Académique Documents

Professionnel Documents

Culture Documents

Smart Wiper

Transféré par

Amit Bakle100%(1)100% ont trouvé ce document utile (1 vote)

164 vues22 pagesWindshield wipers play a key role in assuring the driver’s safety during precipitation. The traditional wiper systems, however, requires driver’s constant attention in adjusting the wiper speed and the intermittent wiper interval because the amount of precipitation on the windshield constantly varies according to time and vehicle’s speed. Because the manual adjustment of the wiper distracts driver's attention, which may be a direct cause of traffic accidents, many companies have developed automatic wiper systems using some optical

Sensors with various levels of success. This paper presents the development of vision-based smart windshield wiper system that can automatically adjust its speed and intermittent interval according to the amount of water drops on the windshield. The system employs various image processing algorithms to detect water drops and fuzzy logic to determine the speed and the interval of the wiper. [11]

Various sensors are used. The controller detects the sensor input and gives the signal to the driver circuit. The motor driver actuates the motor to run at high speed or low speed based on the amount of rain detected. Initialization of the sensor is done when the vehicle is started and generates the power supply needed for the optimum functioning of the sensor. The threshold voltage value for the sensor is defined for the no rain and when it’s raining, and the voltage will always be low. If the voltage reaches the minimum threshold value, the wiper will do its job at the maximum speed.[12]

Copyright

© © All Rights Reserved

Formats disponibles

DOCX, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentWindshield wipers play a key role in assuring the driver’s safety during precipitation. The traditional wiper systems, however, requires driver’s constant attention in adjusting the wiper speed and the intermittent wiper interval because the amount of precipitation on the windshield constantly varies according to time and vehicle’s speed. Because the manual adjustment of the wiper distracts driver's attention, which may be a direct cause of traffic accidents, many companies have developed automatic wiper systems using some optical

Sensors with various levels of success. This paper presents the development of vision-based smart windshield wiper system that can automatically adjust its speed and intermittent interval according to the amount of water drops on the windshield. The system employs various image processing algorithms to detect water drops and fuzzy logic to determine the speed and the interval of the wiper. [11]

Various sensors are used. The controller detects the sensor input and gives the signal to the driver circuit. The motor driver actuates the motor to run at high speed or low speed based on the amount of rain detected. Initialization of the sensor is done when the vehicle is started and generates the power supply needed for the optimum functioning of the sensor. The threshold voltage value for the sensor is defined for the no rain and when it’s raining, and the voltage will always be low. If the voltage reaches the minimum threshold value, the wiper will do its job at the maximum speed.[12]

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOCX, PDF, TXT ou lisez en ligne sur Scribd

100%(1)100% ont trouvé ce document utile (1 vote)

164 vues22 pagesSmart Wiper

Transféré par

Amit BakleWindshield wipers play a key role in assuring the driver’s safety during precipitation. The traditional wiper systems, however, requires driver’s constant attention in adjusting the wiper speed and the intermittent wiper interval because the amount of precipitation on the windshield constantly varies according to time and vehicle’s speed. Because the manual adjustment of the wiper distracts driver's attention, which may be a direct cause of traffic accidents, many companies have developed automatic wiper systems using some optical

Sensors with various levels of success. This paper presents the development of vision-based smart windshield wiper system that can automatically adjust its speed and intermittent interval according to the amount of water drops on the windshield. The system employs various image processing algorithms to detect water drops and fuzzy logic to determine the speed and the interval of the wiper. [11]

Various sensors are used. The controller detects the sensor input and gives the signal to the driver circuit. The motor driver actuates the motor to run at high speed or low speed based on the amount of rain detected. Initialization of the sensor is done when the vehicle is started and generates the power supply needed for the optimum functioning of the sensor. The threshold voltage value for the sensor is defined for the no rain and when it’s raining, and the voltage will always be low. If the voltage reaches the minimum threshold value, the wiper will do its job at the maximum speed.[12]

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOCX, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 22

TABLE OF CONTENTS

1. Introduction ............................................................................................ Error! Bookmark not defined.

1.1. History .......................................................................................................................... 3

1.2 Need Of Smart wiper System4

2. Product Description and Goals ........................................................................................................... 5

3. Design Approach and Details .............................................................................................................. 6

3.1. Design Approach ............................................................................................................ 6

3.2. Codes and Standards ..................................................................................................... 17

4. Project Demonstration ........................................................................... Error! Bookmark not defined.

5. ADVANTAGES .................................................................................................................................. 19

6. DISADVANTAGES ........................................................................................................................... 19

7. APLLICATION..20

8. SUMMARY AND CONCLUSION21

9. REFERENCES22

INTRODUCTION

I have pleasure in introducing our new project SMART WIPER

SYSTEM, which is fully equipped by sensors circuit and wiper motor.It is a genuine

project which is fully equipped and designed for Automobile vehicles. This forms an

integral part of best quality.

The Automatic rain operated wiper system is a fully automation project.

This is an era of automation where it is broadly defined as replacement of

manual effort by mechanical power in all degrees of automation.

Degrees of automation are of two types, viz.

Full automation.

Semi automation.

In semi automation a combination of manual effort and mechanical power is

required whereas in full automation human participation is very negligible.

HISTORY

The first mechanical windshield wipers had to be operated by hand! Either the driver or a

passenger had to work a crank to make the wipers go back and forth. Mary Anderson, from New

York City, was awarded a patent in 1903 for a window cleaning device. Once the invention was

protected by patent, she tried to interest companies into producing the device. No one was

interested, so Mary put the patent in a drawer and eventually it expired. With closed bodywork

generally available during the 20s, cars were equipped with windowed doors to protect

passengers from bad weather and dust. From 1916, manual windshield wipers replaced

squeegees. Automatic windshield wipers were invented in 1921. Called "Folberths," after their

inventors, Fred and Willaim Folberth, they were powered by an "air engine," a device connected

by a tube to the inlet pipe of the cars motor.

The electric version, attached to the top of the windshield, was created by Bosch in 1926, but

was reserved only for luxury models.

Robert Kearns (1928-2005) patented intermittent powered wipers in 1967. He demonstrated the

system to Ford Motor Company, which introduced automobiles with intermittent wipers in 1978.

Other automakers soon followed.

Robert W. Kearns spent years in litigation against Ford Motor and Chrysler for using his idea,

and eventually won multimillion-dollar judgments. Robert Kearns, 77, died February 26, 2005.

The National Highway and Transportation Safety Association reports that twenty-six

percent of all car accidents are caused by distractions due to talking on cell phones, eating while

driving, and other similar distractions that take a drivers focus off the road . The distraction

considered in this project is the adjustment of wiper speed based on the intensity of precipitation

falling. By eliminating the need for drivers to adjust wiper speed while driving, the number of

accidents caused by distraction can be slightly reduced.

In full automation human participation is very negligible.

NEED FOR AUTOMATION:

Automation can be achieved through computers, hydraulics, pneumatics, robotics,

etc., of these sources, pneumatics form an attractive medium for low cost automation.

Automation plays an important role in automobile.

Nowadays almost all the automobile vehicle is being atomized in order to product

the human being. The automobile vehicle is being atomized for the following reasons.

To achieve high safety

To reduce man power

To increase the efficiency of the vehicle

To reduce the work load

To reduce the vehicle accident

To reduce the fatigue of workers

Less Maintenance cost

The major components of the Automatic rain operated wiper are follows

Conductive Sensor

Class frame and Supporting Structure

Battery

Wiper Motor and its arrangement

1. PRODUCT DESCRIPTION AND GOALS

Detect intensity of rainfall

Activate wipers automatically once rainfall is detected

Avoid adverse effects of extraneous and environmental factors

Meet or exceed the response time of the driver

Make adaptable to all vehicles

Develop high reliability

Create with ease of installation

The primary goal is to automatically detect rainfall and activate the wipers without driver

interaction.

2. DESIGN APPROACH AND DETAILS

2.1.Design Approach

2.1.1. High-level Functional Blocks

. The system is able to detect the presence of rain droplets, process that data coming from the

sensors, and enable and control the motor.

Figure 1 High-level Functional Block Diagram

The rain detection box contains a series of rain sensors. The data processing unit encloses

the microcontroller, and the motor control module is composed of the wiper motor and its control

circuit. After establishing the functional diagram, a high level system block diagram was drawn.

Rain

Detection

Data

Processing

Motor

Control

The second diagram represents a more detailed version of the functional diagram.

Figure 2 High-level System Block Diagram

The rain detection unit uses two types of sensors whose outputs are normalized by an input

signal module. The data processing is performed by a microcontroller, and its results are fed into

an output signal module which is the input to the motor control box.

Impedance

Sensor

IR

Sensor

User

Interface

Input

Signal

Module

Microcontroller

Output

Signal

Module

Motor

Controller

Motor

Rain Detection

Data Processing

Motor Control

2.1.2. Rain Detection Unit

2.1.2.1. Impedance Sensors

The system detects rain by using two sorts of sensors. One of them is the impedance grid

sensor shown in fig.3. The grid is made of two comb-like copper plates separated by a minimum

distance of

8

1

in. The sensor is glued to the windshield glass with the help of a strong adhesive

material. The thin configuration of the plates allows the wiper to slide over without peeling them

off. When the plates are dry, the resistance between the two plates is very high, but when water

is between the plates, current can flow between the plates, thus decreasing the resistance. This

operation allows this design to be used as a rain sensor. The sensor becomes

Figure 3 Impedance Grid Sensor with Water Varying Electrical Conduction

operational when one plate is connected to a power source, and the other plate is taken as the

sensor output.

The separation between the plates is strongly related to the sensors sensitivity and its

detection rate [4]. Increasing the distance between the plates decreases the failure rate but it also

decreases the sensitivity of the sensor which is inversely related to the system response time.

Another design issue with the impedance grid sensor is the fact that it can act as an antenna and

produce a floating voltage which can trigger a false detection. A solution to the problem consists

of reducing the sensors size and grounding the output signal appropriately. Two other issues of

concern are copper oxidation (rust) and physical deformation caused by the frictional motion of

the wipers over the grid sensor. The grid sensor in figure 3 is effective at detecting rain, but it

does a poor job relaying how much water is on the windshield glass at any point in time. Since

the system should be fully automatic, there is a need to develop a way to measure the average

distribution of water falling on the glass in order to control the wipers speed. A modified

version of the impedance sensor was designed to provide better intensity measurements. The

new design consists of spacing isolated vertical plates from a single power plate as shown in

Figure 4. Measuring the voltage at these different plates provides a more accurate way of

determining the rate of rainfall. The sensing device can be mounted anywhere on the windshield

where there is no contact with the wipers. This upgraded version of rain sensor suffers from the

same issues as its predecessor, but it provides more functionality.

Figure 4 Three-channel Rain Sensor for Speed Control

2.1.2.2. Optical Sensors

The optical sensors are used to bounce beams of light through the windshield, and look for

disturbances in the beams caused by raindrops at the outside surface of the windshield. The rain

sensor has an emitter that emits pulses of light, coupled into the windshield with a lens. These

beams travel through the windshield at about 45 degrees [2]. Through research it was anticipated

that the infra-red beams were to be totally reflected by the outside surface of the windshield into

the receiver [2]. However, when testing the analog IR sensor supplied by Optek Inc., it was

determined that the infra-red beams were not totally reflected by the windshield, but that the

infra-red beams were approximately 30% reflected by the outside surface of the windshield.

Troubleshooting this issue included using different types of glass to reflect the IR beams and

comparing that output with the results of reflecting the IR beams off a white sheet of paper. In

conclusion, it was determined that the light beams from the IR sensors were not totally reflected

by any type of glass and therefore the design approach was modified. Although the glass did not

reflect 100 percent of the light emitted, there was enough light reflected by the glass to detect the

change in reflectivity due to a raindrop. The downfall is that the rain threshold for the sensor

was lowered and it was not as easy to determine when moisture was present. If rain drops are

present on the outside surface of the windshield, some of the beams escape and this reduces the

intensity of the beams. The detector will measure this reduction in intensity and communicate

that to the rest of the system that actuates the windshield wipers. Error! Reference source not

ound. shows a diagram of the operation.

Figure 5 Diagrams of IR Sensor

2.1.2.3. Input Signal Module

The input signal modules first function is to normalize all sensor signals so that the

microcontroller can safely interface with the rain detection unit by limiting the amount of

incoming current. Each sensor is dedicated a separate part within the input signal module.

Figure 6 shows the internal circuit corresponding to the impedance grid sensor. All other sensors

have a similar input circuit.

Figure 6 Input Circuit for Impedance Grid Sensor

The sensitivity is controlled by a potentiometer that can be manually tuned by a user. The

protective resistor below the potentiometer makes sure that the overall system remains stable and

functional regardless of users settings. The capacitor introduces a low-pass filter that helps

stabilize the sensor output so that the microcontroller makes more accurate readings. The input

circuit also solves the floating voltage problem by providing a ground between the sensor and the

microcontroller.

2.1.3.Data Processing Unit

2.1.3.1. Microcontroller and Control Logic

The data processing unit is composed of a microcontroller and an output signal module.

The AVR Atmega8 microcontroller was finally selected over the initial TI MSP430 because of

its higher output power and number of analog-to-digital channels. The communication between

the computer programmer and the microcontroller is done via serial peripheral interface bus

(SPI).

Figure 7 Summary of System Control Logic

Once the system is enabled, the system initialization block checks if the sensors are

operational, sets the corresponding input and output pins, and determines if the power is high

enough to keep the microcontroller running. After performing all the necessary checks, the

program reads voltages from the impedance grid sensor and IR sensor in a sequential order. If

water is detected, the microcontroller sends a signal to a power relay so that the wiper motor is

activated at its lowest speed. Afterward, the microcontroller reads the speed control sensor and

determines the appropriate motor speed by powering other relays.

The additional relays affects change the amount of power going to the motor. The loop

continues as long as all the sensors detect water on the windshield.

2.1.3.2. Output Signal Module

The output signal module is the bridge between the design system and the existing

automobile windshield wiper system. Figure 8 depicts how the microcontroller is connected to

the relays driving the motor control board.

Figure 8 Relays and Microcontroller Connections

The control process for the project stops after the output signal module because the motor control

unit is foreign to the system. However, for installation purposes, the user should be able to

integrate the design product to an existing automobile. Therefore, only general interfacing

information is required to be provided to the user. However, in order to demonstrate the overall

project, a motor and a control module circuit were acquired and tested.

2.2.Codes and Standards

The sensor and the microcontroller are governed by universal standards such as the NEC,

the National Electric Code [7]. The microcontroller will also abide by the SPI protocol in order

to load in a program from the PC. In automobiles, information from one sensor and/or data from

one system can be communicated with other systems using multiplex wiring to reduce the

number of sensors and the amount of wire used in a vehicle [7]. Two predominant protocols

have emerged as standards, but several other protocols exist that are specific to manufacturers'

applications. The Society of Automotive Engineers (SAE) has established SAE J1850 as the

standard for multiplexing and data communications in U.S. automobiles [8]. However, data

communications for trucks and On-Board Diagnostics II (OBDII) are based on the Controller

Area Network (CAN) protocol developed by Robert Bosch GmbH [9].

The SAE Vehicle Network for Multiplexing and Data Communications (Multiplex)

Committee has defined three classes of vehicle networks: Classes A, B and C [8]. Class A is for

low-speed applications such as body lighting [8]. Class B is for data transfer between nodes to

eliminate redundant sensors and other system elements [8]. Class C is for high-speed

communications and data rates typically associated with real-time control systems [8]. The

project will be considered as a class C application.

3. PROJECT DEMONSTRATION

The project demonstration for the smart wiper system prototype tests for the successful

detection of rain, tests for the intensity of that rain, and activates one of four speeds of the

windshield wiper. The system activates within 500 milliseconds as originally specified under the

voltage requirements. The prototype achieves all the product goals and specifications set out by

the proposal, however, the temperature range specification was not able to be tested. The

prototype was tested in a room temperature environment so additional testing need be performed

to determine whether the system has the same functionality at the extreme temperatures of the

technical specifications. Figure 10 shows a photograph of the actual prototype of the project. As

can be seen from the figure roughly 3 ft of plexiglass, mounted in a wooden frame, serves as the

automobile windshield. The plexiglass is angled at about 37 degrees to mimic automobile

windshields. Mounted below the plexiglass are the wiper linkage kit as well as the wiper pulse

motor controls and wiper motor. The IR sensors are located at position A on the figure and the

impedance sensors are located at position B. The system controls are housed behind the

plexiglass including the microcontroller and all input/output signal modules. To start the system,

the user would first connect the power leads to the breadboard with a DC power supply. System

should be supplied with a voltage greater than 5 volts. User should be sure to connect the

positive terminal of the voltage source to the red post of the breadboard #1 and the negative

terminal to the black post. Once the system is powered up, the user will also need to connect 12

V and GND to breadboard #2 which is connected to the relays that control the wiper motor

housed below the plexiglass. After these connections are made, the user will turn on the system

by switching on the power switch on breadboard #1. Rain will be simulated using a spray bottle;

the user will spray water on the glass near any one of the sensors and the system will react within

500 milliseconds. The speeds of the windshield wiper will vary depending on the amount of

water sprayed onto the plexiglass.

Figure 10.a Microncontroller and Relays

9 Figure 10.b Project Prototype

A

B

B

Breadboard #1

Breadboard #2

10

ADVANTAGES

Low cost automation project.

Free from wear adjustment.

Less power consumption

Operating Principle is very easy.

Installation is simplified very much.

It is possible to operate Manually/automatically by proving

On/Off switch.

Sensor cost is very low due to conductive sensor

APPLICATIONS

Four wheeler application

DISADVANTAGES

1. This system applied in the case of water falling on the class only.

2. Addition cost is required to install this system to four wheeler.

4. SUMMARY AND CONCLUSIONS

In conclusion, the automated wiper system was designed, developed, and demonstrated to

detect rain and actuate the automobile wipers based on the intensity of that rain. The

demonstration is able to simulate the operation of the system as if installed in an automobile.

I was able to successfully complete the project and satisfactorily meet the proposal goal of

automating the drivers response to rain within the specified amount of time of 500 milliseconds.

Though the system functioned as desired, in retrospect i would have selected different design

approaches. After noticing that more accuracy was required from the IR sensor to adequately

detect the intensity of rain we would have selected a more applicable IR sensor. The initial goals

and objectives were to expand upon existing automatic wiper technologies to make a more

reliable yet economically priced system. As shown by the project demonstration and the cost

analysis, these goals and objectives were met. Recommendations for future versions of the

product include using more sophisticated IR sensors, including a voice recognition feature, and

raising all the power windows in the vehicle when rain is detected. Although the project met our

goals, another production cycle should be initiated to improve the reliability of the system and

include the features mentioned in the future versions.

REFERENCES

[1] NHTSA Data Sheet, 2001, Available HTTP: http://www-nrd.nhtsa.dot.gov/departments/nrd-

12/809-716/pages/longdesc.htm

[2] The Rain Tracker Makes Driving More Enjoyable, [Online Document], Available HTTP:

http://www.raintracker.com/ProductInfo.htm

[3] TRW Automotive Electronics: Rain Sensor, 2007, [Online Document], Available HTTP:

http://www.trw.com/images/rain_sensor.pdf

[4] M. Ucar, H. Ertunc, and O. Turkoglu, The Design and Implementation of Rain Sensitive

Triggering System for Windshield Wiper Motor, In IEEE IEMDC, 2001, pp. 329-336.

[5] H. Kurihata, T. Takahashi, I. Ide, Y. Mekada, H. Murase, Y. Tamatsu, and T. Miyahara,

Rainy Weather Recognition from in-Vehicle Camera Images for Driver Assistance , In

IEEE Intelligent Vehicles Symposium, 2005, pp. 205-210

[7] National Fire Protection Association, 2007, [Online Document], Available HTTP:

http://www.nfpa.org/

[8] Atsushi Yamashita, Susumu Kato and Toru Kaneko Robust Sensing against Bubble Noises in

Aquatic Environments with a Stereo Vision System

[9] CAN Specification, 1991, [Online Document], Available HTTP:

http://esd.cs.ucr.edu/webres/can20.pdf

[10] G. Muller, Windshield Wiper System with Rain Detector, U.S. patent no. 5015931, issued

June 11, 1991

[11] Joonwoo Son Seon Bong Lee

Intelligent Rain Sensing and Fuzzy Wiper Control Algorithm for Vision-based Smart Windshield Wiper

System.

[12] Abhishek Shukla Rohan Dwivedi Design and Implementation of Vision System

Aid in Windscreen Assembly

Vous aimerez peut-être aussi

- DC Gear Motor - Wiper Motor-1Document3 pagesDC Gear Motor - Wiper Motor-1ankush belkarPas encore d'évaluation

- Wiper & Washer PDFDocument27 pagesWiper & Washer PDFtavi2mePas encore d'évaluation

- Device Craft Wiper Motor SpecDocument15 pagesDevice Craft Wiper Motor SpecrogerrosePas encore d'évaluation

- 060 Actuators For RobotsDocument69 pages060 Actuators For RobotsMohamad YazidPas encore d'évaluation

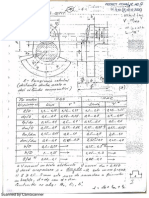

- Flange Coupling Lab PDFDocument25 pagesFlange Coupling Lab PDFAli Raza MalikPas encore d'évaluation

- AVL Guia de InstalaçãoDocument36 pagesAVL Guia de InstalaçãohenevilPas encore d'évaluation

- Short ReportDocument2 pagesShort ReportRaj MandloiPas encore d'évaluation

- Literature Review: Automatic Pneumatic Bumper and Braking SystemDocument10 pagesLiterature Review: Automatic Pneumatic Bumper and Braking Systemkathir venkatachalamPas encore d'évaluation

- Pertemuan 13 - ClutchesDocument81 pagesPertemuan 13 - Clutchesanonim 1178Pas encore d'évaluation

- Magneto Abrasive Flow MachiningDocument24 pagesMagneto Abrasive Flow MachiningArjun M BetageriPas encore d'évaluation

- Grid Coupling PDFDocument8 pagesGrid Coupling PDFchristine100% (1)

- Corexy 04926139Document11 pagesCorexy 04926139CicciputtPas encore d'évaluation

- Contactless Hall Effect Torque Sensor For EPASDocument8 pagesContactless Hall Effect Torque Sensor For EPASJessica OwensPas encore d'évaluation

- Design and Devolopment of Semi Automatic Glass Cleaning MachineDocument14 pagesDesign and Devolopment of Semi Automatic Glass Cleaning MachineNandkumar BabarPas encore d'évaluation

- Device Load Monitor With Programmable Meter For Energy AuditDocument3 pagesDevice Load Monitor With Programmable Meter For Energy AuditMandeep G KashyapPas encore d'évaluation

- Accident Alert in Modern Traffic System With CameraDocument12 pagesAccident Alert in Modern Traffic System With CameraLeander Lawrence100% (1)

- Redesign-Rollator's Parking Brake SystemDocument16 pagesRedesign-Rollator's Parking Brake Systemjerrison samuelPas encore d'évaluation

- 267 Button Operated Electromagenetic Gear Changer For Two Wheeler (Report)Document46 pages267 Button Operated Electromagenetic Gear Changer For Two Wheeler (Report)tariq76100% (5)

- Auto Pilot Mode TechnologyDocument16 pagesAuto Pilot Mode TechnologyPavan SrivatsaPas encore d'évaluation

- Fire Fighter Robot With Night Vision CameraDocument7 pagesFire Fighter Robot With Night Vision CameraKrish KalyanPas encore d'évaluation

- Aerodynamic Modeling and SimulationDocument33 pagesAerodynamic Modeling and Simulationjabach_ahrimanPas encore d'évaluation

- Automobile Brake Failure Indicator and Auxiliary Braking SystemDocument20 pagesAutomobile Brake Failure Indicator and Auxiliary Braking SystemPiyush PatilPas encore d'évaluation

- Pipe Climbing RobotDocument3 pagesPipe Climbing RobotMectrosoft Creative technologyPas encore d'évaluation

- Pneumatic Bike: A Step To Future: V. Lohit A. Imran MohideenDocument3 pagesPneumatic Bike: A Step To Future: V. Lohit A. Imran MohideenTanviPas encore d'évaluation

- Design and Structural Analysis of Inbuilt Car Jack SystemDocument5 pagesDesign and Structural Analysis of Inbuilt Car Jack SystemAshish Kumar GarhwalPas encore d'évaluation

- Application of Brushless DC Motor in MilitaryDocument10 pagesApplication of Brushless DC Motor in Militarymighty_heart100% (1)

- Remote Controlled Screw Jack 2014 AcDocument58 pagesRemote Controlled Screw Jack 2014 AcChockalingam AthilingamPas encore d'évaluation

- Design PDFDocument3 pagesDesign PDFKochuzPas encore d'évaluation

- Regenerative Suspension SystemDocument24 pagesRegenerative Suspension Systemvineeth100% (1)

- A Seminar ON Compliant Mechanisms: Kaje Rajesh S. En. No. 30802009 TY B-Tech Mechanical EngineeringDocument21 pagesA Seminar ON Compliant Mechanisms: Kaje Rajesh S. En. No. 30802009 TY B-Tech Mechanical EngineeringRajesh Shyamrao Kaje100% (2)

- Butten Operated Electromangnetic Gear Changer For Two WheelerDocument64 pagesButten Operated Electromangnetic Gear Changer For Two WheelermkkfakesPas encore d'évaluation

- Two Dimensional CFD Analysis of A Hydraulic Gear PumpDocument18 pagesTwo Dimensional CFD Analysis of A Hydraulic Gear PumpsaravanaPas encore d'évaluation

- SEPM All QueDocument364 pagesSEPM All Quepriyanka mallawatPas encore d'évaluation

- Centrifugal Clutch Design and EquationsDocument2 pagesCentrifugal Clutch Design and Equationsstallone21Pas encore d'évaluation

- Design of A Real Time Smart Honking SystemDocument6 pagesDesign of A Real Time Smart Honking SystemArka MajumdarPas encore d'évaluation

- Balancing MachineDocument18 pagesBalancing MachineMuhummad ZeeshanPas encore d'évaluation

- Metrology and Measurements Unit IiiDocument153 pagesMetrology and Measurements Unit Iiijaikrishna100% (1)

- Seminar Report 3C2Document41 pagesSeminar Report 3C2Pritish KumarPas encore d'évaluation

- Hcci EngineDocument155 pagesHcci Engineriyaz ahmedPas encore d'évaluation

- Power Generation Using Speed Breaker Ieee FormatDocument7 pagesPower Generation Using Speed Breaker Ieee Formatnagarjuna888Pas encore d'évaluation

- 62235-mt - Thermal Power PlantsDocument2 pages62235-mt - Thermal Power PlantsSRINIVASA RAO GANTAPas encore d'évaluation

- 08 CH-6, Fluid Motion Within Combustion ChamberDocument24 pages08 CH-6, Fluid Motion Within Combustion ChamberAhsan AliPas encore d'évaluation

- Modeling and Simulation of Reluctance Motor Using Digital ComputerDocument5 pagesModeling and Simulation of Reluctance Motor Using Digital ComputerroyourboatPas encore d'évaluation

- 360 Rotating Trolly Shubham Rawat ProjectDocument30 pages360 Rotating Trolly Shubham Rawat ProjectShubham RawatPas encore d'évaluation

- Ccmai ArboreDocument13 pagesCcmai ArboreEduard Gheorghe100% (1)

- I.C.Engine Modeling and SimulationDocument2 pagesI.C.Engine Modeling and SimulationWork WearautoPas encore d'évaluation

- Automated Pneumatic Sheet Metal Cutting MachineDocument6 pagesAutomated Pneumatic Sheet Metal Cutting MachineRushikesh PatilPas encore d'évaluation

- ABB - General Purpose Motors Cast Iron - GB 092003Document49 pagesABB - General Purpose Motors Cast Iron - GB 092003ivanjaviergutierrezoPas encore d'évaluation

- Working of Single Plate ClutchDocument1 pageWorking of Single Plate ClutchBikash Das50% (2)

- A Review of Structural and Thermal Analysis of Traction MotorsDocument11 pagesA Review of Structural and Thermal Analysis of Traction MotorsGari PastranaPas encore d'évaluation

- Introduction To R.T.P.P: 1.1 GeneralDocument12 pagesIntroduction To R.T.P.P: 1.1 GeneralSairam Kumar ChowdaryPas encore d'évaluation

- Stair Climbing Wheel ChairDocument4 pagesStair Climbing Wheel ChairMukesh KhairnarPas encore d'évaluation

- Pneumatic Speed Breaker With Day Night Control (PSB)Document40 pagesPneumatic Speed Breaker With Day Night Control (PSB)Giri TharanPas encore d'évaluation

- Regenerative Braking of BLDC MotorsDocument21 pagesRegenerative Braking of BLDC Motorsalthaf hussainPas encore d'évaluation

- DESIGN - AND - FABRICATION - OF - AUTOMATIC - SPRAY - PAINTING - MACHINE - Ijariie7676 PDFDocument7 pagesDESIGN - AND - FABRICATION - OF - AUTOMATIC - SPRAY - PAINTING - MACHINE - Ijariie7676 PDFHussain MuslimPas encore d'évaluation

- Energy, Energy Transfer, and General Energy Analysis: Thermodynamics: An Engineering ApproachDocument32 pagesEnergy, Energy Transfer, and General Energy Analysis: Thermodynamics: An Engineering ApproachMuhammad Awais khanPas encore d'évaluation

- Differential Transformation Method for Mechanical Engineering ProblemsD'EverandDifferential Transformation Method for Mechanical Engineering ProblemsPas encore d'évaluation

- Railway Wegon Breaking SystemDocument34 pagesRailway Wegon Breaking SystemAmit Bakle75% (4)

- Railway Wegon Breaking SystemDocument34 pagesRailway Wegon Breaking SystemAmit Bakle75% (4)

- Homogeneous Charge Compression HCCIDocument28 pagesHomogeneous Charge Compression HCCIAmit BaklePas encore d'évaluation

- HcciDocument23 pagesHcciAmit BaklePas encore d'évaluation

- SeminarDocument31 pagesSeminarAmit BaklePas encore d'évaluation

- The Energy Challenge: Part A Part BDocument57 pagesThe Energy Challenge: Part A Part BAmit BaklePas encore d'évaluation

- 1 s2.0 S0301751604000432 MainDocument10 pages1 s2.0 S0301751604000432 Maindeepakkumar2626Pas encore d'évaluation

- Xl4600 UserDocument27 pagesXl4600 UserJoško ListešPas encore d'évaluation

- Patient Monitoring and Care Systems: Dr. Adrian MondryDocument20 pagesPatient Monitoring and Care Systems: Dr. Adrian MondryVijay KumarPas encore d'évaluation

- Design and Analysis of AlgorithmsDocument35 pagesDesign and Analysis of AlgorithmssprisPas encore d'évaluation

- Quick Installation Guide: Wireless N150 Adsl2+ Router DSL-2730UDocument16 pagesQuick Installation Guide: Wireless N150 Adsl2+ Router DSL-2730ULovis NKPas encore d'évaluation

- Experiment No. 3Document12 pagesExperiment No. 3Lemuel Larin0% (1)

- E 50Document71 pagesE 50Ruído AudiovisuaisPas encore d'évaluation

- Factory Acceptance Test Plan - LTE ENodeBDocument6 pagesFactory Acceptance Test Plan - LTE ENodeBLaura VillarrealPas encore d'évaluation

- 2016 Mini Catalog - APDocument40 pages2016 Mini Catalog - APLaily Noor OkvitasariPas encore d'évaluation

- Types of Addressing ModesDocument17 pagesTypes of Addressing ModesNic JonesPas encore d'évaluation

- IP HeaderDocument1 pageIP HeaderbajjiboyPas encore d'évaluation

- Buk453 100aDocument7 pagesBuk453 100amicrowave440Pas encore d'évaluation

- Layer 2 Tunnel Protocol Version 3 - CiscoDocument117 pagesLayer 2 Tunnel Protocol Version 3 - CiscoВладан ДакићPas encore d'évaluation

- P Terentii ComoediaeDocument366 pagesP Terentii Comoediaenomen tertiumPas encore d'évaluation

- 01 - Basic Management ConfigurationDocument54 pages01 - Basic Management ConfigurationHuỳnh Ngọc ThươngPas encore d'évaluation

- 8051 At89s52Document18 pages8051 At89s52Sanjana SinghPas encore d'évaluation

- Legion Pro 7 16IRX8H 82WQ00B7MJDocument2 pagesLegion Pro 7 16IRX8H 82WQ00B7MJlhkhorPas encore d'évaluation

- 1.wpo-01 Wcdma Radio Theory-53Document53 pages1.wpo-01 Wcdma Radio Theory-53sabirelnaraPas encore d'évaluation

- AWR TestwaveDocument4 pagesAWR TestwaveteomondoPas encore d'évaluation

- AMIBIOS ROM Utilities User GuideDocument116 pagesAMIBIOS ROM Utilities User GuidefocalshiftPas encore d'évaluation

- System Operation, HEUIDocument34 pagesSystem Operation, HEUICuu LongPas encore d'évaluation

- VLSI LAB Manual 2014 PDFDocument67 pagesVLSI LAB Manual 2014 PDFraghvendrmPas encore d'évaluation

- COMPAL LS-3803P, 3804P (JBL00, JBL01, JBL02) 2008-05-12, Rev 1.0 (A00) - IO Board PDFDocument5 pagesCOMPAL LS-3803P, 3804P (JBL00, JBL01, JBL02) 2008-05-12, Rev 1.0 (A00) - IO Board PDFGerman ValenciaPas encore d'évaluation

- Modulos Reles SiemensDocument226 pagesModulos Reles SiemensFreddy JaramilloPas encore d'évaluation

- Ccnpv7.1 Switch Lab4-1 STP StudentDocument45 pagesCcnpv7.1 Switch Lab4-1 STP StudentCarlos Alberto Pedraza CruzPas encore d'évaluation

- Service Manual Sony Vaio VGN CDocument0 pageService Manual Sony Vaio VGN CannaliaxPas encore d'évaluation

- For Biomedical Engineering Mumbai University T.E. Sem 6 SyllabusDocument4 pagesFor Biomedical Engineering Mumbai University T.E. Sem 6 SyllabusAsNaikPas encore d'évaluation

- FSV03Document24 pagesFSV03elangopi89Pas encore d'évaluation

- C++ Sound ProgramDocument4 pagesC++ Sound ProgramPradeepta Kumar SethiPas encore d'évaluation

- Teknoware Product Catalogue 2012 Edition2Document122 pagesTeknoware Product Catalogue 2012 Edition2jayakanthan1985Pas encore d'évaluation

- Y16 Ew102Document6 pagesY16 Ew102mehdi810Pas encore d'évaluation