Académique Documents

Professionnel Documents

Culture Documents

Case Studies of Some Concrete Structural Failures

Transféré par

Bandilung TzTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Case Studies of Some Concrete Structural Failures

Transféré par

Bandilung TzDroits d'auteur :

Formats disponibles

Case studies of some concrete Case studies of some concrete

structural failures

R bi Whittl Robin Whittle

Design Errors Design Errors

Design errors alone are seldom the cause of the failure

of a structure When failure does occur it is usually the of a structure. When failure does occur it is usually the

result of errors in at least three different aspects of

construction (e.g. design, detailing, and construction construction (e.g. design, detailing, and construction

errors).

Case Study 1

Collapse of a reinforced concrete structure, Collapse of a reinforced concrete structure,

This factory building included concrete columns and a

steel truss for the roof.

Concreteguttertofactorybuilding

Guttercollapse

Edge beam and column connection

Concrete gutter

Edge beam

Column

Loadingatfailure

Crane cage and

Sand 18.6kN

g

bricks 6kN

L4 J 4 K4

H4

I4 L4 J 4 K4

H4

I4

Mechanismoffailure(1)

Piles of sand

and bricks and bricks

Steel truss.

Beam and gutter

start to rotate

Cracks start

to open up

Mechanism of failure (2)

Sand and bricks

collect into corner

Steel truss.

Cracks start

tto open up

Th t l b

Beam and gutter

continue to rotate

and start to move

out and down.

The outer column bars

stay attached to the beam

and drag the outer face of

the column away.

The full length links

fail as the column

bars pull out

out and down.

Mechanismoffailure(3)

Steel truss.

Column outer bars remain

attached to the beam.

The outer links

fail as the column

bars pull out and

down.

Beam and gutter fall,

dragging the outer

column bars with them.

Cracks extends down the

l il i h h column until either the

column bars fail or pull

out at a lap.

2T8s

2T20s

Steel truss.

Reinforcement layout

T10s@100

links @ 300 (stopped off at beam cage)

2T20s

T8 links@130

T8 (stopped off at beam cage)

T20s T20s

2T16s

links @ 300 T8links @ 300 T8

Thebeamhadbeendesignedtotakethetorsionfromthegutterloadingbutthejoint

withthecolumnhadnotbeendesignedtotakethetorsion.

Thetoptwolinksinthecolumnhadbeendetailedtoencloseallthecolumn

mainbarsbutthecontractorhadreducedtheirlengthforeaseofconstruction.

Even if these links had been constructed correctly they would have been Eveniftheselinkshadbeenconstructedcorrectlytheywouldhavebeen

inadequatetosupporttheloading.

cracks form

Simple model of failure mechanism

cracks form

T1

G tt l b

T1

applied

torque

tension

Gutter slab

compression

T2

tension

Appliedtorquefromselfweight

plussandandbrickpile=76kNm

Column

T2

p p

Resistancefromtensilestrength

ofconcrete(say2MPa)=74kNm ( y )

Appliedloadexceedsresistance

Summary

Two people were killed

Design error. No consideration was given in the

calculations of howforces were transmitted through the calculations of how forces were transmitted through the

joint between the edge beam and column.

Detailing error. Inadequate connection between beam

and column reinforcement.

Construction error. Column links were excluded for

convenience

Case Study 2

Widespread cracking in p g

post-tensioned/reinforced concrete frame

This structure did not collapse but the cause of the cracking

took a long time to establish and the subsequent litigation

was very costly was very costly.

The design was of a five storey car park for which the

construction period was extremely short (8 months) In construction period was extremely short (8 months). In

consequence the prestressing work was carried out under a

very tight schedule.

The post-tensioned

prestressed beamwas prestressed beam was

cast in one operation

and fully stressed a few

days later.

Fi e da s after stressing Five days after stressing

cracks appeared in

many parts of the many parts of the

structure.

Problem

Whilst the problem was debated, in order to proceed with

t ti ith i i d l th t i construction with minimum delay, the prestressing was

altered to a two-stage process only 50% applied at first

and the remaining prestress after two weeks and the remaining prestress after two weeks.

After much discussion it was concluded that when early y

thermal effects were included with the other shortening

effects, the total shortening of the prestressed beams was

ffi i t t th ki sufficient to cause the cracking.

Temperature Time effect on concrete

As the chemical action

of the cement takes

place the concrete place the concrete

heats up.

During this period the g p

concrete is plastic and

the increase in volume

results in a fatter results in a fatter

rather than a longer

beam.

However when the

cooling phase starts

the concrete has

hardened and is no

longer plastic. The

length shortens. length shortens.

The cracking of the parts of the structure resulted in a change in the

Summary

The cracking of the parts of the structure resulted in a change in the

programme of work causing extra cost to the Main Contractor.

Although the contract was completed on time the ensuing dispute was Although the contract was completed on time the ensuing dispute was

very costly.

When the case came to court it was agreed that it was reasonable

h h i l i ld h b to assume that, at that time, a normal engineer would not have been

expected to include early thermal effects in the analysis. The code of

practice stated that unless the lesser section dimension is greater

than 600mm and the cement content is greater than 400kg/m

3

there is

no need to consider early thermal effect.

The result of the investigation brought about a change to normal The result of the investigation brought about a change to normal

design procedures. It is now common to consider early thermal

effects in the design of long length continuous reinforced and

t db d l b prestressed beams and slabs.

Case Study 3

Temperature effects on a Temperature effects on a

long-span hybrid structure

The ground level of a two storey underground car park slab was

not covered Ambient temperature changes caused continual not covered. Ambient temperature changes caused continual

movement.

The structure consisted of 16m spanning hollowcore units bearing

on precast concrete beam nibs.

Movement joints had been shown on the drawings but these did

not function correctly for a variety of reasons not function correctly for a variety of reasons.

Causes of cracking

Movement

Hard material can

prevent movement

Friction can

Movement

Rotation

Rotation

Rotation can Friction can

cause cracking

(a) (b)

Rotation can

cause spalling

(c) (a) (b) (c)

The upper surface of the slab was exposed to the weather and in

particular to large variations in temperature The latter caused particular to large variations in temperature. The latter caused

movement and rotation of the units and their supports. This resulted in

severe cracking of the supporting nibs and in some places cracking at

the end of the hollowcore units Even after repair of the cracks they the end of the hollowcore units. Even after repair of the cracks they

reappeared each subsequent year for more than five years.

Shear tension

Possible failure mechanisms for

the hollowcore units

Anchorage

slip

Large crack

close to

Shear tension

crack

close to

support

(a)

(b)

H ll it i h tl l bl t th ff t f ki Hollowcore units are inherently vulnerable to the effects of cracking

close to the support as there is no shear reinforcement and they

rely on the tension strength of the concrete.

Anchorage bond failure can occur when cracks occur close to the

support. This can cause the prestressing strands to slip. The crack

size increases until the unit fails either in anchorage bond (a) or in

shear (b).

Summary

The reoccurrence of cracking of the supporting nibs each year

eventually required a temporary support structure to be built.

Protection from falling concrete was also required.

Concern that the hollowcore slabs might eventually fail in shear or g y

anchorage has led to the possibility of a rebuild.

The cost of remedial work and litigation fees have escalated each The cost of remedial work and litigation fees have escalated each

year as the decision on what action to take is delayed.

Lesson: It is essential to name a single designer or engineer who Lesson: It is essential to name a single designer or engineer who

retains overall responsibility for the stability of the structure, the

compatibility of the design, and details of the parts and components,

h ll f th d i i l di d t ili f th t even where some or all of the design including detailing of those parts

and components are not carried out by this engineer.

Case Study 4 Case Study 4

Piled raft for tower block Piled raft for tower block

The design of the raft assumed that the walls of the two level

basement car parks would act with the raft over the piles to transmit

the shear and bending forces to the outer piles the shear and bending forces to the outer piles.

The walls of the basement had almost full height openings, placed

one above the other, and contained only nominal reinforcement.

Original design

Columns

Core walls

The combined strength of

these walls plus the 1.5m

thick slab was quite thick slab was quite

inadequate to transmit

the loads.

The mistake was

discovered whilst the

tower block was being

Possible line of shear failure

g

constructed.

Basement car parks

Piled raft

Schematic arrangement of new raft

The remedial work

required a newraft required a new raft

to be constructed

beneath the existing

Existing raft

one

Existing raft

3.5m

Piles scabbled to

take newconcrete

New supplementary

raft to take shear

take new concrete

Remedial work

Placing of concrete for the lower part of the new raft was carried out

conventionally.

I d t hi d b d ith th i ti ft th t f In order to achieve good bond with the existing raft the upper part of

the new raft was packed with single sized aggregate and then

grouted with a retarded and fluid cement paste.

The grout was introduced under pressure to the back of the pour

through a complicated system of metal pipes, pinned to the

underside of the existing raft The method produced a wall of grout underside of the existing raft. The method produced a wall of grout

that extended from top to bottom of the pour and that flowed forward

towards the peripheral shutters with the top surface behind the

bottom bottom.

Pipes were so placed to let the air our in front of the grout surface,

then to indicate where and when the grout had arrived, and then to g

allow grouting to continue from immediately behind the advancing

wall of grout. Grouting was continuous until the work was complete.

Inappropriate Use of Inappropriate Use of

Code of Practice Clauses

Case Study 5 y

Ferry Bridge Cooling Tower Collapse

This incident should really be in a chapter of its own as the failure

resulted in a change of philosophy in the design code of practice, CP resulted in a change of philosophy in the design code of practice, CP

114. Although there were some defects in wall thickness, it was

concluded that the main cause of the collapse was because the design

value chosen for the wind load was too small No account had been value chosen for the wind load was too small. No account had been

taken of the venturi effect of the wind passing through the towers

upwind.

This collapse ensured the early adoption of a limit state code of practice

in the UK resulting in a completely new approach to design. The first

draft of the Unified code appeared in 1968 and in 1972 it was published draft of the Unified code appeared in 1968 and in 1972 it was published

as CP110. This was the first comprehensive limit state code of

practice ever published.

InNovember1965,threeoutof

eightcoolingtowerscollapsed

duringahighwind.

Eachtowerwas375feethigh

Thewindloadintheinitialdesign

i l d ti t d wasseriouslyunderestimated.

CP114 PermissibleStressDesign

wasused.

Thiscollapseensuredtheearly

adoptionoflimitstatedesign.

In1968thefirstdraftofthe

unifiedcodeappeared.

In 1972 this was published as In1972thiswaspublishedas

CP110.

Thewindspeedpassingbetween

theupwindtowersincreased

i ifi l hi d hi h significantly.Thiscausedahigher

windforceonthedownwindtowers.

Itispossiblethatconsiderationof

the load combinations required for theloadcombinationsrequiredfor

limitstatedesignmighthavebeen

sufficienttopreventthecollapse.

Load combination

W

G

Permissible Stress Design:

(CP114)

h

w

G

( )

G x b/2 W x h

w

w

New Limit State Design:

(CP110)

1 0 (G b/2) 1 4 (W h )

b

1.0 (G x b/2) 1.4 (W x h

w

)

Inadequate Assessment of q

Critical Force Paths

Case Study 6 Case Study 6

Shear wall with holes and corner supports Shear wall with holes and corner supports

A multi-storey shear wall required so many openings (windows,

doors etc) that the load path became very complicated doors, etc) that the load path became very complicated.

The designer assumed that the load would flow to the corners at

each floor and then track vertically down the edge of the wall. y g

Since the wall was built insitu as a homogenous structure, strain

compatibility caused the load to flow back into the full width of wall.

The result was that several storeys of load were supported by a

deep beam at the bottom of the wall, which transferred the load to

its end supports at first floor level. its end supports at first floor level.

Deep beam failure

Design Behaviour

Thedesignassumed

thattheloadfrom

the wall would be

Theactualload

transfertothe

corner columns took thewallwouldbe

transferredtothe

cornercolumnsat

eachfloorlevel.

cornercolumnstook

placeatthebottom

ofthewall.

The height of the

Thetieforcesat

eachfloorlevelwere

Theheightofthe

naturalarchwas

only0.6xtheSpan.

small.

Thiscausedlarge

horizontaltieforces

atthebottomofthe

ll

No wall

wall.

No wall

o a

(a)

(b)

Model of force path

Th d f th

actual

force path

tie

Theassumedforcepath

downtheedgeswould

not require ties at top and

assumed

force path

force path

notrequiretiesattopand

bottom.

tie

Howeverwithoutthese

theactualforcepath

ld l k

without tie rein-

wouldcauselargecracks

toopenupatthetopand

bottom surfaces

forcement large

cracks form

bottomsurfaces

Case Study 7

Design of boot nibs

The conventional assumption taken for the effective depth and lever

arm for a short cantilever is unsafe for a boot nib.

The design compression zone for such a model would be close to The design compression zone for such a model would be close to

the bottom face of the beam and likely to fall outside the beam

reinforcement (both the links and main reinforcement).

Strut and tie modelling is helpful to understand why this is so. The

strut must be supported mechanically by the reinforcement of the

supporting beam. The effective lever armbecomes much smaller supporting beam. The effective lever arm becomes much smaller

and the tension force in the nib top reinforcement much larger than

assumed by the short cantilever approach.

Design of boot nibs

Traditionaldesignofcantileversandnibsassumesaneffectivedepth,d

c

,betweenthe

c

outercompressionfaceandthecentroidoftensionreinforcement.Thiscouldcause

thebottomlayerofconcreteinthecoverzonetospalloff.

The strut should be designed to shed its load on to the corner bar of the beam The

d

Thestrutshouldbedesignedtosheditsloadontothecornerbarofthebeam.The

verticalcomponentoftheforceisthentakenbythelinkleg.

d

b

z

b

F

Ed

a

c

F

c

F

c

=F

Ed

xa

c

/z

b

Forceinlinkleg:

H

Ed

F

t2d

F

t2d

=F

c

+F

ed

Thisisadditiontoany

shear that the link is

z

n

z

F

t1d

shearthatthelinkis

carrying.

d

c

z

c

Poor detailing

Case Study 8

Failureofcellularwallstructure

inanoffshoreoilplatform p

Sleipner offshore oil platform collapse

Theplatformincludedalargecellular

concretestructurebelowthethree

towers.

Duringconstructiontheplatform

underwentsubmergingfordeck

matingafterwhichtheplanwasto

raiseitagainandtowittoitsfinal

h l f ld positionintheoilfield.

Itwasduringthesubmersionthatone

f th t i ll i th ll l t t ofthetricellsinthecellularstructure

failed.

This caused uncontrollable sinking Thiscauseduncontrollablesinking

thatledtoanimplosionofthe

structureandcompletecollapse.

Plan form of the cellular structure

see detail see detail

Tri-cell wall shape

550

800

Water

pressure

5

8

0

0

Actual shape of construction

Originaldesignshape

i h li d i l ll

Actualshapeofconstruction

withcylindricalwalls

Thenaturalarchactionprovidedbythegeometrywasnotpresentinthemodifiedform.

Thequadrilateralfiniteelementsfortheanalysisweredistortedintheregionofthetricell

cornersfromtheidealsquareshape.Thisledtoerrorsintheresults.

Tri-cell joint detail

Thecriticalshearsectionwas

f d h h d d b reinforcedwithTheadedbars.

Thedesignrequiredthatthe

lengthoftheTheadedbarsto g

extendacrossthefullwidthof

section.

As they were difficult to fix

compression

failure

Astheyweredifficulttofix

throughtheouterlayerof

reinforcementitwasdecidedto

reduce their length.

initial cracking

'T' headed bar

as required

reducetheirlength.

Acrackedformedatacornerof

thecellandspreadtotheendof

the T bar

'T' headed bar

as fixed

theTbar.

Waterpressurebecameactivein

thecrack.

as fixed

water pressure

Ashearcrackdevelopedintothe

compressionzoneandthisfailed

in a brittle manner.

p

inabrittlemanner.

Summary

This catastrophic failure was the result of a number of errors:

The analysis program was set up with a finite element mesh that was

too coarse to provide accurate shear results.

The T headed bars were too short and allowed the shear resistance

t b f Thi b bl th i f th f il to become unsafe. This was probably the primary cause of the failure.

There was minimal checking of the design and detailing.

In previous designs the geometry of tri-cells had been formed by

intersecting cylinders. The geometry of tri-cells was altered on this

project in order to make the formwork simpler to construct project in order to make the formwork simpler to construct.

Unfortunately the new form did not allow arching action to take place.

The rebuild retained the cylindrical geometry in the tri-cells and the The rebuild retained the cylindrical geometry in the tri cells and the

reinforcement was detailed to ensure mechanical linkage. T headed

bars were extended to the outer reinforcement.

Case Study 9 Case Study 9

Camden School for Girls

Assembly hallroofcollapse

This disaster could also be called the miracle of the decade. On 13

J une, 1973 late in the evening the roof of the assembly hall crashed to g y

the ground.

In the words of the caretaker, he heard a loud rumble, went to

investigate by torch light and found the whole roof weighing many investigate by torch light, and found the whole roof weighing many

tons had collapsed.

Twenty four hours before this event some five hundred parents had Twenty four hours before this event some five hundred parents had

attended a meeting in the hall, chairs were still laid out.

Camden School for Girls

Edge beamwhich had Edge beam which had

supported the precast

beams

Part of the roof

which had

collapsed on to

the chairs below

Collapsed roof lying on the floor below Collapsed roof lying on the floor below

Summary

The principal cause of the collapse was inadequate

bearing for beam seatings and deterioration of concrete

t b d Thi f th fi t b ildi f d at beam ends. This was one of the first buildings found

to have suffered from the effects of high alumina cement.

This was an example of inadequate design and poor

detailing of the end bearing nibs built into the supporting g g pp g

beam for the precast beams. The reduction in strength

caused by HAC left no margin for temperature effects.

The combination of these effects was likely to have

triggered the collapse triggered the collapse.

Case Study 10

Ronan Point collapse

Precast concrete panel building

This collapse was a significant event for the industry in This collapse was a significant event for the industry in

the UK and marked the partial demise of the precast

industry. Large precast panel and frame construction

became much less popular in the following two decades.

Information gathered from the incident led to major g j

changes to the UK Building Regulations (1970) and codes

of practice (starting with the precast concrete code,

CP 116, in 1970) with regard to progressive collapse and

robustness. More recently the Eurocodes have included

accidental load and robustness clauses accidental load and robustness clauses.

In the early hours of 16 May

1968 a gas explosion in a g p

bathroom on an upper floor

shook the building, resulting in

h i ll f the instantaneous collapse of

part of one wing of the building.

Four people were killed.

The cause of collapse: The cause of collapse:

The possibility of unusual, and hence non-codified, loads occurring

was not considered in design. g

The structure was inadequately mechanically tied together.

Comment

Traditional two-storey housing, pre World War 2, would not

have had any engineering input; brick wall thicknesses and

ti b fl j i t i ib d b th L d Cit timber floor joist sizes were prescribed by the London City

Council Building By-laws, and similar regulations outside

London London.

There had been gas explosions before this incident in

similar types of dwelling but the damage and any similar types of dwelling, but the damage, and any

casualties, had usually been limited to one household, and

the risk was accepted as a fact of life. p

There were no precedents for progressive collapse, when

system building was introduced. y g

Poor Construction

Case Study 11

Car park collapse

Pipers Row

Car park collapse

The car park was constructed using the lift slab method. This involved e ca pa as co s uc edus g e s ab e od s o ed

casting the slabs one on top of another on the ground. Precast columns

were positioned and then the slabs were jacked up the columns until at

the correct level The slabs were then held in place by the use of wedges the correct level. The slabs were then held in place by the use of wedges.

This form of construction had been used in many places in the UK

during the 1970s and 80s and has been a common formof construction during the 1970s and 80s and has been a common form of construction

in the USA. It has provided reasonably robust structures. The very

nature of the construction method focuses attention on the column/slab

j i t I it ti th t t h li d th t joint. In some situations the structure has relied on the moment

resistance of these joints, i.e. an unbraced frame. In other situations

separate insitu core structures have been built to take the sway forces.

In March 1997 a 120 tonne section of the roof of the car park collapsed

onto the floor below . This occurred at 3am when, fortunately, nobody y y

was around. It was immediately clear from the debris that a punching

shear failure had taken place.

Final connection between the slab and the column was made via a steel

collar in the slab and a steel insert in the column into which wedges were

fixed.

The steel collar supported the slab on angles that formed an H in plan.

Summary

The 230mm thick slab was constructed with concrete

of highly variable quality.

Areas of low quality concrete deteriorated probably

through freeze thaw action.

In some places this deterioration had occurred to a

depth of 100mm and this had been repaired.

The repair was poorly bonded to the parent material.

This left a slab which was effectively split into two

layers with the only connection being the longitudinal

steel passing through the repair into the original concrete.

Further deterioration of the original concrete, and in

particular its bond strength to the top steel, reduced what

composite action existed until failure occurred.

Case Study 12

Flat slab construction for a hotel

For a short time in the early 1970s the Government provided loans for

the construction of hotels. In order to be eligible the construction

period had to be very tight.

The workmanship of some of the hotels built at this time was shoddy The workmanship of some of the hotels, built at this time, was shoddy.

For one such hotel this was not discovered until twenty years later

when a major refurbishment was taking place j g p

Hotel of the 1970s

This shows the structural layout of a typical floor, flat slab. The depth

of the slab was 250mm. The spans along the building were 7.2m and

across the building were 6.1m and 7.4m.

The top surface of the slabs was very uneven and did not appear to have

Problem

The top surface of the slabs was very uneven and did not appear to have

been levelled (by hand or power float). In some places boot marks had

been left.

Cracks (generally not larger than 0.3mm width) had occurred on the upper

surface radiating from the corners of the columns with one or two small

cracks running tangentially. Large cracks (up to 1mm width) had occurred g g y g ( p )

at some of the construction joints.

The deflection of one of the slab bays of an upper floor was large, over

75 75mm.

An independent adviser decided that:

the punching shear was close to its limit Additional steel shear heads the punching shear was close to its limit. Additional steel shear heads

were constructed and fitted to all column slab intersections.

the bending strength of the longer spanning bays was at its limit.

After a year of measuring the deflection of one bay of the slab it was

found that no movement had occurred. The reason for such large

deflections was not understood deflections was not understood.

In one of the bays the skirting board between two edge columns had been

made in two equal lengths split in the middle (as shown) Deflections of

A second independent check revealed:

made in two equal lengths split in the middle (as shown). Deflections of

between 15 and 20mm had occurred below each half of the skirting board.

This represented an edge deflection of up to 50mm.

Since the skirting board was attached to the wall it was likely that it was

fitted this way and that much of the deflection had taken place before fitted this way and that much of the deflection had taken place before

construction of the wall.

This was confirmed by finding that the bottom courses of the external wall

had been laid on the sagging shape of the slab and the following courses had been laid on the sagging shape of the slab and the following courses

adjusted so that they were level at the window sills above the floor.

Summary

The second independent check concluded:

Punching shear capacity: Both BS 8110 and BS EN 1992-1-1)

provide reliable methods for predicting punching shear capacity using

The second independent check concluded:

characteristic values for the concrete strength instead of the factored

design values and the as built information concerning the

reinforcement (i.e. the size, spacing and cover to the bars). An ( , p g )

assessment of the safety can be made by comparing the worst

credible loads with the resistance.

F thi it ti th l l ti h d th t th t dibl l d

Bending capacity: The top cover to the reinforcement near the

For this situation the calculations showed that the worst credible loads

could be carried with a sufficient safety factor.

Bending capacity: The top cover to the reinforcement near the

column supports was found to be on average 30mm more than

specified.

Once reasonable moment redistribution had been included in the

calculations there was still sufficient overall moment capacity in the

slab without requiring any reduction to the design safetyfactors. slab without requiring any reduction to the design safety factors.

Conclusion

Although the construction workmanship had been very

poor the structure was not in danger of collapsing.

A great deal of money had been spent unnecessarily.

Case Study 13

Precast concrete tank

A liquid storage tank was constructed with precast wall panels. The

diameter and height of the tank were 12.2m and 7m.

The tank collapsed suddenly within two years of construction.

Liquid storage tank

1

2

.

2

m

Anchor unit

The vertical panels were held in place by unbonded prestressed tendons

threaded through horizontal PVC ducts, embedded in the concrete and

fully encircling the tank at set levels throughout the height.

Section through precast panel

23mm PVC duct

Interface with

adjacent unit

In order to achieve watertight construction of the edges of the

wall units required to be built with very small tolerances. A rubber

f strip was inserted within the joint between each set of adjacent

panels. The water tests showed leaks. Several attempts were

made to seal these before watertightness was achieved.

Plastic sheathing and grease around the tendons was intended to

provide protection fromcorrosion provide protection from corrosion.

Detail at anchorage of tendons

PVC d t t

Anchorage cast

into concrete

7-wire greased tendon

PVC duct cast

into concrete

Screw in cap

Sheath over tendon

cut back from end

filled with grease

Sheath over tendon

cut back from end

The grease used in this particular type of unbonded tendon (12.5mm

diameter Tyesa 7-wire strand) was found to emulsify when in contact y ) y

with water. This allowed any water that had penetrated the anchor

zone not only to come into contact with the bare part of the tendons

but also to penetrate into the sheathing. but also to penetrate into the sheathing.

Summary

The alloy steel of the particular prestressing tendons

d i thi t t h d i t t used in this structure had a microstructure

susceptible to stress-corrosion cracking, and the

stress in the tendons was greater than 50%of the stress in the tendons was greater than 50% of the

yield strength.

Moisture in contact with the tendons provided a Moisture in contact with the tendons provided a

corrosive environment.

On examination after the collapse it was found that On examination after the collapse, it was found that

stress-corrosion cracking had taken place in many

parts of the unbonded tendons.

Poor Management

Case Study 14

Placing of precast units Placing of precast units

Floor collapse

precast slab jacked

into position

The spine beam carrying

PLACINGOFPRECASTUNITS

precast slabs

wall supporting

The spine beam, carrying

precast planks, lost its bearing

because a labourer, in trying to

jack one of the final planks into

precast slabs

pp g

spine beam

jac o e o e a pa s o

position, actually levered out

the wall panel supporting the

end of the spine beam.

i b

p

This caused the spine beam to

lose its bearing which led to the

collapse of the floor

spine beam

wall shifted outwards causing

i b t f ll ff it b i

t l b j k d

collapse of the floor.

spine beam to fall off its bearing

precast slab jacked

into position

Plan

lacer bars not in

l t ti f j ki

The lacer bars had not been

inserted at the time of erecting

and laying of the floor elements.

place at time of jacking

Section

Summary

This is an example where the management should have had

more control on howthe erection and placing of precast units more control on how the erection and placing of precast units

took place.

More importantly, it should have ensured that the lacer bars

at the ends of the spine beam were in place before the

erection of floor units took place.

Poor Planning

Case Study 15

Power station on the river Thames

The power station was constructed on the north bank of the Thames

in the early 1960s Originally it was to be coal fired to produce in the early 1960s. Originally it was to be coal fired to produce

1500MW.

Th f d ti f th t ti it 20 000 i f d The foundations of the power station sit on 20,000 reinforced

concrete piles.

Special on site casting yard

Each pile was 430mm square, 18m long.

Piling rig

Several pile rigs were set up with

diesel driven hammers.

A il h i t d i t iti d A pile was hoisted into position and

then given a tap by the hammer to get

the point of the pile through the top

crust of the marshland.

Then under its own weight the pile

dropped 15mthrough the mud! dropped 15m through the mud!

Each pile was then driven into the

gravel to a specified set. g p

Piling commenced from the edge of the

Procedure

g g

site closest to the river and continued

inland 250m placing piles at 1.5m

centres (on average) centres (on average).

This took about eighteen months.

Excavation for the foundations started Excavation for the foundations started

from the same end and commenced

six months after the start of piling.

Concreting of the foundations also

started from the same end of the site.

After a year after the start of piling After a year after the start of piling,

when concreting of the foundations

had reached about a 1/3 of the way

l th it it di d th t along the site, it was discovered that

the tops of the piles that were still

exposed were moving.

Measurements showed that this movement was up to 1.5m !

Remedial work

a) Additional 600 vertical piles to compensate the

reduction in vertical capacity of the existing piles

b) Additional 200 raked piles to compensate the horizontal

force component caused by the bent piles.

The resulting remedial and extra work caused by this

movement was very large. For example the existing piles

no longer followed the plan layout for the eight inlet and

outlet culverts that wound their way through the site

bringing cooling water to the condensers and returning it to bringing cooling water to the condensers and returning it to

the River Thames.

On site decisions making changes to the design had to On site decisions, making changes to the design, had to

be taken each day

Summary

The programme for the contracts on this project did not

foresee the problems caused by progressing the work from

one end of the site to the other.

In previous similar projects there had been a significant

delay between piling and the start of excavation which delay between piling and the start of excavation which

allowed enough time for much of the soil pressure to

dissipate.

In order to keep a tight programme one possible solution

might have been to start the piling fromboth ends of the might have been to start the piling from both ends of the

site.

Deliberate Malpractice

Case Study 16

Floor with excessive deflection

Case Study 16

The building in question was a telephone exchange and had

been built in the mid 1970s, ten years earlier than the

i ti ti Th l b f t i l d b h d b d i d investigation. The slab of a typical end bay had been designed

as single way spanning between two shallow haunched beams.

The span was 9m with a slab only 250mm thick which many

engineers would consider to be too thin.

Ten years after the building had been completed the operators

were complaining that the deflection was still increasing and were complaining that the deflection was still increasing and

causing some of the switch-gear to become faulty. The

designers asked for a second opinion on the design of the slab.

The calculations and drawings were checked and no major flaw

was found. It was just conceivable that creep and shrinkage

effects were still increasing Asite visit was arranged effects were still increasing. A site visit was arranged.

A

Typical end bay layout

9 m

600

A

250 thick slab

300

250 thick slab

Excessive deflection

(still increasing after 10

years) years)

AA

A - A

Summary (1)

The visit to site included the inspection of the slab close to a column.

The screed had been removed to expose the top surface of the

t t l l b A d h k f th h d f th t structural slab. As a crude check of the hardness of the concrete

surface, a penknife was used. Quite unexpectedly the blade of the knife

penetrated into the concrete surface right up to the hilt ! A further

check of the soffit of the slab gave a similar result.

An additional interesting feature of the soffit was the presence of a

number of shallowdisc shaped (flying saucers) pieces of concrete number of shallow disc shaped ( flying saucers ) pieces of concrete

(150mm diameter) which were separating from the surface. One such

piece came away as it was being examined.

Although the slab had been designed to span one-way, the supporting

beam was sufficiently flexible for the slab to behave more like a flat

slab The flying saucers had occurred in the compression areas of the slab. The flying saucers had occurred in the compression areas of the

soffit and were considered to be the effect of spalling.

Summary (2)

It was clear that the slab in question required immediate additional

support and the rest of the building required core testing.

After cores had been taken throughout the building it was discovered

that the concrete cube strength, which should have been 25MPa, was

on average only 5MPa on average only 5MPa.

The sub-contractor had deliberately reduced the cement content in y

the specified mix. Major remedial work followed.

C St d 17 Case Study 17

Insitu columns supporting a precast building

This building was constructed with precast elements above ground.

Below ground the foundations, columns and beams were

constructedinsitu constructed insitu.

Construction had reached an advanced stage when cracks

d i th i it l j t b l th ti ith th appeared in the insitu columns just below the connection with the

precast columns.

Layout of elements

Precast beams, columns

and slabs and slabs

See detail of column

connection

Insitu beams and columns

connection

Street level

Existing

Transfer beams

retaining

wall

Intended construction procedure

Column cast with large

polystyrene box-out

Polystyrene totally

removed; CHS 114 dia

dowel cast in with fresh

concrete filling box out concrete filling box-out

Column reinforced

as normal

As constructed

Only thin layer of

concrete cast in

CHS dowel pushed

into polystyrene

concrete cast in

top of column

Onlytop layer of Only top layer of

polystyrene removed

Existing insitu Existing insitu

column

Load from 7

First sign of imminent failure

Precast column

floors above

Grouting tube

Severe cracking of

i it l ll

Load from precast unit

supported on thin outer

shell of insitu column

insitu column wall

Insitu column

Remedial work

In order to repair the top of the insitu columns the

load fromthe precast building had to be removed load from the precast building had to be removed.

This was achieved by providing props and jacks y p g p p j

close to the existing precast columns at each floor

level and creating a new load path to the ground.

This released the load in the insitu columns below, and

allowed the required remedial work to take place allowed the required remedial work to take place

- reconstruction of the top of the insitu columns.

Thank you for your attention

Vous aimerez peut-être aussi

- Case Studies of Some Concrete Structural Failures ICEDocument96 pagesCase Studies of Some Concrete Structural Failures ICEAhmed Nurul100% (1)

- Lecture Notes on Reinforced Concrete DesignD'EverandLecture Notes on Reinforced Concrete DesignPas encore d'évaluation

- Concrete Structures: Repair, Rehabilitation and StrengtheningD'EverandConcrete Structures: Repair, Rehabilitation and StrengtheningPas encore d'évaluation

- Reinforced Concrete Buildings: Behavior and DesignD'EverandReinforced Concrete Buildings: Behavior and DesignÉvaluation : 5 sur 5 étoiles5/5 (1)

- Corrosion and its Consequences for Reinforced Concrete StructuresD'EverandCorrosion and its Consequences for Reinforced Concrete StructuresPas encore d'évaluation

- Structural Crack StudyDocument9 pagesStructural Crack StudyNurmuliana Abdul WahabPas encore d'évaluation

- Defects in Concrete Structures With Focus On Identifying Concrete Cracks and How To Fix Them - Waterstop SolutionsDocument24 pagesDefects in Concrete Structures With Focus On Identifying Concrete Cracks and How To Fix Them - Waterstop SolutionsNicolasMontoreRos100% (1)

- Building Failure - Causes and Case StudiesDocument14 pagesBuilding Failure - Causes and Case Studiesresha bhatiaPas encore d'évaluation

- Thermal Analysis of Long Buildings For Elimination of Exp JointDocument16 pagesThermal Analysis of Long Buildings For Elimination of Exp JointShirke Sanjay100% (1)

- Anchorage of Reinforcing BarsDocument148 pagesAnchorage of Reinforcing BarsAntonette Marie ElgarioPas encore d'évaluation

- Building DefectsDocument41 pagesBuilding DefectsVaibhav HireraddiPas encore d'évaluation

- Wall Crack and Methodology of RepairDocument6 pagesWall Crack and Methodology of RepairMohamed Raffik Bagha100% (1)

- Design of Piles Under Cyclic Loading: SOLCYP RecommendationsD'EverandDesign of Piles Under Cyclic Loading: SOLCYP RecommendationsAlain PuechPas encore d'évaluation

- GuidelineOnStructuralFireEngineering (Part2)Document62 pagesGuidelineOnStructuralFireEngineering (Part2)Leung LiangPas encore d'évaluation

- Lateral Force CollectorsDocument11 pagesLateral Force Collectorsx620Pas encore d'évaluation

- Rehabilitation of Masonry StructuresDocument17 pagesRehabilitation of Masonry StructuresEugeniu PrisacariPas encore d'évaluation

- Hollow Core Planks Application and Design GuideDocument46 pagesHollow Core Planks Application and Design Guidemixi1978100% (1)

- Shoring and Reshore PDFDocument6 pagesShoring and Reshore PDFᜇᜒᜌᜓᜈᜎ᜔ᜇ᜔ ᜊᜒᜇᜓᜌ᜔Pas encore d'évaluation

- Design of Reinforced Concrete Deep Beam For Strength and SeviceabilityDocument390 pagesDesign of Reinforced Concrete Deep Beam For Strength and SeviceabilityEgidijus VenckusPas encore d'évaluation

- Acceptable Crack WidthsDocument6 pagesAcceptable Crack WidthsRagu NathanPas encore d'évaluation

- Slab Raft Foundation PresentationDocument25 pagesSlab Raft Foundation PresentationOsarieme Osakue100% (1)

- Wind Design Aiap016809 PDFDocument86 pagesWind Design Aiap016809 PDFvigwolfPas encore d'évaluation

- Allowable Stress Design of Concrete MasonryDocument6 pagesAllowable Stress Design of Concrete Masonrying_fernandogalvez2015Pas encore d'évaluation

- Slip MembraneDocument1 pageSlip MembranescchungPas encore d'évaluation

- Punching Shear PDFDocument13 pagesPunching Shear PDFmohamedadel100Pas encore d'évaluation

- FoundationDocument41 pagesFoundationhamnahrico100% (1)

- Reshore Design For Concrete BuildingsDocument7 pagesReshore Design For Concrete BuildingsJason Toralde100% (1)

- Vehicle Design Live Loads On Box CulvertsDocument91 pagesVehicle Design Live Loads On Box CulvertsRichard Vachon0% (1)

- Tall Buildings: The Proceedings of a Symposium on Tall Buildings with Particular Reference to Shear Wall Structures, Held in the Department of Civil Engineering, University of Southampton, April 1966D'EverandTall Buildings: The Proceedings of a Symposium on Tall Buildings with Particular Reference to Shear Wall Structures, Held in the Department of Civil Engineering, University of Southampton, April 1966A. CoullÉvaluation : 5 sur 5 étoiles5/5 (1)

- Tilt Up Construction PDFDocument32 pagesTilt Up Construction PDFLauren Grant100% (2)

- Shear Wall and Frame Interaction TerminologyDocument5 pagesShear Wall and Frame Interaction TerminologyGRD Journals100% (1)

- Concrete Slab Repair PDFDocument6 pagesConcrete Slab Repair PDFZac Francis Daymond100% (1)

- Flexible Vs RigidDocument1 pageFlexible Vs Rigidsilvereyes18Pas encore d'évaluation

- Code of Pactice For Dead and Imposed Loads 2011Document30 pagesCode of Pactice For Dead and Imposed Loads 2011iyhkPas encore d'évaluation

- Chapter 4.2 Building Near TreesDocument40 pagesChapter 4.2 Building Near TreesDan Thompson67% (3)

- Roofs and Roofing: Performance, Diagnosis, Maintenance, Repair and The Avoidance of DefectsDocument53 pagesRoofs and Roofing: Performance, Diagnosis, Maintenance, Repair and The Avoidance of DefectsJakelynPas encore d'évaluation

- Thermal Analysis of Long BuildingsDocument64 pagesThermal Analysis of Long BuildingsShirke Sanjay100% (1)

- Failures That Changed Perception of Our Designs-InG IABSE December 14Document22 pagesFailures That Changed Perception of Our Designs-InG IABSE December 14Subramanian NarayananPas encore d'évaluation

- Steel Framed FloorsDocument12 pagesSteel Framed Floorsyoki_triwahyudi50% (2)

- Repair and RehabilitationDocument22 pagesRepair and RehabilitationConstro FacilitatorPas encore d'évaluation

- Detailing of Reinforcement in Concrete Structures Volume 1Document244 pagesDetailing of Reinforcement in Concrete Structures Volume 1Ahmed Refaey100% (4)

- Design and Reanalysis of Pile Cap Under EccentricityDocument8 pagesDesign and Reanalysis of Pile Cap Under EccentricityovikbasuPas encore d'évaluation

- Structural Design in Concrete and Steel CE7112Document3 pagesStructural Design in Concrete and Steel CE7112ahmadsawalmahPas encore d'évaluation

- Beam SlabDocument66 pagesBeam Slabmadkik100% (1)

- ConcreteRebar101 - University (Compatibility Mode)Document105 pagesConcreteRebar101 - University (Compatibility Mode)Ronald Kahora100% (1)

- Checklist For Forensic Structural Engineering InspectionDocument1 pageChecklist For Forensic Structural Engineering InspectionAmanda SmithPas encore d'évaluation

- CFRP For Strengthening StructuresDocument42 pagesCFRP For Strengthening Structuresraziasalim100% (1)

- Structural Building Defects - Crack in FoundationDocument4 pagesStructural Building Defects - Crack in Foundationmyrayaya100% (1)

- Defects in Building:: A) Structural DefectDocument12 pagesDefects in Building:: A) Structural DefectkalimPas encore d'évaluation

- Analysis and Design of Shear Wall With Various Openings CriteriaDocument5 pagesAnalysis and Design of Shear Wall With Various Openings CriteriaEditor IJTSRDPas encore d'évaluation

- Rules of Thumb: Graduate Manual Design TipsDocument10 pagesRules of Thumb: Graduate Manual Design TipsDebendra Dev KhanalPas encore d'évaluation

- Footing Design As Per AstmDocument102 pagesFooting Design As Per AstmZankar R ParikhPas encore d'évaluation

- Theory of Structure: Post-Tensioned SlabsDocument18 pagesTheory of Structure: Post-Tensioned SlabsPuru VashisthPas encore d'évaluation

- Course Book of Foundation For Civil Engineering 2012-2013 PDFDocument23 pagesCourse Book of Foundation For Civil Engineering 2012-2013 PDFMomayKradookkradic100% (2)

- Post Tensioned SlabsDocument44 pagesPost Tensioned SlabsMaad Ahmed Al-Maroof100% (2)

- Section 5 - 5: Switch Board MCC Room Genset RoomDocument3 pagesSection 5 - 5: Switch Board MCC Room Genset RoomBandilung TzPas encore d'évaluation

- General Conditions and Design ParametersDocument2 pagesGeneral Conditions and Design ParametersBandilung TzPas encore d'évaluation

- Schedule Waste Storage ST 01 A1 GRDDocument1 pageSchedule Waste Storage ST 01 A1 GRDBandilung TzPas encore d'évaluation

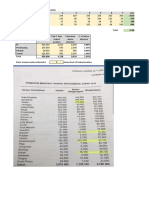

- This Chart Shows The Past Week Covid Daily Cases in Sabah, MalaysiaDocument1 pageThis Chart Shows The Past Week Covid Daily Cases in Sabah, MalaysiaBandilung TzPas encore d'évaluation

- Greater KK Infection 7aug21Document1 pageGreater KK Infection 7aug21Bandilung TzPas encore d'évaluation

- Greater KK Infection 7aug21 Raw DataDocument1 pageGreater KK Infection 7aug21 Raw DataBandilung TzPas encore d'évaluation

- Pile Capacity CheckDocument9 pagesPile Capacity CheckBandilung TzPas encore d'évaluation

- February 14 2018Document1 pageFebruary 14 2018Bandilung TzPas encore d'évaluation

- Geotechnical Investigation and Monitoring Results of A LandslideDocument9 pagesGeotechnical Investigation and Monitoring Results of A LandslideBandilung TzPas encore d'évaluation

- Chronology of Davids PsalmsDocument4 pagesChronology of Davids Psalmszandara blissPas encore d'évaluation

- Clay Mineral of SabahDocument10 pagesClay Mineral of SabahBandilung TzPas encore d'évaluation

- Hostel Lower RoofDocument1 pageHostel Lower RoofBandilung TzPas encore d'évaluation

- Elastic Stability of Square Stiffened PlateDocument13 pagesElastic Stability of Square Stiffened PlateBandilung TzPas encore d'évaluation

- Analysis and Design of A 47-Story Reinforced Concrete Structure PDFDocument14 pagesAnalysis and Design of A 47-Story Reinforced Concrete Structure PDFovikbasuPas encore d'évaluation

- Failure Characteristics of Reinforced Concrete Beams Repaired With CFRP CompositesDocument14 pagesFailure Characteristics of Reinforced Concrete Beams Repaired With CFRP CompositesBandilung TzPas encore d'évaluation

- Building Structures and TechnologyDocument98 pagesBuilding Structures and TechnologyBandilung Tz100% (1)

- Economic Long Span Concrete Floor SlabsDocument51 pagesEconomic Long Span Concrete Floor Slabsocenkt100% (10)

- Jacked-In Pipe Reinforcement of A Deep Excavation in Soft SoilDocument8 pagesJacked-In Pipe Reinforcement of A Deep Excavation in Soft SoilBandilung Tz100% (1)

- Full Solution Manual For Practical Management Science 6Th by Winston PDF Docx Full Chapter ChapterDocument36 pagesFull Solution Manual For Practical Management Science 6Th by Winston PDF Docx Full Chapter Chapteruproll.curst.s5csd100% (12)

- Typology As A Form of ConventionDocument11 pagesTypology As A Form of ConventionMahoor SajjadiPas encore d'évaluation

- Baterie Incalzire Electrica Circulara Vents NK 250 6.0 3Document4 pagesBaterie Incalzire Electrica Circulara Vents NK 250 6.0 3Valentin MalihinPas encore d'évaluation

- Method of Statement For Road WorksDocument3 pagesMethod of Statement For Road WorksBun Sothea100% (2)

- Evaluasi Kerusakan Permukaan Jalan Dengan Metode Pavement Condition Index Pci Pada Ruas Jalan Isimu - PaguyamanDocument11 pagesEvaluasi Kerusakan Permukaan Jalan Dengan Metode Pavement Condition Index Pci Pada Ruas Jalan Isimu - PaguyamanRichrisna WaasPas encore d'évaluation

- Housekeeping Room Attendant WorksheetDocument2 pagesHousekeeping Room Attendant WorksheetGede Sepran Jaya67% (3)

- JACKODUR Thermal Insulation & Formwork System PDFDocument12 pagesJACKODUR Thermal Insulation & Formwork System PDFCal MoranPas encore d'évaluation

- 2018-06-01 The Artists MagazineDocument118 pages2018-06-01 The Artists MagazineLucas Cockshott100% (2)

- Davinci BridgeDocument7 pagesDavinci BridgeJamesPas encore d'évaluation

- Art and Technology in The Nineteenth and Twentieth Centuries by Pierre FrancastelDocument341 pagesArt and Technology in The Nineteenth and Twentieth Centuries by Pierre FrancastelArtanis100% (1)

- Tagsing-Buyo NHS: 2 Summative Test in Mapeh 9 SY 2020-2021Document3 pagesTagsing-Buyo NHS: 2 Summative Test in Mapeh 9 SY 2020-2021John DiestroPas encore d'évaluation

- Test Bank For Business A Practical Introduction WilliamsDocument36 pagesTest Bank For Business A Practical Introduction Williamshermeticfairhoodr2ygm100% (47)

- CSEC Technical Drawing 2010 P31 - Building DrawingDocument5 pagesCSEC Technical Drawing 2010 P31 - Building DrawingRicardo EdwardsPas encore d'évaluation

- 00.blending Unit - Roof - LayoutDocument1 page00.blending Unit - Roof - LayoutMartens HategePas encore d'évaluation

- DocxDocument11 pagesDocxKennedy Gitonga ArithiPas encore d'évaluation

- Design of Reinforced Concrete SectionsDocument30 pagesDesign of Reinforced Concrete Sectionsjeovan100% (1)

- Structure Details FOR Foundation: Practical Architectural Training-Fun Begins (For Interns and Freshers)Document37 pagesStructure Details FOR Foundation: Practical Architectural Training-Fun Begins (For Interns and Freshers)Divya Varshney100% (1)

- QiyamDocument7 pagesQiyammounikaPas encore d'évaluation

- Masonry WorksDocument8 pagesMasonry WorksSabre D. ButitoPas encore d'évaluation

- 3DMark - CopieDocument3 pages3DMark - CopieGamerOfEnderPas encore d'évaluation

- PDS TOPAZ INTERIOR FILLER 38840 en-GBDocument4 pagesPDS TOPAZ INTERIOR FILLER 38840 en-GBJalil TahirPas encore d'évaluation

- D102 TR3 S094 TL3 S093 TL3: COUNTERTOP PLAN 2 (Vanity) 1Document1 pageD102 TR3 S094 TL3 S093 TL3: COUNTERTOP PLAN 2 (Vanity) 1hadeer younsPas encore d'évaluation

- 10.14 Mva Transformer Foundation: Input Data Rebar Work Footing SizeDocument3 pages10.14 Mva Transformer Foundation: Input Data Rebar Work Footing SizeDesign explorer olomizanaPas encore d'évaluation

- Bolted ConnectionDocument86 pagesBolted ConnectionPooja MistryPas encore d'évaluation

- Motor CoolingDocument6 pagesMotor CoolingKartickBakshiPas encore d'évaluation

- Week 5 Lec MaterialDocument124 pagesWeek 5 Lec MaterialSoham MukhopadhyayPas encore d'évaluation

- Structural Analysis 1 MS WORDDocument32 pagesStructural Analysis 1 MS WORDJayson PagalPas encore d'évaluation

- Fundamentos de La Lengua Inglesa: Practice Booklet 1st TermDocument82 pagesFundamentos de La Lengua Inglesa: Practice Booklet 1st TermPaola Vanesa MancinoPas encore d'évaluation

- 10 - 12 Arrow Shed ManualDocument39 pages10 - 12 Arrow Shed ManualJason Porter100% (2)

- Housing in Boveresses - Fruehauf, Henry & Viladoms - ArchDailyDocument10 pagesHousing in Boveresses - Fruehauf, Henry & Viladoms - ArchDailyarchpavlovicPas encore d'évaluation