Académique Documents

Professionnel Documents

Culture Documents

Vent-Axia Flexible Round Duct Data Sheet

Transféré par

iask5275Description originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Vent-Axia Flexible Round Duct Data Sheet

Transféré par

iask5275Droits d'auteur :

Formats disponibles

117

from Vent-Axia

Vinyl Coated Flexible ducting

116

Vinyl Coated Flexible Ducting

EuroflexTM120

from Vent-Axia

Fire Test Data

In BSCP 413:1973 it is recommended that for flexible

(ducting) connections the materials of construction should

preferably be noncombustible; alternatively:

i when tested in accordance with the propagation test in

BS 476 Part 6, should have an index of performance not

exceeding 12, of which not more than 6 should derive from

the initial period of the test.

ii when involved in a fire should generate a minimum amount

of smoke and toxic gases.

In practice, flexible ducting is tested to BS476 Parts 7 & 8 and

should satisfy the requirements in (ii).

BS476 Part 7 deals with surface spread of flame test for

materials and provides a method of classification according

to the rate and distance of spread of flame across them

(Class 1 limits flame spread to 165mm in 11/2 minutes). BS476

Part 8 provides a method of assessing the integrity (time

resistance of fire penetration) of flexible ducting connections.

In BSCP 413 flexible joints are required to have a resistance to

the penetration of fire of at least 15 minutes when tested in

accordance with BS 476 Part 8 and should be constructed of

material rated Class 1 in the surface spread of flame test in

BS 476 without treatment and should not give off excessive

quantities of smoke when burnt. In the absence of other

criteria, many enforcing Authorities appear to use this as a

guideline to the required fire performance of flexible

connections.

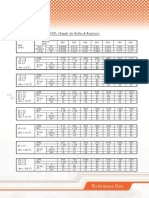

Product Range

Nominal Bore

Ins mm Code No

2 50 12900051

3 75 12903076

4 100 12904102

114 12900114

5 125 12905127

6 150 12906152

160 12900160

7 175 12907180

8 200 12908203

9 225 12909229

10 250 12910254

12 300 12912305

315 12900315

14 350 12914356

16 400 12916406

18 450 12918456

20 500 12920508

22 550 12922556

24 600 12924608

Specifications

Vinyl coated fibreglass fabric supported by a coated spring steel

wire helix.

Colour: grey

Operating temperature: -5C to +93C

Working pressure: -240Pa to +2450Pa

Standard length: 6.0m

Minimum bend radius: 0.6 x diameter

100000

10000

1000

100

10

-1 1 10 100

Pressure loss in Pa per metre

450

400

350

300/315

250

200

150

100

75

Pressure Loss Graph

A

i

r

V

o

l

u

m

e

m

3

/

h

Application Data

The installation of air conditioning and mechanical ventilation

systems may affect the fire risk within a building. The extent

and detail of statutory control and other specialist interests

varies according to the design, use, occupation and location of

the building and the type of air conditioning or ventilation

system proposed. It is essential that all appropriate authorities

be fully consulted at an early stage (e.g. District Surveyor,

Superintending Architect, Fire Department, etc.)

Where air distribution systems pass through various sections of

a building they may provide a ready path for the spread of

smoke and fire. The designer should ensure that wherever

practicable the materials specified for the system should be non-

combustible or difficult to ignite and possess a good rating of

surface spread of flame when tested in accordance with the

appropriate parts of BS476. In addition, such materials should

not generate smoke or toxic fumes when subjected to fire or

heat. The suitability of many materials will need to be agreed by

the enforcing authority. Since there is no published list of

acceptable materials the designer or installer may be required to

provide authoritative test data for the products it is intended

to use.

Codes of Practice and Regulations dealing with fire safety

aspects of ventilation systems frequently refer to flexible joints

and connections:

Flexible Joints

Flexible joints are normally provided to prevent vibration

and /or allow for thermal movements in the system and should

not exceed 300mm in length.

Flexible Connections

Flexible connections are normally provided at the extremities of

the ductwork system to facilitate site connections to grilles,

diffusers, air boxes and combined air/light fixtures, mixing

boxes and terminal units. Such connectors are nearly always

provided for by the use of factory manufactured circular flexible

ducting.

Various types are available, since airflow/pressure drop

characteristics, acoustic and thermal properties may all be

important to system design. From the fire safety viewpoint

BSCP 413:1973 recommends that flexible connections should

not exceed 3.7 m in length and should not pass through fire-

resisting walls, floors or partitions.

Euroflex Type 120 coated flexible fibreglass

ducting has been independently tested at

Warrington Research Centre as defined by

BS476.

Traditional style flexible ducting giving a rugged,

economical flexible duct with an exceptional fire

integrity

Heavy duty vinyl coated fibreglass fabric with

high mechanical strength

Independently tested to BS 476 pt. 20; fire

integrity of 76 mins

Independently tested to BS 476 pt. 7; Class 1

material

Independently tested to BS 476 pt. 6; Propagation

index 1:3, Sub index h: 2

Six metre standard length for convenience and

economy

Sizes range from 50 to 600mm nominal bore

diameter.

D

u

c

t

d

i

a

m

e

t

e

r

m

m

119

from Vent-Axia

Aluminium Flexible Ducting

118

Aluminium Flexible Ducting

EuroflexTM130

from Vent-Axia

Fire Test Data

In BSCP 413:1973 it is recommended that for flexible

(ducting) connections the materials of construction should

preferably be noncombustible; alternatively:

i when tested in accordance with the propagation test in BS476

Part 6, should have an index of performance not exceeding 12,

of which not more than 6 should derive from the initial

period of the test.

ii when involved in a fire should generate a minimum amount

of smoke and toxic gases.

In practice, flexible ducting is tested to BS476 Parts 7 & 8 and

should satisfy the requirements in (ii).

BS476 Part 7 deals with surface spread of flame test for

materials and provides a method of classification according to

the rate and distance of spread of flame across them (Class 1

limits flame spread to 165mm in 11/2 minutes). BS476 Part 8

provides a method of assessing the integrity (time resistance

of fire penetration) of flexible ducting connections.

In BSCP 413 flexible joints are required to have a resistance

to the penetration of fire of at least 15 minutes when tested

in accordance with BS 476 Part 8 and should be constructed

of material rated Class 1 in the surface spread of flame test

in BS 476 without treatment and should not give off excessive

quantities of smoke when burnt. In the absence of

other criteria, many enforcing Authorities appear to use this

as a guideline to the required fire performance of

flexible connections.

Product Range

Nominal Bore

Ins mm Code No

3 75 13903076

4 100 13904102

5 125 13905127

6 150 13906152

160 13900160

7 175 13907180

8 200 13908203

9 225 13909229

10 250 13910254

12 300 13912305

315 13900315

Specifications

Aluminium, flexible duct, constructed from a multiple layer

laminate, based on aluminium/polyester/ aluminium enclosing

and supported by a high tensile continuous steel helix.

Operating temperature: -20C to +120C

Extended length: 10 metres

Compressed length: 0.7m

Working pressure: Up to 2450Pa

Minimum bend radius: 0.6 x diameter

Pressure Loss Graph

P

r

e

s

s

u

r

e

l

o

s

s

i

n

P

a

p

e

r

m

e

t

r

e

Temp C

Application Data

The installation of air conditioning and mechanical ventilation

systems may affect the fire risk within a building. The extent

and detail of statutory control and other specialist interests

varies according to the design, use, occupation and location of

the building and the type of air conditioning or ventilation

system proposed. It is essential that all appropriate authorities

be fully consulted at an early stage (e.g. District Surveyor,

Superintending Architect, Fire Department, etc.).

Where air distribution systems pass through various sections of

a building they may provide a ready path for the spread of

smoke and fire. The designer should ensure that wherever

practicable the materials specified for the system should be non-

combustible or difficult to ignite and possess a good rating of

surface spread of flame when tested in accordance with the

appropriate parts of BS476. In addition, such materials should

not generate smoke or toxic fumes when subjected to fire or

heat. The suitability of many materials will need to be agreed by

the enforcing authority. Since there is no published list of

acceptable materials the designer or installer may be required to

provide authoritative test data for the products it is intended

to use.

Codes of Practice and Regulations dealing with fire safety

aspects of ventilation systems frequently refer to flexible joints

and connections:

Flexible Joints

Flexible joints are normally provided to prevent vibration and

/or allow for thermal movements in the system and should not

exceed 300mm in length.

Flexible Connections

Flexible connections are normally provided at the extremities of

the ductwork system to facilitate site connections to grilles,

diffusers, air boxes and combined air/light fixtures, mixing

boxes and terminal units. Such connectors are nearly always

provided for by the use of factory manufactured circular

flexible ducting.

Various types are available, since airflow/pressure drop

characteristics, acoustic and thermal properties may all be

important to system design. From the fire safety viewpoint

BSCP 413:1973 recommends that flexible connections should

not exceed 3.7m in length and should not pass through fire-

resisting walls, floors or partitions.

Euroflex Type 130 has been independently

tested at Warrington Research Centre as defined

by BS 476.

Air Volume m

3

/h

Super compressible flexible ducting constructed

from multiple layer aluminium laminate

Ten metre length compresses to 0.7m

individually packaged

High tensile steel helix offers excellent resistance

to crushing

Independently tested to BS 476 pt, 20; fire

integrity of 39mins

Independently tested to BS 476 pt, 7; Class D1

material

Sizes range from 75 to 315mm nominal bore

diameter.

121

from Vent-Axia

Multiple Layered Aluminium Flexible Ducting

120

Multiple Layered Aluminium Flexible Ducting

EuroflexTM150

from Vent-Axia

Fire Test Data

In BSCP 413:1973 it is recommended that for flexible

(ducting) connections the materials of construction should

preferably be noncombustible; alternatively:

i when tested in accordance with the propagation test in

BS 476 Part 6, should have an index of performance not

exceeding 12, of which not more than 6 should derive from

the initial period of the test.

ii when involved in a fire should generate a minimum amount

of smoke and toxic gases.

In practice, flexible ducting is tested to BS476 Parts 7 & 8 and

should satisfy the requirements in (ii).

BS476 Part 7 deals with surface spread of flame test for

materials and provides a method of classification according to

the rate and distance of spread of flame across them (Class 1

limits flame spread to 165mm in 11/2 minutes). BS476 Part 8

provides a method of assessing the integrity (time resistance

of fire penetration) of flexible ducting connections.

In BSCP 413 flexible joints are required to have a resistance

to the penetration of fire of at least 15 minutes when tested

in accordance with BS 476 Part 8 and should be constructed

of material rated Class 1 in the surface spread of flame test

in BS 476 without treatment and should not give off

excessive quantities of smoke when burnt. In the absence

of other criteria, many enforcing Authorities appear to use

this as a guideline to the required fire performance of

flexible connections.

Product Range

Specifications

Super compressible, aluminium, flexible duct, constructed

from a multiple layer laminate, based on aluminium/

polyester/aluminium with fibreglass scrim reinforcement.

Enclosing and supported by a high tensile continuous

steel helix.

Operating temperature: -20C to +120C

Extended length: 10 metres

Compressed length: 1.4m

Working pressure: Up to 2450Pa

Minimum Bend Radius: 0.6 x diameter

Pressure Loss Graph

Air Volume m

3

/h

Temp C

Application Data

The installation of air conditioning and mechanical ventilation

systems may affect the fire risk within a building. The extent

and detail of statutory control and other specialist interests

varies according to the design, use, occupation and location of

the building and the type of air conditioning or ventilation

system proposed. It is essential that all appropriate authorities

be fully consulted at an early stage (e.g. District Surveyor,

Superintending Architect, Fire Department, etc.).

Where air distribution systems pass through various sections of

a building they may provide a ready path for the spread of

smoke and fire. The designer should ensure that wherever

practicable the materials specified for the system should be non-

combustible or difficult to ignite and possess a good rating of

surface spread of flame when tested in accordance with the

appropriate parts of BS476. In addition, such materials should

not generate smoke or toxic fumes when subjected to fire or

heat. The suitability of many materials will need to be agreed by

the enforcing authority. Since there is no published list of

acceptable materials the designer or installer may be required to

provide authoritative test data for the products it is intended

to use.

Codes of Practice and Regulations dealing with fire safety

aspects of ventilation systems frequently refer to flexible joints

and connections:

Flexible Joints

Flexible joints are normally provided to prevent vibration and

/or allow for thermal movements in the system and should not

exceed 300mm in length.

Flexible Connections

Flexible connections are normally provided at the extremities

of the ductwork system to facilitate site connections to grilles,

diffusers, air boxes and combined air/light fixtures, mixing

boxes and terminal units. Such connectors are nearly always

provided for by the use of factory manufactured circular

flexible ducting.

Various types are available, since airflow/pressure drop

characteristics, acoustic and thermal properties may all be

important to system design. From the fire safety viewpoint

BSCP 413:1973 recommends that flexible connections should

not exceed 3.7 m in length and should not pass through fire-

resisting walls, floors or partitions.

Euroflex Type 150 has been independently

tested at Warrington Research Centre as defined

by BS 476.

Super compressible flexible duct constructed

from multiple layer aluminium laminate with

fibreglass scrim reinforcement

Ten metre length compresses to 0.7m

individually packaged

Extremely robust construction offers exceptional

resistance to crushing and sagging

Independently tested to BS 476 pt, 20; fire

integrity of 41mins

Sizes range from 75 to 600mm nominal bore

diameter.

Nominal Bore

Ins mm Code No

3 75 15903076

4 100 15904102

5 125 15905127

6 150 15906152

160 15900160

7 175 15907180

8 200 15908203

9 225 15909229

10 250 15910254

12 300 15912305

315 15900315

14 350 15914356

16 400 15916406

18 450 15918456

20 500 15920508

22 550 15922556

24 600 15924608

123

from Vent-Axia

Thermal Flexible Ducting

122

Thermal Flexible Ducting

EuroflexTM200

from Vent-Axia

Fire Test Data

In BSCP 413:1973 it is recommended that for flexible

(ducting) connections the materials of construction should

preferably be noncombustible; alternatively:

i when tested in accordance with the propagation test in

BS 476 Part 6, should have an index of performance not

exceeding 12, of which not more than 6 should derive from

the initial period of the test.

ii when involved in a fire should generate a minimum amount

of smoke and toxic gases.

In practice, flexible ducting is tested to BS476 Parts 7 & 8 and

should satisfy the requirements in (ii).

BS476 Part 7 deals with surface spread of flame test for

materials and provides a method of classification according to

the rate and distance of spread of flame across them (Class 1

limits flame spread to 165mm in 11/2 minutes). BS476 Part 8

provides a method of assessing the integrity (time resistance

of fire penetration) of flexible ducting connections.

In BSCP 413 flexible joints are required to have a resistance

to the penetration of fire of at least 15 minutes when tested

in accordance with BS 476 Part 8 and should be constructed

of material rated Class 1 in the surface spread of flame test

in BS 476 without treatment and should not give off

excessive quantities of smoke when burnt. In the absence of

other criteria, many enforcing Authorities appear to use this

as a guideline to the required fire performance of

flexible connections.

Product Range

Specifications

Insulated aluminium duct, Euroflex Super inner core with a

uniform layer of fibreglass insulation and tough outer jacket of

reinforced aluminium laminate acting as a vapour barrier.

Operating temperature: -20C to +120C

Extended length: 10 metres

Compressed length: 1.4m

Working pressure: Up to 2450Pa

Minimum Bend Radius: 0.6 x diameter +0.085m Pressure Loss Graph

Air Volume m

3

/h

Temp C

Application Data

The installation of air conditioning and mechanical ventilation

systems may affect the fire risk within a building. The extent

and detail of statutory control and other specialist interests

varies according to the design, use, occupation and location of

the building and the type of air conditioning or ventilation

system proposed. It is essential that all appropriate authorities

be fully consulted at an early stage (e.g. District Surveyor,

Superintending Architect, Fire Department, etc.).

Where air distribution systems pass through various sections of

a building they may provide a ready path for the spread of

smoke and fire. The designer should ensure that wherever

practicable the materials specified for the system should be non-

combustible or difficult to ignite and possess a good rating of

surface spread of flame when tested in accordance with the

appropriate parts of BS476. In addition, such materials should

not generate smoke or toxic fumes when subjected to fire or

heat. The suitability of many materials will need to be agreed by

the enforcing authority. Since there is no published list of

acceptable materials the designer or installer may be required to

provide authoritative test data for the products it is intended

to use.

Codes of Practice and Regulations dealing with fire safety

aspects of ventilation systems frequently refer to flexible joints

and connections:

Flexible Joints

Flexible joints are normally provided to prevent vibration and

/or allow for thermal movements in the system and should not

exceed 300mm in length.

Flexible Connections

Flexible connections are normally provided at the extremities of

the ductwork system to facilitate site connections to grilles,

diffusers, air boxes and combined air/light fixtures, mixing

boxes and terminal units. Such connectors are nearly always

provided for by the use of factory manufactured circular flexible

ducting.

Various types are available, since airflow/pressure drop

characteristics, acoustic and thermal properties may all be

important to system design. From the fire safety viewpoint

BSCP 413:1973 recommends that flexible connections should

not exceed 3.7 m in length and should not pass through fire-

resisting walls, floors or partitions.

Euroflex Thermal Type 200 has been

independently tested at Warrington Research

Centre as defined by BS 476.

Pre-installed flexible duct with 25mm high density

fibreglass insulation and scrim reinforced

aluminium laminate vapour barrier

10 metre length compresses to 1.4m individually

packaged

Independently tested to BS 476 pt, 20; fire

integrity of 27 mins

Independently tested to BS 476 pt, 7; Class D1

material

Independently tested to BS 476 pt, 6; Propagation

index 1: 8.1, Sub index h: 5.1

Size range from 75 to 500mm nominal bore

diameter.

Nominal Bore

Ins mm Code No

3 75 20903076

4 100 20904102

5 125 20905127

6 150 20906152

160 20900160

7 175 20907180

8 200 20908203

9 225 20909229

10 250 20910254

12 300 20912305

315 20900315

14 350 20914356

16 400 20916406

18 450 20918456

20 500 20920508

125

from Vent-Axia

Acoustic Flexible Ducting

124

Acoustic Flexible Ducting

EuroflexTM350

from Vent-Axia

Product Range

Pressure Loss Graph

A

i

r

V

o

l

u

m

e

m

3

/

h

Pressure loss in Pa per metre

Application Data

There are several aspects to be considered when addressing the

problem of noise (simply defined as unwanted sound in air

movement systems). The first and most important point is that

close attention to predicted noise levels at the system design

stage will prove far more cost effective than attempts to

eliminate noise once the system has been installed. Euroflex

Type 350 Acoustic has been specifically designed to provide a

quick and effective solution to the problems of noise

transmission into and from ventilated areas.

Specifications

Pre-insulated fibreglass skrim inner duct with a uniform layer of

fibreglass insulation all enclosed by a reinforced aluminium

laminate vapour barrier.

Operating temperature: -20C to +140C

Extended length: 6 metres

Working pressure: Up to 2450Pa

Minimum Bend Radius: 0.65 x diameter +0.06m

Insertion Loss/Metre

Specifically designed for noise attenuation giving

exceptional insertion loss over a wide frequency

spectrum

Six metre standard length

Independently tested to bs 476 pt. 7; class d1

aluminium vapour barrier material

Sizes range from 75 to 500mm nominal bore

diameter

Flexible Attenuation Loss Across Sound Spectrum

Diameter Hz

Inside

mm 63 125 250 500 1K 2K 4K 8K

75 100 4 12 16 30 30 30 30 25

125 175 3 7 9 20 20 19 18 17

200 225 2 5 7 15 16 15 14 13

250 350 2 4 5 10 12 11 10 9

400 500 1 3 3 7 8 8 7 6

Nominal Bore

Ins mm Code No

3 75 35903076

4 100 35904102

5 125 35905127

6 150 35906152

160 35900160

7 175 35907180

8 200 35908203

9 225 35909229

10 250 35910254

12 300 35912305

315 35900315

14 350 35914356

16 400 35916406

18 450 35918456

20 500 35920508

450

400

300

250

200

150

125

100

75

Vous aimerez peut-être aussi

- Installation guide for Electrolux rangehood modelsDocument12 pagesInstallation guide for Electrolux rangehood modelsauslanOZPas encore d'évaluation

- Lokring I Single Ring 01.07.2013Document58 pagesLokring I Single Ring 01.07.2013Sandra Mabel Leguizamon100% (1)

- PalDuct Phenolic Datasheet MEDocument2 pagesPalDuct Phenolic Datasheet MERamadan RashadPas encore d'évaluation

- Carriage Bolts and Nuts DIN 603 (Bolt) DIN 934 (Nut)Document1 pageCarriage Bolts and Nuts DIN 603 (Bolt) DIN 934 (Nut)Srinivasa TemkarPas encore d'évaluation

- Flexible Ducting Guide - Tecflex 400 and Tectherm 400 SeriesDocument4 pagesFlexible Ducting Guide - Tecflex 400 and Tectherm 400 Seriessharique hasanPas encore d'évaluation

- ADC Flexible Duct Performance & Installation Standards. Installation Guidelines. 4th Ed.Document8 pagesADC Flexible Duct Performance & Installation Standards. Installation Guidelines. 4th Ed.John EvansPas encore d'évaluation

- Flex Duct Systems CatalogDocument12 pagesFlex Duct Systems CatalogWilliam HarrisPas encore d'évaluation

- 4 Egg Crate Grills PDFDocument6 pages4 Egg Crate Grills PDFMUHAMMED SHAFEEQPas encore d'évaluation

- Phuong Phap Tinh Tai Theo Phan Mem MistralDocument8 pagesPhuong Phap Tinh Tai Theo Phan Mem Mistralntt_121987Pas encore d'évaluation

- Non Return Damper PDFDocument7 pagesNon Return Damper PDFMUHAMMED SHAFEEQPas encore d'évaluation

- General Information About The Planning Manual Ventilation Technology For LaboratoriesDocument10 pagesGeneral Information About The Planning Manual Ventilation Technology For LaboratoriesRenato MendesPas encore d'évaluation

- Volume Control DampersDocument4 pagesVolume Control Dampersdignified34Pas encore d'évaluation

- Louver Design ConsiderationsDocument4 pagesLouver Design ConsiderationsArt JamesPas encore d'évaluation

- Access Door 2010Document4 pagesAccess Door 2010Roy Anthone LaysonPas encore d'évaluation

- Multistage Multioutlet PumpDocument11 pagesMultistage Multioutlet Pumpmajortay100% (1)

- ASLI 02 Supply Air Grilles Set - AIR ConditioningDocument21 pagesASLI 02 Supply Air Grilles Set - AIR ConditioningAminul Hassan50% (2)

- CO2 Sensor RoomDocument8 pagesCO2 Sensor RoomTrần Khắc ĐộPas encore d'évaluation

- Dasco 10-18Document9 pagesDasco 10-18Ahmed Azad100% (1)

- Remote Radiator Systems For Generator SetsDocument2 pagesRemote Radiator Systems For Generator SetsJohn P KPas encore d'évaluation

- 39 Space Air DistributionDocument25 pages39 Space Air DistributionPRASAD326100% (3)

- Air Distribution SystemDocument77 pagesAir Distribution SystemRohit JainPas encore d'évaluation

- Package UnitDocument60 pagesPackage Unitintequab100% (2)

- CB3 Me-13Document1 pageCB3 Me-13J-R MERLIN CabatoPas encore d'évaluation

- 093 Paint Booth VentDocument3 pages093 Paint Booth VentFajar Hadi CrisnamurtiPas encore d'évaluation

- Fdocuments - in Ariston Water Heater CatalogueDocument68 pagesFdocuments - in Ariston Water Heater CatalogueMahmoudPas encore d'évaluation

- Duct CalculationsDocument38 pagesDuct CalculationsDilnesa EjiguPas encore d'évaluation

- Ashrae 15-34-Rev 3 MitsubishiDocument7 pagesAshrae 15-34-Rev 3 MitsubishiJosho SandovalPas encore d'évaluation

- Hydroheater Auto Manual VersionDocument45 pagesHydroheater Auto Manual VersionVishal Nawalgaria100% (3)

- As 2254-1988 Acoustics - Recommended Noise Levels For Various Areas of Occupancy in Vessels and OffshoreDocument5 pagesAs 2254-1988 Acoustics - Recommended Noise Levels For Various Areas of Occupancy in Vessels and OffshoreSAI Global - APACPas encore d'évaluation

- HB v6 ch7Document75 pagesHB v6 ch7artukovicPas encore d'évaluation

- Hunter GP100 08-2003 PDFDocument1 pageHunter GP100 08-2003 PDFaymanmkPas encore d'évaluation

- PalDuct PIR Datasheet ME en 10 16Document2 pagesPalDuct PIR Datasheet ME en 10 16fahad0% (1)

- Air Distribution SystemDocument21 pagesAir Distribution SystemRohit JainPas encore d'évaluation

- SKM FCU High Static DetailDocument28 pagesSKM FCU High Static DetailInzamamPas encore d'évaluation

- Daikin Packaged Unit UAYQ-C Series Engineering DataDocument58 pagesDaikin Packaged Unit UAYQ-C Series Engineering DataMichaelPas encore d'évaluation

- H 250/M9 H 250/M7: Installation and Operating InstructionsDocument68 pagesH 250/M9 H 250/M7: Installation and Operating InstructionsPadam tanker Singh funny videosPas encore d'évaluation

- BOSS™ Pressurisation Units and Expansion Vessels PDFDocument16 pagesBOSS™ Pressurisation Units and Expansion Vessels PDFRIFASPas encore d'évaluation

- Copeland ZP SeriesDocument4 pagesCopeland ZP Seriesakram rasheed shaikPas encore d'évaluation

- Supply Air DiffuserDocument6 pagesSupply Air Diffuserntt_121987Pas encore d'évaluation

- Fan Fundamentals - Greenheck (May2005)Document24 pagesFan Fundamentals - Greenheck (May2005)jagdishgharotePas encore d'évaluation

- 6-Dampers N Louvers Performance N Selection-Ruskin Titus-Mayank SinghalDocument7 pages6-Dampers N Louvers Performance N Selection-Ruskin Titus-Mayank SinghalabhishekPas encore d'évaluation

- M 269-96 (2008) (Turnbuckles and Shackles)Document25 pagesM 269-96 (2008) (Turnbuckles and Shackles)tran_lamPas encore d'évaluation

- Heat Gain From Electrical and Control Equipment in Industrial Plants, Part II, ASHRAE Research Project RP-1395Document4 pagesHeat Gain From Electrical and Control Equipment in Industrial Plants, Part II, ASHRAE Research Project RP-1395Michael LagundinoPas encore d'évaluation

- YCM Series - Catalog PUBL-8441 (0418)Document36 pagesYCM Series - Catalog PUBL-8441 (0418)jotace469Pas encore d'évaluation

- 1 Are Series SCD RCD Cat v08Document20 pages1 Are Series SCD RCD Cat v08adils1Pas encore d'évaluation

- Structure Maintainer, Group H (Air Conditioning & Heating): Passbooks Study GuideD'EverandStructure Maintainer, Group H (Air Conditioning & Heating): Passbooks Study GuidePas encore d'évaluation

- PVC Duct Installation GuideDocument10 pagesPVC Duct Installation GuidecitramuaraPas encore d'évaluation

- Flex Head para RociadoresDocument2 pagesFlex Head para RociadoresjoravicaPas encore d'évaluation

- DCDocument25 pagesDCaries26marchPas encore d'évaluation

- MAHU Catalogue 2015Document16 pagesMAHU Catalogue 2015Ong MatPas encore d'évaluation

- Pressure Volume Calculator 02Document6 pagesPressure Volume Calculator 02Jenny Cecilia Ureña ZuriPas encore d'évaluation

- Paint Booth HVAC Control SystemDocument6 pagesPaint Booth HVAC Control SystemPraveenkumar KashyabPas encore d'évaluation

- Promat Self Supporting DuctsDocument9 pagesPromat Self Supporting DuctsBen CarrollPas encore d'évaluation

- Flexible Ductwork Report - November 2011v2Document69 pagesFlexible Ductwork Report - November 2011v2bommobPas encore d'évaluation

- Tarecpir Project Spec Inst GuideDocument64 pagesTarecpir Project Spec Inst GuideFaizal YaacobPas encore d'évaluation

- SS333 1996 Fire DamperDocument18 pagesSS333 1996 Fire DamperAaron Ang100% (2)

- HVAC Ductwork SpecificationDocument4 pagesHVAC Ductwork SpecificationhvacwallyPas encore d'évaluation

- Kaiflex Specification DomesticDocument5 pagesKaiflex Specification Domesticnaseema1Pas encore d'évaluation

- Fire Protection CDPDocument29 pagesFire Protection CDPPopa IulianPas encore d'évaluation

- Prihoda Recycled Fabric Duct SpecificationDocument5 pagesPrihoda Recycled Fabric Duct SpecificationaverentzPas encore d'évaluation

- Ascot Roller Shutter General BrochureDocument16 pagesAscot Roller Shutter General Brochureiask5275Pas encore d'évaluation

- Cable Trunking Test Report BS 4678 IEC61084 G275Document5 pagesCable Trunking Test Report BS 4678 IEC61084 G275iask5275Pas encore d'évaluation

- BCA Accessibility Code 2013Document0 pageBCA Accessibility Code 2013hoshientung3119Pas encore d'évaluation

- Secure Access Module SAM Card OverviewDocument23 pagesSecure Access Module SAM Card Overviewiask5275Pas encore d'évaluation

- ABACUS High Mast Data SheetDocument74 pagesABACUS High Mast Data Sheetiask5275Pas encore d'évaluation

- Atlas Aluminium Datasheet 5052 Rev Oct 2013Document3 pagesAtlas Aluminium Datasheet 5052 Rev Oct 2013Jason-chungPas encore d'évaluation

- Ascot Fire Roller Shutters BrochureDocument8 pagesAscot Fire Roller Shutters Brochureiask5275Pas encore d'évaluation

- Alcoa Aluminum 5052 6061 Data SheetDocument2 pagesAlcoa Aluminum 5052 6061 Data Sheetiask5275Pas encore d'évaluation

- CITEL SPD Surge Protection Device Catalog 2013Document136 pagesCITEL SPD Surge Protection Device Catalog 2013iask527567% (3)

- En 124 Access Cover Frame Loading (Gully)Document1 pageEn 124 Access Cover Frame Loading (Gully)iask5275Pas encore d'évaluation

- Sympholux Infrastructure Solution GuideDocument19 pagesSympholux Infrastructure Solution Guideiask5275Pas encore d'évaluation

- Macau GDSE Energy Saving GuidelineDocument21 pagesMacau GDSE Energy Saving Guidelineiask5275Pas encore d'évaluation

- ADT Intrusion Alarm CatalogueDocument144 pagesADT Intrusion Alarm Catalogueiask5275Pas encore d'évaluation

- SCHWING Concrete Pump Working Range DrawingsDocument57 pagesSCHWING Concrete Pump Working Range Drawingsiask527583% (6)

- 3M Zinc Spray 16-501 Data SheetDocument2 pages3M Zinc Spray 16-501 Data Sheetiask5275Pas encore d'évaluation

- TANDA HongKong Fire Door BrochureDocument18 pagesTANDA HongKong Fire Door Brochureiask5275Pas encore d'évaluation

- ATDEC Spacedec Workstation Desk Adjustable SD-POS-HA Data SheetDocument4 pagesATDEC Spacedec Workstation Desk Adjustable SD-POS-HA Data Sheetiask5275Pas encore d'évaluation

- ADS Corrugated Heavy Duty Pipe Data SheetDocument4 pagesADS Corrugated Heavy Duty Pipe Data Sheetiask5275Pas encore d'évaluation

- Italy Mont Blanc Tunnel Fire 1999 Case StudyDocument3 pagesItaly Mont Blanc Tunnel Fire 1999 Case Studyiask5275Pas encore d'évaluation

- UK Mortar Brief Introduction of ScreedingDocument3 pagesUK Mortar Brief Introduction of Screedingiask5275Pas encore d'évaluation

- Philips UV Light Data SheetDocument17 pagesPhilips UV Light Data Sheetiask5275Pas encore d'évaluation

- ABB Circuit Breaker Bus Communication Manual Vol-9 (MOE+AUX-E)Document2 pagesABB Circuit Breaker Bus Communication Manual Vol-9 (MOE+AUX-E)iask5275Pas encore d'évaluation

- ABB Circuit Breaker AUX-E MOE Trip Unit InstructionDocument23 pagesABB Circuit Breaker AUX-E MOE Trip Unit Instructioniask5275Pas encore d'évaluation

- KSB Know-How, Volume 0 - Selecting-Centrifugal-Pumps-data PDFDocument92 pagesKSB Know-How, Volume 0 - Selecting-Centrifugal-Pumps-data PDFRodrigo Astudillo AedoPas encore d'évaluation

- RUSKIN Fire and Smoke Damper Application GuideDocument16 pagesRUSKIN Fire and Smoke Damper Application Guideiask5275100% (2)

- Air-Water Systems For Air Conditioning Design ManualDocument60 pagesAir-Water Systems For Air Conditioning Design ManualSchreiber_Dieses100% (1)

- TROX Air Flow Control Design ManualDocument36 pagesTROX Air Flow Control Design Manualiask5275Pas encore d'évaluation

- Keurig Gourmet Single Cup Home Brewing System: Section 1Document11 pagesKeurig Gourmet Single Cup Home Brewing System: Section 1Tijuan MuhammadPas encore d'évaluation

- Types and Forms of CommunicationDocument22 pagesTypes and Forms of CommunicationayeshaPas encore d'évaluation

- Guide to Cross-Subject Area ReportsDocument19 pagesGuide to Cross-Subject Area Reportssatyanarayana NVSPas encore d'évaluation

- Sdo385 50hz Doosan GeneratorDocument4 pagesSdo385 50hz Doosan GeneratorsunshinemachineryPas encore d'évaluation

- ISO 9000 Audit Checklist for Quality Management SystemsDocument28 pagesISO 9000 Audit Checklist for Quality Management SystemsphilipalexjonesPas encore d'évaluation

- ĐỀ CƯƠNG ÔN TẬP HỌC KÌ 1-LỚP 12Document15 pagesĐỀ CƯƠNG ÔN TẬP HỌC KÌ 1-LỚP 12Anh Duc VuPas encore d'évaluation

- Drilling RisersDocument13 pagesDrilling Risersadvantage025Pas encore d'évaluation

- Earning Elivery Odalities Study Notebook: Guinayangan North DistrictDocument48 pagesEarning Elivery Odalities Study Notebook: Guinayangan North DistrictLORENA CANTONG100% (1)

- Ake Products 001 2016Document171 pagesAke Products 001 2016davidPas encore d'évaluation

- Adruino LCD, Test CodeDocument20 pagesAdruino LCD, Test CodeDaniel Evans100% (1)

- Hypac C 766 C 778Document4 pagesHypac C 766 C 778Dave100% (1)

- 5054 s09 QP 1Document20 pages5054 s09 QP 1Hany ElGezawyPas encore d'évaluation

- Functional Molecular Engineering Hierarchical Pore-Interface Based On TD-Kinetic Synergy Strategy For Efficient CO2 Capture and SeparationDocument10 pagesFunctional Molecular Engineering Hierarchical Pore-Interface Based On TD-Kinetic Synergy Strategy For Efficient CO2 Capture and SeparationAnanthakishnanPas encore d'évaluation

- QO™ Load Centers - QO124M200PDocument4 pagesQO™ Load Centers - QO124M200PIsraelPas encore d'évaluation

- Project Synopsis: "Employee Motivation at Syndicate Bank"Document5 pagesProject Synopsis: "Employee Motivation at Syndicate Bank"SubhamSahaPas encore d'évaluation

- Practical File Class XDocument5 pagesPractical File Class XJaiPas encore d'évaluation

- PreviewpdfDocument50 pagesPreviewpdfMarcosGouvea100% (1)

- SANY HDForklift Brochure-112018Document14 pagesSANY HDForklift Brochure-112018Rossman Mejicanos100% (1)

- Air Blue E-TicketDocument1 pageAir Blue E-TicketMuneeb Ahmed100% (3)

- Hwids - 2012 05 22 - 19 04 00Document9 pagesHwids - 2012 05 22 - 19 04 00RONAL DAMIANO PAREJAPas encore d'évaluation

- Cisco and Duo Presentation 8.2.18Document8 pagesCisco and Duo Presentation 8.2.18chris_ohaboPas encore d'évaluation

- WHLP in Reading and Writing Week 8Document4 pagesWHLP in Reading and Writing Week 8Manuel Despabiladeras0% (2)

- Sany - SCC8300 Crawler CraneDocument52 pagesSany - SCC8300 Crawler CraneNunoPas encore d'évaluation

- Curtis E50 Pump Parts ListDocument8 pagesCurtis E50 Pump Parts ListrobertPas encore d'évaluation

- Ethics UNAM IsakDocument74 pagesEthics UNAM IsakIsak Isak IsakPas encore d'évaluation

- A Pilot's Guide To ILS PRM ApproachesDocument4 pagesA Pilot's Guide To ILS PRM ApproachesgregmPas encore d'évaluation

- FormatCARS KAAUH Alqahtani 106Document8 pagesFormatCARS KAAUH Alqahtani 106ZEYNOPas encore d'évaluation

- Non-Permanence Risk Report Template (Short Form) : Instructions For Completing TheDocument5 pagesNon-Permanence Risk Report Template (Short Form) : Instructions For Completing Theferrian prabowoPas encore d'évaluation

- Components of GlobalizationDocument26 pagesComponents of GlobalizationGiyan KhasandraPas encore d'évaluation

- Advantages and Disadvantages of Social MediaDocument2 pagesAdvantages and Disadvantages of Social MediaCeleste GalvanPas encore d'évaluation