amp cannot be repai red and, i f damaged

or faul ty, the set l amp/auto headl amp ambi ent l i ght

sensor uni t must be repl aced.

DIAGNOSIS AND TESTING

VEHICLE THEFT SECURITY SYSTEM

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

The Vehi cl e Theft Securi ty System (VTSS) and the

Chrysl er Col l i si on Detecti on (CCD) data bus network

shoul d be di agnosed usi ng the DRB scan tool and the

proper Di agnosti c Procedures manual . The DRB scan

tool wi l l provi de confi rmati on that the CCD data bus

i s functi onal , that the Body Control Modul e (BCM) i s

enabl ed and putti ng the proper messages on the CCD

data bus, that the BCM i s enabl ed and recei vi ng the

proper hard-wi red i nputs and sendi ng the proper

hard-wi red outputs, and that the Powertrai n Control

Modul e (PCM) i s enabl ed and recei vi ng the CCD

data bus messages from the BCM.

Refer to the proper Di agnosti c Procedures manual

and the Vehi cl e Theft Securi ty System menu i tem on

the DRB scan tool for the procedures. Refer to 8W-39

- Vehi cl e Theft Securi ty System i n Group 8W - Wi r-

i ng Di agrams for compl ete ci rcui t descri pti ons and

di agrams.

RELAYS

The horn rel ay i s l ocated i n the Power Di stri buti on

Center (PDC) i n the engi ne compartment. The auto

headl amp and park l amp rel ays are l ocated i n the

juncti on bl ock i n the passenger compartment. Each

of these rel ays (Fi g. 1) can be tested as descri bed i n

the fol l owi ng procedure, however the ci rcui ts they

are used i n do vary. To test the rel ay ci rcui ts, refer to

the ci rcui t descri pti ons and di agrams i n 8W-39 -

Vehi cl e Theft Securi ty System i n Group 8W - Wi ri ng

Di agrams.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

Remove the rel ay from the PDC or juncti on bl ock

as descri bed i n thi s group to perform the fol l owi ng

tests:

(1) A rel ay i n the de-energi zed posi ti on shoul d

have conti nui ty between termi nal s 87A and 30, and

no conti nui ty between termi nal s 87 and 30. I f OK, go

to Step 2. I f not OK, repl ace the faul ty rel ay.

(2) Resi stance between termi nal s 85 and 86 (el ec-

tromagnet) shoul d be 75 5 ohms. I f OK, go to Step

3. I f not OK, repl ace the faul ty rel ay.

(3) Connect a battery to termi nal s 85 and 86.

There shoul d now be conti nui ty between termi nal s

30 and 87, and no conti nui ty between termi nal s 87A

and 30. I f OK, test the rel ay ci rcui ts. I f not OK,

repl ace the faul ty rel ay.

Fig. 1 Relay Terminals

8Q - 4 VEHICLE THEFT/SECURITY SYSTEMS ZJ

DESCRIPTION AND OPERATION (Continued)

REMOVAL AND INSTALLATION

DOOR AJAR SWITCH

(1) Di sconnect and i sol ate the battery negati ve

cabl e.

(2) Remove the screw that secures the door ajar

swi tch to the pi l l ar at the rear of the door openi ng

(Fi g. 2).

(3) Pul l the swi tch out from the mounti ng hol e i n

the door openi ng far enough to access the wi re har-

ness connector.

(4) Unpl ug the wi re harness connector from the

swi tch.

(5) Reverse the removal procedures to i nstal l .

Ti ghten the swi tch mounti ng screw to 1.7 Nm (15 i n.

l bs.).

DOOR LOCK CYLINDER SWITCH

(1) Di sconnect and i sol ate the battery negati ve

cabl e.

(2) Remove the bezel near the i nsi de door l atch

rel ease handl e by i nserti ng a strai ght-bl aded screw-

dri ver i n the notched end of the bezel and pryi ng

gentl y upwards.

(3) Remove the screw l ocated beneath the bezel

that secures the front door tri m panel to the i nner

door panel (Fi g. 3).

(4) Remove the tri m cap and screw near the rear

of the front door armrest.

(5) Remove the tri m cap and screw at the upper

front corner of the front door tri m panel .

(6) Remove the screw l ocated above the front door

speaker gri l l e on the front door tri m panel .

(7) Usi ng a tri m sti ck or another sui tabl e wi de

fl at-bl aded tool , gentl y pry the front door tri m panel

away from the door around the peri meter to rel ease

the tri m panel retai ners.

NOTE: To aid in the removal of the trim panel, start

at the bottom of the panel.

(8) Pul l the front door tri m panel away from the

i nner door panel far enough to access and unpl ug the

wi re harness connectors from the door modul e and, i f

the vehi cl e i s so equi pped, from the front door cour-

tesy l amp.

(9) Pul l the watershi el d away from the rear access

hol es i n the front door i nner panel .

(10) Remove the U-cl i p retai ner that secures the

l ock cyl i nder to the outer door panel (Fi g. 4).

(11) Di sconnect the door l ock cyl i nder actuator rod

from the door l atch by unsnappi ng the pl asti c

retai ner.

Fig. 2 Door Ajar Switch Remove/Install

Fig. 3 Front Door Trim Panel Remove/Install

Fig. 4 Door Lock Cylinder Remove/Install

ZJ VEHICLE THEFT/SECURITY SYSTEMS 8Q - 5

(12) Pul l the l ock cyl i nder out of i ts mounti ng hol e

from the outsi de of the door panel far enough to pry

the l ock cyl i nder swi tch off of the back of the l ock

cyl i nder (Fi g. 5).

(13) From the i nsi de of the door unpl ug the l ock

cyl i nder swi tch wi re harness connector and remove

the swi tch from the door.

(14) Reverse the removal procedures to i nstal l .

Ti ghten the mounti ng screws to 2.2 Nm (20 i n. l bs.).

LIFTGATE AJAR SWITCH

(1) Di sconnect and i sol ate the battery negati ve

cabl e.

(2) Open the l i ftgate.

(3) Remove the screws that secure the l i ftgate

l ower tri m panel to the l i ftgate i nner panel (Fi g. 6).

(4) Usi ng a tri m sti ck or another sui tabl e wi de

fl at-bl aded tool , gentl y pry the peri meter edges of the

tri m panel away from the l i ftgate i nner panel to

rel ease the retai ners.

NOTE: To aid in the removal of the trim panel, start

at the bottom of the panel.

(5) Remove the l i ftgate tri m panel from the vehi -

cl e.

(6) Remove the three screws that secure the l i ft-

gate l atch to the l i ftgate (Fi g. 7).

(7) Di sconnect the l i ftgate handl e l atch actuator

rod from the l atch.

(8) Unpl ug the l i ftgate ajar swi tch wi re harness

connector from the l atch.

(9) Remove the l atch from the l i ftgate.

(10) Reverse the removal procedures to i nstal l .

Ti ghten the l atch mounti ng screws to 7 Nm (62 i n

l bs.).

Fig. 5 Door Lock Cylinder Switch Remove/Install -

Typical

Fig. 6 Liftgate Trim Panel Remove/Install

Fig. 7 Liftgate Latch/Lock Components

8Q - 6 VEHICLE THEFT/SECURITY SYSTEMS ZJ

REMOVAL AND INSTALLATION (Continued)

LIFTGATE LOCK CYLINDER SWITCH

(1) Di sconnect and i sol ate the battery negati ve

cabl e.

(2) Open the l i ftgate.

(3) Remove the screws that secure the l i ftgate

l ower tri m panel to the l i ftgate i nner panel (Fi g. 8).

(4) Usi ng a tri m sti ck or another sui tabl e wi de

fl at-bl aded tool , gentl y pry the peri meter edges of the

tri m panel away from the l i ftgate i nner panel to

rel ease the retai ners.

NOTE: To aid in the removal of the trim panel, start

at the bottom of the panel.

(5) Remove the l ower l i ftgate tri m panel from the

vehi cl e.

(6) Pry the l i ftgate l ock cyl i nder swi tch off of the

back of the l ock cyl i nder (Fi g. 9).

(7) Unpl ug the l ock cyl i nder swi tch wi re harness

connector and remove the swi tch from i nsi de the l i ft-

gate.

(8) Reverse the removal procedures to i nstal l .

Ti ghten the mounti ng screws to 2.2 Nm (20 i n. l bs.).

LIFTGLASS AJAR SWITCH

(1) Di sconnect and i sol ate the battery negati ve

cabl e.

(2) Open the l i ftgate.

(3) Remove the screws that secure the l i ftgate

l ower tri m panel to the l i ftgate i nner panel (Fi g. 10).

(4) Usi ng a tri m sti ck or another sui tabl e wi de

fl at-bl aded tool , gentl y pry the peri meter edges of the

tri m panel away from the l i ftgate i nner panel to

rel ease the retai ners.

NOTE: To aid in the removal of the trim panel, start

at the bottom of the panel.

(5) Remove the l ower l i ftgate tri m panel from the

vehi cl e.

(6) Remove the two nuts that secure the l i ftgl ass

l atch to the l i ftgate i nner panel (Fi g. 11).

Fig. 8 Liftgate Trim Panel Remove/Install

Fig. 9 Liftgate Lock Cylinder Switch Remove/Install

Fig. 10 Liftgate Trim Panel Remove/Install

Fig. 11 Liftglass Ajar Switch Remove/Install

ZJ VEHICLE THEFT/SECURITY SYSTEMS 8Q - 7

REMOVAL AND INSTALLATION (Continued)

(7) Unpl ug the wi re harness connectors for the l i ft-

gl ass l atch sol enoi d and the l i ftgl ass ajar swi tch.

(8) Remove the l i ftgl ass l atch from the l i ftgate.

(9) Reverse the removal procedures to i nstal l .

Ti ghten the l atch mounti ng nuts to 11 Nm (100 i n.

l bs.). Ti ghten the tri m panel mounti ng screws to 2.2

Nm (20 i n. l bs.).

AUTO HEADLAMP AND PARK LAMP RELAYS

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Di sconnect and i sol ate the battery negati ve

cabl e.

(2) Remove the fuse access panel by unsnappi ng i t

from the ri ght cowl si de tri m panel .

(3) Remove the push nut that secures the ri ght

cowl si de tri m panel to the juncti on bl ock stud (Fi g.

12).

(4) Remove the two screws that secure the ri ght

cowl si de tri m panel to the ri ght front door openi ng

tri m.

(5) Remove the ri ght cowl si de tri m panel from the

ri ght cowl si de i nner panel .

(6) Unpl ug the headl amp or park l amp rel ay from

the juncti on bl ock.

(7) I nstal l the headl amp or park l amp rel ay by

al i gni ng the rel ay termi nal s wi th the cavi ti es i n the

juncti on bl ock and pushi ng the rel ay fi rml y i nto

pl ace.

(8) Connect the battery negati ve cabl e.

(9) Test the rel ay operati on.

(10) Rei nstal l the ri ght cowl si de tri m and the fuse

access panel .

HORN RELAY

(1) Di sconnect and i sol ate the battery negati ve

cabl e.

(2) Remove the cover from the Power Di stri buti on

Center (PDC) (Fi g. 13).

(3) Refer to the l abel on the PDC for horn rel ay

i denti fi cati on and l ocati on.

(4) Unpl ug the horn rel ay from the PDC.

(5) I nstal l the horn rel ay by al i gni ng the rel ay ter-

mi nal s wi th the cavi ti es i n the PDC and pushi ng the

rel ay fi rml y i nto pl ace.

(6) I nstal l the PDC cover.

(7) Connect the battery negati ve cabl e.

(8) Test the rel ay operati on.

SET LAMP

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

Fig. 12 Right Cowl Side Trim Remove/Install

Fig. 13 Power Distribution Center

8Q - 8 VEHICLE THEFT/SECURITY SYSTEMS ZJ

REMOVAL AND INSTALLATION (Continued)

(1) Di sconnect and i sol ate the battery negati ve

cabl e.

(2) Usi ng a tri m sti ck or another sui tabl e wi de

fl at-bl aded tool , gentl y pry the cowl top tri m panel off

of the i nstrument panel top pad (Fi g. 14).

(3) Pul l the tri m panel up far enough to access and

unpl ug the wi re harness connector for the sol ar sen-

sor, or to remove the sol ar sensor from the cowl top

tri m, i f the vehi cl e i s so equi pped.

(4) Remove the cowl top tri m panel from the

i nstrument panel .

(5) Remove the auto headl amp l i ght sensor/vehi cl e

theft securi ty system set l amp mounti ng screw near

the dri ver si de defroster duct outl et.

(6) Pul l the set l amp up from the top of the i nstru-

ment panel far enough to access and unpl ug the wi re

harness connector.

(7) remove the set l amp from the i nstrument

panel .

(8) Reverse the removal procedures to i nstal l .

Ti ghten the mounti ng screw to 2.2 Nm (20 i n. l bs.).

Fig. 14 Cowl Top Trim Remove/Install

ZJ VEHICLE THEFT/SECURITY SYSTEMS 8Q - 9

REMOVAL AND INSTALLATION (Continued)

Vous aimerez peut-être aussi

- Vehicle Theft Security Systems GuideDocument6 pagesVehicle Theft Security Systems GuideDaniel TorresPas encore d'évaluation

- Vehicle Theft - Security SystemsDocument8 pagesVehicle Theft - Security SystemsrenimoPas encore d'évaluation

- VEHICLE+THEFT JeepDocument12 pagesVEHICLE+THEFT Jeepthomas ruldu100% (1)

- ZJ Power Lock Systems 8P - 1Document8 pagesZJ Power Lock Systems 8P - 1Dalton WisePas encore d'évaluation

- Dodge Ram Truck 2003 Factory Service Manual - Vehicle Theft SecurityDocument5 pagesDodge Ram Truck 2003 Factory Service Manual - Vehicle Theft Securitysoly fedoPas encore d'évaluation

- Manual Vehicle Theft Security SystemDocument12 pagesManual Vehicle Theft Security Systemgrib44Pas encore d'évaluation

- ZG Vehicle Theft/Security Systems 8Q - 1Document22 pagesZG Vehicle Theft/Security Systems 8Q - 1ensmartisPas encore d'évaluation

- Speed Control SystemDocument8 pagesSpeed Control SystemDalton WisePas encore d'évaluation

- ZJ Chime/Buzzer Warning Systems 8U - 1Document4 pagesZJ Chime/Buzzer Warning Systems 8U - 1Dalton WisePas encore d'évaluation

- Owner'S ManualDocument40 pagesOwner'S ManualDanijel LudoškiPas encore d'évaluation

- Dokumen - Tips Isuzu 07tf Immobilizer Training Ver1Document50 pagesDokumen - Tips Isuzu 07tf Immobilizer Training Ver1Chamila tharanga madushanPas encore d'évaluation

- Aps 15 CLDocument19 pagesAps 15 CLJose GonzalezPas encore d'évaluation

- ZJ Power Window Systems 8S - 1Document8 pagesZJ Power Window Systems 8S - 1Dalton WisePas encore d'évaluation

- Jump-Starting, Vehicle Equipped With Theft Security System. After TheDocument4 pagesJump-Starting, Vehicle Equipped With Theft Security System. After TheChristian MartinezPas encore d'évaluation

- AnlgSich 04.1 enDocument24 pagesAnlgSich 04.1 enemanuel92Pas encore d'évaluation

- Bnwas Setup ManualDocument19 pagesBnwas Setup ManualMady kPas encore d'évaluation

- Imobiliser 9T-11 PDFDocument11 pagesImobiliser 9T-11 PDFMohsen MoradiPas encore d'évaluation

- Immobilizer System Diagnosis and RepairDocument685 pagesImmobilizer System Diagnosis and Repairalberto 32100% (1)

- Daewoo Nubira Manual InglesDocument1 032 pagesDaewoo Nubira Manual Inglesivan_georgiev34793% (15)

- Chrysler Neon 99 - Immobiliser SystemDocument4 pagesChrysler Neon 99 - Immobiliser SystemeephantomPas encore d'évaluation

- Daewoo Nubira j100 Factory Service ManualDocument20 pagesDaewoo Nubira j100 Factory Service Manualpaul100% (50)

- ZJ Wiper and Washer Systems 8K - 1Document16 pagesZJ Wiper and Washer Systems 8K - 1Dalton WisePas encore d'évaluation

- Nstallation and Iring: HapterDocument46 pagesNstallation and Iring: HapterKurabachew EndeshawePas encore d'évaluation

- Q71S 230V Control Board Sliding Gate - Mystrike 5 & 8: Instruction GuideDocument26 pagesQ71S 230V Control Board Sliding Gate - Mystrike 5 & 8: Instruction GuideRomain DreuillesPas encore d'évaluation

- ESD & Turbine 1Document82 pagesESD & Turbine 1JHANSI100% (1)

- Control EngineeringDocument19 pagesControl EngineeringAmirul Zahim AzharPas encore d'évaluation

- 93ZJ Secc 8Q Vehicle Theft Security SystemDocument12 pages93ZJ Secc 8Q Vehicle Theft Security Systemhelgith74Pas encore d'évaluation

- Control & Instrumentation 2Document0 pageControl & Instrumentation 2SHIVAJI CHOUDHURY100% (3)

- A Fail-Safe Microprocessor-Based System For Interlocking RailwaysDocument6 pagesA Fail-Safe Microprocessor-Based System For Interlocking RailwaysNikunj AggarwalPas encore d'évaluation

- MAINTENANCE TITLEDocument51 pagesMAINTENANCE TITLEtomallor101Pas encore d'évaluation

- Excalibur AL-900ATV2Document11 pagesExcalibur AL-900ATV2ribach9469Pas encore d'évaluation

- BWA Users ManualDocument14 pagesBWA Users ManualIrawan SetiawanPas encore d'évaluation

- Om4e ObDocument30 pagesOm4e ObPatrick ByronPas encore d'évaluation

- Basics of Trips, Interlocks, Permissives & Sequences - Thermal Power Plant A-ZDocument110 pagesBasics of Trips, Interlocks, Permissives & Sequences - Thermal Power Plant A-Zashok100% (1)

- Manejo Service ToolDocument35 pagesManejo Service ToolClementePas encore d'évaluation

- Grand Cherokee WJ 2000Document14 pagesGrand Cherokee WJ 2000العقار امين عيسىPas encore d'évaluation

- Smart Wiring System (SWS) : Click On The Applicable Bookmark To Selected The Required Model YearDocument61 pagesSmart Wiring System (SWS) : Click On The Applicable Bookmark To Selected The Required Model Yearsled novaPas encore d'évaluation

- Cruise Control System: SectionDocument5 pagesCruise Control System: SectionFSR1407Pas encore d'évaluation

- Chime Buzzer Warning SystemsDocument4 pagesChime Buzzer Warning SystemsArt DoePas encore d'évaluation

- MLS2000S PDFDocument34 pagesMLS2000S PDFMukesh Singh100% (3)

- diagramas etac SWSDocument546 pagesdiagramas etac SWSAlberto AbarcaPas encore d'évaluation

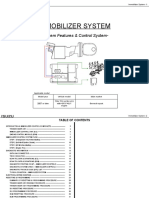

- Immobilizer System: - System Features & Control SystemDocument50 pagesImmobilizer System: - System Features & Control SystemChanakaAnuruddha100% (12)

- CCS PDFDocument4 pagesCCS PDFTony JenPas encore d'évaluation

- Passsive Restraint Systems GuideDocument12 pagesPasssive Restraint Systems GuideDane WallacePas encore d'évaluation

- 6300 055d Sentinel Installation Manual M SenzorDocument29 pages6300 055d Sentinel Installation Manual M SenzorBairon Alvira ManiosPas encore d'évaluation

- En 4j2 9t02 PDFDocument13 pagesEn 4j2 9t02 PDFBlakess SpanPas encore d'évaluation

- Isuzu 07TF Immobilizer Training Ver1Document50 pagesIsuzu 07TF Immobilizer Training Ver1Teddy KhantPas encore d'évaluation

- Automotive Electronic Diagnostics (Course 2)D'EverandAutomotive Electronic Diagnostics (Course 2)Évaluation : 4 sur 5 étoiles4/5 (2)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisD'EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisÉvaluation : 4 sur 5 étoiles4/5 (2)

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusD'EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusPas encore d'évaluation

- Industrial Automation and Control System Security PrinciplesD'EverandIndustrial Automation and Control System Security PrinciplesÉvaluation : 4.5 sur 5 étoiles4.5/5 (7)

- Security Operations Center - Analyst Guide: SIEM Technology, Use Cases and PracticesD'EverandSecurity Operations Center - Analyst Guide: SIEM Technology, Use Cases and PracticesÉvaluation : 4 sur 5 étoiles4/5 (1)

- SCADA: Supervisory Control and Data Acquisition, Fourth EditionD'EverandSCADA: Supervisory Control and Data Acquisition, Fourth EditionÉvaluation : 4 sur 5 étoiles4/5 (8)

- Semi-Markov Models: Control of Restorable Systems with Latent FailuresD'EverandSemi-Markov Models: Control of Restorable Systems with Latent FailuresPas encore d'évaluation

- Ezg InaDocument2 pagesEzg InaDalton WisePas encore d'évaluation

- Ezg inDocument8 pagesEzg inDalton WisePas encore d'évaluation

- Ezg 23Document54 pagesEzg 23Dalton WisePas encore d'évaluation

- Transmission and Transfer Case Guide for 42/44RE Automatic and NV242/249 Transfer CasesDocument296 pagesTransmission and Transfer Case Guide for 42/44RE Automatic and NV242/249 Transfer CasesDalton WisePas encore d'évaluation

- Ezg 25aDocument8 pagesEzg 25aDalton WisePas encore d'évaluation

- Speed Proportional Steering System GuideDocument6 pagesSpeed Proportional Steering System GuideDalton WisePas encore d'évaluation

- Ezg 24aDocument12 pagesEzg 24aDalton WisePas encore d'évaluation

- Chrysler Corporation: Service Manual Supplement 1998 Grand CherokeeDocument4 pagesChrysler Corporation: Service Manual Supplement 1998 Grand CherokeeDalton WisePas encore d'évaluation

- Ezg 25Document20 pagesEzg 25Dalton WisePas encore d'évaluation

- Ezg 24Document54 pagesEzg 24Dalton WisePas encore d'évaluation

- Ezg 21aDocument14 pagesEzg 21aDalton WisePas encore d'évaluation

- Ezg 22Document10 pagesEzg 22Dalton WisePas encore d'évaluation

- Ezg 14aDocument40 pagesEzg 14aDalton WisePas encore d'évaluation

- Ezg 19Document26 pagesEzg 19Dalton WisePas encore d'évaluation

- ZG Exhaust System and Intake Manifold 11 - 1Document4 pagesZG Exhaust System and Intake Manifold 11 - 1Dalton WisePas encore d'évaluation

- Ezg 13Document12 pagesEzg 13Dalton WisePas encore d'évaluation

- ZJ Exhaust System and Intake Manifold 11 - 1Document10 pagesZJ Exhaust System and Intake Manifold 11 - 1Dalton WisePas encore d'évaluation

- Ezg 14Document66 pagesEzg 14Dalton WisePas encore d'évaluation

- Ezg 9aDocument48 pagesEzg 9aDalton WisePas encore d'évaluation

- Ezg 9Document120 pagesEzg 9Dalton WisePas encore d'évaluation

- Power Mirror SystemsDocument8 pagesPower Mirror SystemsDalton WisePas encore d'évaluation

- Ezg 8wDocument488 pagesEzg 8wDalton WisePas encore d'évaluation

- ZJ Power Seat Systems 8R - 1Document8 pagesZJ Power Seat Systems 8R - 1Dalton WisePas encore d'évaluation

- Ezg 8vDocument10 pagesEzg 8vDalton WisePas encore d'évaluation

- ZJ Power Window Systems 8S - 1Document8 pagesZJ Power Window Systems 8S - 1Dalton WisePas encore d'évaluation

- Electrically Heated Systems: Defogger SystemDocument10 pagesElectrically Heated Systems: Defogger SystemDalton WisePas encore d'évaluation

- ZJ Chime/Buzzer Warning Systems 8U - 1Document4 pagesZJ Chime/Buzzer Warning Systems 8U - 1Dalton WisePas encore d'évaluation

- Ezg 8qaDocument12 pagesEzg 8qaDalton WisePas encore d'évaluation

- IDS, Firewall & HoneypotDocument11 pagesIDS, Firewall & Honeypotanon_100036097100% (4)

- Emerging Trendsof ICTin Teachingand LearningDocument14 pagesEmerging Trendsof ICTin Teachingand LearningJesse JollyPas encore d'évaluation

- OVH - Account in Rescue ModeDocument4 pagesOVH - Account in Rescue ModesuperpulsarPas encore d'évaluation

- Traditional Symmetric-Key CiphersDocument73 pagesTraditional Symmetric-Key CiphersKevin SarserPas encore d'évaluation

- SAP Overview SAP Security IntegrationDocument40 pagesSAP Overview SAP Security IntegrationCarlo SerioPas encore d'évaluation

- A 20-Year-Old Entrepreneur'S Success StoryDocument4 pagesA 20-Year-Old Entrepreneur'S Success Storyjavadene100% (1)

- CNS Unit-3Document35 pagesCNS Unit-3gayatriPas encore d'évaluation

- AdMedika Company ProfileDocument4 pagesAdMedika Company ProfilePKU muhammadiyahPas encore d'évaluation

- Falcon Private BankDocument64 pagesFalcon Private BankChevy ShopPas encore d'évaluation

- Sony Kdf-E42a10 - E50a10 TV SMDocument173 pagesSony Kdf-E42a10 - E50a10 TV SMferdialvascribdPas encore d'évaluation

- Students Monitoring System Using Rfid With Sms Notification of Junior High School in Colegio de KidapawanDocument5 pagesStudents Monitoring System Using Rfid With Sms Notification of Junior High School in Colegio de KidapawanBaby Laica RicafortPas encore d'évaluation

- Find Admin Panels Using Google DorksDocument16 pagesFind Admin Panels Using Google Dorksputra include100% (1)

- SAP Made Easy - by ShannuDocument151 pagesSAP Made Easy - by ShannuSandeep Kumar T100% (1)

- Online Examination SystemDocument18 pagesOnline Examination SystemAtul Kumar Singh100% (1)

- Account Statement From 1 Apr 2021 To 19 Jun 2021: TXN Date Value Date Description Ref No./Cheque No. Debit Credit BalanceDocument9 pagesAccount Statement From 1 Apr 2021 To 19 Jun 2021: TXN Date Value Date Description Ref No./Cheque No. Debit Credit BalanceNrusingha Prasad MishraPas encore d'évaluation

- Brayne 2017Document32 pagesBrayne 2017tigubarcelos2427Pas encore d'évaluation

- Journal Volume 4 2016 MobileAppsDocument68 pagesJournal Volume 4 2016 MobileAppsFurkaan AlikhanPas encore d'évaluation

- ASD535 DS T131193 en e 0Document10 pagesASD535 DS T131193 en e 049036218Pas encore d'évaluation

- LapSim (1) User GuideDocument67 pagesLapSim (1) User GuideDiego AlvarezPas encore d'évaluation

- ch30 PDFDocument54 pagesch30 PDFaniPas encore d'évaluation

- 76 MM GunDocument50 pages76 MM GunKidus Yado GirmaPas encore d'évaluation

- IT - ISCAP - Mariana Malta: Cloud ComputingDocument18 pagesIT - ISCAP - Mariana Malta: Cloud ComputingMarian IonciuPas encore d'évaluation

- DATA Privacy Consent Form For AcademicsDocument4 pagesDATA Privacy Consent Form For AcademicsSt.William's MagsingalPas encore d'évaluation

- 457975Document48 pages457975Marc GlebPas encore d'évaluation

- Syllabus: AIT 673 - Cyber Incident Handling/Response: Term: Spring 2018Document12 pagesSyllabus: AIT 673 - Cyber Incident Handling/Response: Term: Spring 2018ggcvbcPas encore d'évaluation

- File Deleted Winmail - Dat - AA - V3.rar - AA - V3.exe Has Been Removed Since It Was Found To Be Infe Cted With Virus VirusDocument1 pageFile Deleted Winmail - Dat - AA - V3.rar - AA - V3.exe Has Been Removed Since It Was Found To Be Infe Cted With Virus VirusThiago AbraaoPas encore d'évaluation

- 17 03 2021Document3 pages17 03 2021OjjkkoPas encore d'évaluation

- Reply Form SR - Irene ProfileDocument5 pagesReply Form SR - Irene ProfileJack RooneyPas encore d'évaluation

- 6400 RecoveryDocument5 pages6400 RecoveryNguyễn Công CườngPas encore d'évaluation

- Fundamental Computer Investigation Guide For WindowsDocument55 pagesFundamental Computer Investigation Guide For WindowsBfischer19850% (1)