Académique Documents

Professionnel Documents

Culture Documents

Continuously Variable Transmission (CVT) : Group 23

Transféré par

08088338Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Continuously Variable Transmission (CVT) : Group 23

Transféré par

08088338Droits d'auteur :

Formats disponibles

GROUP 23

CONTINUOUSLY

VARIABLE

TRANSMISSION

(CVT)

CONTENTS

CVT. . . . . . . . . . . . . . . . . . . . . . . . . . . 23-2

GENERAL INFORMATION. . . . . . . . . . . . . 23-2

ELECTRONIC CONTROL SYSTEM. . . . . . 23-3

EEPROM. . . . . . . . . . . . . . . . . . . . . . . . . . . 23-3

CONTROLLER AREA NETWORK (CAN)

COMMUNICATION. . . . . . . . . . . . . . . . . . . 23-3

RATIO PATTERN . . . . . . . . . . . . . . . . . . . . 23-3

DIAGNOSIS CLASSIFICATION TABLE . . . 23-4

ATF WARMER (ATF COOLER) . . . . . . . . . 23-5

TRANSMISSION CONTROL . . . . . . . 23-6

GENERAL INFORMATION . . . . . . . . . . . . . 23-6

SELECTOR LEVER ASSEMBLY . . . . . . . . 23-7

CVT ERRONEOUS OPERATION

PREVENTION MECHANISMS . . . . . . . . . . 23-8

Main

Index

CVT

CONTINUOUSLY VARIABLE TRANSMISSION (CVT)

23-2

CVT

GENERAL INFORMATION

M2231000100165

The F1C1A transmission is adopted for the CVT.

This transmission is basically the same as conven-

tional transmission.

The ATF warmer (ATF cooler) is adopted.

SPECIFICATIONS

Item Specification

Transmission model F1C1A

Engine model 4A91

Torque converter Type 3-element, 1-stage, 2-phase type

Lock-up Provided

Stall torque ratio 2.0

Transmission type Forward automatic continuously variable (steel belt type),

1st in reverse

Gear ratio Forward 2.319 " 0.445

Reverse 2.588

Clutch A pair of multi-plate system

Brake A pair of multi-plate system

Manual control system P-R-N-D-Ds-L (smart shift)

Function Variable speed control Yes

Line pressure control Yes

Direct engagement control Yes

N-D/N-R control Yes

Shift pattern control Yes

Self-diagnosis Yes

Failsafe Yes

Oil pump Type External gear pump

Configuration Built-in (chain drive)

Control method Electronic control (INVECS-III)

Transmission oil Specified lubricants DIA QUEEN ATF SP III

Quantity L 8.1

Main

Index

Group

TOC

CVT

CONTINUOUSLY VARIABLE TRANSMISSION (CVT)

23-3

ELECTRONIC CONTROL SYSTEM

EEPROM

M2231012000024

Because EEPROM has been used, even if the bat-

tery terminals or control unit connectors are discon-

nected, the necessary learned values are stored in

the engine-CVT-ECU to prevent a loss of shift qual-

ity. (Initialisation is available by M.U.T.-III).

CONTROLLER AREA NETWORK (CAN)

COMMUNICATION

M2231017000018

CAN

*

communication has been adopted for commu-

nication with other ECUs in order to decrease the

number of wires and ensure information transmis-

sion. For CVT control, the engine-CVT-ECU receives

the following signals.

CAN COMMUNICATION INPUT SIGNAL TABLE

Input signal Transmitter ECU

Average vehicle speed signal from drive wheels ABS-ECU

Motor current signal EPS-ECU

EPS warning lamp illumination request signal

Compressor signal Meter and A/C-ECU

NOTE:

*

: For more information about CAN (Control-

ler Area Network), refer to GROUP 54C P.54C-2.

RATIO PATTERN

M2231013000061

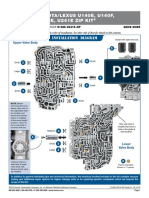

AC403740AE

Engine speed

(r/min)

Vehicle speed (km/h)

0 100 150 50

1,000

2,000

4,000

3,000

5,000

7,000

6,000

OD

LOW

Accelerator

fully closed, 20%

40%

Accelerator

fully open

60%

80%

Main

Index

Group

TOC

CVT

CONTINUOUSLY VARIABLE TRANSMISSION (CVT)

23-4

DIAGNOSIS CLASSIFICATION TABLE

M2231015000056

Item Diagnosis Data list Actuator

test

Code No. Trouble symptoms Item No. Display

Crank angle sensor

" "

01 r/min

"

CVT fluid temperature sensor 15 Open circuit 08

#C "

16 Short circuit

Line pressure sensor 18 Open circuit 09 MPa

"

19 Short circuit

Turbine speed sensor 22 Open circuit 02 r/min

"

Primary speed sensor 23 Open circuit 03 r/min

"

26 System failure

Secondary speed sensor 24 Open circuit 04 r/min

"

25 System failure

Accelerator pedal position sensor (APS)

" "

06 mV

"

Primary pressure sensor 27 Open circuit 11 MPa

"

28 Short circuit

Gear ratio

" "

12 Displays the

gear ratio.

"

Line pressure control solenoid valve 31 Open circuit/short

circuit

16 % 01

Shift control solenoid valve 32 Open circuit 15 % 02

36 Short circuit

Damper clutch control solenoid valve 33 Open circuit 14 % 03

37 Short circuit

Clutch pressure control solenoid valve 34 Open circuit 17 % 04

38 Short circuit

Shift system 42 System failure

" " "

Damper clutch system 44 System failure 10 r/min

"

45

Clutch system 46 System failure

" " "

48

Inhibitor switch 51 Open circuit 26 P/R/N/D/Ds/L

"

52 Short circuit

Stop lamp switch 53 Open circuit 33 ON/OFF

"

54 Short circuit

Battery voltage

" "

24 V

"

CVT control relay 56 Open circuit 25 V 11

Steel belt system 59 System failure

" " "

Line pressure system 57 System failure

" " "

71

72

Main

Index

Group

TOC

CVT

CONTINUOUSLY VARIABLE TRANSMISSION (CVT)

23-5

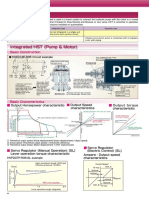

ATF WARMER (ATF COOLER)

M2230000600082

AC403052AC

ATF

Engine coolant

Sectional view

ATF Warmer

(ATF Cooler)

Thermo valve

AC403006

CVT CVT CVT

Thermostat

Thermo

valve

ATF warmer (ATF cooler) ATF warmer (ATF cooler)

: Engine coolant

: ATF

<Engine coolant temperature:

85C or more>

Engine coolant flows through

all the sections.

<Engine coolant temperature:

75 - 85C>

Engine coolant flows through

the heater and the ATF warmer.

<Engine coolant temperature:

75C or less>

Engine coolant flows through

the heater only. AC

: Valve open

: Valve closed

Thermostat

Thermo

valve

ATF warmer (ATF cooler)

Thermo

valve

Thermostat

R

a

d

i

a

t

o

r

E

n

g

i

n

e

H

e

a

t

e

r

R

a

d

i

a

t

o

r

E

n

g

i

n

e

H

e

a

t

e

r

R

a

d

i

a

t

o

r

E

n

g

i

n

e

H

e

a

t

e

r

The ATF warmer (ATF cooler) is adopted. (the ATF

cooler incorporating the radiator is not adopted)

At the start of running, the temperature of the engine

coolant rises earlier than that of the ATF. The ATF

warmer utilizes this characteristic to raise the ATF

temperature as early as possible to an appropriate

level (70 - 80 #C). It also controls fluid temperature

stably and reduces ATF agitation resistance to

improve fuel consumption ratio.

In addition, a thermo-valve has been adopted to

restrict the engine coolant supply to the ATF warmer

(ATF cooler) until the engine coolant temperature

reaches the appropriate temperature when low tem-

perature start in winter, giving the priority to the heat-

ing performance.

Main

Index

Group

TOC

TRANSMISSION CONTROL

CONTINUOUSLY VARIABLE TRANSMISSION (CVT)

23-6

TRANSMISSION CONTROL

GENERAL INFORMATION

M2232000100447

$ A smart shift type selector lever has been

adopted in order to facilitate walkthrough

between the seats.

$ A gun grip type selector lever knob has been

adopted for better operation and easier visual

recognition of the switches arranged in the centre

panel.

$ The selector lever assembly has been a single

unit made by aluminium die casting for better

accuracy and fewer parts, resulting in the light-

weight and compact structure.

$ The selector lever has been designed to be com-

pact and appropriately configured not to interfere

with the energy absorbing mechanism on the

steering column upon impact of the vehicle.

$ In order to prevent abrupt start by erroneous

operation of selector lever, a CVT erroneous

operation prevention mechanism (the shiftlock

mechanism and key interlock mechanism) has

been adopted.

COMPONENT VIEW

AC206842

AC206864

AC207638AB

P

R

N

D

Ds

L

Inhibitor switch

Transmission

control cable

Selector lever

assembly

Main

Index

Group

TOC

TRANSMISSION CONTROL

CONTINUOUSLY VARIABLE TRANSMISSION (CVT)

23-7

SELECTOR LEVER ASSEMBLY

M2232002000190

AC206896 AC206898

AC206897 AC206899

AC207644AB

Selector lever

(P position)

Push button

Lock cam

A

Detent pin

Front of vehicles

Selector lever

(except for P position)

Detent pin

Detent block

Operation

1. When the selector lever is in the P position, the

detent pin is engaged with the lock cam. When

the pushbutton on the selector lever is pressed,

the detent pin moves in the direction A as illus-

trated in the figure to rotate the lock cam.

2. When the detent pin rotates the lock cam to dis-

engage, the selector lever can go over the pro-

truding part of the detent block. This enables

shifting the selector lever.

Main

Index

Group

TOC

TRANSMISSION CONTROL

CONTINUOUSLY VARIABLE TRANSMISSION (CVT)

23-8

CVT ERRONEOUS OPERATION PREVENTION MECHANISMS

M2232003000104

SHIFT LOCK MECHANISM

Only when the following two conditions are satisfied,

the selector lever can be shifted from the P position

to another position:

$ When the brake pedal is depressed

$ When the ignition key is in other than the LOCK

(OFF) position

When the brake pedal is not depressed

AC206902AB

Brake pedal

Shiftlock cable

Stopper

Lever

Rod

Lock cam

Detent pin

When the selector lever is in the P position with the

brake pedal not depressed, the shiftlock cable stop-

per keeps the lever locked so that the rod and lock

cam do not move.

As a result of this, the pushbutton of the selector

lever linked to the detent pin cannot be pressed and

the selector lever cannot be shifted from the P posi-

tion to another position.

When the brake pedal is depressed

AC206903AB

Brake pedal

Shiftlock cable

Stopper

Lever

Rod

Lock cam

Detent pin

When the brake pedal is depressed, the stopper is

pulled by the shiftlock cable so that the lever

becomes unlocked.

Then the lock cam linked to the rod can also rotate

so that the selector lever can be shifted from the P

position to another position by pressing the pushbut-

ton.

NOTE: When the brake pedal is depressed with the

ignition key in the LOCK (OFF) position, the selector

lever cannot be shifted from the P position to another

position.

Main

Index

Group

TOC

TRANSMISSION CONTROL

CONTINUOUSLY VARIABLE TRANSMISSION (CVT)

23-9

When the ignition key is in the LOCK (OFF) position or pulled out (With the selector

lever in the P position)

AC206911AB

Slider

Ignition key

LOCK (OFF) position

Projection of rotor

Key interlock cable

Lock cam

Rod

Lever

Engine starting

switch assembly

In the engine starting switch assembly, the slider is

engaged with the groove of the key interlock cable,

and the slider is locked by the projection of the rotor

so that the key interlock cable as well as the lever,

rod, and lock cam does not move.

As a result of this, any attempt to shift the selector

lever is prevented. The pushbutton on the selector

lever cannot be pressed because the lock cam does

not rotate, then the selector lever cannot be shifted

from the P position to another position.

Main

Index

Group

TOC

TRANSMISSION CONTROL

CONTINUOUSLY VARIABLE TRANSMISSION (CVT)

23-10

When the ignition key is in other than the LOCK (OFF) position (With the selector

lever in the P position)

AC206912AB

A

Slider

Ignition key

ACC to START

position

Projection of rotor

Key interlock cable

Lock cam

Rod

Lever

Engine starting

switch assembly

The rotor in the engine starting switch assembly has

a notch between ACC and START so that the slider

becomes unlocked.

Then the slider can move in the direction A as illus-

trated in the figure to allow the lock cam to rotate so

that the selector lever can be shifted from the P posi-

tion to another position by pressing the pushbutton.

NOTE: When the ignition key is in other than the

LOCK (OFF) position with the brake pedal not

depressed, the selector lever cannot be shifted from

the P position to another position.

KEY INTERLOCK MECHANISM

When the selector lever is not in the P position, the

ignition key cannot be turned to the LOCK (OFF)

position and pulled out.

Main

Index

Group

TOC

TRANSMISSION CONTROL

CONTINUOUSLY VARIABLE TRANSMISSION (CVT)

23-11

When pulling out the key with the selector lever in other than the P position

AC206912AC

B

A

A

Slider

Ignition key

ACC to START

position

Projection of rotor

Key interlock cable

Lock cam

Rod

Lever

Engine starting

switch assembly

The lock cam is kept in a rotated condition, and the

key interlock cable is kept pulled in direction A as

illustrated in the figure. In this state, the slider in the

engine starting switch assembly is moved and locked

in direction B as illustrated in the figure.

As a result of this, any attempt to turn the ignition key

to the LOCK (OFF) position is prevented because

the slider prevents the rotor from rotating, and the

ignition key can only turn up to the ACC position and

cannot be pulled out.

Main

Index

Group

TOC

TRANSMISSION CONTROL

CONTINUOUSLY VARIABLE TRANSMISSION (CVT)

23-12

When pulling out the key with the selector lever in the P position

AC206911AC

A

A

Slider

Ignition key

ACC to START

position

Projection of rotor

Key interlock cable

Lock cam

Rod

Lever

Engine starting

switch assembly

Detent pin

When releasing the pushbutton on the selector lever

with the selector lever in the P position, the lock cam

is rotated by the detent pin. Then the key interlock

cable is moved by the lock cam in direction A as illus-

trated in the figure.

As a result of this, the slider in the engine starting

switch assembly is unlocked. The rotor can then turn,

and the ignition key can be pulled out by turning it to

the LOCK (OFF) position.

Main

Index

Group

TOC

Vous aimerez peut-être aussi

- CVT Mitsubishi 1Document12 pagesCVT Mitsubishi 1Humberto Lojan50% (2)

- Valve Body PDFDocument9 pagesValve Body PDFTimur TOT100% (1)

- 4AT Automatic TransDocument132 pages4AT Automatic TransvarelafPas encore d'évaluation

- Automatic Transmission Serial Numbers T-tc004-96Document3 pagesAutomatic Transmission Serial Numbers T-tc004-96emboko100% (1)

- U340 441E DescriptionDocument25 pagesU340 441E Descriptionruslan1580Pas encore d'évaluation

- A541e Automatic TransaxleDocument132 pagesA541e Automatic TransaxleHuey_7480% (10)

- A750-A761E VacTestLocationsDocument5 pagesA750-A761E VacTestLocationsPedroMecanico100% (5)

- Jf405e PDFDocument4 pagesJf405e PDFvaskaserv60% (5)

- Valve Body PDFDocument9 pagesValve Body PDFTimur TOT100% (2)

- Manual V4aw2 PDFDocument543 pagesManual V4aw2 PDFEmersonPas encore d'évaluation

- Hyundai A4AF1-2 - A4BF1-1Document4 pagesHyundai A4AF1-2 - A4BF1-1Tal Benyamin67% (6)

- A 240Document89 pagesA 240Mario Diaz Lopez100% (1)

- Valve BodyDocument5 pagesValve BodyPablo MontesPas encore d'évaluation

- Atf Drain & Fill & Leveling - Camry U760eDocument13 pagesAtf Drain & Fill & Leveling - Camry U760echuck8726842667% (3)

- Honda Civic (96-98) Transmission Service Manual PDFDocument286 pagesHonda Civic (96-98) Transmission Service Manual PDFAnderson Lodi100% (1)

- (Hyundai I10 2007-) (Kia Morning 2011-, Picanto 2009-, Ray 2012-, Suria 2006-2011) 4 SPEED FWD With Lock Up (Electronic Control)Document4 pages(Hyundai I10 2007-) (Kia Morning 2011-, Picanto 2009-, Ray 2012-, Suria 2006-2011) 4 SPEED FWD With Lock Up (Electronic Control)EduRoiPas encore d'évaluation

- Aw 03 72le Aw0373leDocument195 pagesAw 03 72le Aw0373leBrian AqifPas encore d'évaluation

- Toyota A340FDocument1 pageToyota A340FReydeEspa171% (7)

- Aw03 PDFDocument15 pagesAw03 PDFamazonagirl19Pas encore d'évaluation

- F4A4x at Manual PDFDocument135 pagesF4A4x at Manual PDFDener Rogerio Dos SantosPas encore d'évaluation

- Gearbox k310 PDFDocument3 pagesGearbox k310 PDFmaq804850% (10)

- U140e U241e Zip inDocument10 pagesU140e U241e Zip inAnonymous DNM4ZI100% (4)

- F1CJA CVT ManualDocument84 pagesF1CJA CVT ManualGlen100% (4)

- Isuzu Aw03 72lDocument12 pagesIsuzu Aw03 72ljosedavid24088879% (14)

- Aisin Automatic Transaxle PDFDocument234 pagesAisin Automatic Transaxle PDFAdal VeraPas encore d'évaluation

- Nissan CVT Wiring DiagramDocument3 pagesNissan CVT Wiring Diagrambruceauto88% (16)

- KM 175 PDFDocument96 pagesKM 175 PDFJhonny100% (2)

- Ac60E/F: Now Available Transtec Overhaul Kit TheDocument1 pageAc60E/F: Now Available Transtec Overhaul Kit Thedexolbranch67% (6)

- CVT F1c1aDocument58 pagesCVT F1c1abyk22288% (8)

- F4A4x at ManualDocument135 pagesF4A4x at Manualcavp271% (7)

- JF016E-JF017E Vacuum Manual Valve BodyDocument4 pagesJF016E-JF017E Vacuum Manual Valve Bodyak_adamPas encore d'évaluation

- 54 Mitsubishi 2 R4A51 V4A51 R5A51Document8 pages54 Mitsubishi 2 R4A51 V4A51 R5A51Marlon OrtegaPas encore d'évaluation

- A760EDocument47 pagesA760ENeqcer Martínez100% (3)

- Mazda 626 2002 Wiring Diagram Ecu FS-07-01Document1 pageMazda 626 2002 Wiring Diagram Ecu FS-07-01ViA Masters100% (1)

- MG3 Circuit DiagramDocument76 pagesMG3 Circuit Diagrammehdi100% (1)

- Jf405e PDFDocument4 pagesJf405e PDFМаратPas encore d'évaluation

- F 1 C 1Document2 pagesF 1 C 1Abel Gonzalez100% (7)

- U-340 Valve BodyDocument19 pagesU-340 Valve BodyAle100% (4)

- Transmision Nissan RE0F10ADocument4 pagesTransmision Nissan RE0F10Aubaldolinda67% (3)

- Nissan R E 4 R 0 2 A: Automatic Transmission Service Group 18639 SW 107TH AVENUE Miami, Florida 33157 (305) 670-4161Document95 pagesNissan R E 4 R 0 2 A: Automatic Transmission Service Group 18639 SW 107TH AVENUE Miami, Florida 33157 (305) 670-4161skyship skyship50% (2)

- 6 Speed TrannyDocument52 pages6 Speed Trannykuwaiti27100% (3)

- F4ael PDFDocument120 pagesF4ael PDFPablo Cansas100% (2)

- Transmisión AUT 03 - 72L Service ManualDocument134 pagesTransmisión AUT 03 - 72L Service ManualJose nicolas Perez VasquezPas encore d'évaluation

- Automatic Manual TransmissionDocument56 pagesAutomatic Manual Transmissionrey1004100% (3)

- 15 - Automatic TransaxleDocument246 pages15 - Automatic TransaxleesquisofPas encore d'évaluation

- Technical Service Information3Document4 pagesTechnical Service Information3JosePas encore d'évaluation

- JM at - 20040129Document11 pagesJM at - 20040129wreckedweaselPas encore d'évaluation

- U 340Document19 pagesU 340yosergey100% (2)

- SSP-283 6 Speed Automatic Gearbox Audi A8 03' Part 2 PDFDocument26 pagesSSP-283 6 Speed Automatic Gearbox Audi A8 03' Part 2 PDFRizwan HameedPas encore d'évaluation

- A 960eDocument28 pagesA 960elucasgratao100% (3)

- Brake ControlDocument212 pagesBrake ControllogammicPas encore d'évaluation

- Diagrama Electrico Exc.Document2 pagesDiagrama Electrico Exc.Becker Orlando Perez FIallos100% (1)

- 07 - Tfaw3 We 0431Document266 pages07 - Tfaw3 We 0431jrrodrigueza2100% (2)

- Chrysler Dakota Part11Document24 pagesChrysler Dakota Part11Sašo Brunšek-BrunoPas encore d'évaluation

- U 340Document19 pagesU 340ruslan1580Pas encore d'évaluation

- A340-Le TransmissionDocument24 pagesA340-Le TransmissionLuisGonzalezPas encore d'évaluation

- 320C Hydraulic Excavator Electrical SchematicDocument2 pages320C Hydraulic Excavator Electrical Schematicluiscampos7792% (12)

- CVT Transmission Part2Document8 pagesCVT Transmission Part2ryba1100% (1)

- MSB 97e17 502 PDFDocument10 pagesMSB 97e17 502 PDFAutof FerreiraPas encore d'évaluation

- g3 Air System AbaDocument15 pagesg3 Air System Aba08088338Pas encore d'évaluation

- V6 Auto TransDocument9 pagesV6 Auto Trans08088338Pas encore d'évaluation

- Kia Sorento 2.4 ChargerDocument1 pageKia Sorento 2.4 Charger08088338Pas encore d'évaluation

- Water Pump Cleaning and InspectionDocument1 pageWater Pump Cleaning and Inspection08088338Pas encore d'évaluation

- Technical Service Bulletin: Sorento Digital Clock Losing TimeDocument4 pagesTechnical Service Bulletin: Sorento Digital Clock Losing Time08088338Pas encore d'évaluation

- Technical Service Bulletin: - DescriptionDocument4 pagesTechnical Service Bulletin: - Description08088338Pas encore d'évaluation

- General Body Construction Unibody DescriptionDocument3 pagesGeneral Body Construction Unibody Description08088338Pas encore d'évaluation

- Evaporative Emission Control System DescriptionDocument1 pageEvaporative Emission Control System Description08088338Pas encore d'évaluation

- Data Link Communications Description and OperationDocument1 pageData Link Communications Description and Operation08088338Pas encore d'évaluation

- S53 Manual TransaxleDocument2 pagesS53 Manual Transaxle08088338Pas encore d'évaluation

- 2005 Audi A6 / Quattro (4F) : Submodel: Engine Type: Liters: Fuel Delivery: FuelDocument1 page2005 Audi A6 / Quattro (4F) : Submodel: Engine Type: Liters: Fuel Delivery: Fuel08088338Pas encore d'évaluation

- Engine Coolant Fan Replacement 1 0l LMT 1 19l Lc5 and 1 2l LmuDocument1 pageEngine Coolant Fan Replacement 1 0l LMT 1 19l Lc5 and 1 2l Lmu08088338Pas encore d'évaluation

- Ford BTR Transmission Repair Manual PDFDocument100 pagesFord BTR Transmission Repair Manual PDF08088338100% (2)

- 231Document4 pages23108088338Pas encore d'évaluation

- 13 ToyotaDocument105 pages13 Toyota0808833867% (3)

- 307-01 - Digital Transmission Range (TR) SensorDocument6 pages307-01 - Digital Transmission Range (TR) Sensor08088338Pas encore d'évaluation

- Ford 30 V600Document7 pagesFord 30 V60008088338Pas encore d'évaluation

- Circuit Diagram: Luggage Compartment Light Ceiling LampDocument1 pageCircuit Diagram: Luggage Compartment Light Ceiling Lamp08088338Pas encore d'évaluation

- Subaru WRX 97 To 98 Full PinoutsDocument1 pageSubaru WRX 97 To 98 Full Pinouts08088338Pas encore d'évaluation

- Circult DiagramDocument1 pageCircult Diagram08088338Pas encore d'évaluation

- Xtunter-E3 User Manual v8.4Document62 pagesXtunter-E3 User Manual v8.408088338Pas encore d'évaluation

- Mechanical Projects ListDocument3 pagesMechanical Projects ListJatin PahujaPas encore d'évaluation

- Ikr17 RulesDocument52 pagesIkr17 RulesAnandPas encore d'évaluation

- PHD Thesis D'Andrea DaniloDocument155 pagesPHD Thesis D'Andrea DaniloGardenia AndradePas encore d'évaluation

- Steyr Terrus Tractor BrochureDocument44 pagesSteyr Terrus Tractor Brochuresalah100% (1)

- Endurance - ARDocument247 pagesEndurance - ARarun kumarPas encore d'évaluation

- "Beach Cleaning Equipment": Project Reference No.: 37S0546Document3 pages"Beach Cleaning Equipment": Project Reference No.: 37S0546Paul ThomasPas encore d'évaluation

- Reasons of Failures of CvtsDocument5 pagesReasons of Failures of CvtsLalit Kumar JainPas encore d'évaluation

- k310 CorollaCVTDocument20 pagesk310 CorollaCVTdaniel92% (13)

- RE0F08ADocument182 pagesRE0F08ARobert Moreau100% (2)

- Bajaj Auto Limited Service DepartmentDocument30 pagesBajaj Auto Limited Service Departmentvisugue_260% (1)

- MC-10164446-0001 LineartronicDocument6 pagesMC-10164446-0001 LineartronicossoskiPas encore d'évaluation

- Speed Sensors For Transmission Control: ApplicationDocument3 pagesSpeed Sensors For Transmission Control: ApplicationJOSE EDUARDO NOGUERON LOPEZPas encore d'évaluation

- Transmission SystemDocument71 pagesTransmission Systemrijorijorijo100% (1)

- 420r16021 PDFDocument719 pages420r16021 PDFАКПП СервисPas encore d'évaluation

- Gepida - 2015 (Kerékpár, Kiegészítő)Document108 pagesGepida - 2015 (Kerékpár, Kiegészítő)Norbert PappPas encore d'évaluation

- FPC Unit 1Document28 pagesFPC Unit 1Ravi MishraPas encore d'évaluation

- Honda CVT ManualDocument142 pagesHonda CVT ManualHussein Mohamed94% (36)

- 2015 Toyota Corolla - DRIVER SIDE JUNCTION BLOCK ASSEMBLY FUSE LISTDocument8 pages2015 Toyota Corolla - DRIVER SIDE JUNCTION BLOCK ASSEMBLY FUSE LISTRyan PringlePas encore d'évaluation

- Transmission Repair Manuals CVT JF011E (RE0F10A), RE0F06A - Rebuild InstructionsDocument13 pagesTransmission Repair Manuals CVT JF011E (RE0F10A), RE0F06A - Rebuild Instructionseduone6567% (3)

- Automotive Mitsubishi Tooling PDFDocument24 pagesAutomotive Mitsubishi Tooling PDFAlex GăuruşPas encore d'évaluation

- Chapter 41: Transmission 1: Dr. Bassam A. TayehDocument17 pagesChapter 41: Transmission 1: Dr. Bassam A. TayehNinja HeroesPas encore d'évaluation

- HST CatalogDocument6 pagesHST CatalogDharmesh patelPas encore d'évaluation

- Handbook of Repair: Manufacturer: "Mecalac Sas"Document70 pagesHandbook of Repair: Manufacturer: "Mecalac Sas"Farid RezigPas encore d'évaluation

- Seminar Report ManasDocument19 pagesSeminar Report ManasAbhay Gupta100% (1)

- Nissan Kicks HR 13 Brochure - A4 - Nissan Next Guidelines - WebDocument18 pagesNissan Kicks HR 13 Brochure - A4 - Nissan Next Guidelines - WebRajishkumar RadhakrishnanPas encore d'évaluation

- Catalog All New Kijang Innova Zenix Hybrid EvDocument12 pagesCatalog All New Kijang Innova Zenix Hybrid EvAbraham AnugrahPas encore d'évaluation

- AU301 Auto TransmissionDocument2 pagesAU301 Auto TransmissionvaisakmctPas encore d'évaluation

- A Continuously Variable TransmissionDocument11 pagesA Continuously Variable TransmissionHitesh PrajapatPas encore d'évaluation

- 2011 Nissan Service Maintenance GuideDocument59 pages2011 Nissan Service Maintenance GuideMD AFROZ RAZA100% (2)

- Nseries PDFDocument2 pagesNseries PDFDarian BelenisPas encore d'évaluation

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tD'EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tÉvaluation : 4.5 sur 5 étoiles4.5/5 (27)

- Digital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosD'EverandDigital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosÉvaluation : 5 sur 5 étoiles5/5 (1)

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionD'EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionÉvaluation : 4.5 sur 5 étoiles4.5/5 (543)

- 2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersD'Everand2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersÉvaluation : 5 sur 5 étoiles5/5 (1)

- Programming the Raspberry Pi, Third Edition: Getting Started with PythonD'EverandProgramming the Raspberry Pi, Third Edition: Getting Started with PythonÉvaluation : 5 sur 5 étoiles5/5 (2)

- Retro Gaming with Raspberry Pi: Nearly 200 Pages of Video Game ProjectsD'EverandRetro Gaming with Raspberry Pi: Nearly 200 Pages of Video Game ProjectsPas encore d'évaluation

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeD'EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeÉvaluation : 4.5 sur 5 étoiles4.5/5 (10)

- Multiplexed Networks for Embedded Systems: CAN, LIN, FlexRay, Safe-by-Wire...D'EverandMultiplexed Networks for Embedded Systems: CAN, LIN, FlexRay, Safe-by-Wire...Pas encore d'évaluation

- Electronics All-in-One For Dummies, 3rd EditionD'EverandElectronics All-in-One For Dummies, 3rd EditionÉvaluation : 5 sur 5 étoiles5/5 (2)

- INCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesD'EverandINCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesÉvaluation : 5 sur 5 étoiles5/5 (1)

- Analog Design and Simulation Using OrCAD Capture and PSpiceD'EverandAnalog Design and Simulation Using OrCAD Capture and PSpicePas encore d'évaluation

- Current Interruption Transients CalculationD'EverandCurrent Interruption Transients CalculationÉvaluation : 4 sur 5 étoiles4/5 (1)

- Practical Electrical Wiring: Residential, Farm, Commercial, and IndustrialD'EverandPractical Electrical Wiring: Residential, Farm, Commercial, and IndustrialÉvaluation : 3.5 sur 5 étoiles3.5/5 (3)

- Teach Yourself Electricity and Electronics, 6th EditionD'EverandTeach Yourself Electricity and Electronics, 6th EditionÉvaluation : 3.5 sur 5 étoiles3.5/5 (15)

- Open Radio Access Network (O-RAN) Systems Architecture and DesignD'EverandOpen Radio Access Network (O-RAN) Systems Architecture and DesignPas encore d'évaluation

- Hacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsD'EverandHacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsÉvaluation : 3.5 sur 5 étoiles3.5/5 (2)

- Empires of Light: Edison, Tesla, Westinghouse, and the Race to Electrify the WorldD'EverandEmpires of Light: Edison, Tesla, Westinghouse, and the Race to Electrify the WorldÉvaluation : 4 sur 5 étoiles4/5 (87)

- Wearable Sensors: Fundamentals, Implementation and ApplicationsD'EverandWearable Sensors: Fundamentals, Implementation and ApplicationsEdward SazonovPas encore d'évaluation